Odoo16 has added a new feature called "Work Order Dependencies" to help with manufacturing workflow. This function will connect many operations carried out during a single production and properly arrange these work orders. It will be easier for the user to ensure a seamless workflow with effective management of these dependencies, which also results in quick production process compilation and effective resource allocation.

When a manufacturing order is confirmed, work order dependencies, which are truly operations-level dependencies, will affect both planning and the status of work orders. which, if more than one operation is conducted during production, is actually utilized to add an order for the operations. This option allows for the blocking out of one work order by another.

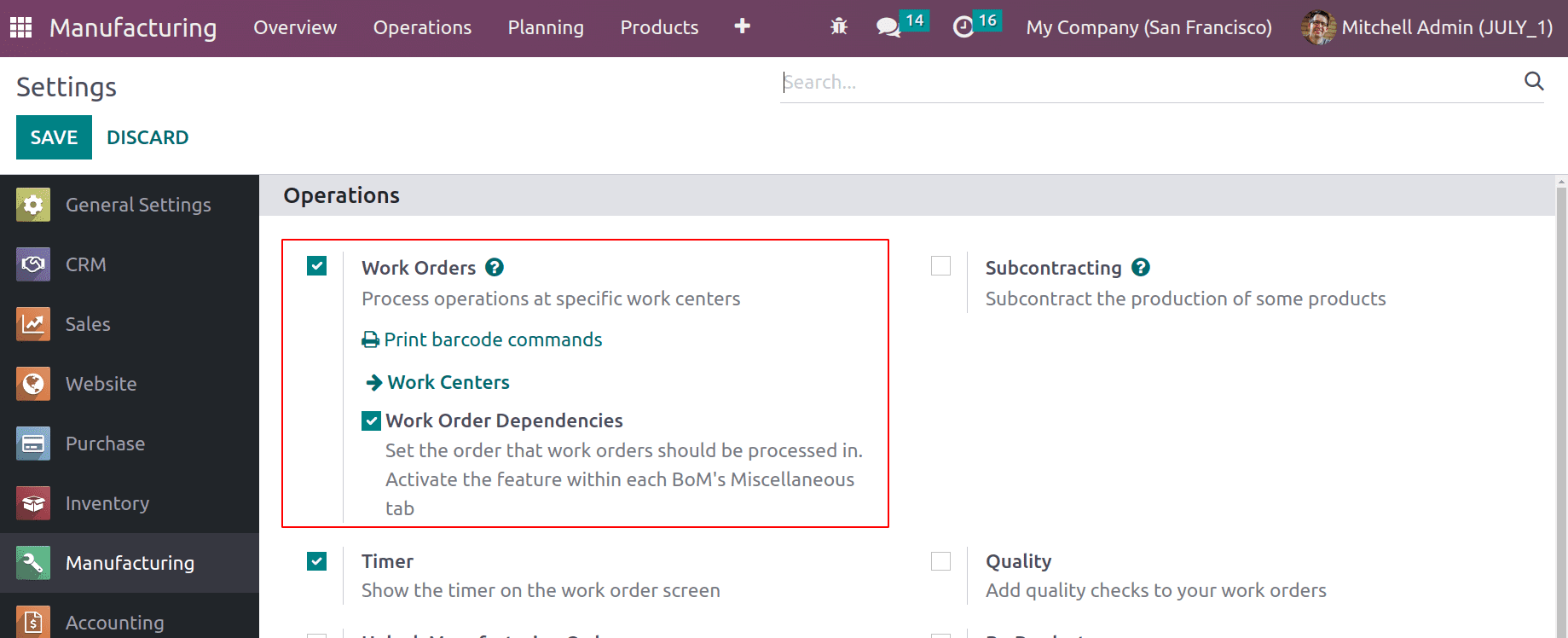

As an example, if Operation A is Blocked by Operation B, Operation A can only begin when Operation B is finished. Let's start by turning on options for work order dependencies. To achieve this, navigate to the Configuration tab and select the settings option. When the Work Orders option is enabled, the Work Order Dependencies option will appear. Enable this as well. Save the settings after that.

Configuration > Settings > Work Orders and Work Order Dependencies > Save

Let's now start the production process by producing a fresh bill of materials. One of the key components in production is the bill of material. Because everything can be set up within a BoM, including operations, byproducts, and all production-related parameters.

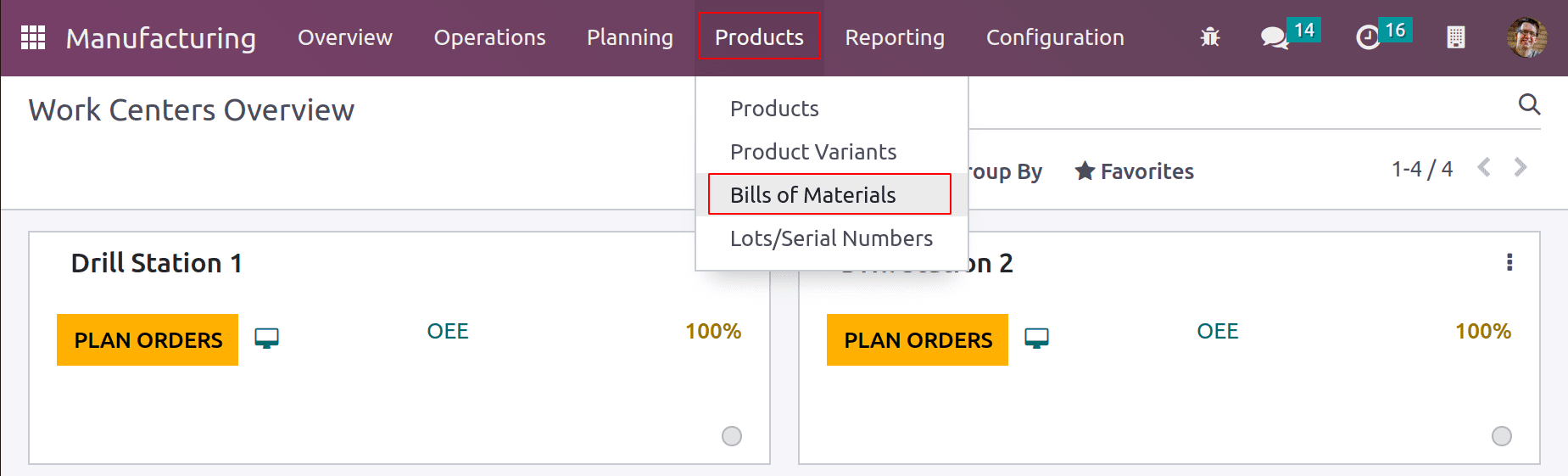

Select the Product tab and then click on the Bill of Materials to start a new BoM. When you click the New button there, a list of previously produced BoMs appears.

Product > Bill of Materials > New

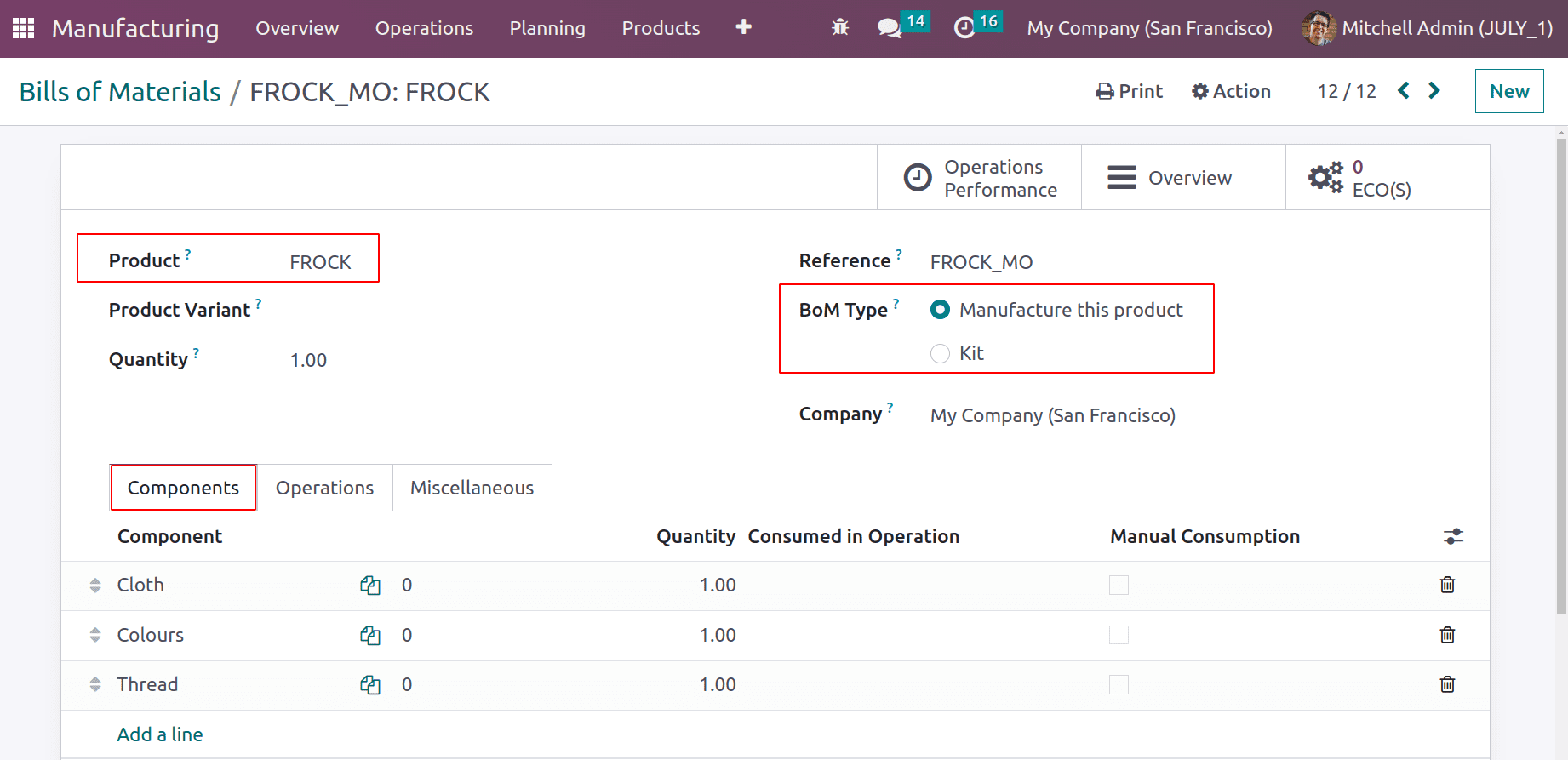

Check out the simple production procedure. Here, the item is a simple FROCK. Here, components like clothes, threads, and colors are used. The user wants to design the Frock, then the colors of the clothing in accordance with the design, and lastly, it is stitched in accordance with the design during manufacturing. The entire process is carried out in stages. Meaning there is a specific order in place to carry out the task. Each stage must be completed by the user in the proper order to produce a quality end product. Work Order Dependencies is a new feature that Odoo16 adds to the BoM to help with this process.

The BoM for the product FROCK is created here. Manufacturing is the chosen BoM Type for this product. In the Component tab, add the raw material.

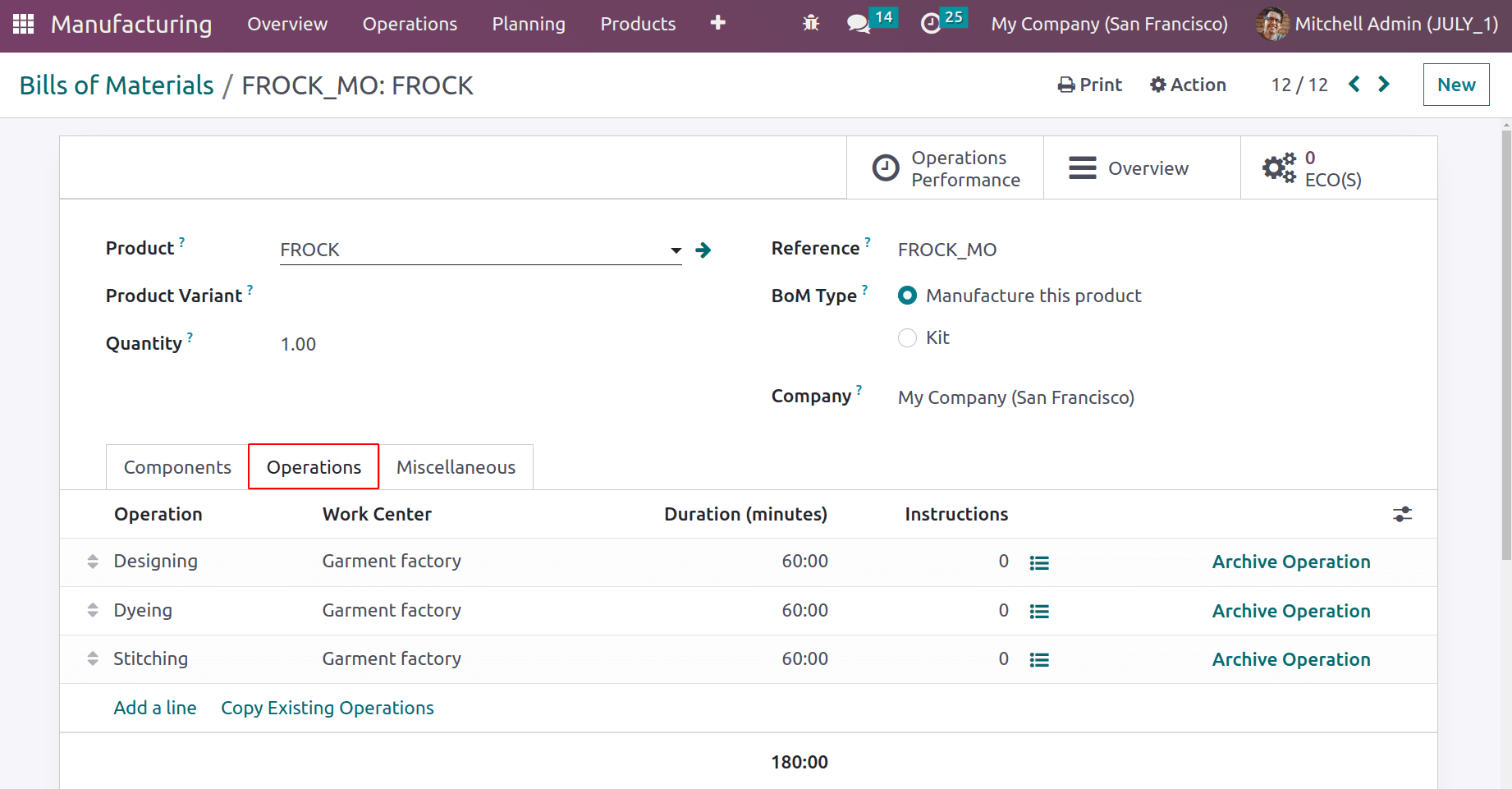

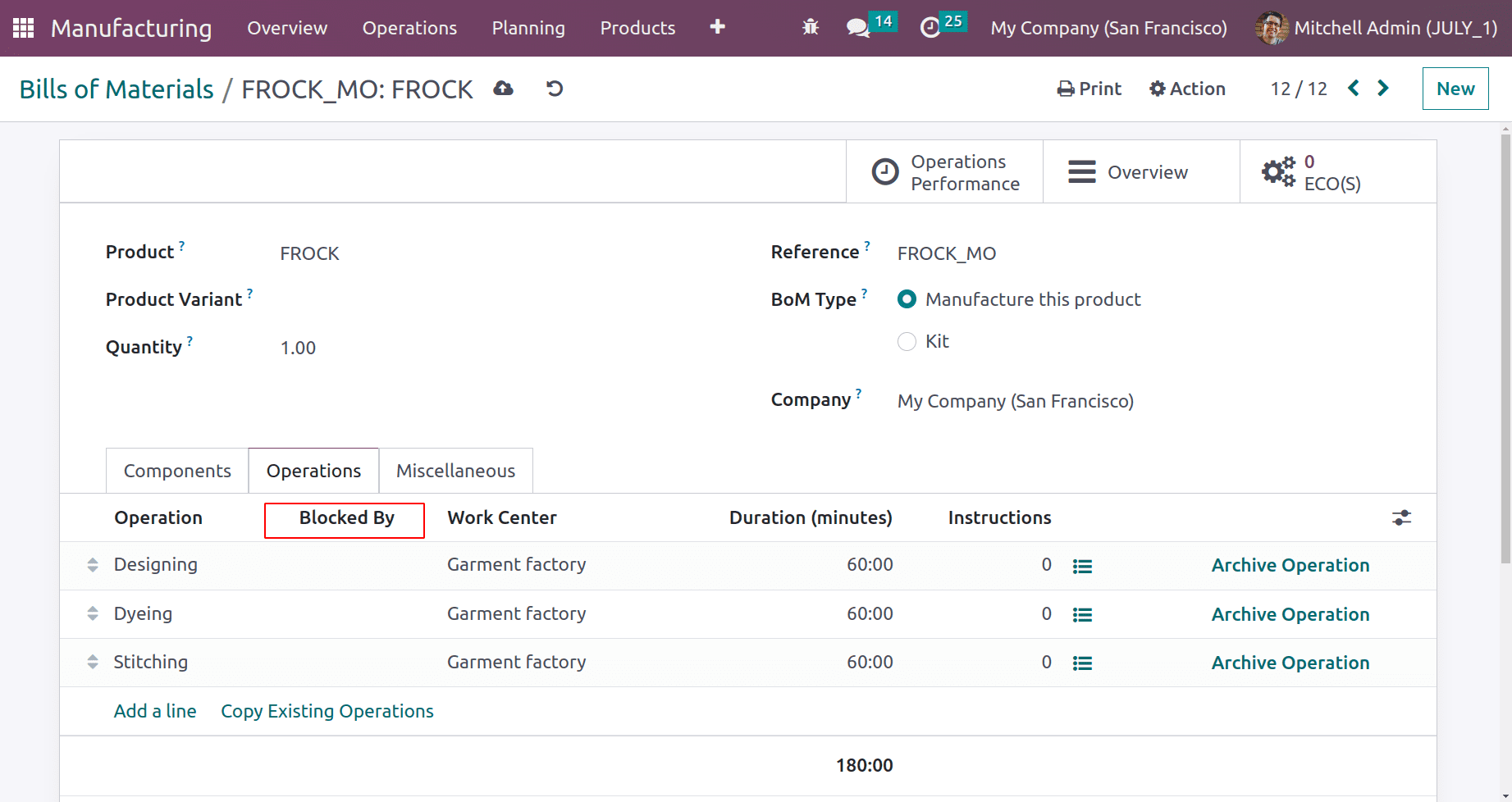

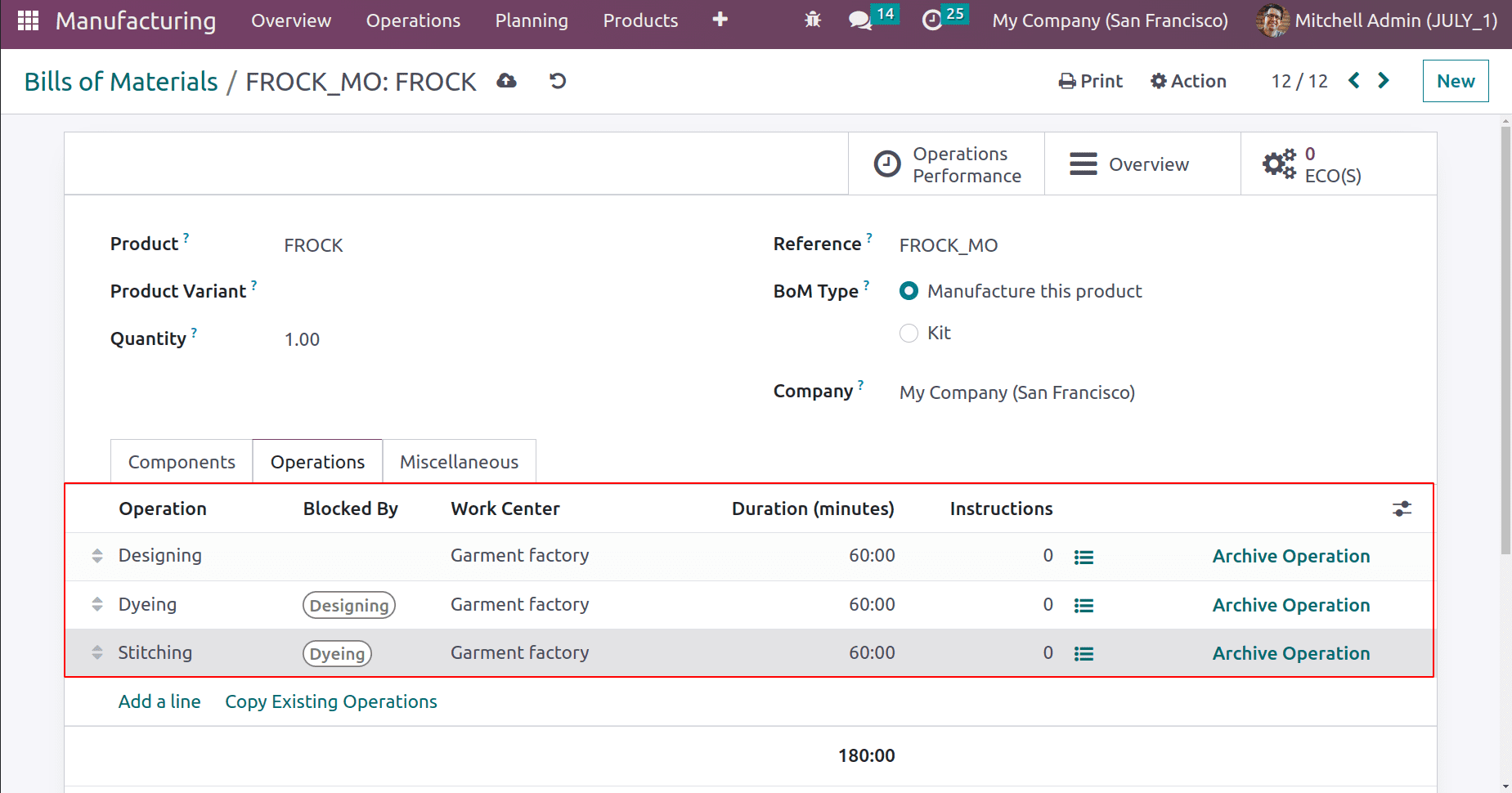

Operations that were carried out during production are added to the Operations tab. Planning three operations, the work center where these operations are performed, and the duration is added here.

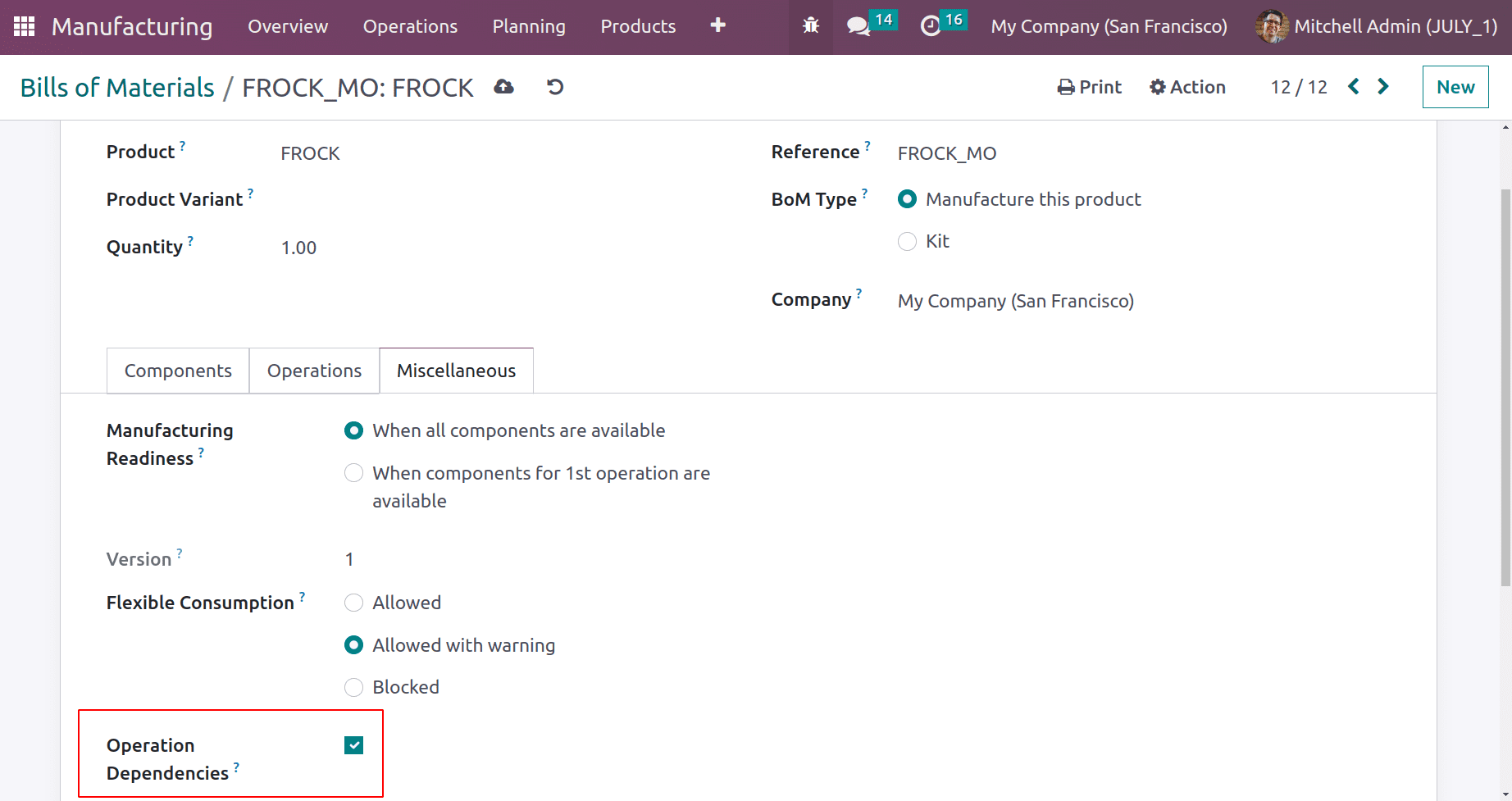

According to this BoM among these three operations, one can perform at any time without any order. To set an order for the operations user must enable the option Operation Dependency from the Miscellaneous tab.

The Operation Dependencies option is located on the Miscellaneous tab. Activate the checkbox. Then the Operation tab will receive a new field named "Blocked By."

Designing is the initial action taken in this situation. Dyeing only works when the first process is finished. After the designing and dying processes are finished, stitching will begin.

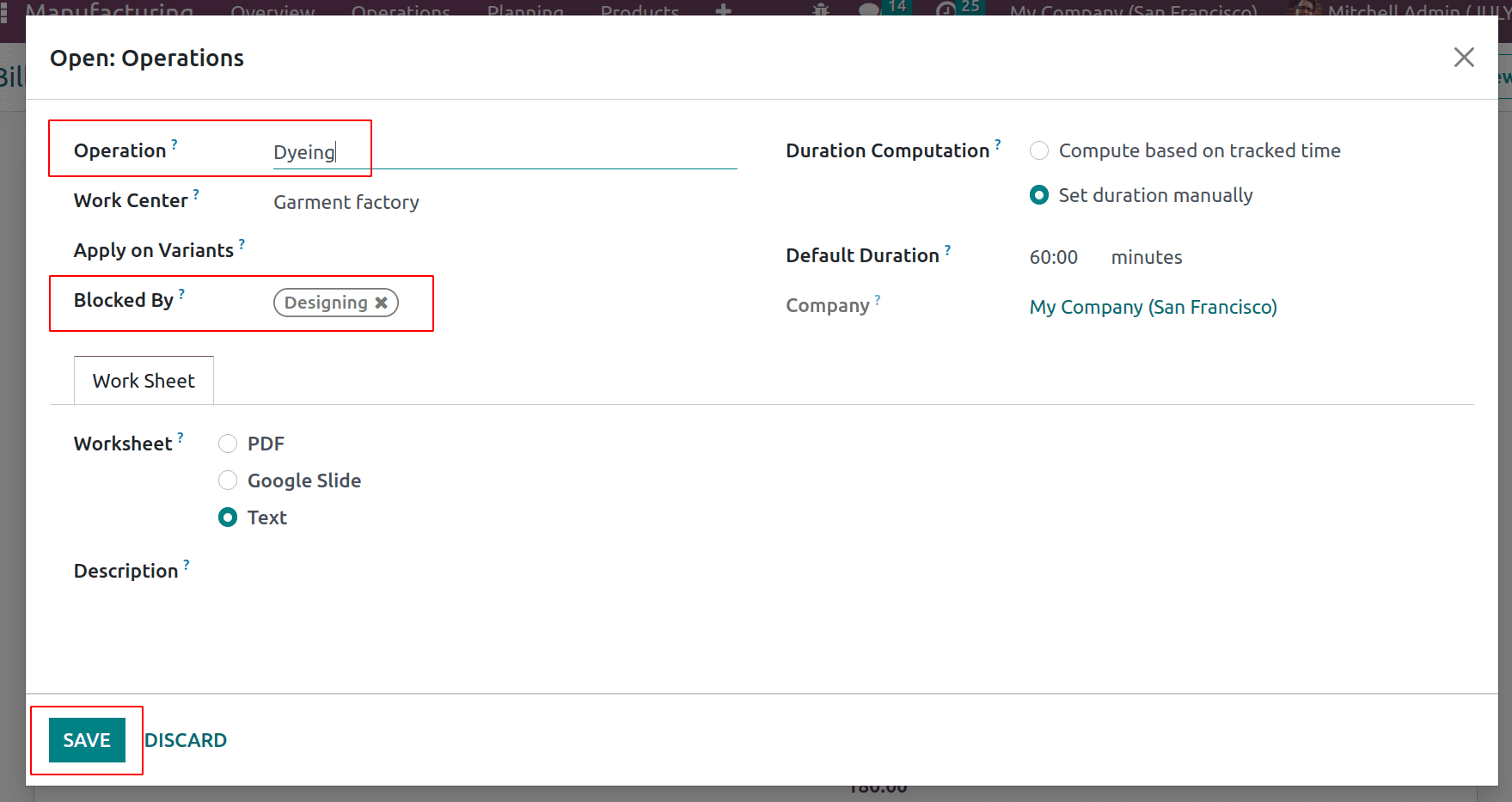

From there, open the second operation. Add the first operation, "Designing," to the Blocked By option. Then save the procedure.

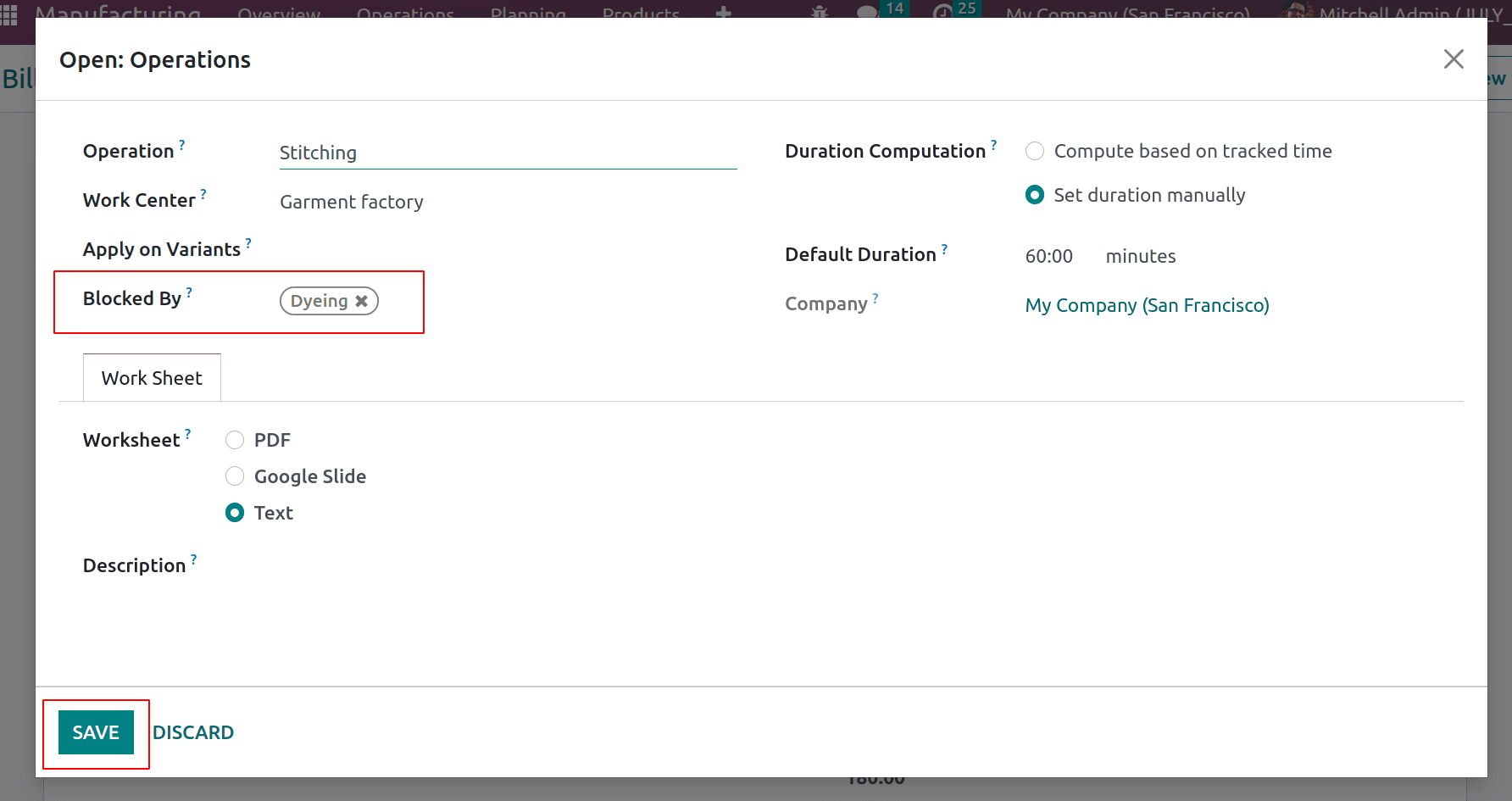

Open the third operation, and in the Blocked By section, add the second operation Dying. save it.

Checking the Operations tab reveals that Dyeing is only carried out once Designing is finished. And Stitching will work once Dyeing is finished.

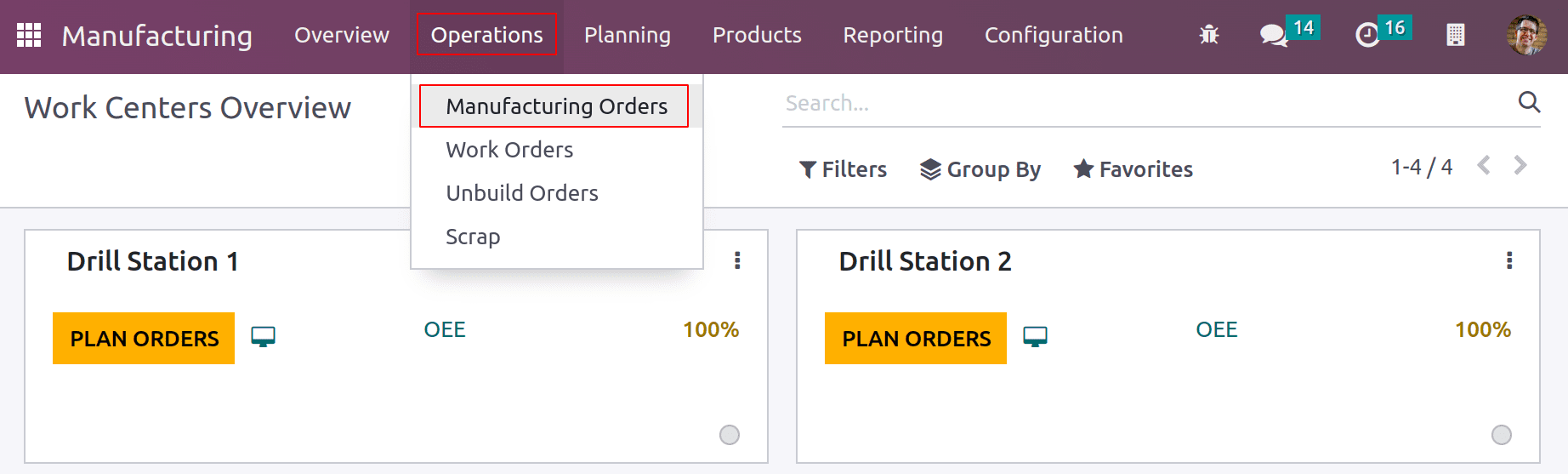

Let's create a Manufacturing order and choose Manufacturing Orders from the Operations tab. Then create a new manufacturing order.

To read more about the important features of the Odoo 16 Manufacturing Module, refer to our industry page Odoo 16 Manufacturing

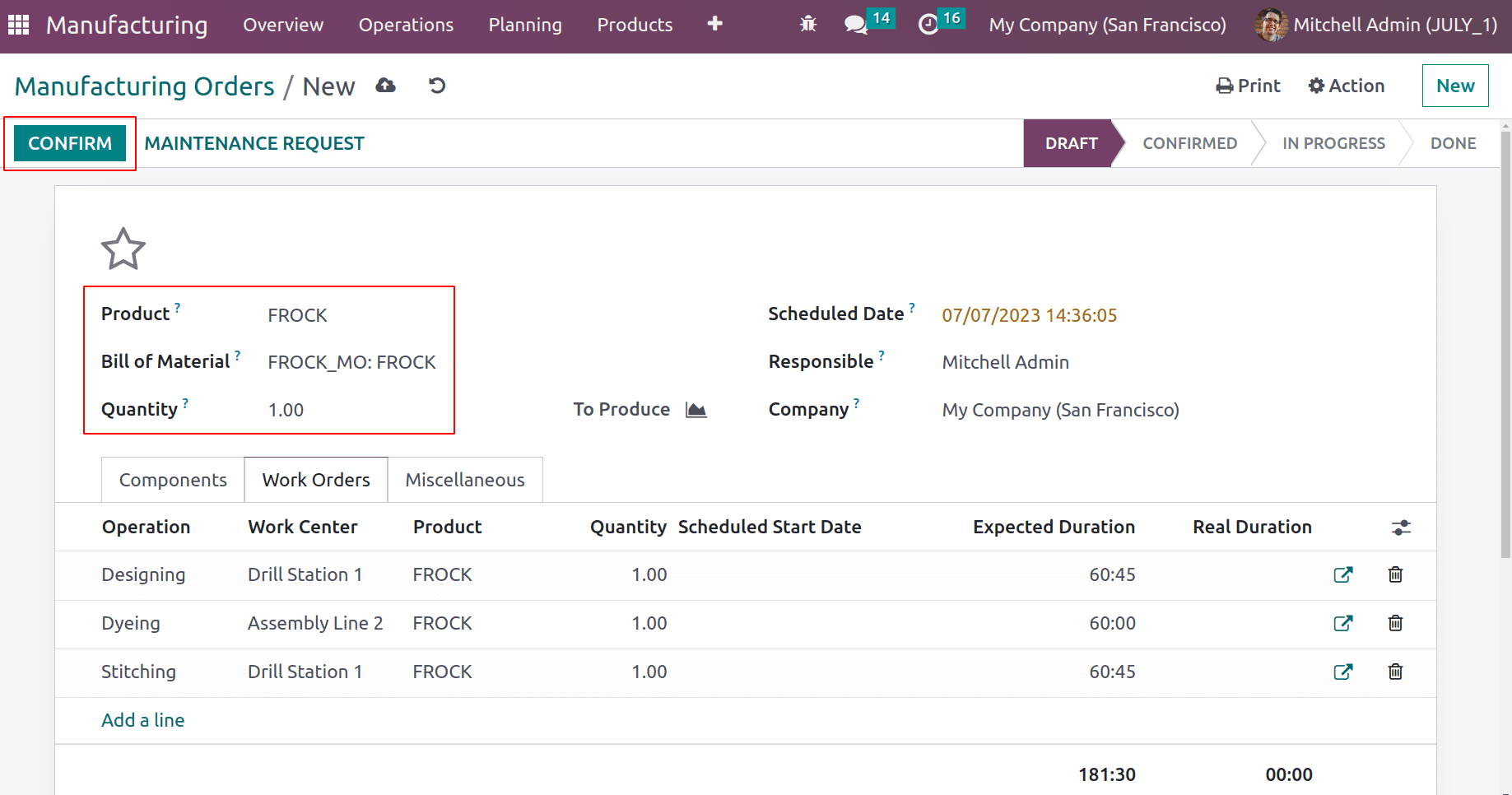

Inside the new manufacturing order add the product and choose the Bill of Material. Add the Quantity, scheduled date, Responsible, and Company. Automatically the configurations of BoM will automatically be taken into this order. Then Confirm the order.

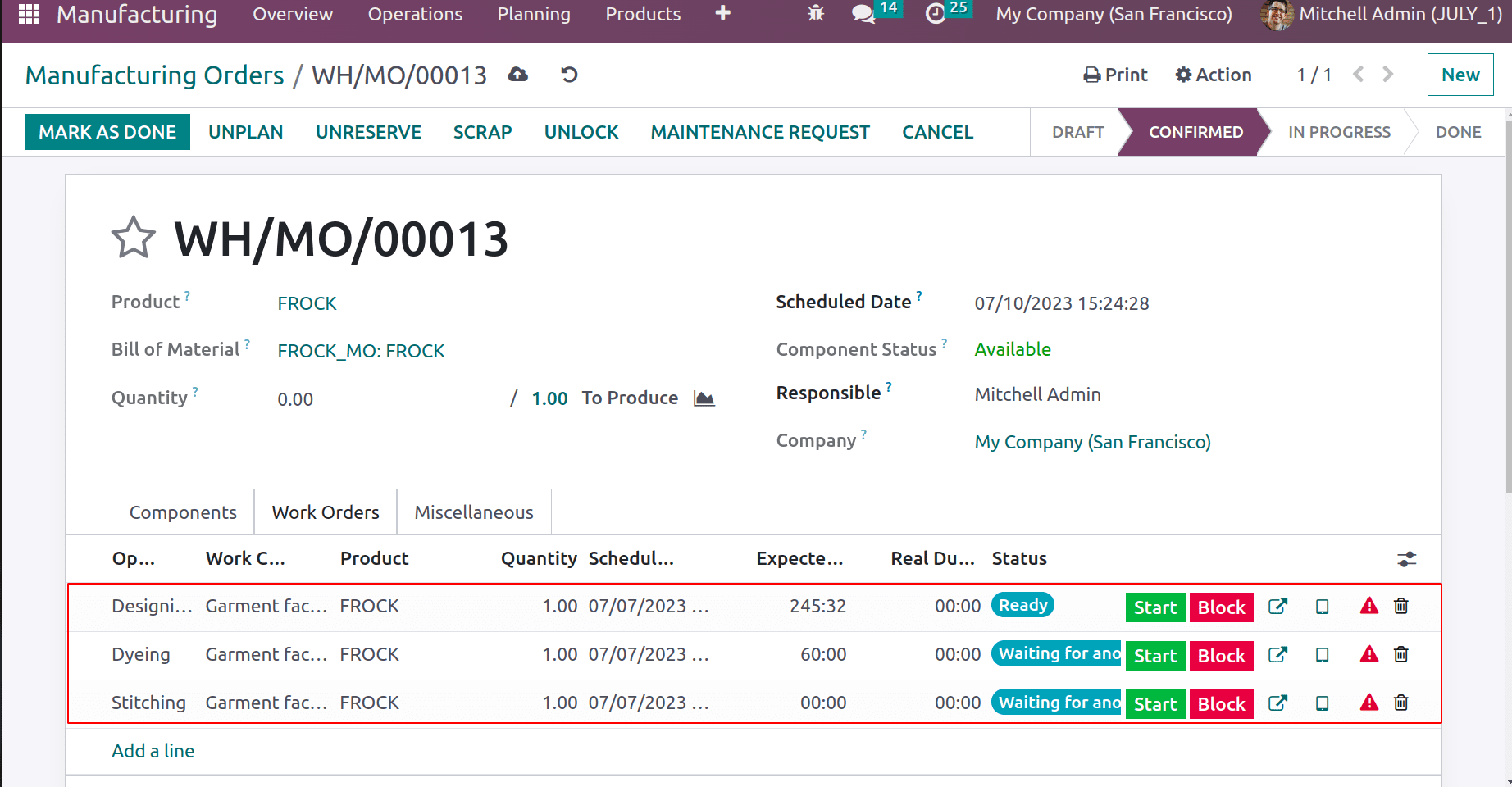

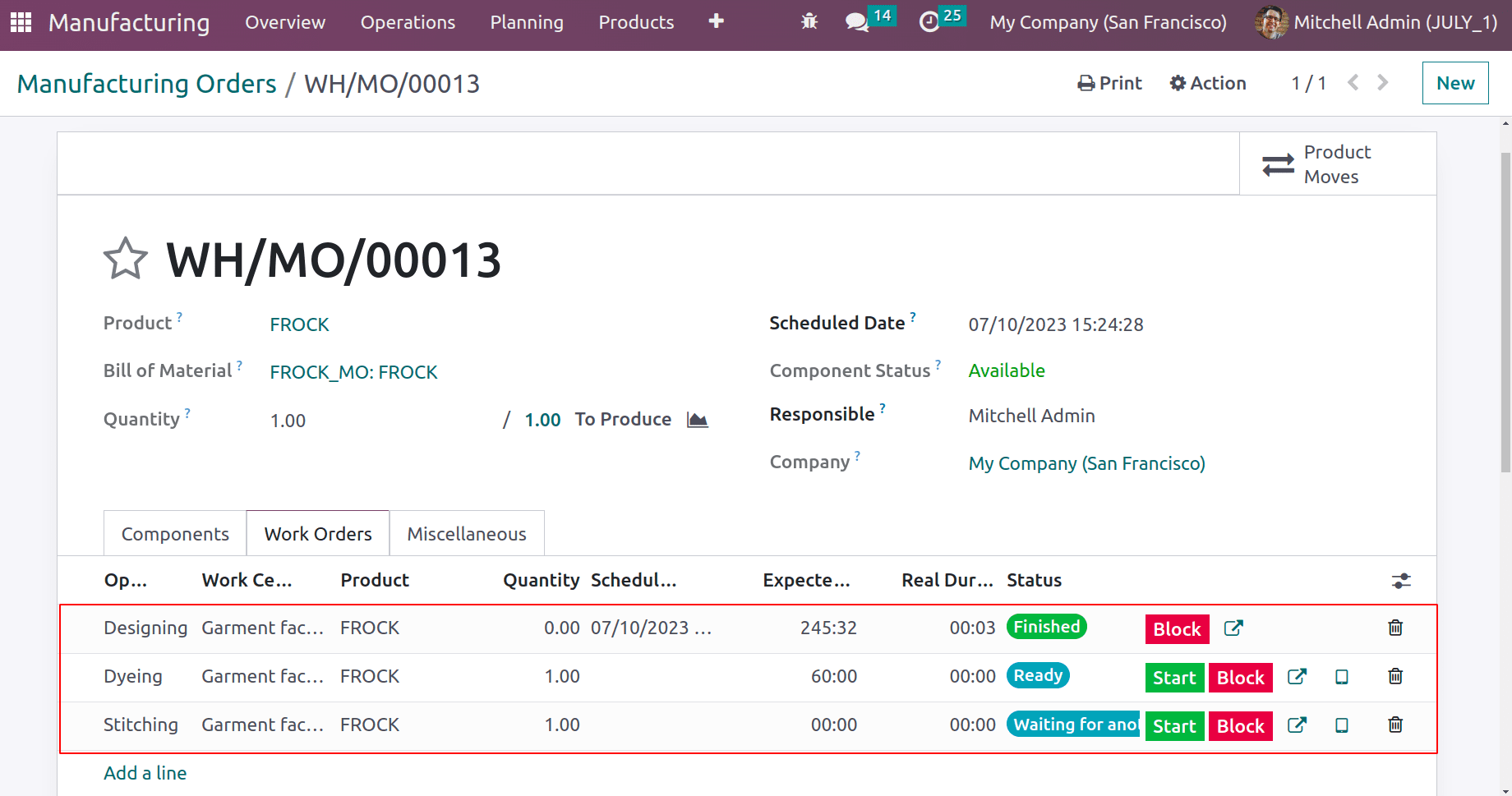

After confirming the order check the Operation tab. Three operations are given. The first operation Designing is in the Ready stage and the other two operations are in Waiting for another WO.

The user can start the procedure by pressing the Start button. Check the status of the operation once more after completing the first one. The first operation is complete, the second is in the "Ready" state, and the third is "Waiting for another WO."

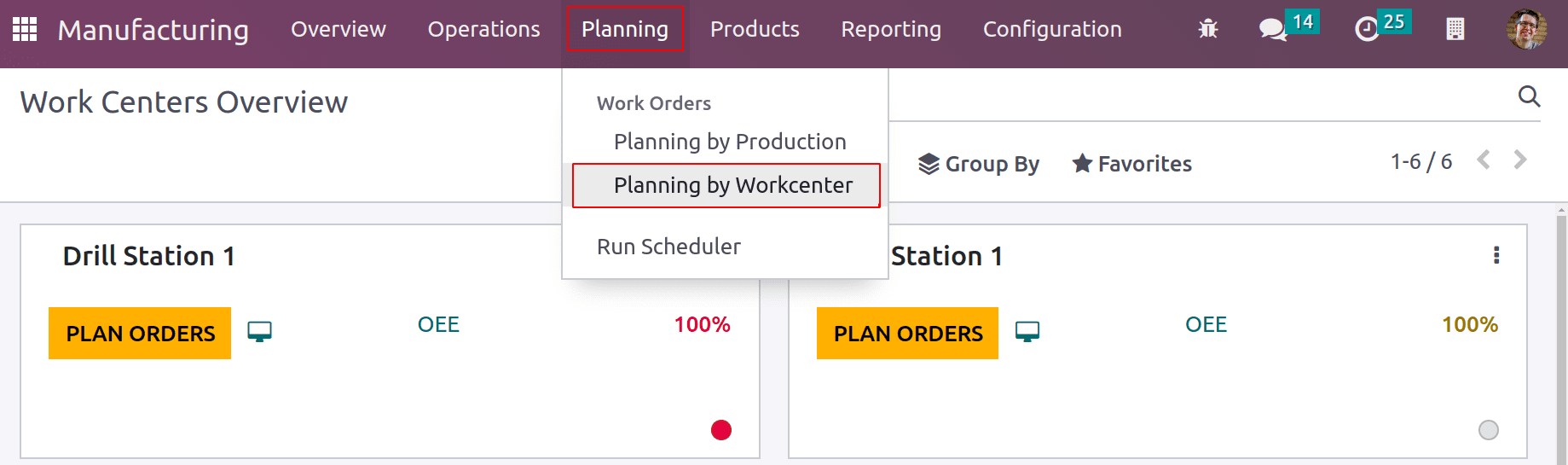

Go to the Planning tab after the operation is finished. Two choices are available. Planning by Production and Planning by work centers. Select the second choice, Workcenters Planning

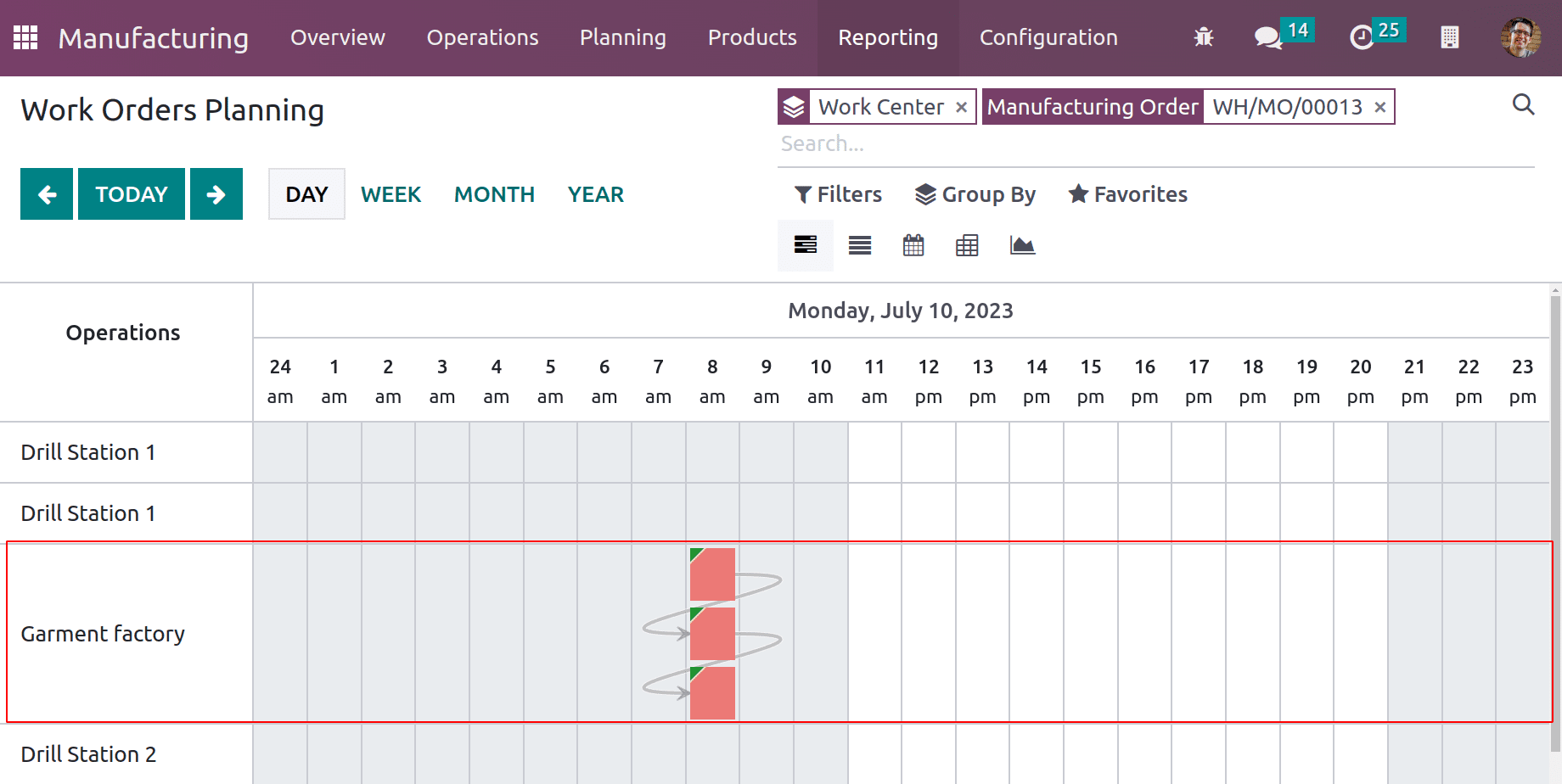

The three operations configured in the Bom are planned in order in the Gantt view. Indicates that an arrow mark that indicates the order in which the procedures were carried out is visible.

Utilizing the Work Order Dependencies option causes this. The order can be manually modified by the user.

In conclusion, properly structuring work orders will aid the organization in making the best use of its resources and shorten the time needed to complete tasks. This, while requiring less effort from the operator, also results in a good yield. As of now, the work order dependence that Odoo 16 introduced is important to the manufacturing process.

To read more about the important features of Odoo 16 manufacturing, refer to our blog What Are The New Features in Odoo 16 Manufacturing