One of the vital sections of the product operation business is product lifecycle management. The procedure of managing a product's lifecycle through design, service, manufacturing, and sales is known as product lifecycle management. Using PLM, a company can quickly develop a new product and lead into the market. The market risk of commodities reduces efficiently and assists in growing your business with the production cycle. Using the PLM, the procurance of goods to the sales activities is managed accurately in a company. You can process and manage a lifecycle of raw material in a firm using the Odoo 15 Product Lifecycle Management module.

This blog gives an idea about Odoo 15 Product Lifecycle Management in Odoo 15.

It is easy to calculate the price needed for a production process in a business using product lifecycle management. Users can identify production costs and plan returns fastly. The tracking, designing, planning, and manufacturing of a material handle accurately within the Odoo 15 Product Lifecycle Management module. Now, let's view some advanced benefits of the Odoo PLM module running in a US company.

Benefits of the Odoo PLM Module

Bill of Materials Management for a Product

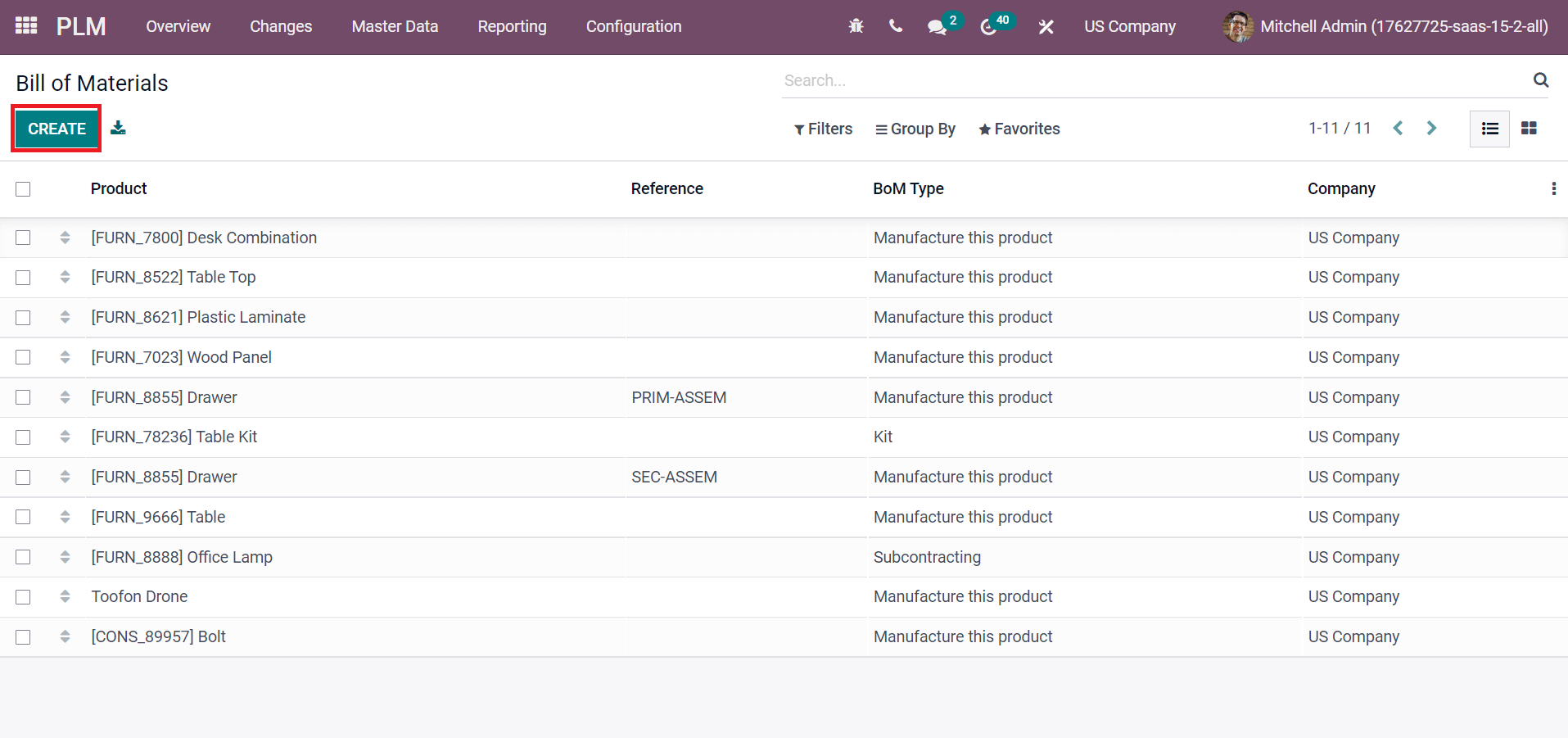

The list of components, quantities, subcomponents, assemblies, and other services for a product is a Bill of Materials. Better BoM support is available to users with the help of the product lifecycle management module in Odoo 15. You can access the Bill of Materials menu from the Master Data tab, and data of existing BoM in your system is visible to you. The Bill of Materials window denotes information such as Product, BoM Type, Company, and reference. Select the CREATE button to develop a new BoM for raw material, as marked in the screenshot below.

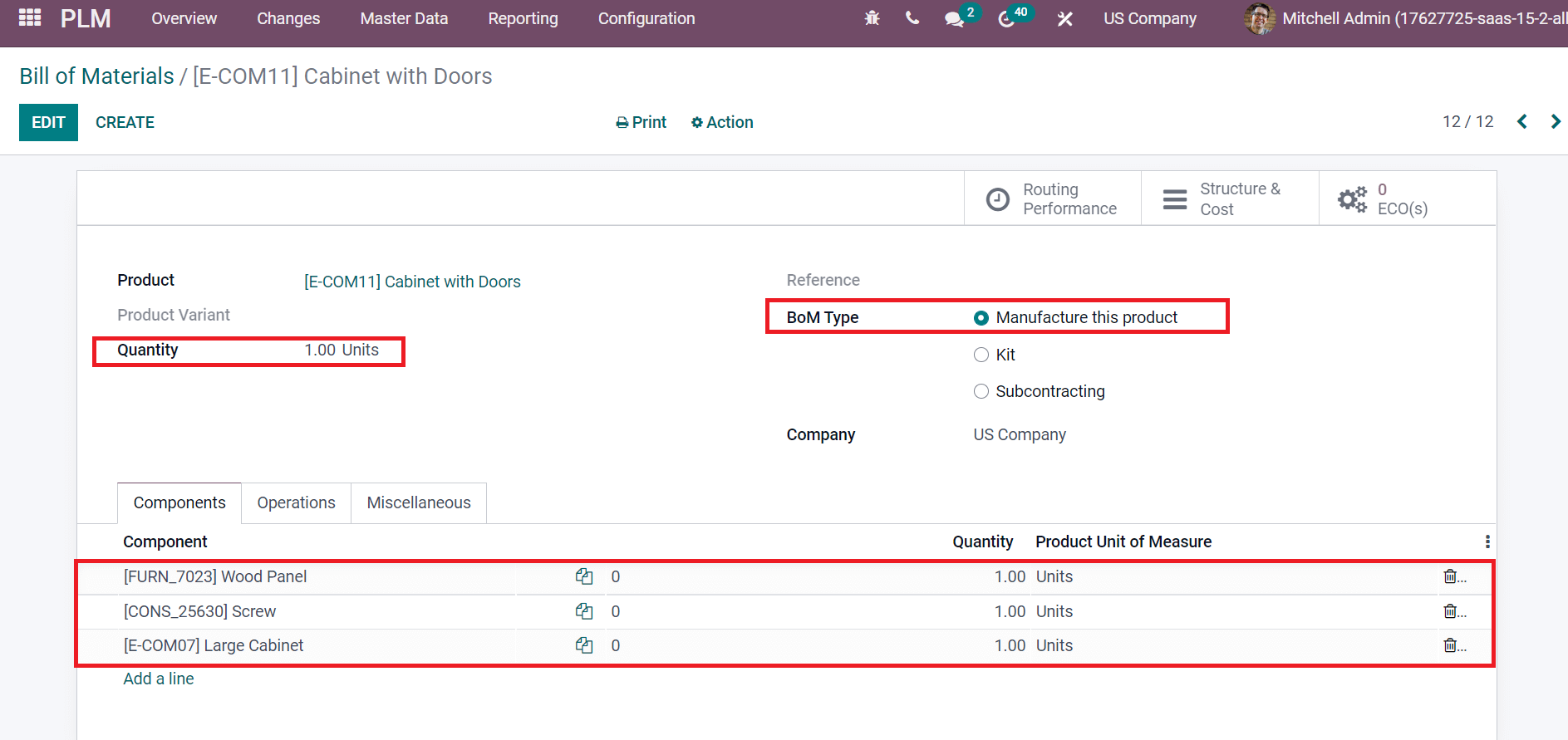

In the Bill of Materials window, we can access a product's Quantity and BoM Type. Users can add components for the manufacturing product as stated in the screenshot below.

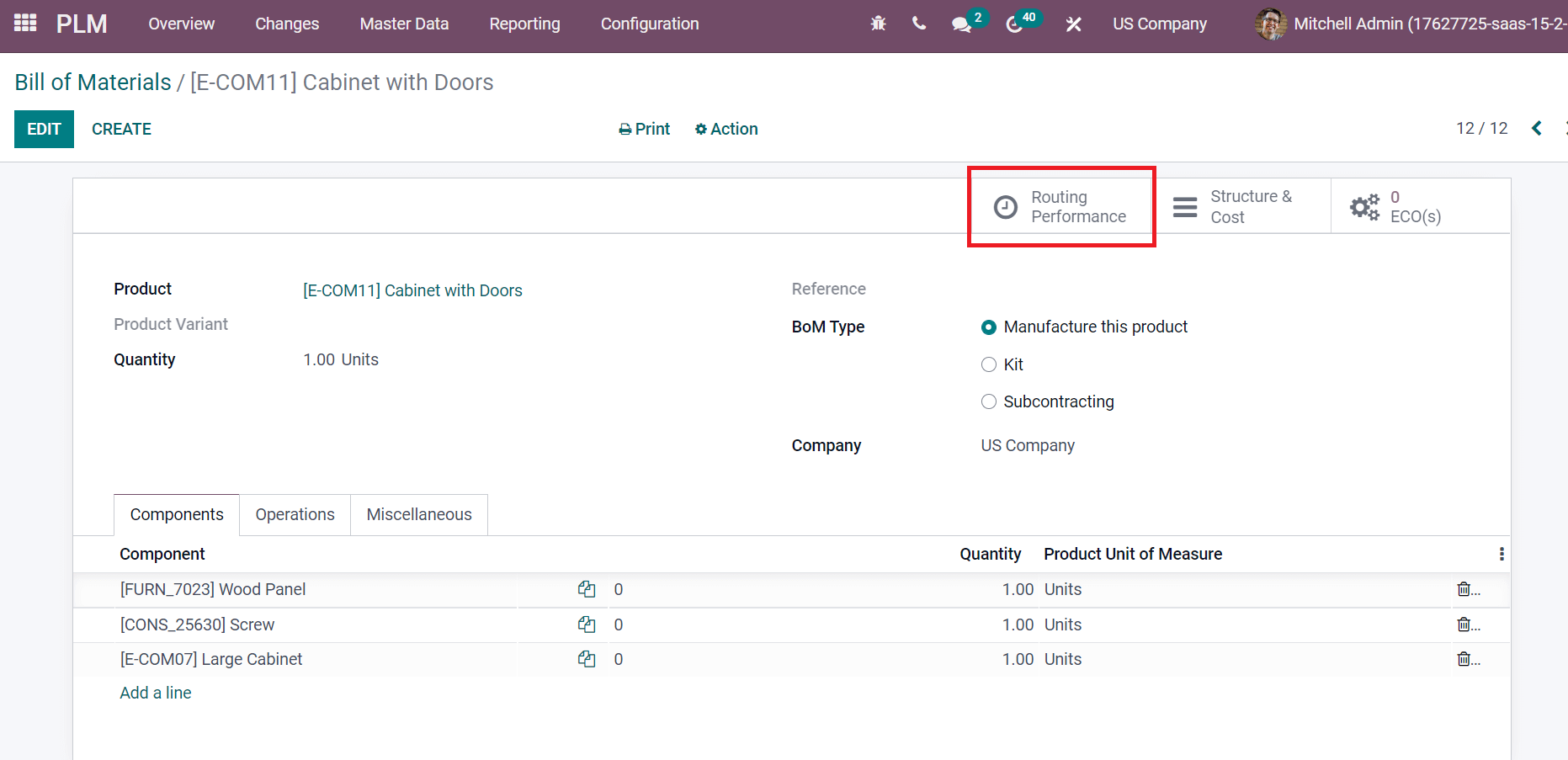

Here, we selected the components such as Wood panels, screws, and Large Cabinets for manufacturing the product Cabinet with Doors. Apart from these, we can track product routes by clicking on the Routing Performance tab, as depicted in the screenshot below.

You can improve the workflow by identifying the structure and cost of a product from the BoM window. Moreover, it is easy to prepare different engineering bills for materials within the Bill of Materials. Hence, we can manage operations of a specific commodity quickly.

Precise Lifecycle Management for your Products

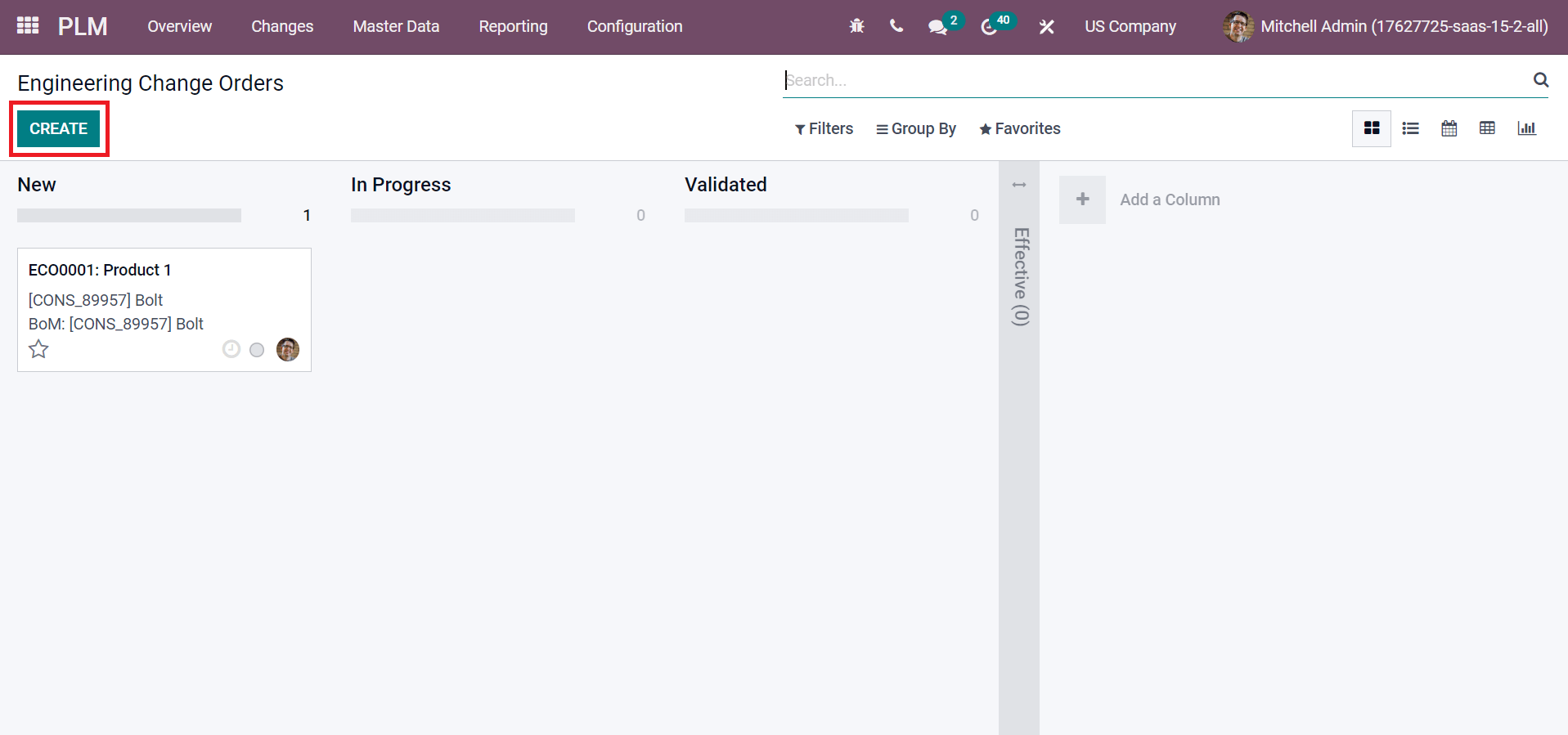

Using Engineering Change Orders (ECOs), we can keep track of the product life cycle. It is possible to get updates and changes to a commodity using ECO. Users can plan to produce BoM for products and set priority using the Engineering Change Orders support. You can get the Engineering Change Orders window by choosing the Changes tab. The created list of ECOs is viewable here, and press the CREATE button to develop a new one, as portrayed in the screenshot below.

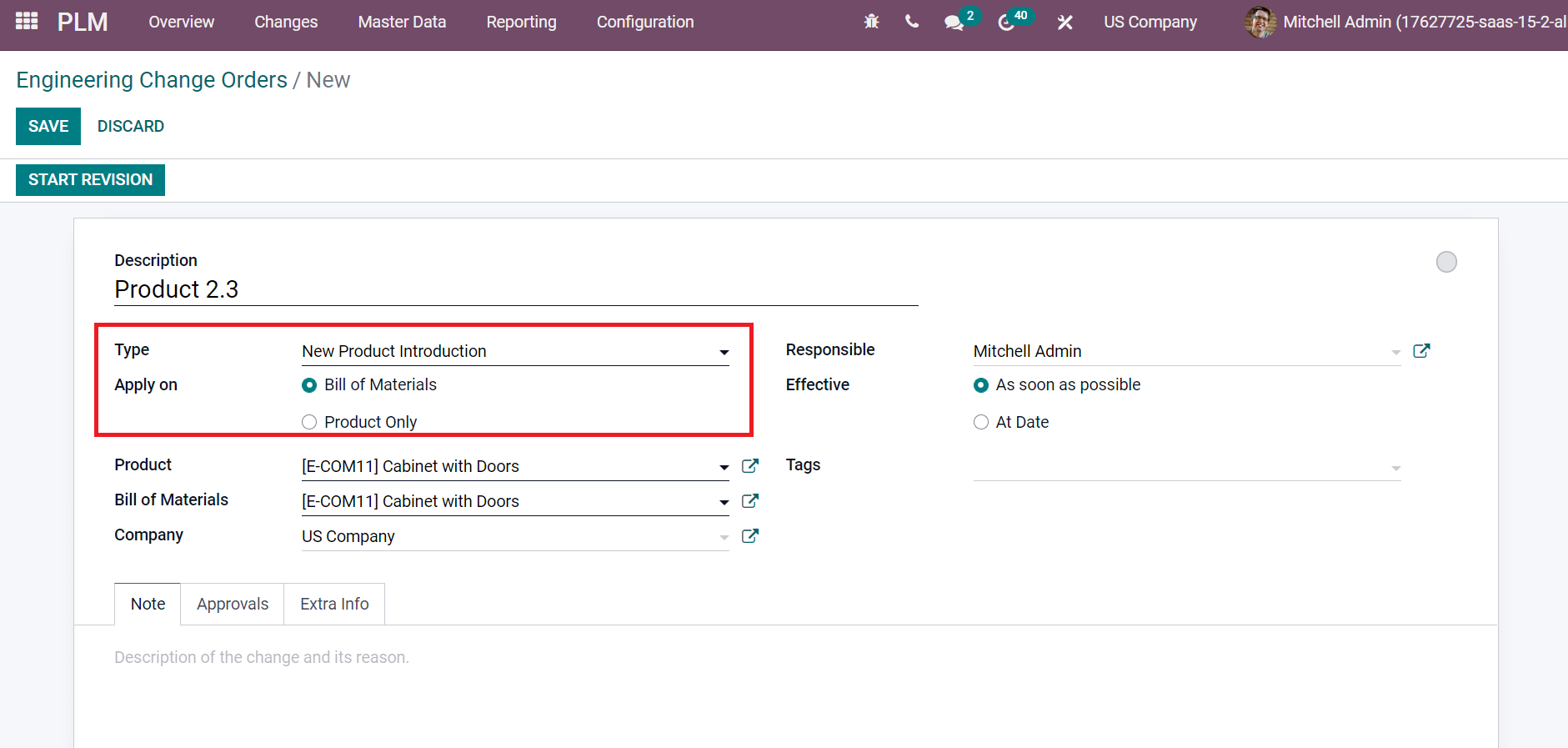

When developing a new product, you need to add the Description and Type of the product. As indicated in the screenshot below, it is necessary to apply changes on a Bill of Material or a Product from the Apply On the field.

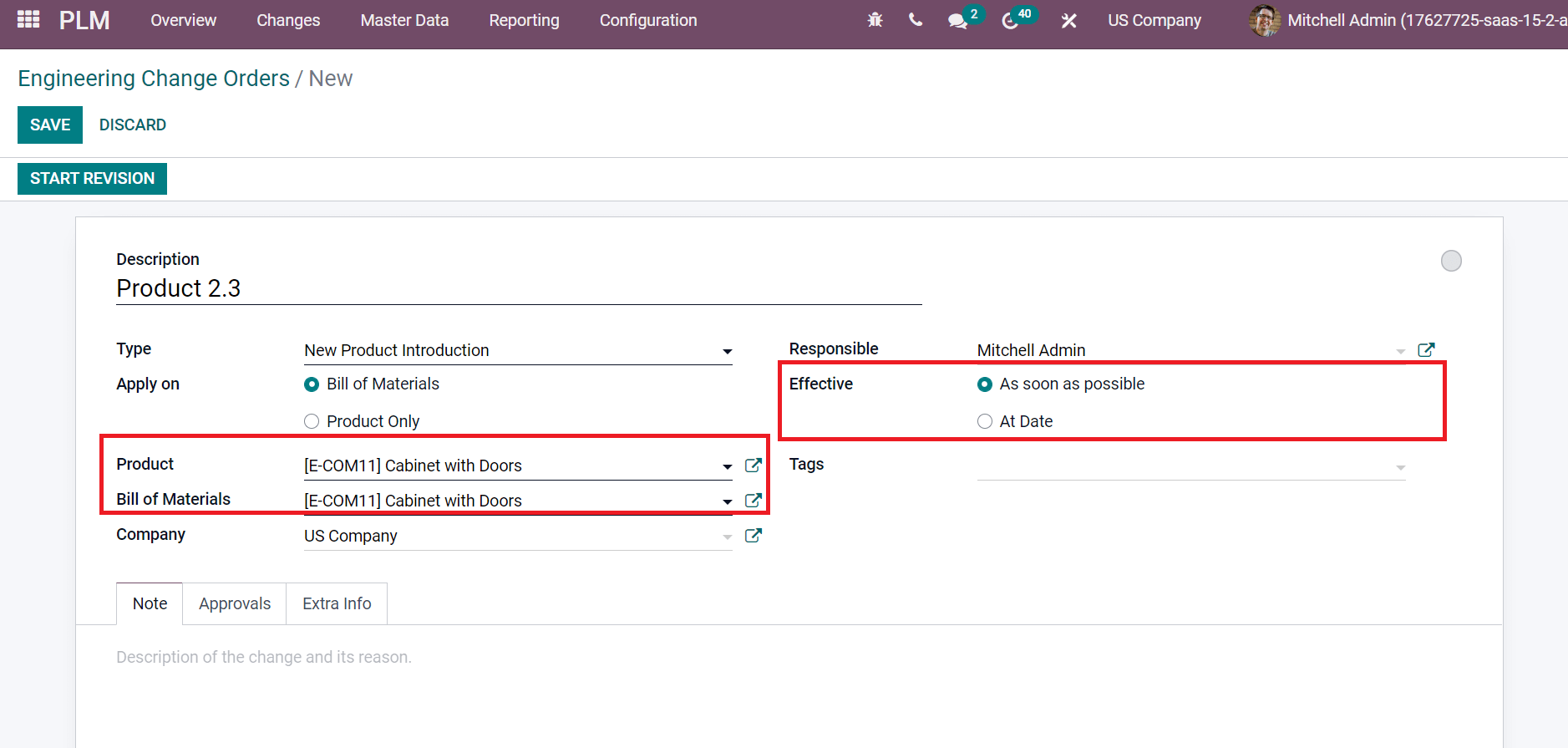

Users must choose the product to make changes, Bill of Materials, and US Company from the Company field. Later, specify a date for changes in the Effective field, such as At Date or As soon as possible.

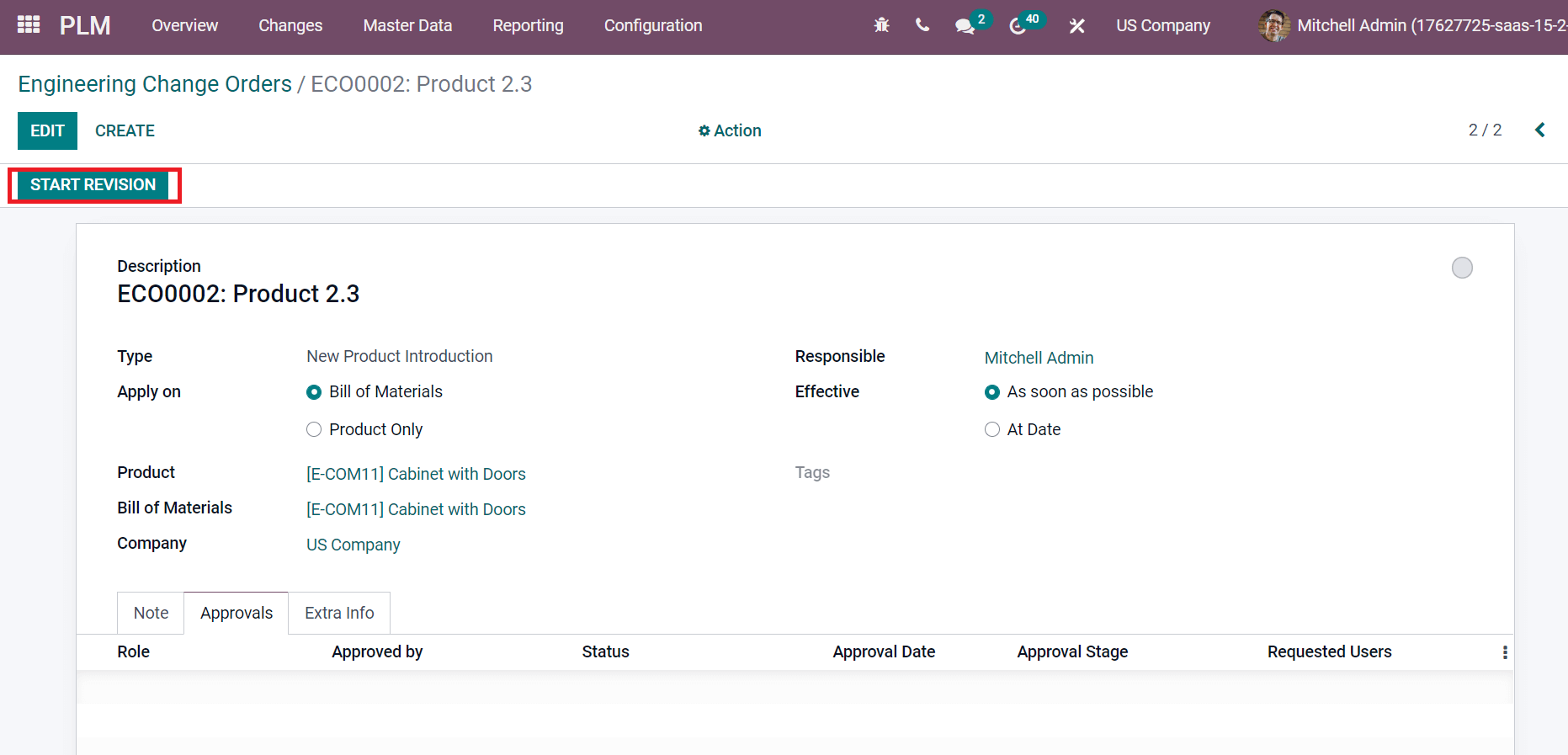

You can begin the revision of the product Cabinet with Doors by clicking on the START REVISION icon.

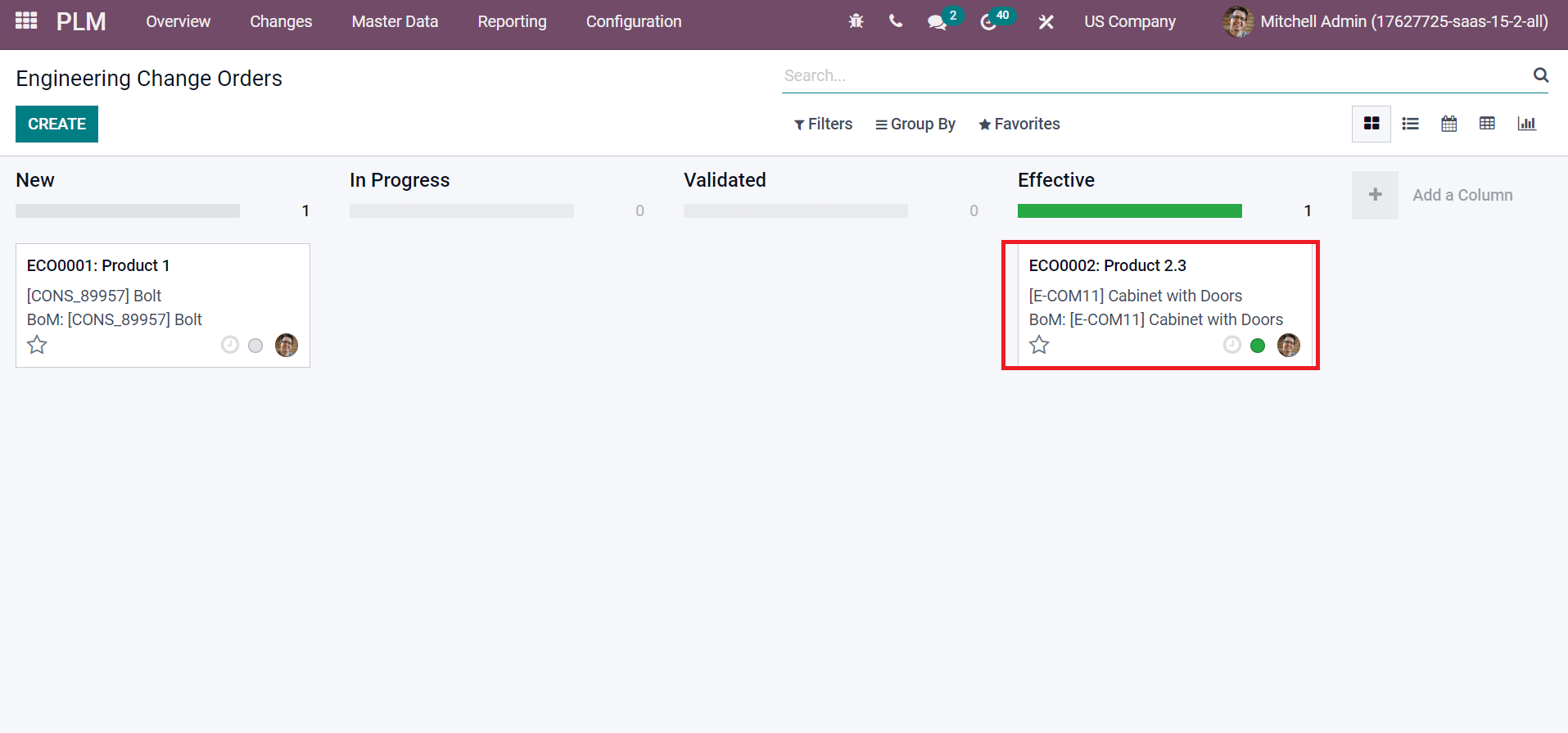

We can make changes to the product after starting the revision. By completing all changes for a commodity, you can see that it is ready for proceeding into the market. The stage for your product comes under the Effective section of the Engineering Change Orders window.

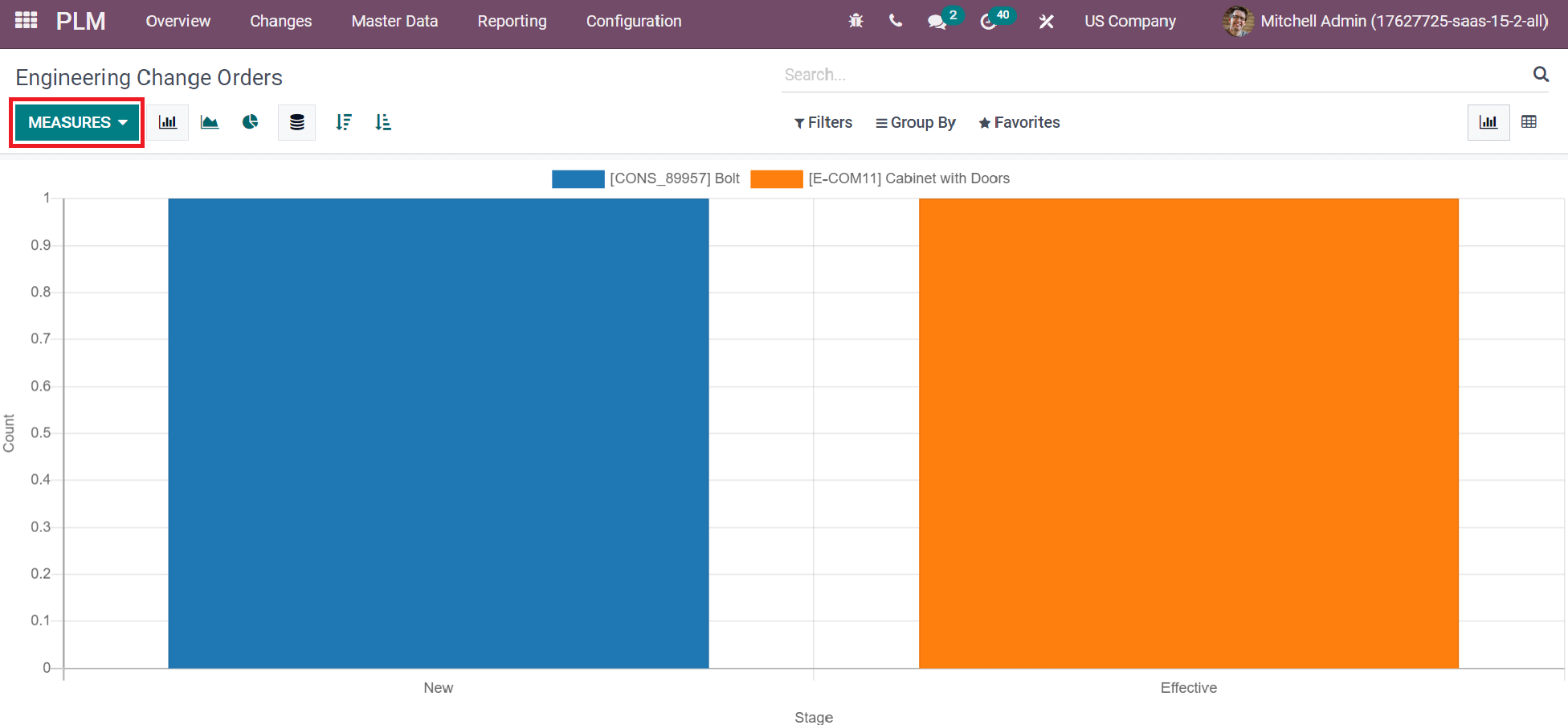

Easy to Analyze the Engineering Change Orders

The Reporting feature in Odoo 15 is beneficial for evaluating your engineering change orders for a commodity. Select the ECOs menu inside the Reporting tab and a viewable graphical representation. In the Graph view, we can see the stage data on the X-axis and the Count on the Y-axis, as specified in the screenshot below.

We can apply various measures, including color, and BoM Revision, to the graph by choosing the MEASURE icon. You can quickly evaluate the progress of engineering change orders to specific products from the Reporting feature of Odoo 15 PLM.

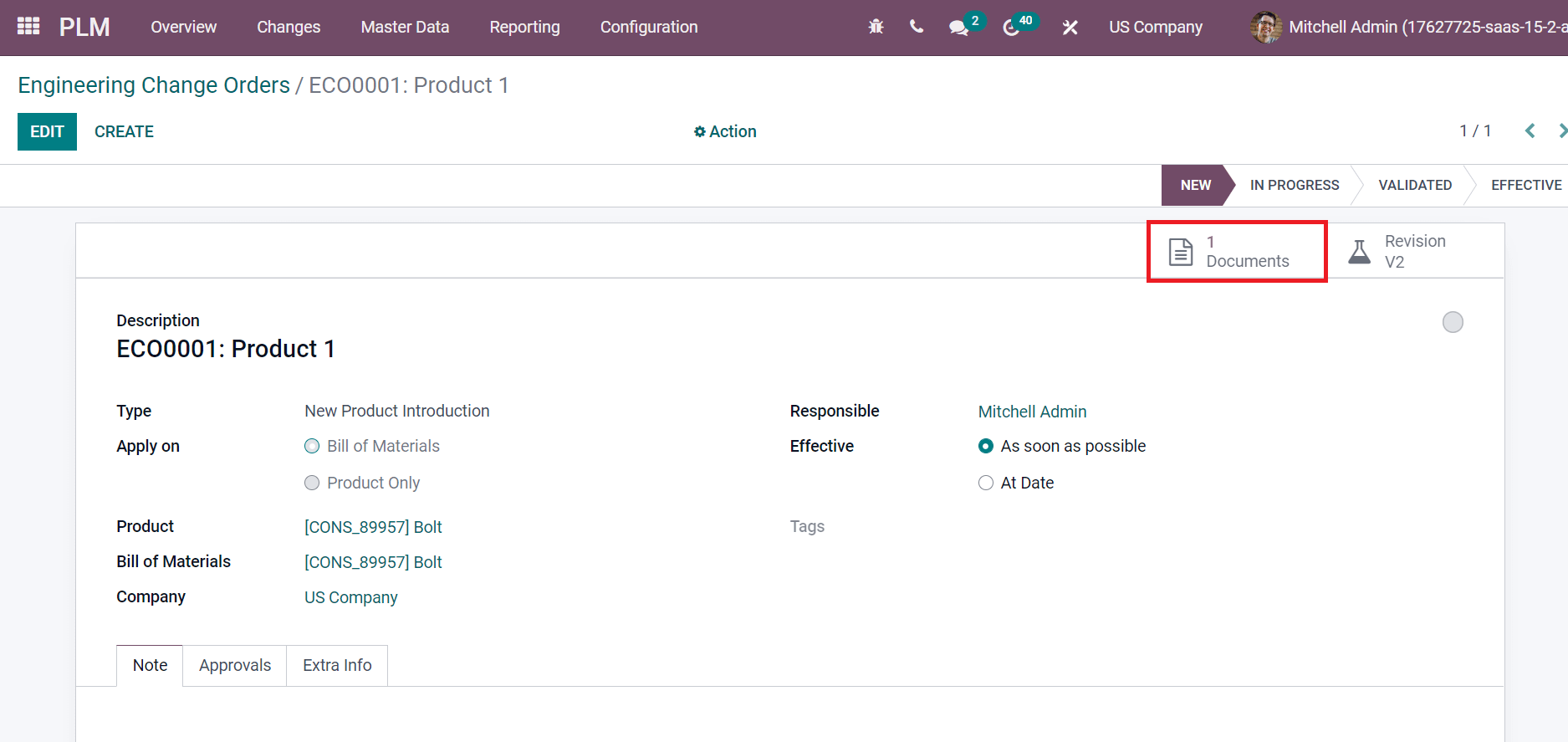

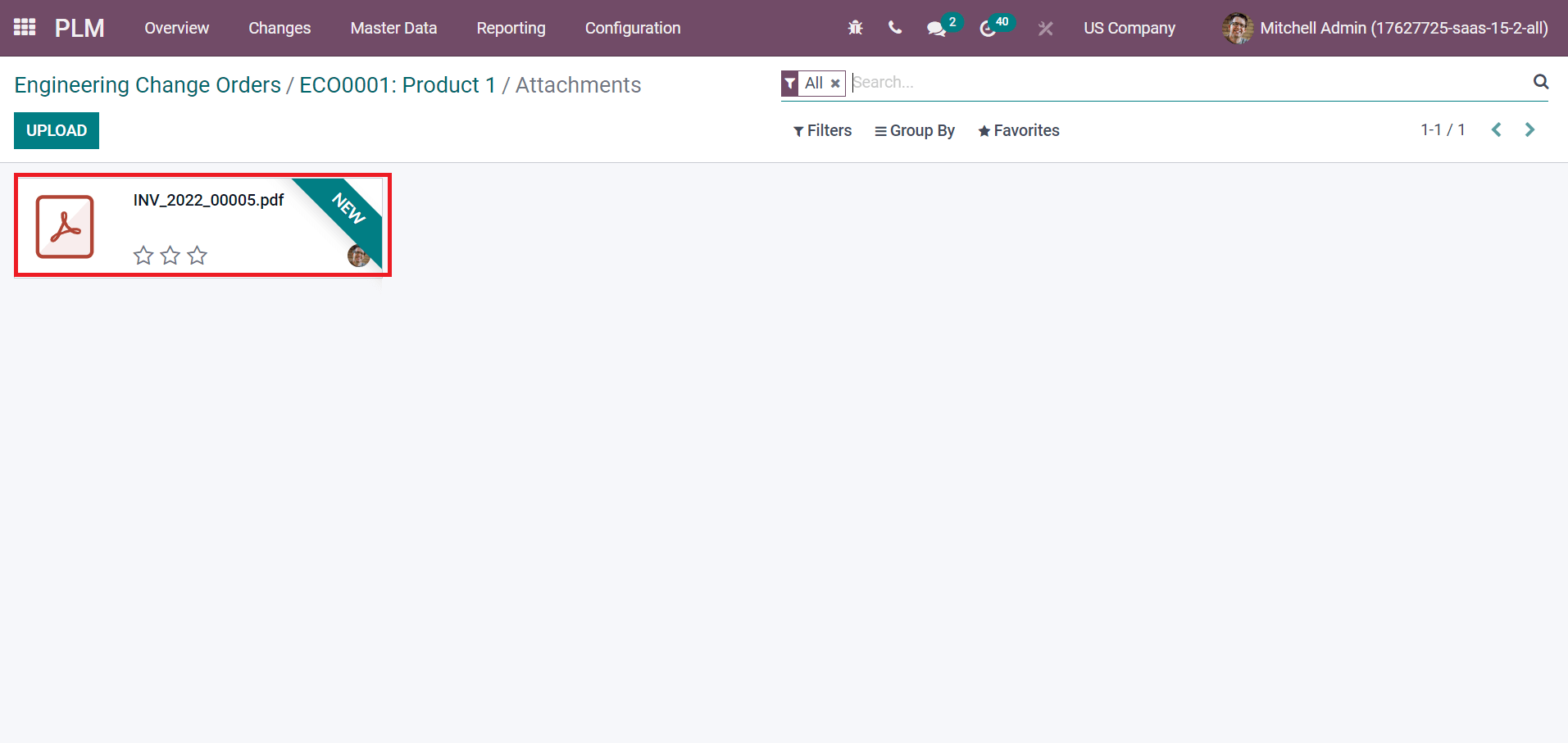

Store the Documents securely inside an ECO

Document management is essential for all activities in a business regarding products or services. Users can upload or store documents inside Engineering Change Orders in Odoo. Select your created ECO from the Odoo 15 PLM module and click on the Documents icon as illustrated in the screenshot below.

Selecting the Documents smart button, you can access the attachment related to your Engineering Change Orders.

A responsible person can trace the document and use it to enhance performance.

Increase Productivity and Reduce Risk in Business

You can speedily access all industry regulations in your business with the assistance of Odoo ERP. High-quality products are imparted as per the manufacturing standards by managing the lifecycle of commodities. It decreases the risk of low-quality raw materials and improves your productivity. The cost reduction for infrastructure development of a product accelerates the manufacturing time, and users can enrich the goods' productivity by tracking workflow, labor force, or design possible using the Odoo PLM module.

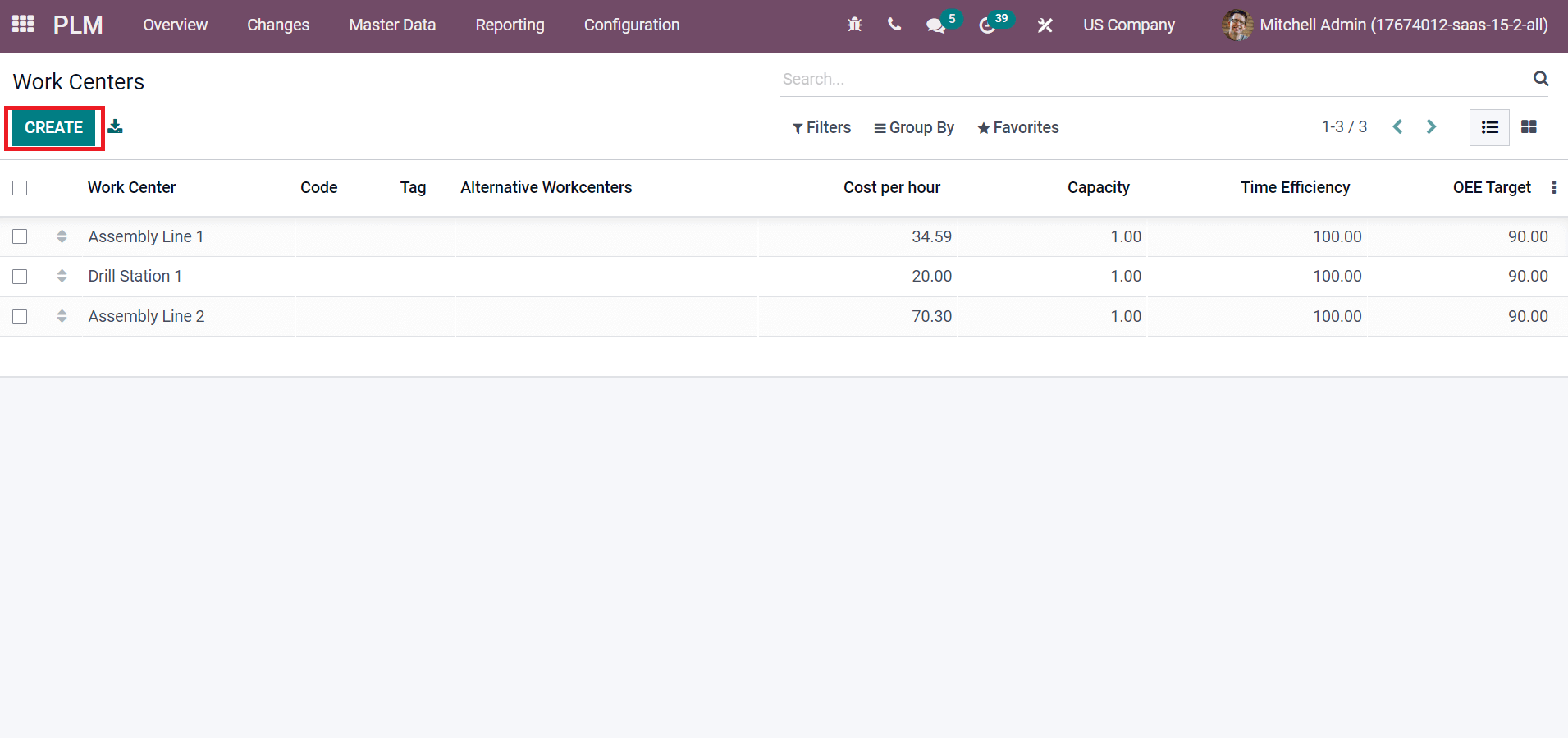

Manage Work Centers and Products for a Business

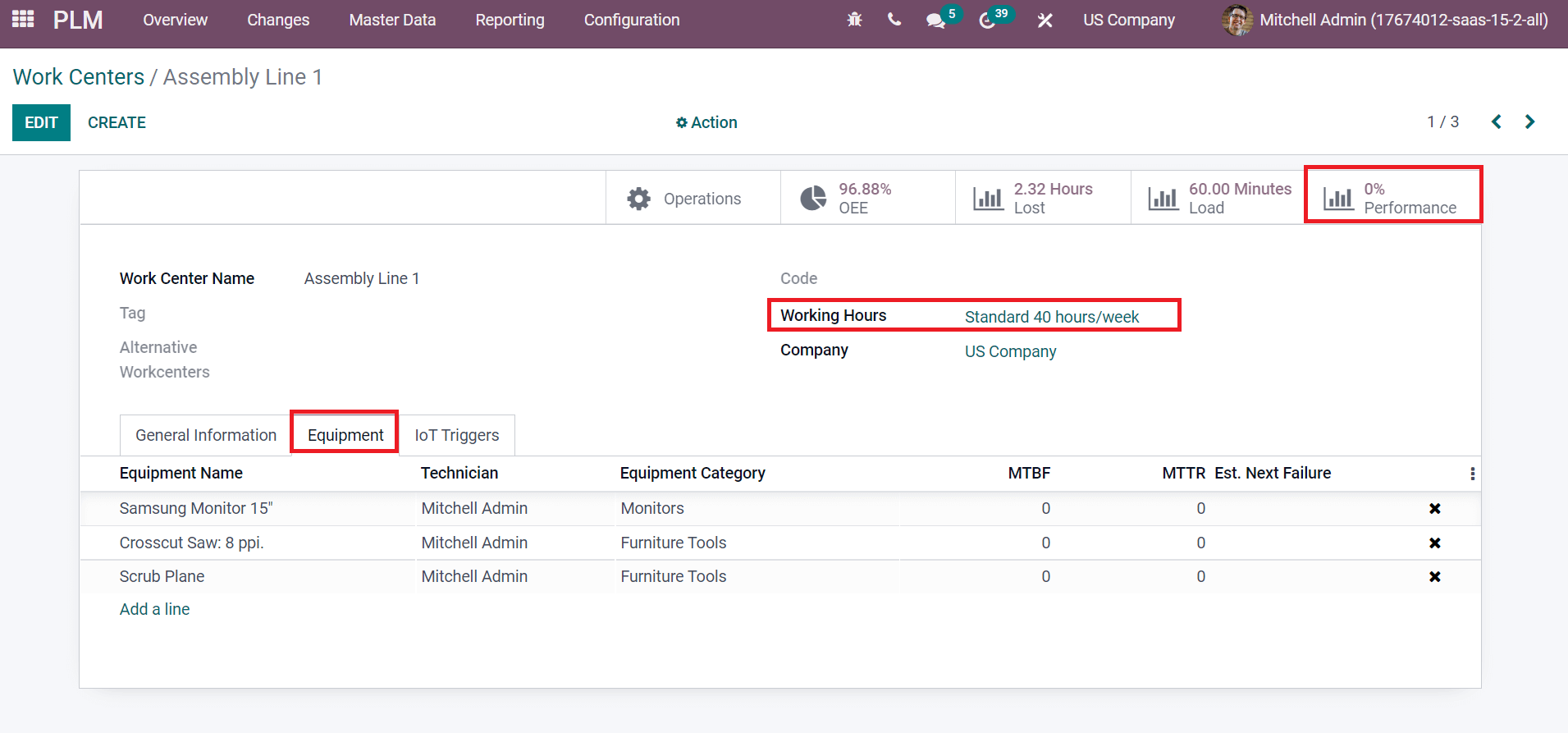

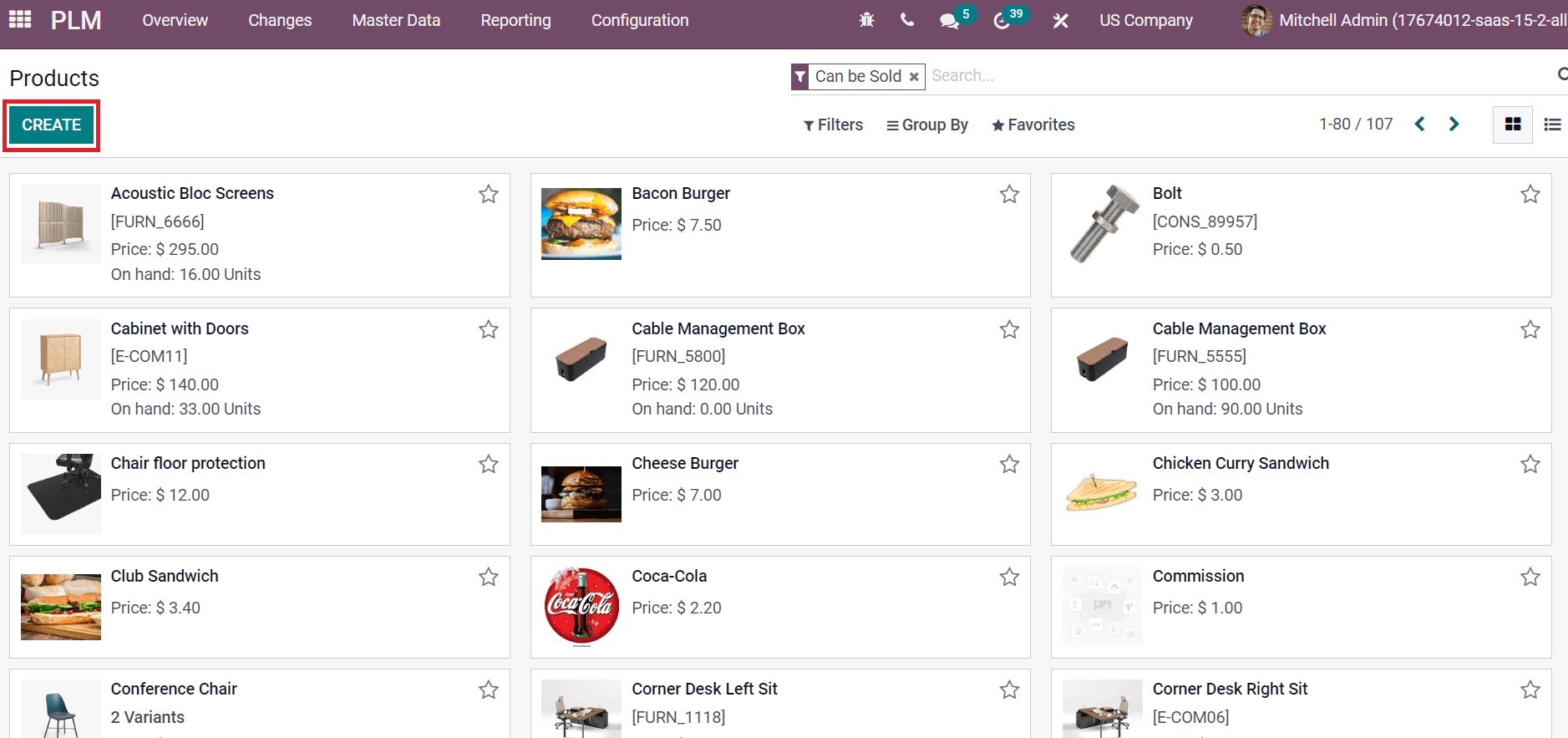

A work center is a space in which manufacturing activities occur in an organization. We can manage the working hours of employees for specific products/services in a company inside a work center. The performance of production operation activities takes place in a work center of a firm. Using Odoo PLM, users can create new work center details and manage products easily. Choose the Work Centers menu from the Master Data, and you can get the list of work centers in your company. Select the CREATE icon as cited in the screenshot below to develop a new work center.

When creating a work center data, it is possible to add equipment details and time needs to produce the products in the Working Hours option.

Users can also analyze the production of a specific work center by clicking on the Performance smart button in the Work Centers window, as shown in the screenshot above. Moreover, we can add all commodities data in a company in the Products window. Select the Products menu from the Master Data tab and click the CREATE icon.

Accelerate Best Quality Products and Share data Quickly

Users can produce the best quality products by changing Engineering Change Orders in Odoo 15 PLM. Furthermore, Odoo PLM is integrated with the Quality module to manage the standard of products. It ensures you set a quality control mechanism and other activities in business. We can track sales information and enrich product quality based on customer feedback. On another side, you do not need to worry about communication delays in your firm. Using Odoo ERP support, users can equally transform facts for retailers and the global market. Data sharing becomes an easy process with the help of Odoo 15.

Apart from these, features of Odoo PLM include acceleration of marketing, centralized information, and configuration. Users can quickly manage a company's BoM and ECOs details of products with the help of Odoo 15 PLM. It is inevitable for businesses to make changes in the data of raw materials and replenish them for future usage. Refer to the given below link to identify about Features of the Odoo 15 PLM Module