A business has to run on timely replenishing of the stock in the inventory. But it should also mean that your stocked items should not go to waste. The replenishment strategies taken in inventory management have to be careful enough to have enough to deliver on time and yet not more than necessary for it to go waste. Not all products can be stocked in large quantities or even be stocked up without enough orders. Consumables and the similar stock would be spoilt and wasted if stocked up.

Proper inventory management would allow all other activities of the supply chain to fall into place and function smoothly. The risk of running out of stock and over-stocked can reflect badly in sales and revenue respectively.

When using a manual tool for inventory management, we run the risk of lacking real-time data on the inventory stocks. This would eventually end up in running out of stocks or overstocking of supplies. The money spent on this alone would cost the company a large sum. Apart from that lost labor and time can reflect badly on employee morale and further productivity.

Having a good inventory management system is not enough, we should be prudent enough to make the best of the available features. For this, we need to understand both effective strategies of inventory management and various features of the inventory management system we have in place.

While we decide on replenishment strategies, we are often unsure of the demand. We find it very challenging to forecast the demand for the products. Different products have varying demand and therefore varying stock replenishment rules. Another challenge in reordering or replenishment is to maintain safety stock. We must ensure that a certain amount of stock is always available to meet unforeseen demands and to avoid stockouts. While doing this it should also be in consideration that we do not overdo and cause stock obsolescence.

The suppliers of various products will have a lead time in fulfilling the purchase. This should not mean that we run out of stock. For this, we have to plan the lead times ahead of time. We have to have effective strategies to avoid these challenges and confusion in the inventory.

Prioritize the items: One thing to always keep in mind is that we should know the correct balance of our inventory. We must learn to prioritize the items in our inventory to determine the frequency, quantity, and safety stock for reordering.

Constant reporting: make sure that there is frequent reporting of the inventory to analyze the stock balance. Studying inventory health would allow us to restrategize reordering rules, shift marketing focus, and set sales strategies to prevent wastage.

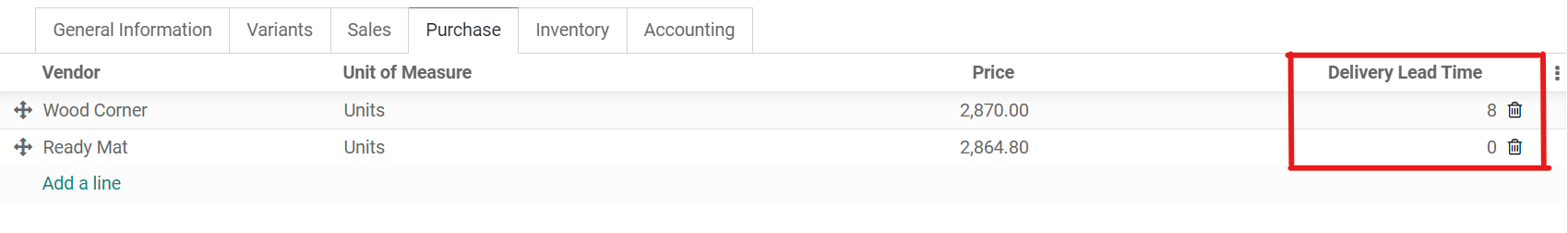

Lead time: understand the lead time of the product bought and the possibility of the safety stock to cover up in the meantime. Readjust the safety stock according to the lead time to buy products at a good price. Paying a high price for faster fulfillment is not necessary if we plan accordingly.

Manage discount quantity: while buying with discounts, ensure that the price we pay is only for the necessary quantity. Buying in bulk because of lower price may not always benefit us as the products may go obsolete and cause more waste than expected, essentially costing us more.

Automate your inventory: it goes without question as we adapt to the change in business. It has proven effective in cutting down the hectic paperwork, documenting struggles, and also by processing things faster. The management systems are a complete database of the business processes and can bring to us real-time reporting and timely alerts, making the work easier and stress-free.

Reordering rules

The reordering rules in Odoo are set for products to manage their stock refill. The rules are set to automate when a purchase order has to be created for a given product. When the stock reaches a minimum stock level, the reordering rules will help us replenish.

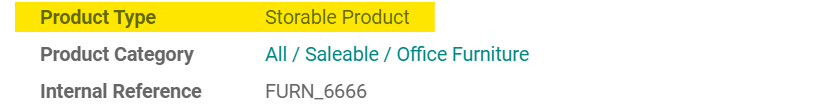

You can open the product window from the Sales, Inventory, or Purchase module of Odoo. From the items displayed, choose a storable product and the recording tab will be available.

Alternatively, we can find the reordering rules in Inventory > Configuration > Products

We can create a new reordering rule for the particular product.

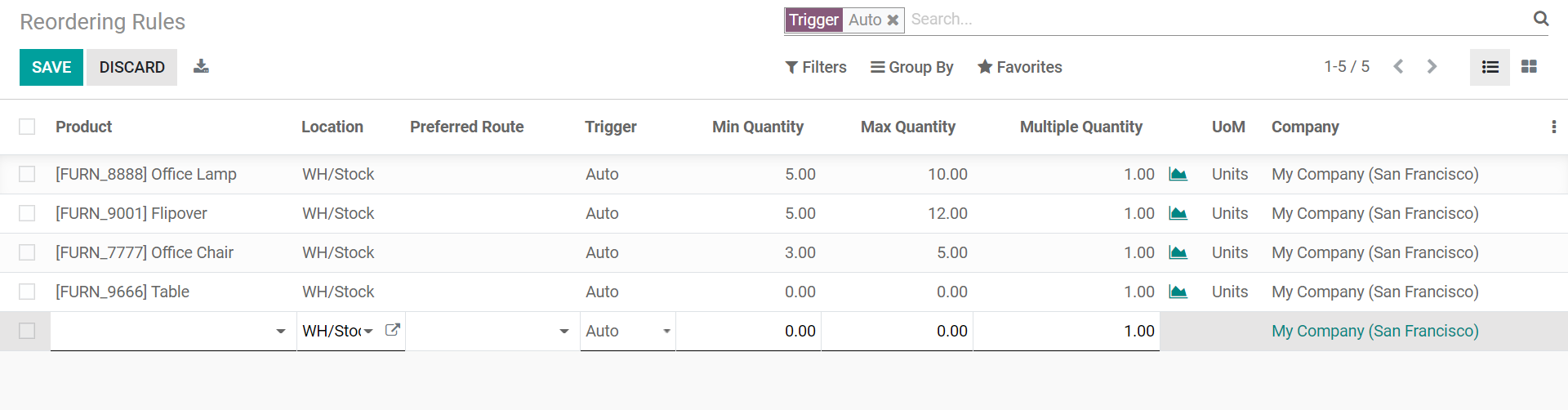

We can enter the product, location and set a preferred route. The preferred route can be ‘manufacture’ or ‘buy’. We can set the minimum and maximum quantities for reordering. The difference between the available quantity and the maximum quantity will be the reordering quantity. We can also control the trigger as auto or manual. The lowest quantity that can be ordered is determined by the multiple quantities.

When the trigger is set at auto, Odoo will create a purchase quotation or a manufacturing order as the product quantity reaches the minimum. The quantity will then be replenished to the maximum quantity set in the rule.

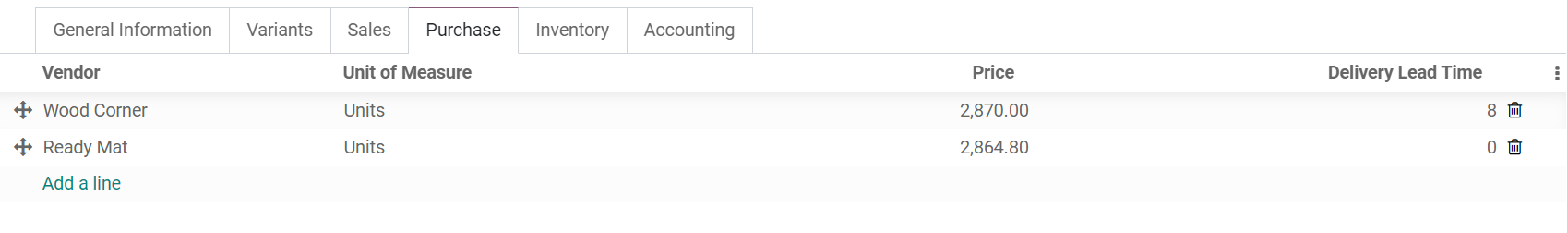

We should ensure that the product is fully configured in order for the reordering rules to work. A product to buy has to have a vendor configured, while manufacturing should have a bill of materials configured.

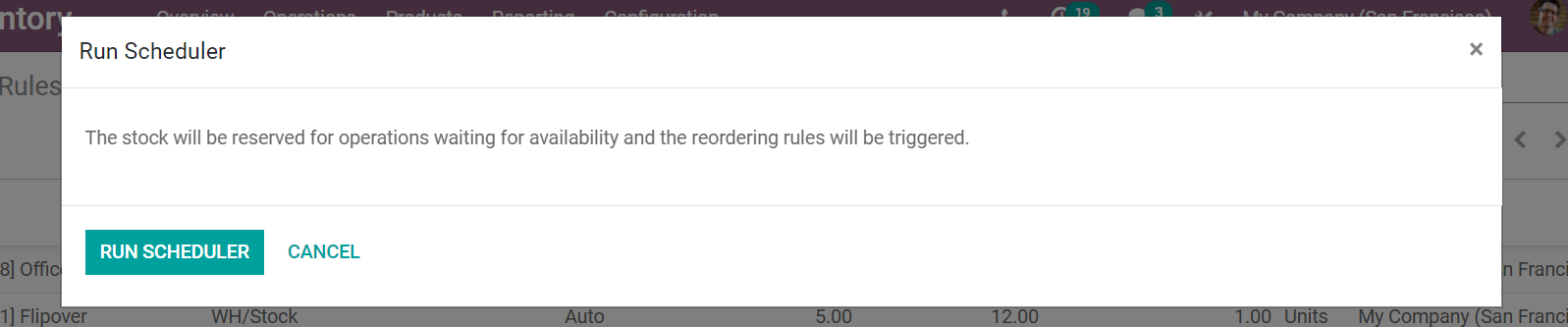

The reordering rules are run when the scheduler runs. The run time is at 12 every night. We can configure the settings in the inventory module.

We can also configure the lead time for the vendors while creating vendors in the product configuration.

Configuring scheduler

We can configure the settings of the scheduler in the Odoo Inventory in order to manage the running of reordering rules.

The scheduler runs the actions based on priority and urgency. Depending on the configuration of the product, the scheduler will run production, task, or a purchase. The default settings run the scheduler once a day. This will validate the procurement that is confirmed and waiting to start.

We can also configure the settings to automate the scheduler. This is done by enabling developer mode and then from settings >technical > automation >scheduled action, we can modify the starting time under Run MRP scheduler Configuration.

You can also read how to replenish products for an overview of manual replenishing of the inventory items.