A bill of material is the documentation of the raw material used for manufacturing a product and other components required for the process. It can also include the instructions for manufacture along with the instructions for the repair process. Usually, bills of material are displayed in a hierarchical way.

We can consider the bill of material as the key source that will inform us about the materials used for the completion of the manufacturing process.

The Bill of Materials is something that we cannot ignore. It is vital for our business and we need to manage the bill of materials to understand its components. It will also help us to get a glance at the way we can assemble the components. It is very important for us to generate an accurate bill of material. A wrong bill of material can at times bring the production to a halt. So to ensure the accuracy of the BoM and efficient completion of the BoM we can depend on software applications. Different ERP solutions offer great assistance to businesses in preparing bills of materials.

There are different types of bills of materials including the ones related to manufacturing, engineering, operations, and design.

In this blog, we are going to talk about manufacturing BoM.

Odoo 14 Bill of Material

As discussed earlier Bill of Materials can be considered as a document that will be useful for the manufacturer to list out all the components used for production. If you are using Odoo 14 Manufacturing Module, the bill of materials support offered by this module ensures the proper listing and documentation of all items. With the help of a BoM, we can take a glance at the components as well as quantity details of the component used for completing the production at different stages. The BoM also helps us to keep track of the routing. That is, it helps to keep a record of the different stages of the manufacturing process. We can prepare a bill of materials for a single-step production as well as multi-stepped production.

With Odoo, the user can effortlessly link multiple BoMs for one single product. That means, the BoM for different levels can be added here. In such cases, the BoM will be documented in hierarchical order.

Managing to the route is also not at all a difficult task with Odoo 14 Manufacturing as the task can be completed with the help of BoM. This can be done in a few steps by creating multi-level BoM. We can also set a new BoM with the help of another BoM using Odoo.

Three key features of Odoo BoM

Optional routing

This feature supports us to generate new routings when we are creating or managing work orders. We will be enabled to sequence our production. This can be done based on the type of routing used.

Version changes

With this feature, we will be able to include configurable alternatives whenever we create orders.

Phantom BoM

This feature encourages the physical production of an item that is not stored but sold as a semi-finished product.

How to set up a BoM?

In some cases, we will not have to assign routing to the Bill of Materials. Such situations arise when we complete the manufacturing process in a simple step. IF the process is completed in a single step we will not have documented the routing.

In such a situation we can generate a BoM just by using the CREATE button. We will, however, have to create a product with the help of the product menu to manage this.

Once the product is created at Manufacturing -> Products -> Products

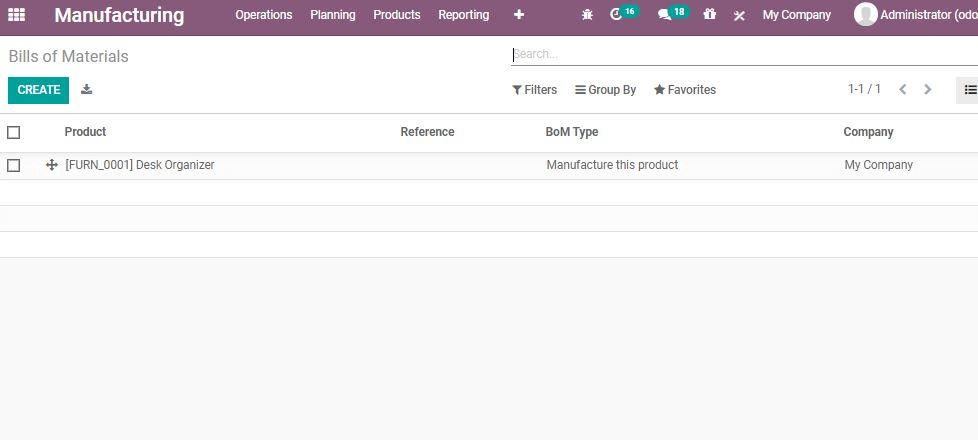

We can go to BoM listed under the Products tab in the Manufacturing Module.

On opening the BoM we will get a window as below.

We can make use of the CREATE option to generate a new BoM.

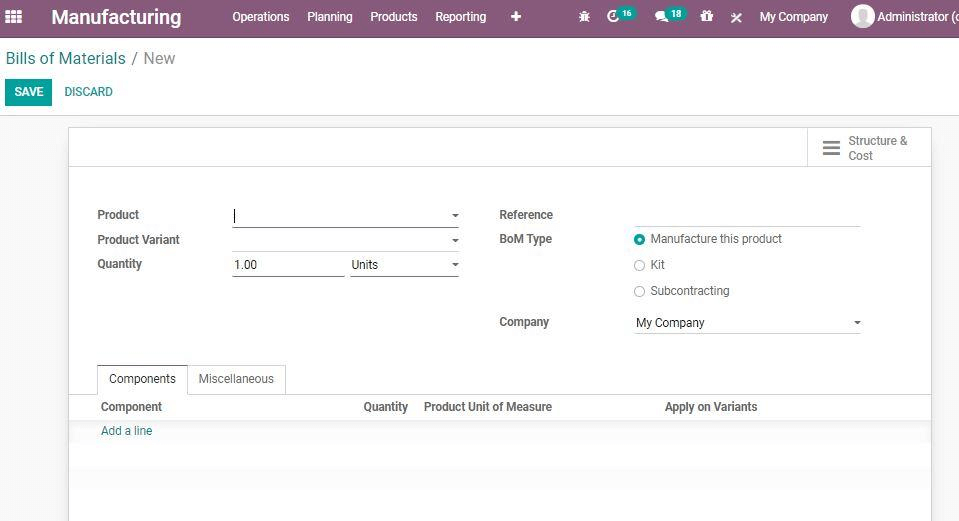

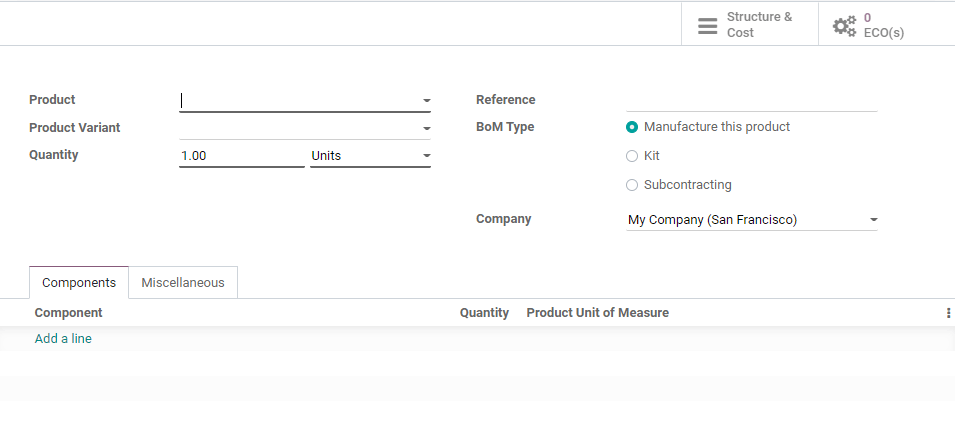

Let us see the main attributes here. They are,

Product: Here we can select the product. As we have already created the product, we can use the dropdown menu to manage the operations. Product Variant: As the product variants will have some changes in the attributes, we can specify the attributes here to prepare an exclusive BoM for the variant.

Quantity: Here, we can include the quantity of the products that we are planning to manufacture.

Routing: In this case, routing means some technical activities to complete the manufacturing. On specifying the routing we can understand that we are using a work order to complete the production process.

BoM Type: Here we can choose the BoM for different types of products. For example, it could be BoM for Manufacturing a product, for Kits, or for Subcontracting.

Now we can check the tabs below. There are two tabs, which are Components and Miscellaneous.

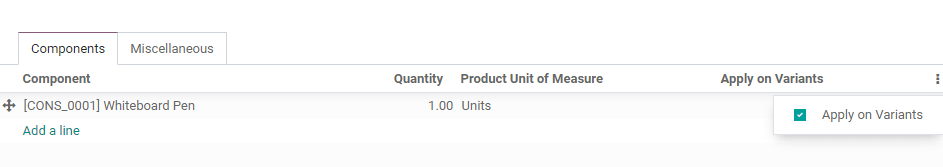

On clicking the Components tab we are enabled to add the components using Add a line feature. This is the place where we can give the details of the components used for the production and the quantity of the components used. As there is an option to add the product unit of measures we can easily identify the number of components used to manufacture a unit of the finished product.

We also have an option to Apply on variants

This field helps us to generate a common bill of material for different variants of the same product.

We can note that it is possible for us to update or delete a BoM from Manufacturing> Products> Bill of Materials.

Set Operations and Routing for BoM

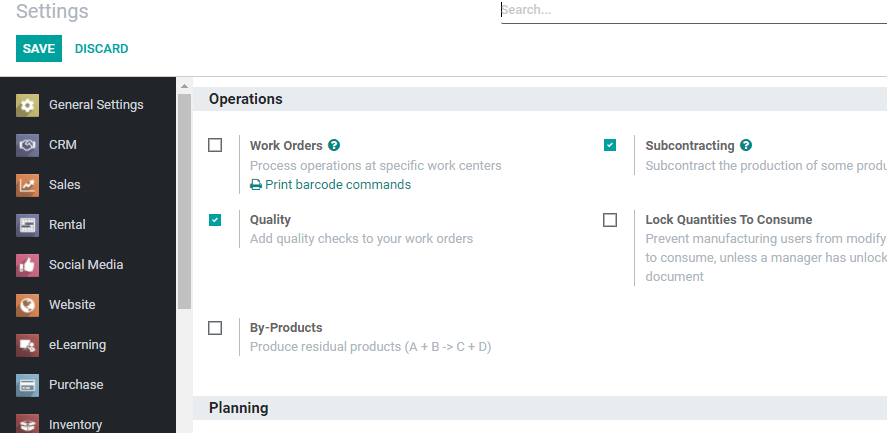

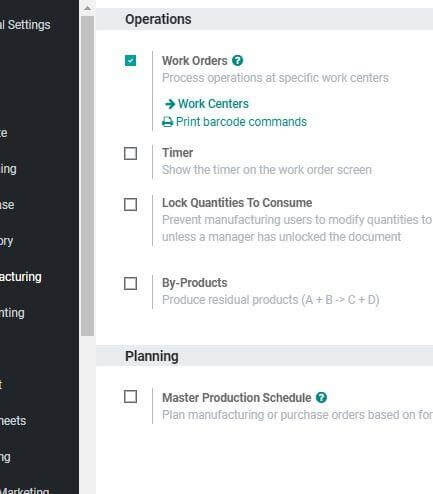

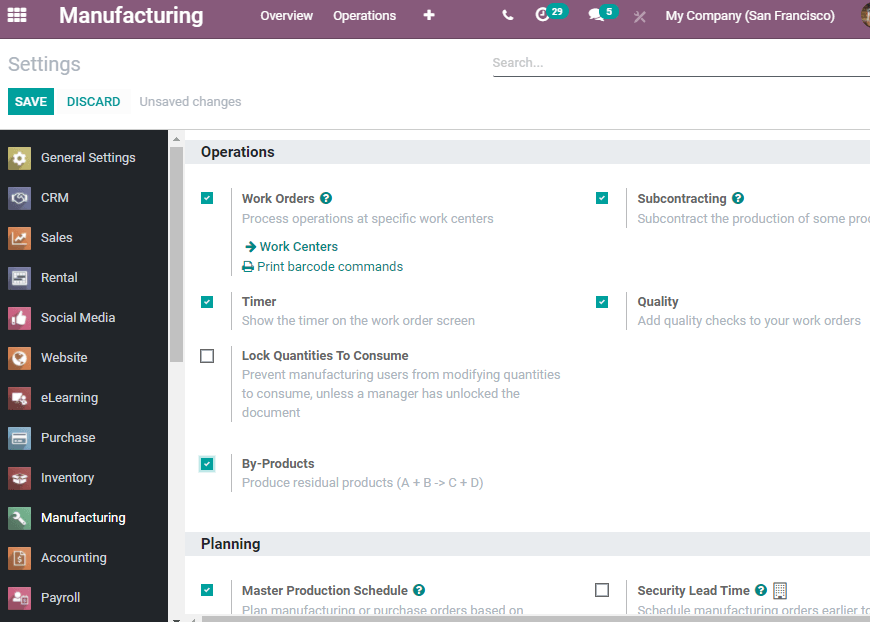

To make use of routing operations we have to introduce Operations Tab in the BoM form. For this we have to configure the Operations. Let us see how. Go to Manufacturing -> Configurations -> Settings first.

Here we can find the Work Orders option

As the routing is done through work order, we have to enable Work Orders

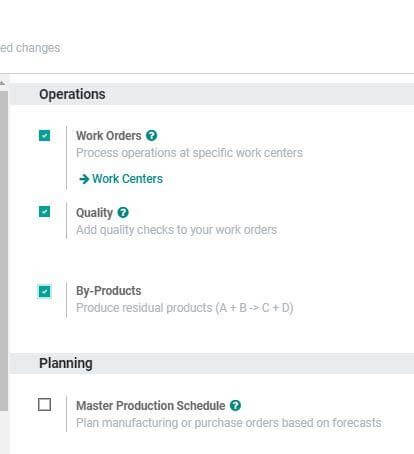

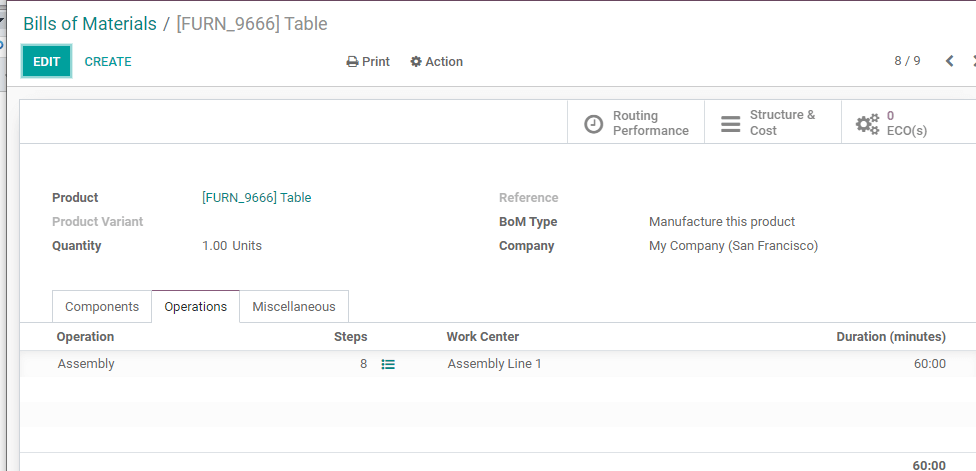

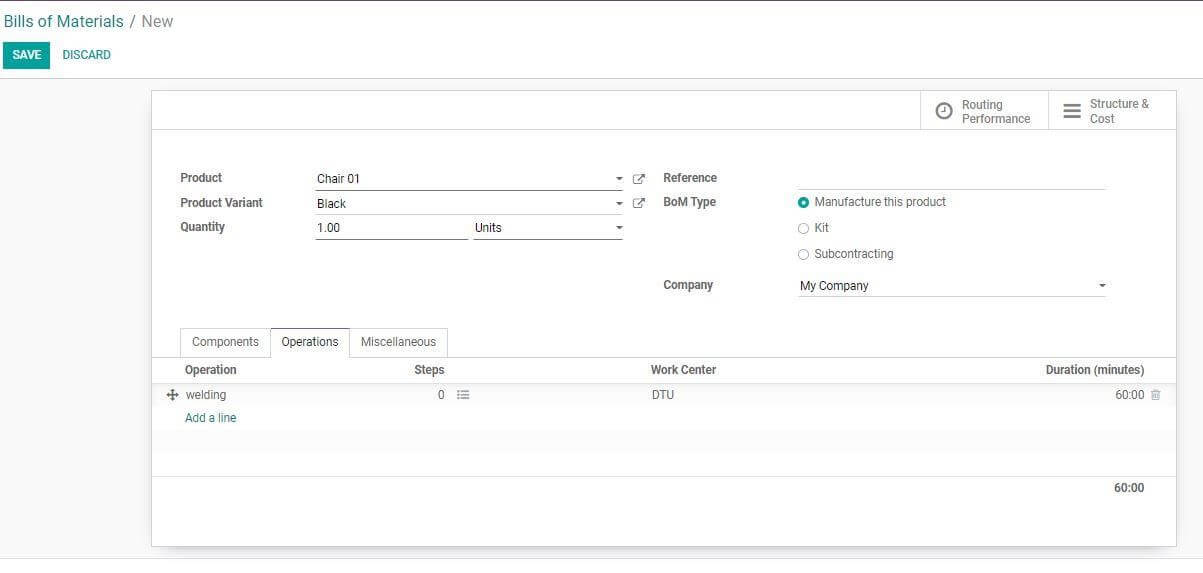

Now we can save the changes and go back to BoM and you can find Operations tab next to Components tab.

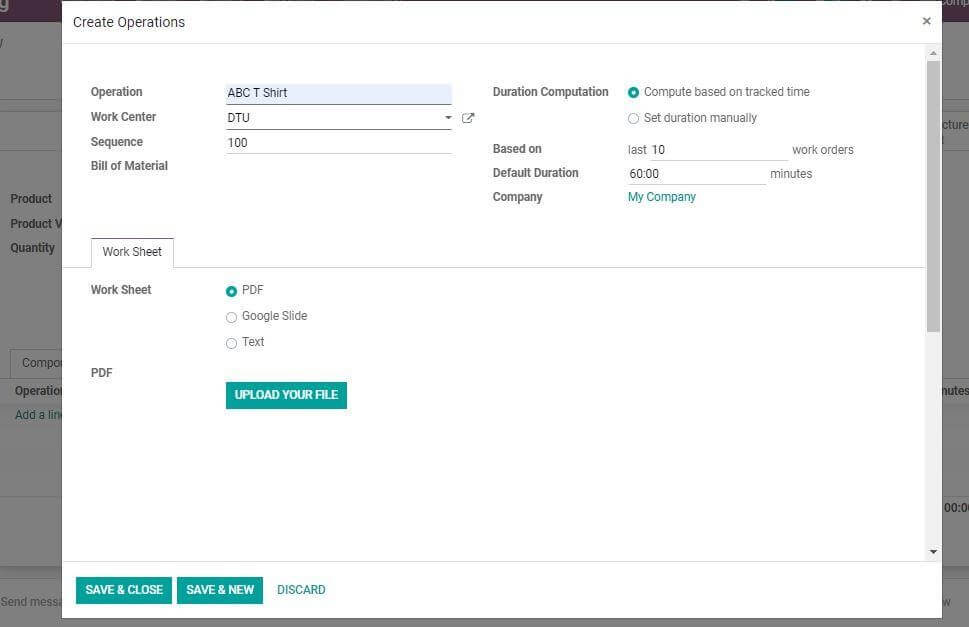

Let us see how to Create Operations

Here, we use Operations to manage routing. We can use the Add a line option for this and create as many routes as we want. We can include any number of steps with this feature.

The key fields here are

Operation: The type of activity

Work center: Work center is the place where the manufacturing process takes place.

Duration Computation: We can make use of this feature to calculate the total time required for the completion of the process. This can be done by computing the duration based on the tracked time and by setting the duration automatically.

We can also find a worksheet tab here. This helps us to finalize the type of worksheet to be uploaded. We can choose from a Text file, a PDF document, and Google Slide. Here, we can also find a tab Worksheet. We can decide the type of worksheet we want to upload. After completing the process you have to SAVE the changes

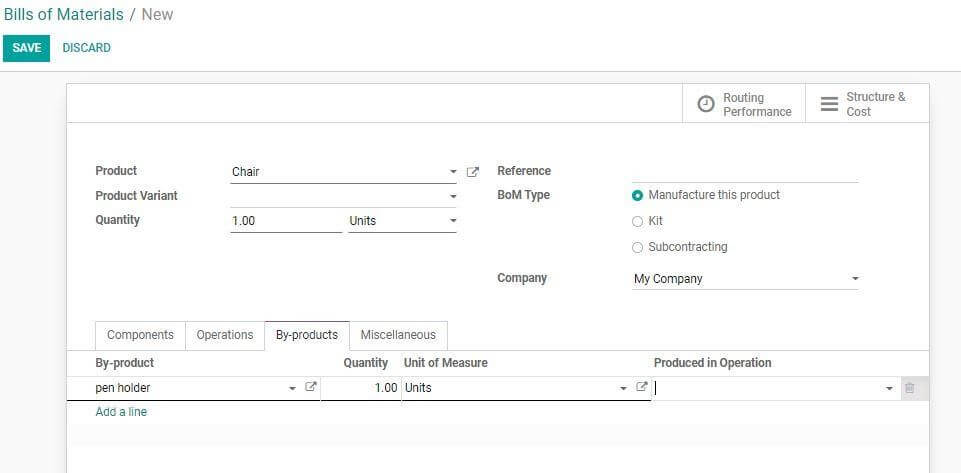

Adding by-products

With Odoo BoM we can also manage by-products. For this we have to set the By-Product option by going to Manufacturing -> Configurations -> Settings> Work Orders

Can you find By-Products? This has to be enabled.

Then save it and return it to BoM. We find additional tab by-products here.

We can add the product name, quantity, UoM, and the stage when it is produced (produced in operation)

This is how Odoo 14 BoM helps us. For more details, visit our website www.cybrosys.com

You can refer to the video about Bills of Materials in Odoo 14 Manufacturing.