Manufacturing is the process of making goods for use or sale, by means of labor, raw materials, and equipment. The essence of manufacturing actually is the transformation of raw materials to finished goods items. These goods might have been supplied to other manufacturers as raw material for the production of much more advanced products or shipped across the wholesalers to retailers and then to customers.

Before starting production, there might require a configuration for the product. It defines the components/raw materials required for production, number of components, workstations, and all. The raw materials are most important for creating a product. These raw materials or components for manufacturing are termed as the Bill of Material (BoM) in Odoo. Sometimes the product may require multiple BoM since it can be created in different ways. Similarly, they can be also used for creating product variants.

Let us see how the bill of materials is created in Odoo 14 Manufacturing.

Odoo 14 provides some changes in the manufacturing module but basic processes are the same. The new feature introduced is:

1. The routing is removed but the operations, workstations can be directly added in the BoM.

2. The consumption of components made it more flexible by adding additional options.

3. Forecasted reports for the components inside the BoM.

4. The popover widget

How to Create a Bill of Material

Bill of Material for a product can be created from Manufacturing Module -> Products -> Bill of materials -> Create.

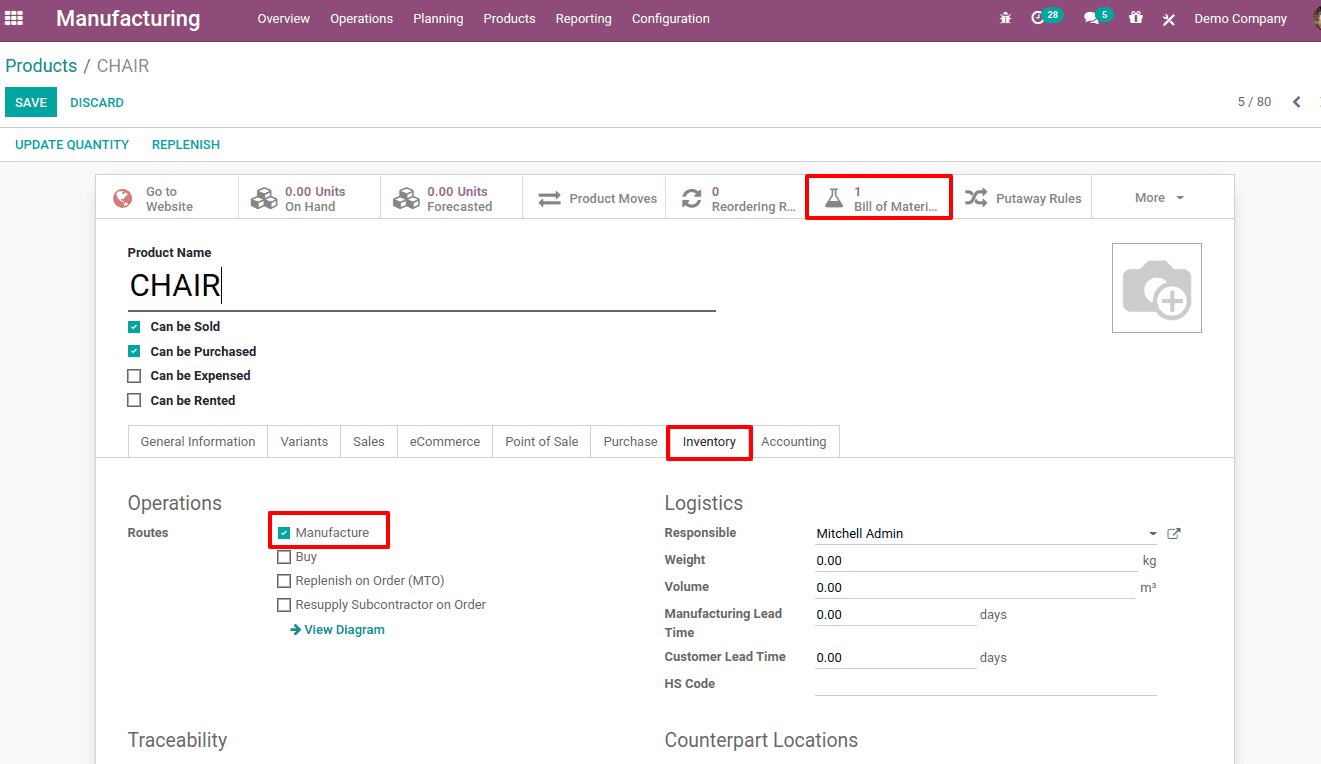

For manufacturing a product, firstly we need the product template. For a product ‘Chair’, it requires a wooden seat, chair legs, screws and bolts. So let us check the product configuration first.

The basic configurations for this product are, under the inventory tab you have to mention the route as ‘Manufacture’ since this product is manufactured. From the product form also the bill of materials can be created, click on the smart tab ‘Bill of Material'. This redirects to the BoM creation form.

There may be some cases of using multi-level bills of materials. The chair has components like the wooden seats, chair legs, screws, and bolts. At the same time to make a wooden seat, it may require wooden panels. So the wooden seat has to be manufactured as per the production of chairs. In such a case, for that product ‘wooden seat’ the route ‘Replenish To Order (MTO)’ should also be enabled. For those components that are purchased for manufacturing, the route ‘Buy’ should be enabled.

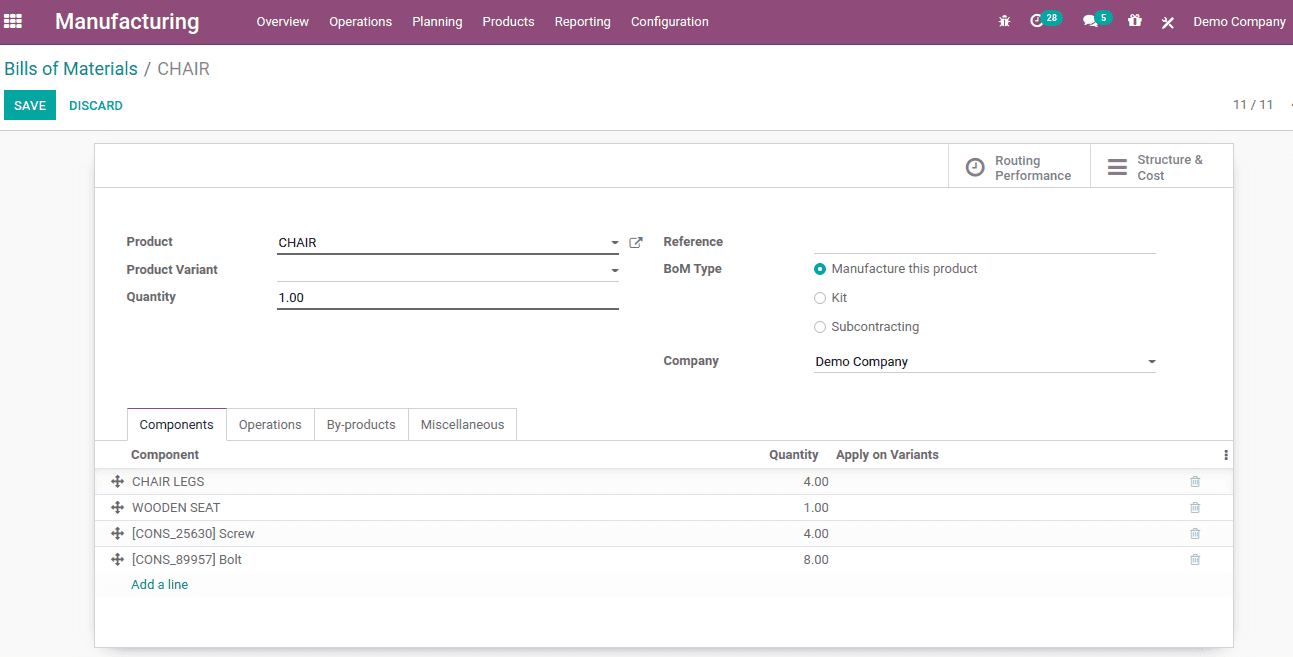

Once all these configurations are set, create the Bill of Materials. The BoM form is as follows:

Add the product to manufacture, quantity to manufacture, reference, and BoM Type.

BoM Type are three types:

1. Manufacture this product: means the product is to produce using the components.

2. Kit: refers to the concept for which the BoM are assembled to make the entire product. Thus the product can also be sold as kits.

3. Subcontracting: refers that we are giving the BoM to some subcontractor so that he will create the product for us. This functionality is only possible if you allow subcontracting from the configuration settings.

The reference is to identify the BoM for the product if it has multiple BoMs.

Here to produce a chair it requires 4 chair legs, 1 wooden seat, 4 screws, and 8 bolts. BoM product variants can also be added in the line.

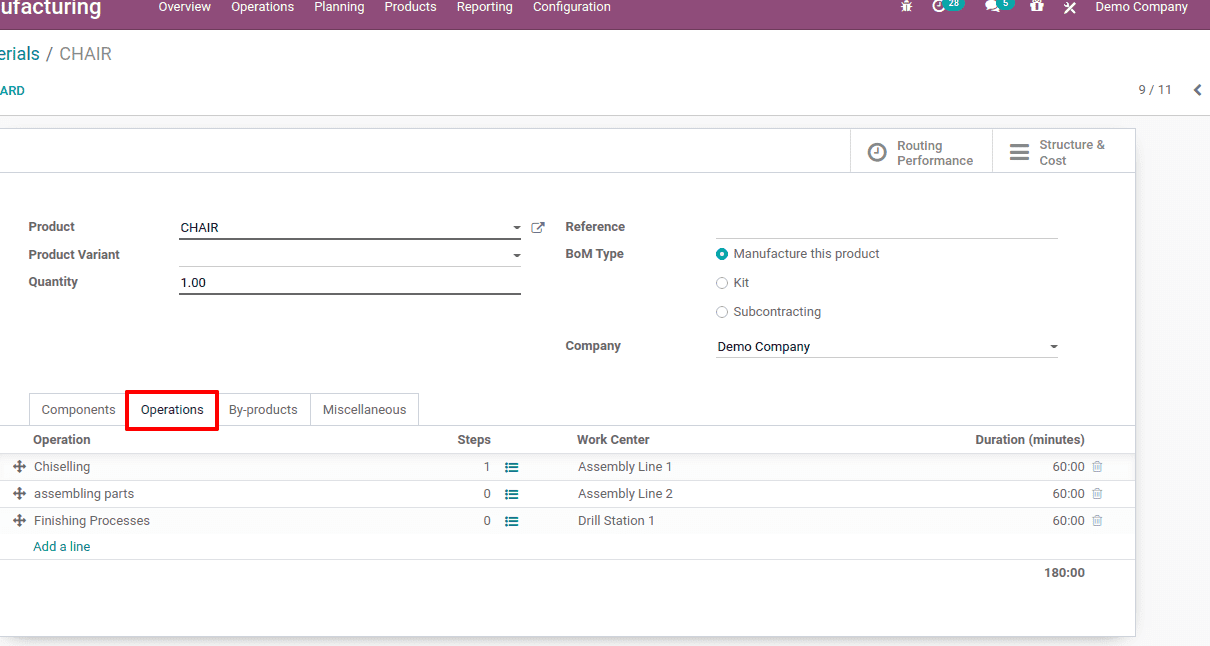

Under the ‘Operations’ Tab, the operation to perform in different workstations is added.

Previously, in the 13th version what we have done is that the operations and corresponding workstations are defined inside the routing and routing are applied on BOM. This will bit confuse users and also when a product enters a workstation it must have to move through all operations inside it. In those cases, we need to manage multiple routes. This is eliminated by adding operations directly in the BoM by Odoo version 14.

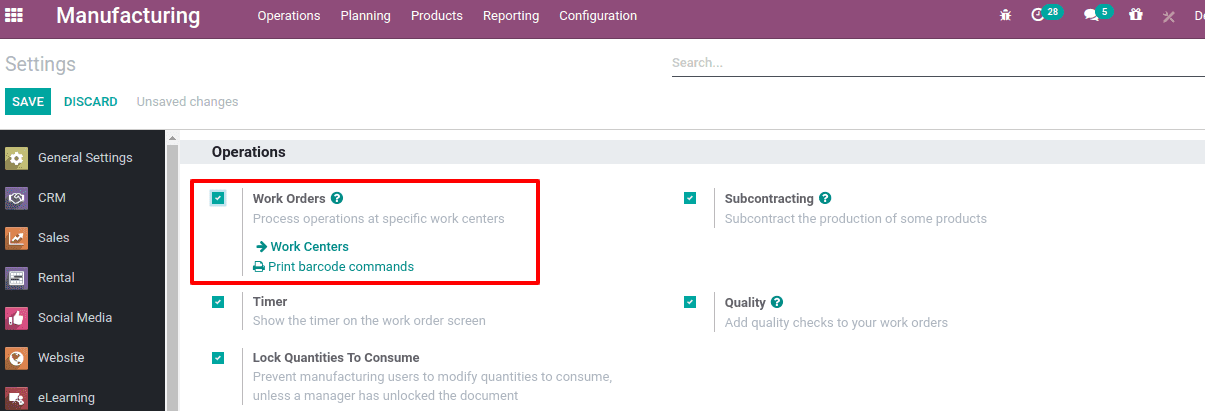

Operations can be created from Manufacturing module -> Configuration -> Operations. This feature is available in a configuration only you enable work orders from the configuration settings.

Now one can see the ‘operations’ and ‘work center’ in the configuration menu. Create an operation.

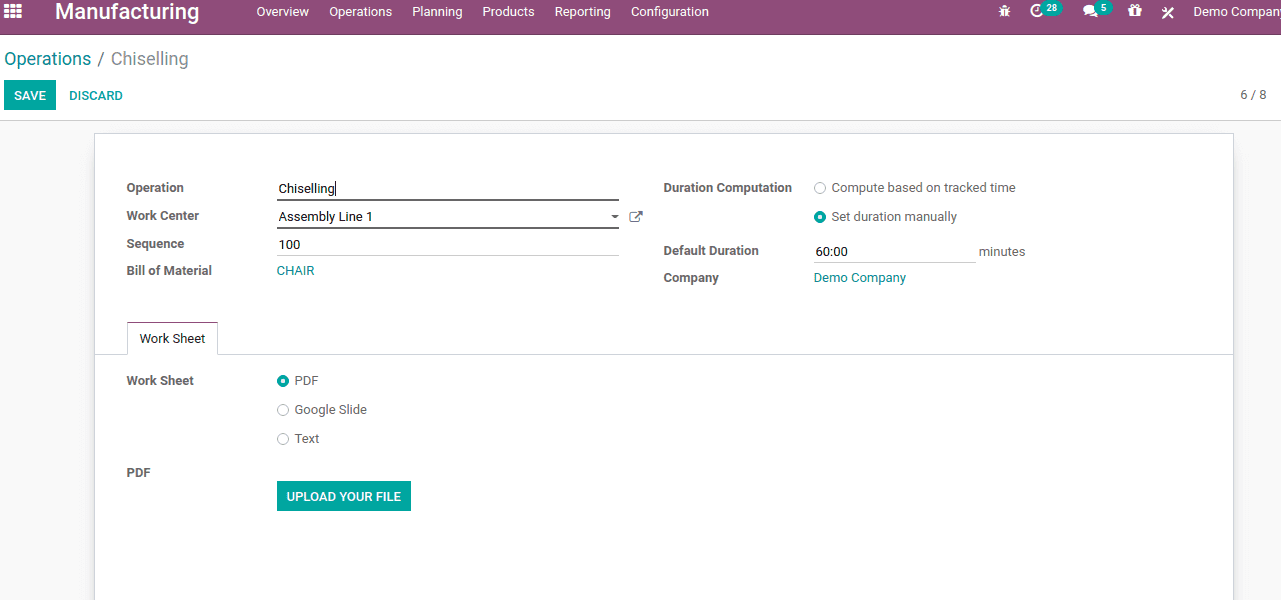

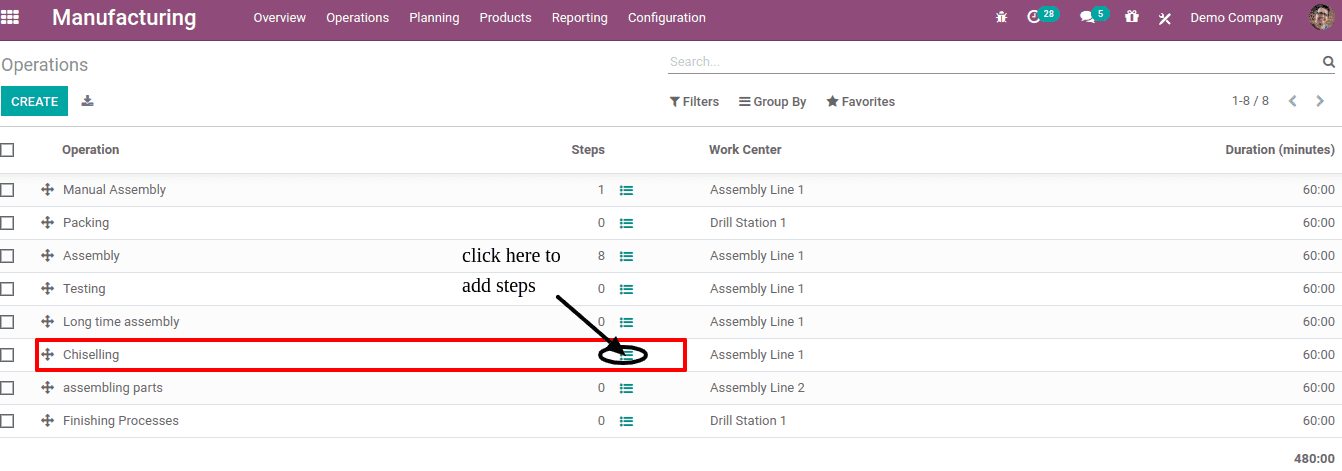

So here add the operation name, the work center in which this operation has to be performed, duration computational, and set default duration. One can also add the worksheets if any. You can upload a PDF file, Google doc link, or a text description and save changes. You can also set steps that are quality points for each operation.

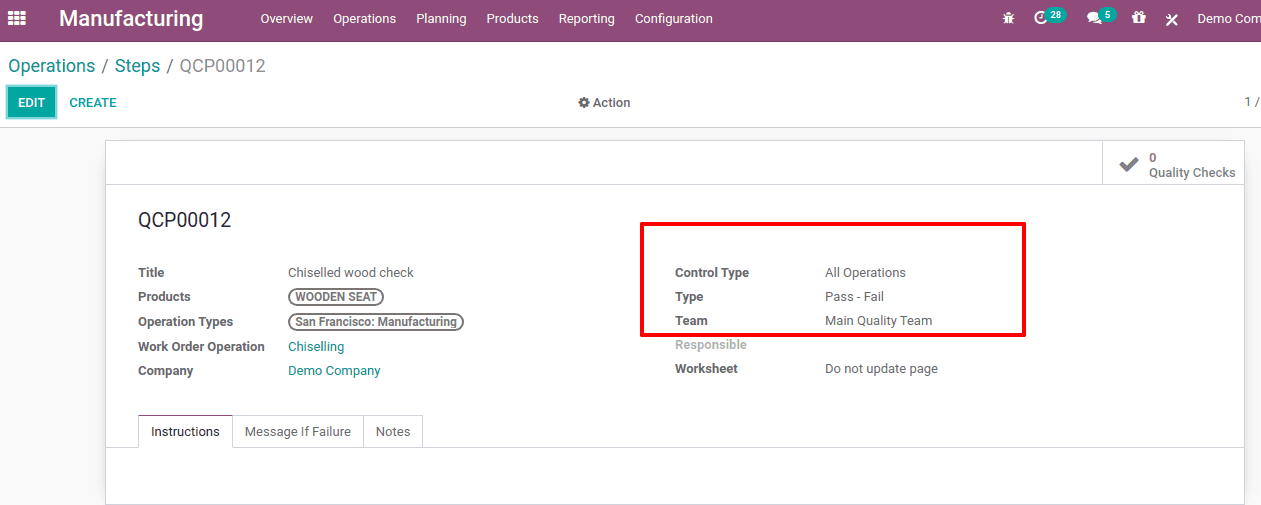

This will redirect to create quality points. Click on create.

Add details, product, operation type, control type, and team, etc, and save.

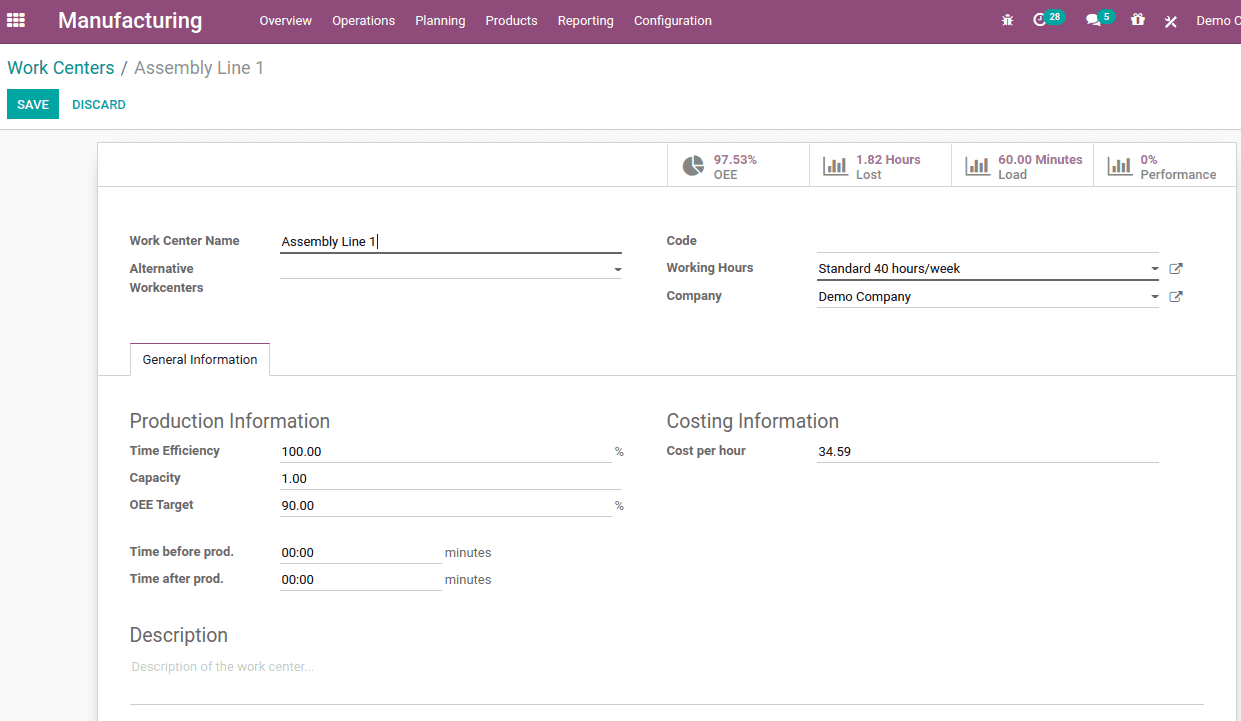

One can create the work center from Manufacturing module -> Configuration -> Workcenter.

So these created operations and work centers are added in the operations tab of the BoM.

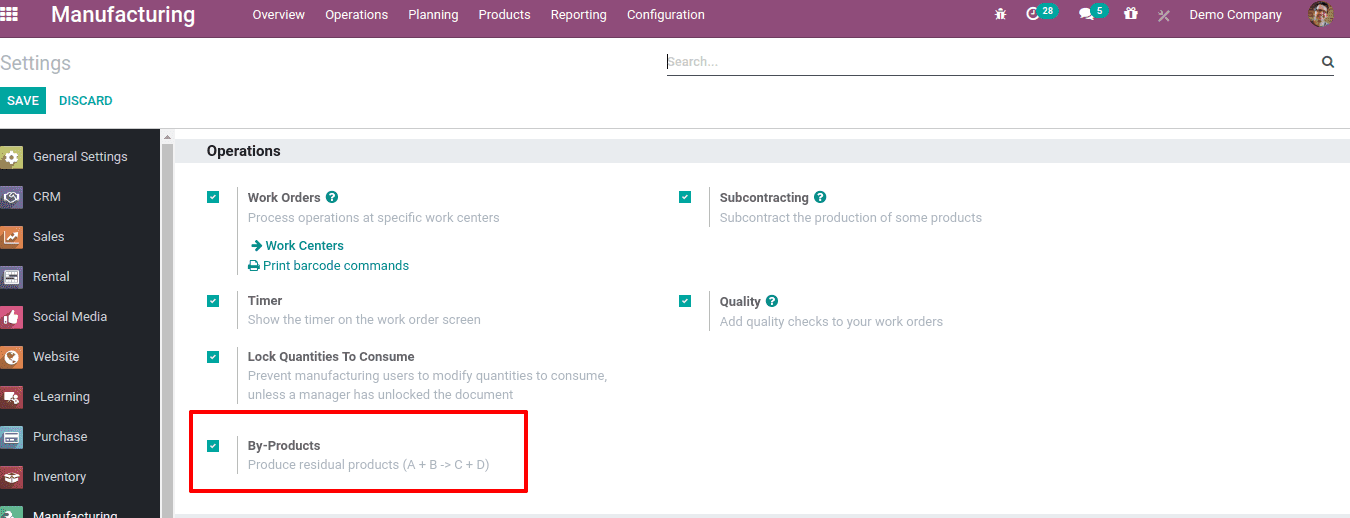

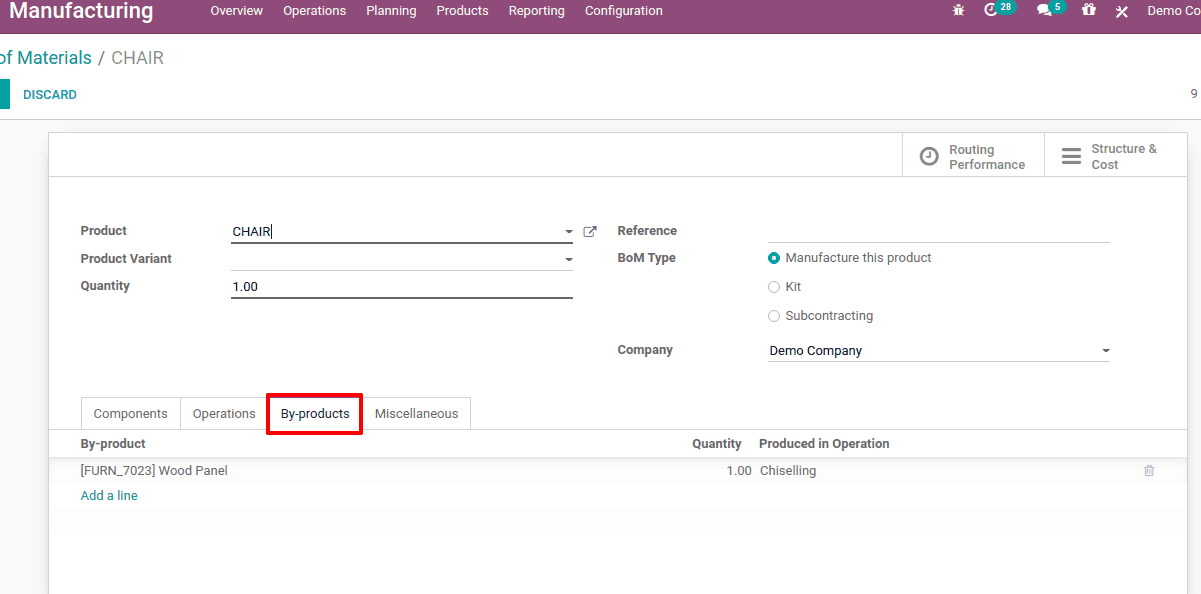

Next is the ‘By-product’ tab, for this feature we have to enable By-Products from manufacturing configuration settings.

This will help to manage the by-products generated during the production process.

So here one can add the by-product, quantity to be generated, and the operation where the product is produced.

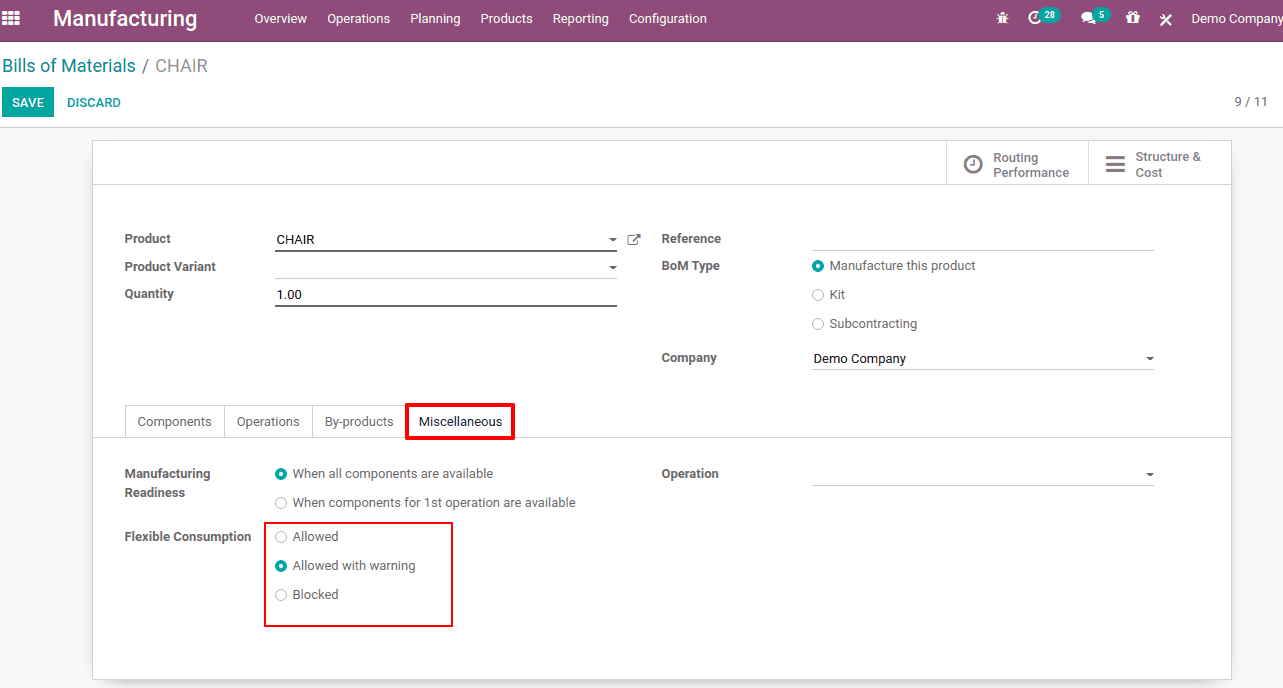

Under the Miscellaneous tab of BoM, the manufacturing readiness and consumption flexibility can be mentioned.

Manufacturing readiness defines when to start the manufacturing process, that is either when all components are available or when components for 1st operation are available. If the manufacturing readiness chooses as ’when all components are available’ the production only starts when all the BoM are available, else it will wait till all the products are available. If ‘when components for 1st operation are available’ is chosen, this will start production if the components for the first operation are available.

Next is flexible consumption, which defines that you can consume less or more components than the quantity defined on the BoM. Compared to the previous version Odoo 14 makes the consumption more flexible with options:

1. Allowed: Allowed for all manufacturing users

2. Allowed with a warning: Allowed for all manufacturing users with a summary of consumption differences when closing the manufacturing order

3. Blocked: Only the manager can close the MO when BoM consumption not respected

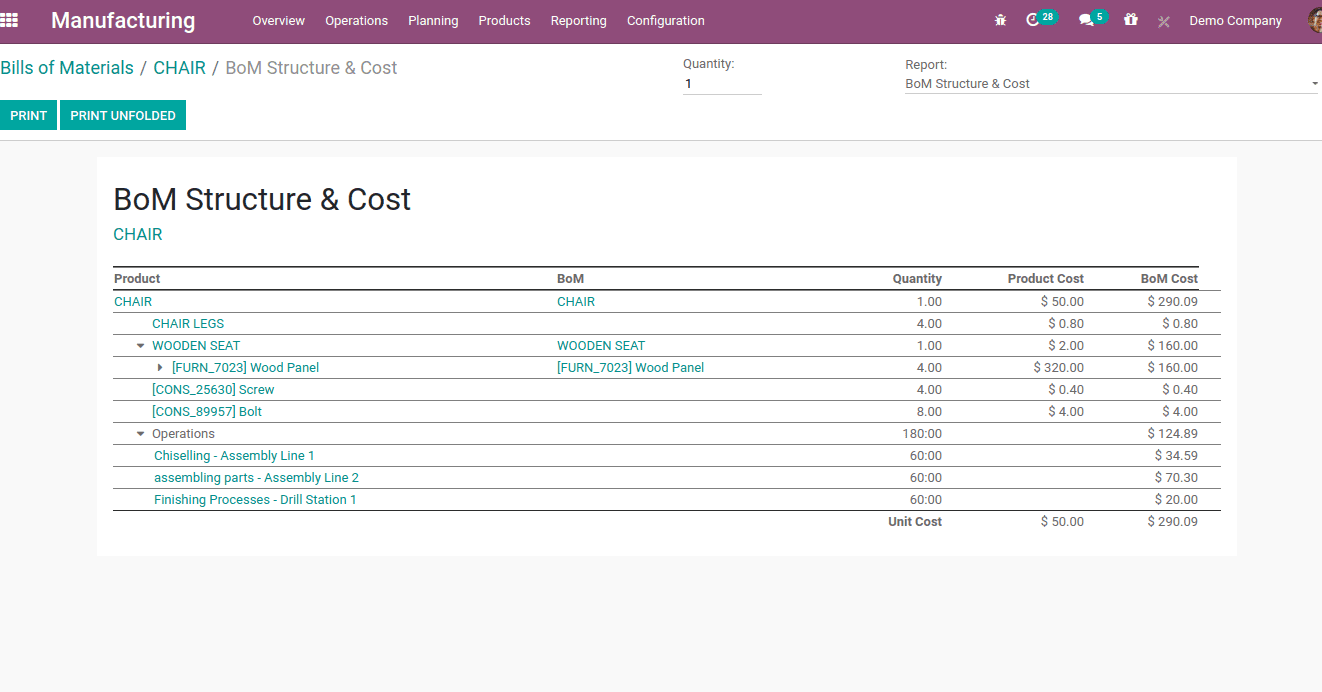

Once all the details are correctly entered, then save the changes. Thus the BoM is set and from now you can create a manufacturing order and the BoM structure and cost can be seen from the smart tab ‘BoM structure $ cost’.

This will help in cost analysis for components and work center operations. The product cost and BoM cost can be separately analyzed. This will be very much useful in scenarios where multi BoMs are used.

Also Read: What's New in Odoo 14