Master production schedule can be defined as the number of products we have to manufacture for a particular period of time to meet the demand for that particular product. It will help the business to plan the purchase of components, scheduling of work centers, and management of staff to meet the requirement.

Odoo a comprehensive manufacturing tool offers the best Master production scheduled feature to help the manufacturing Industry. With the help of a user-friendly page, we offer complete support to the business to manage manufacturing for a particular period.

We as users can decide the period.

ERP tool makes MPS effective and efficient and eases your tasks. It also helps to schedule all activities in a planned manner.

Master Production Schedule or MPS is a highly efficient feature that helps to plan the manufacturing processes. It has the capabilities to help us plan our manufacturing process in the best possible way.

It can help us to get a clear idea of all manufacturing plans and help us foresee the expected challenges and hurdles.

With the help of MPS, we can prioritize our needs in the supply chain as it analyses our requirements as well as the situation.

IT will also ensure to have a steady flow of production,

Benefits of MPS

Ensures efficiency in production

Saves time and money

Replenishment made easy

A quick analysis of requirement

How to use MPS?

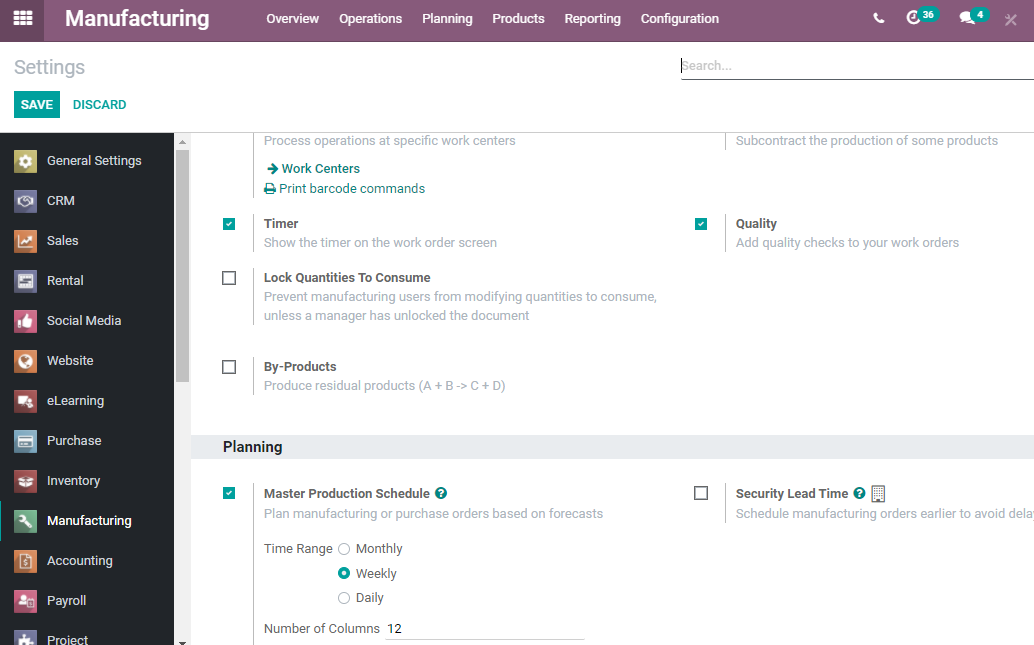

In the manufacturing module, we can find Configuration Menu. Below this we have Settings.

First, let us check this Settings page.

We can find the Master Production Schedule there underneath the Planning Section.

This has to be enabled to make use of the master production schedule facility.

We can also select the time range for the master production schedule here.

We should not forget to Save the changes after enabling the feature.

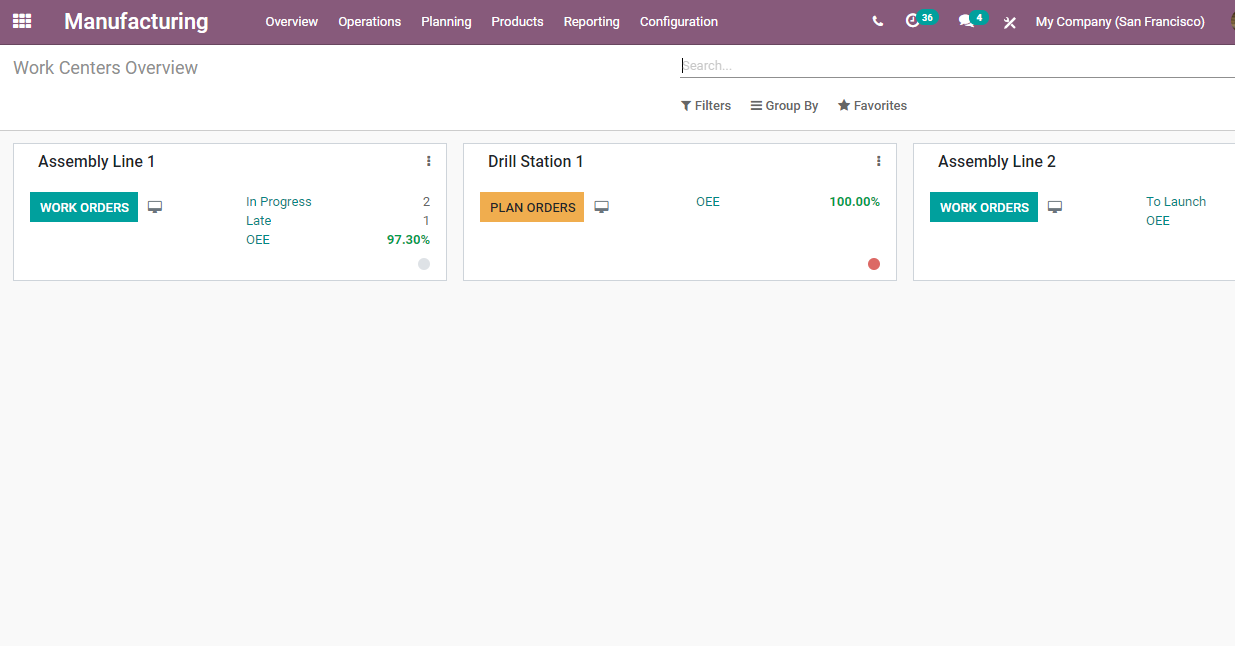

Let us get back to the dashboard.

Can you see the Master Production Schedule?

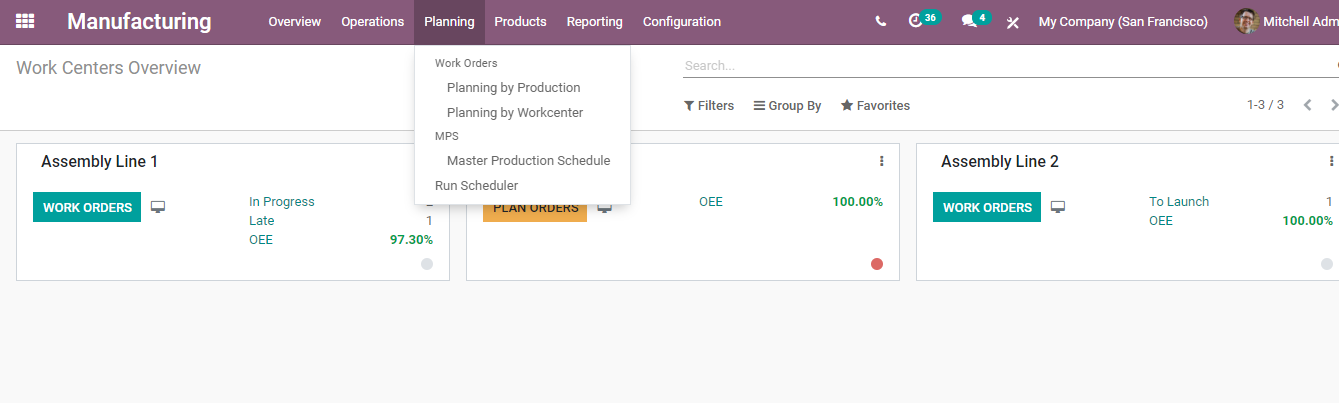

You can view MPS below the Planning menu.

Choose your Master Production Schedule to get a user-friendly and quick to grasp page

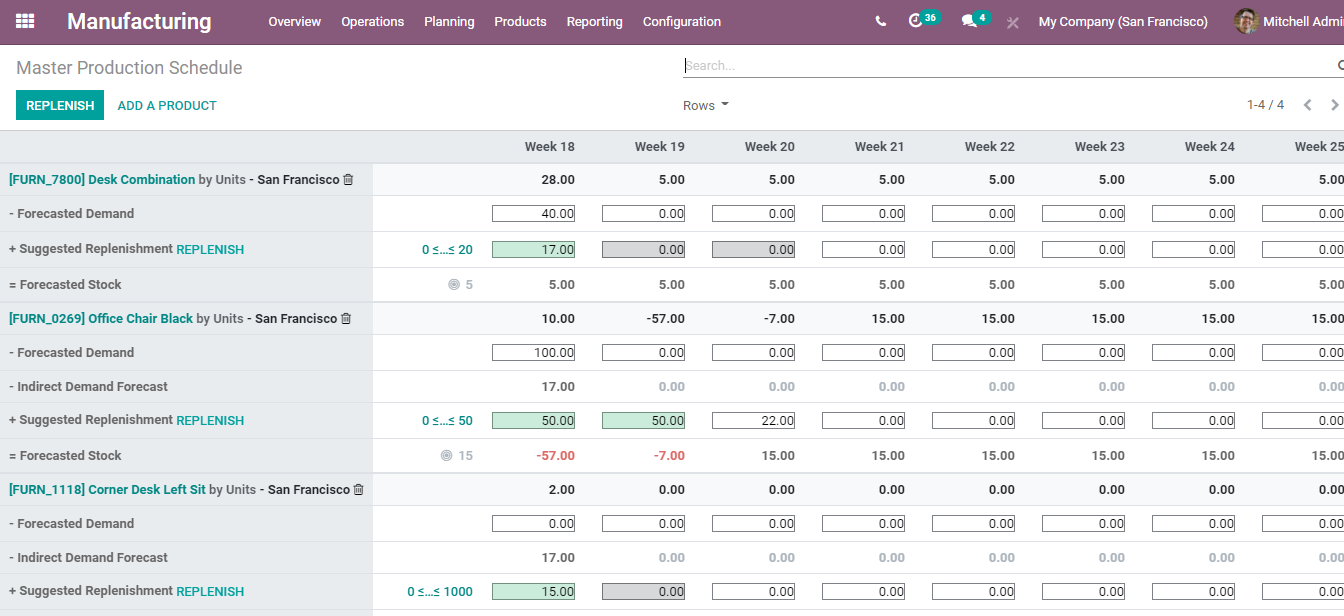

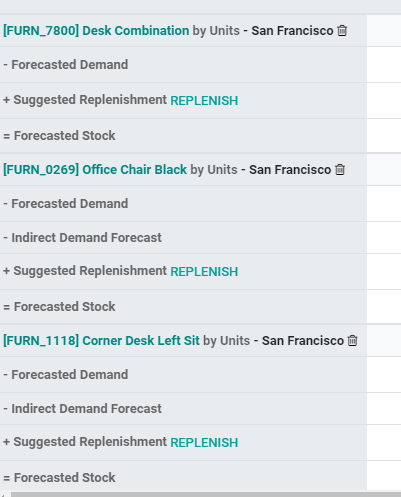

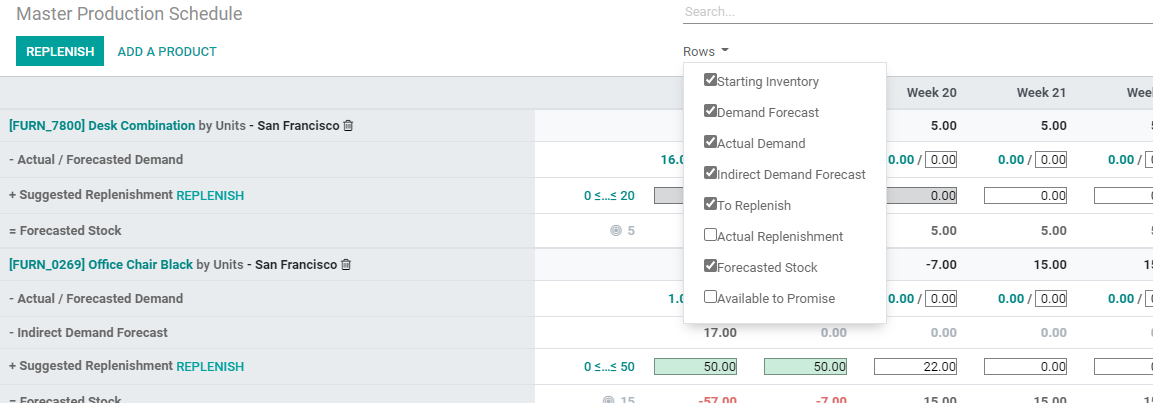

On this page, we can find the master production schedule for different weeks as we had selected the time range as a week.

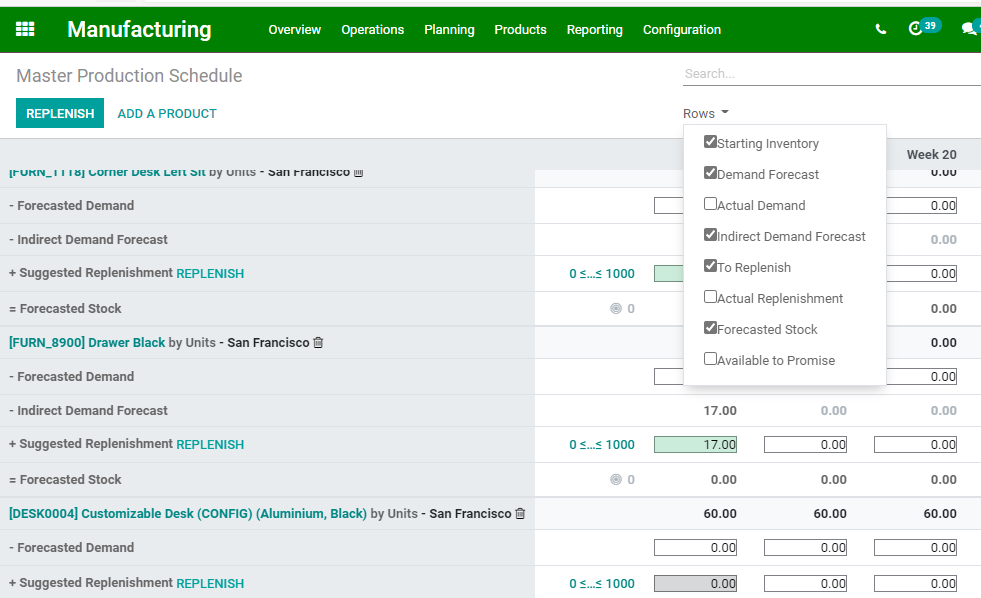

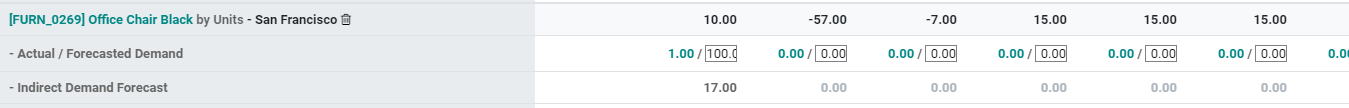

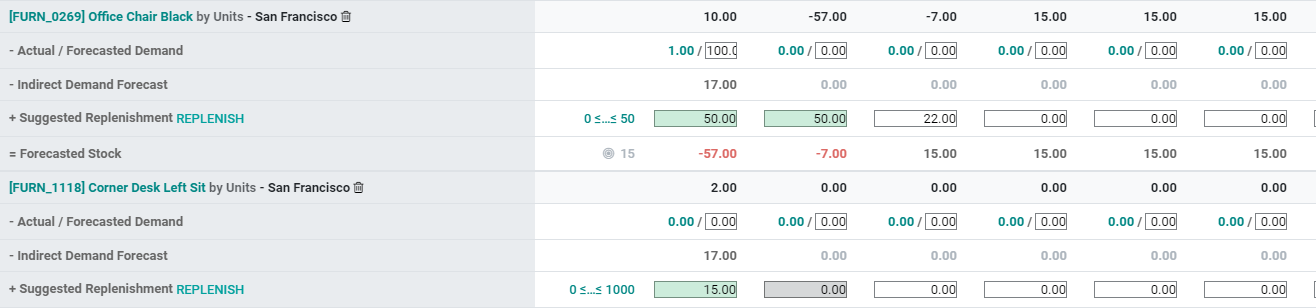

MPS can be prepared for products of our choice. WE can add the details we prefer. This includes details of forecasted demand, suggested replenishment forecasted stock, indirect demand forecast etc.

We can find two main tabs in the page.

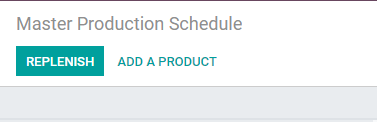

They are REPLENISH and ADD A PRODUCT.

How can we add a product?

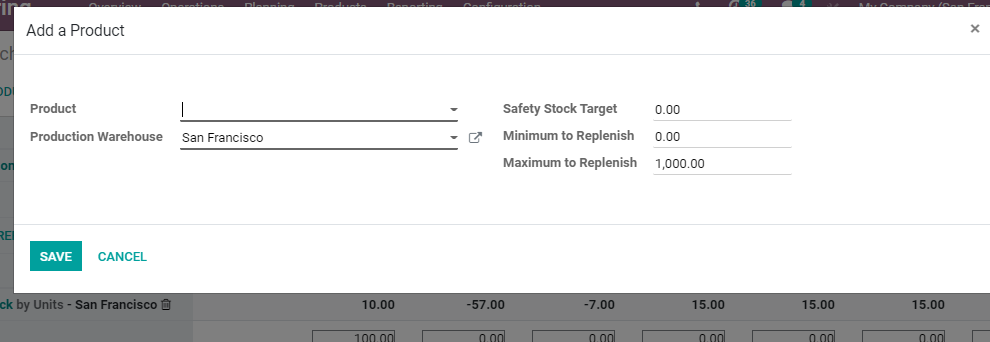

ADD A PRODUCT button can be used to perform this task. A pop up window will be displayed to help you to complete the task. There you can add the product name or use the list to choose the product.

Use the ADD A PRODUCT button and so that a pop up window be shown. There you can add the product name.

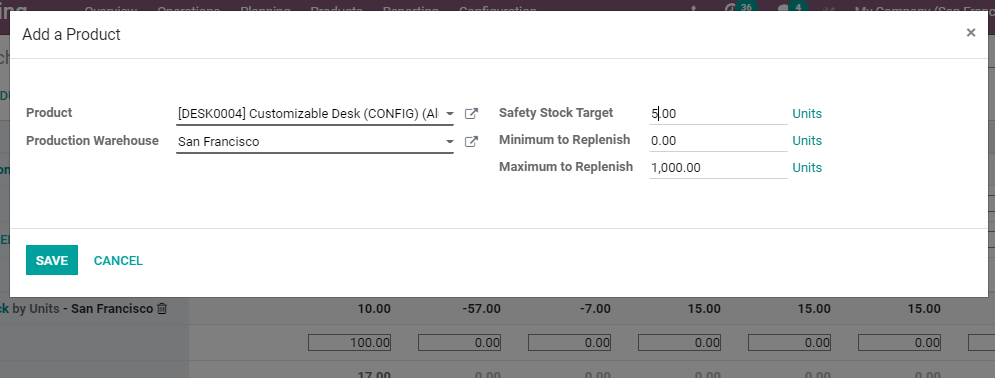

After adding the product we have to set Safety Stock Target.

Here, the safety stock target means the stock that we want at the end of the particular period.

We can also set our Minimum Quantity to Replenish and Maximum quantity to Replenish.

In the above case I have selected Customizable Desk as the product. I have also chosen five as the Safety Stock Target. Let the minim to replenish be 0 and 1000 as maximum to replenish.

We can Save the recently made changes and manage the remaining operations.

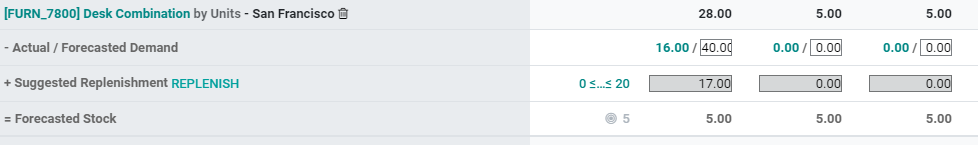

We are back to the MPS page and we can view a lot of data here. Sometimes, there may be some information which is not essential for us. We can remove it from the list view and add some details which we find missing. We can decide the information we want to display here by managing the rows.

See how?

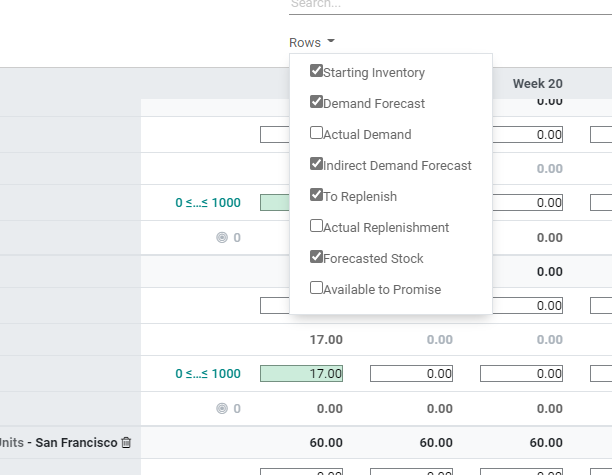

Click on Rows

Here we can enable the information we want to display. We have options like starting inventory, demand forecast, actual demand, indirect demand forecast, to replenish, actual replenishment, forecasted stock and available to promise options.

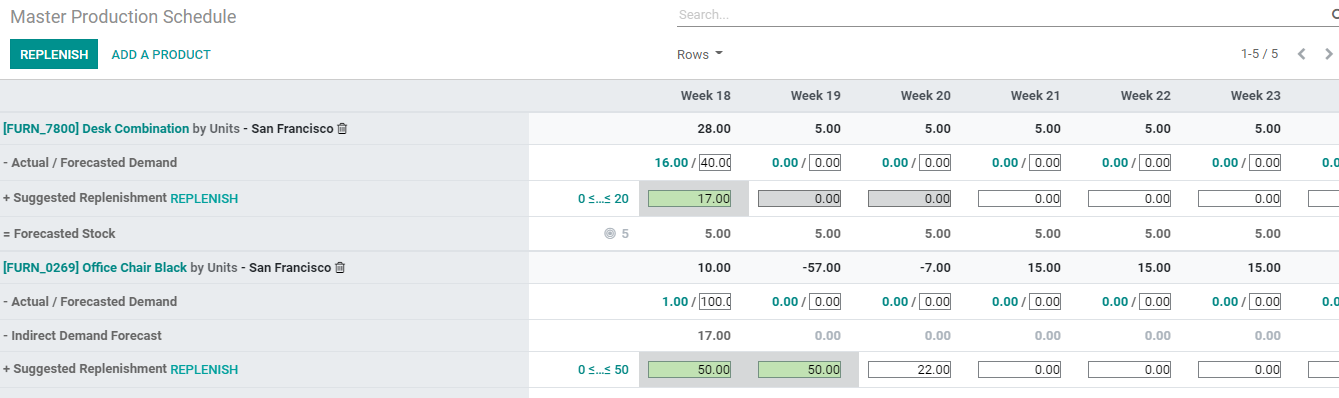

But our key task in a manufacturing industry would be to estimate the demand. We can make use of forecasted demand option to estimate the demand.

Comparing forecasted demand with figures that are provided in the column ‘actual demand’ is also possible. For this we have to enable actual demand option

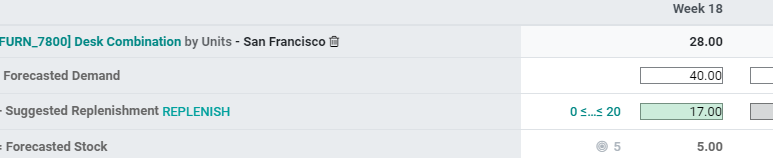

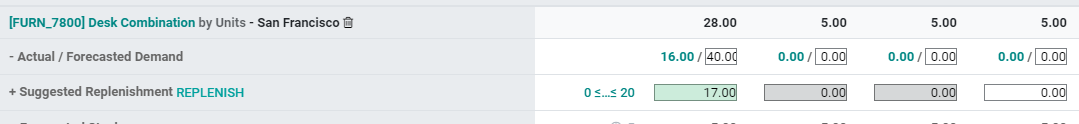

That means the actual demand for Desk combinations is 16 where as the forecastd demand is 40.

Here, actual demand is the confirmed sales.

Another fact we have to take note is that our forecasted demand will have direct impact on the indirect demand for the components or raw materials.

How to Replenish?

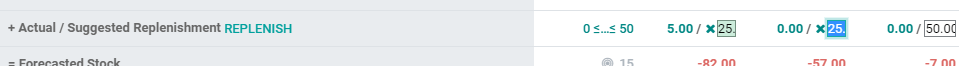

With the help of all different statistics provided in the MPS the system will automatically calculate the quantity to replenish for different periods.

MPS in Manufacturing enables us to do Replenishment using two buttons

One is productvise replenishment using the REPLENISH button near suggested replenishment.

We can also replenish all suggested replenishments together using the REPLENISH tab on the top of the page

Let us first use the Replenish button near suggest replenishment for the product Desk Combination

After clicking Replenish the green colour has changed to grey and the item has been replenished

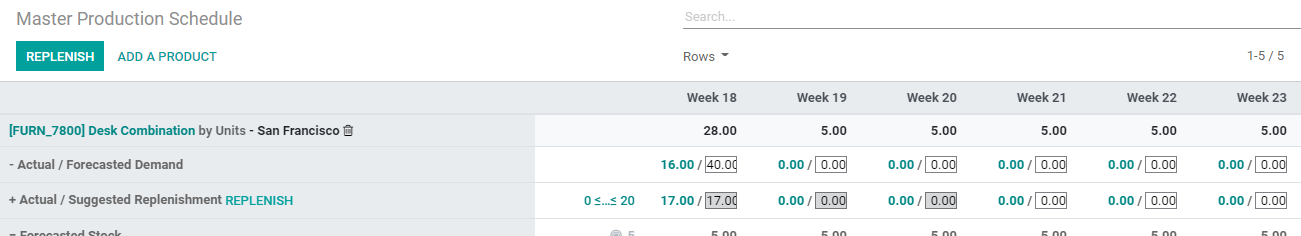

Whenever we do this, the system automatically creates a Request for Quotation or RFQ or Manufacturing Order. We can access the details from here itself. For this we have to enable Actual Replenishment option from the Rows.

Then we get the details of actual/ suggested replenishments.

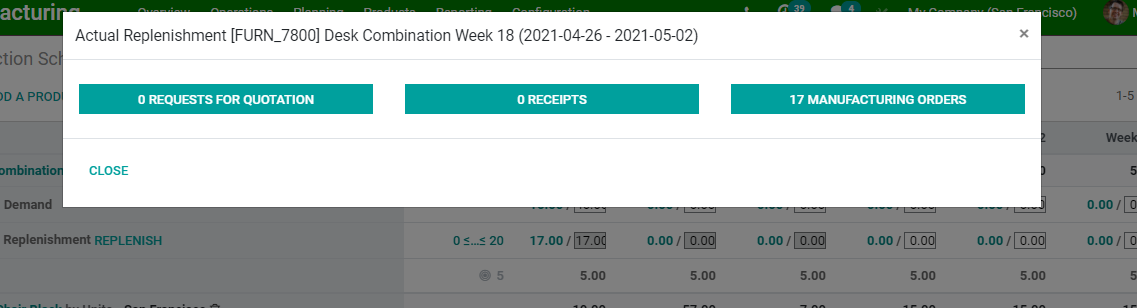

WE can now click the actual replenishment number to get a window

Here we can find the number of RFQ, Receipts or manufacturing orders here.

Here, in the above image we can find that 17 manufacturing orders have been created by the system automatically.

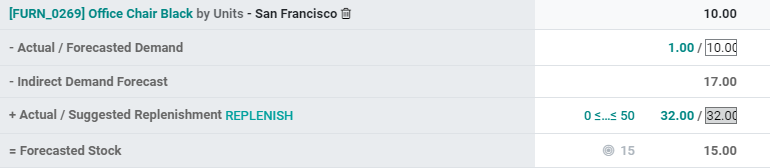

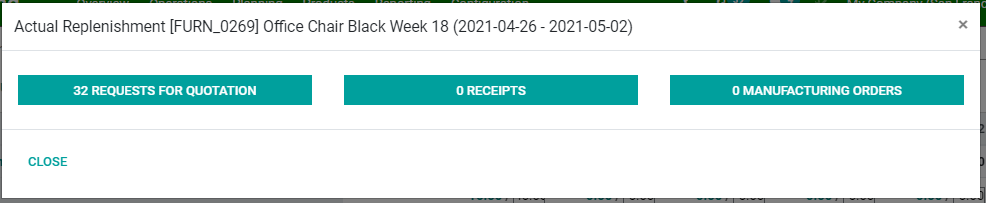

Let us see another example

I have replenished components for Office chair black

Here we can see that 32 RFQ have been created.

Change Replenishment quantity

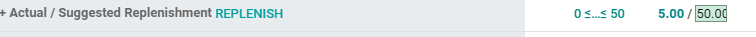

Even though the system suggests replenishment quantities based on the forecasted demand, we can change it. WE have to do it manually in an easy way.

For this we just have to click on the suggested replenishment number and make the changes.

Then we get a close button near the edited number. If we want to reinstate the replenishment created by the system, we can close the editing.

Thus Master Production Schedule in Odoo 14 Manufacturing provides us with comprehensive support to manage all operations.