When it comes to business firms most of them will have multiple warehouses to manage. This may be due to the procurement of products from different locations or to manage your supply chain in an effective way. The companies which operate in different locations and manage different products may need to transfer the products from one location to other. Some companies may have different work centers located at different locations and the raw material supply to these centers may be managed with the help of a main warehouse and sub warehouses. Then also we will have to manage the transfer of the materials based on requirements.

The business will have to manage the transfer to manage sales operations including point of sale, dropship, and delivery operations.

The business ventures managing multiple warehouses may be running many manufacturing units. In these cases, Inventory Transfer means the movement of the inventory. The movement can be between locations or outside the warehouse. Sometimes we have to go for an internal transfer. That means transfer within the warehouses owned by the company. This could be the transfer within a single warehouse or the transfer between different warehouses. There are different ways to manage inventory transfer like automated or manual transfer.

Odoo Inventory to Manage Transfers

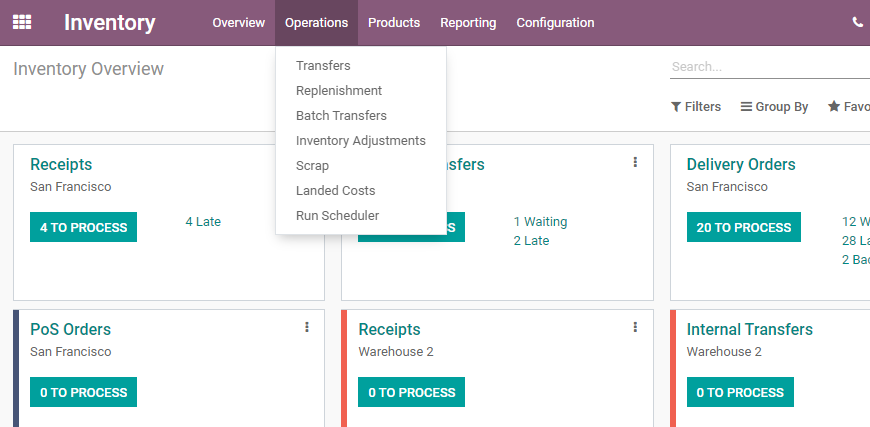

With Odoo Inventory Module we can manage different types of operations. One of the major operations is Transfers. The transfer is the movement of a product between different locations. Other operations supported by Odoo are Replenishment, Inventory Adjustment, Scrap, Landed Costs, and Run Scheduler.

We have to manage these operations efficiently to ensure that the inventory of a business is managed flawlessly.

These types of transfers come to our help when internal transfers are managed. Odoo Inventory supports you to create warehouses and we have discussed the same earlier. Apart from internal transfer we can also manage delivery, receipt, dropship, and manufacture, and carry out the batch transfer.

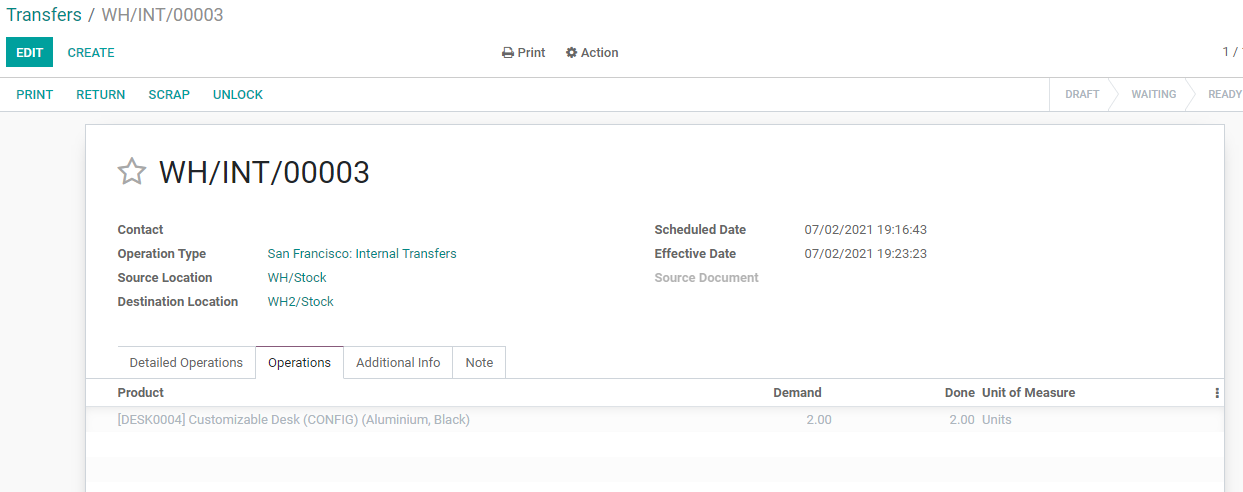

Internal transfer or inter-warehouse transfer can be performed comparatively easier. But the record management and documentation part can involve a lot of complicated procedures even though we are managing inter-warehouse or internal transfer. But with Odoo, we can manage all these operations in an efficient manner. We can easily register internal transfers and manage the operations.

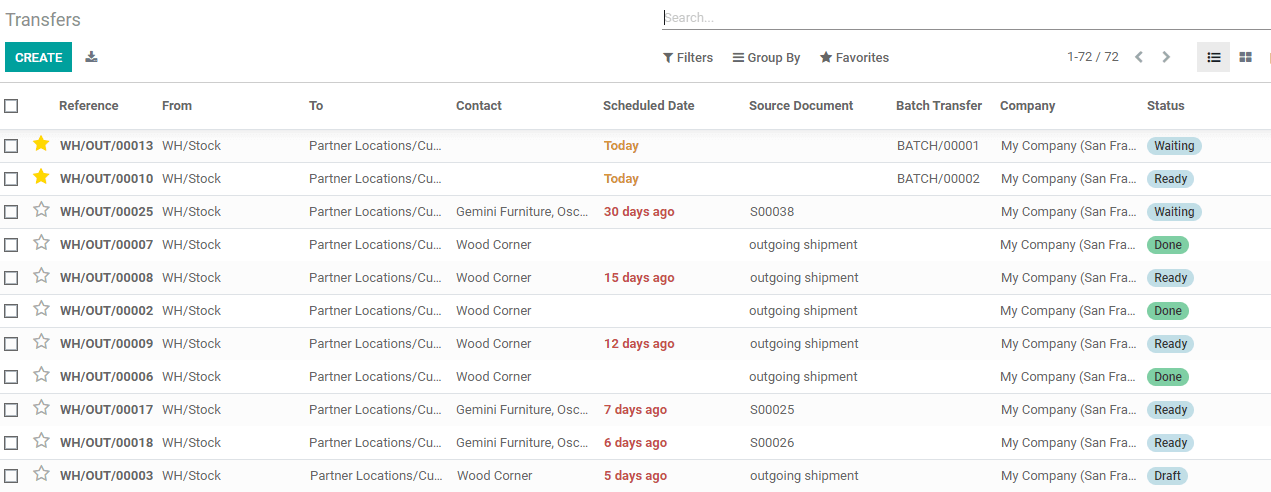

For this, we have to first configure multiple locations by enabling Warehouse settings. After changing the settings we can go to the Operations menu and click open the Transfers.

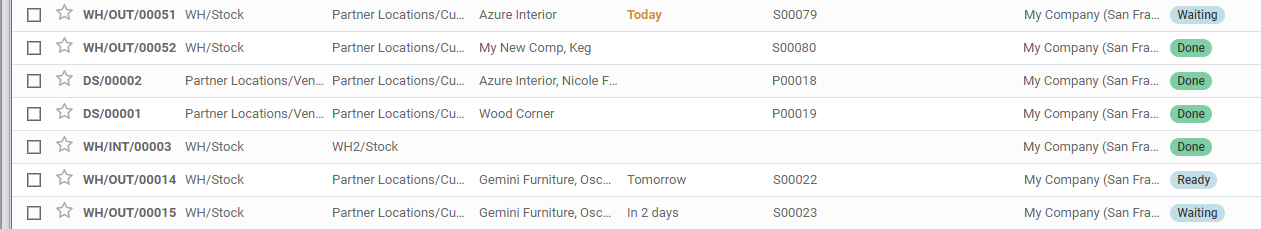

We can find all types of transfers here.

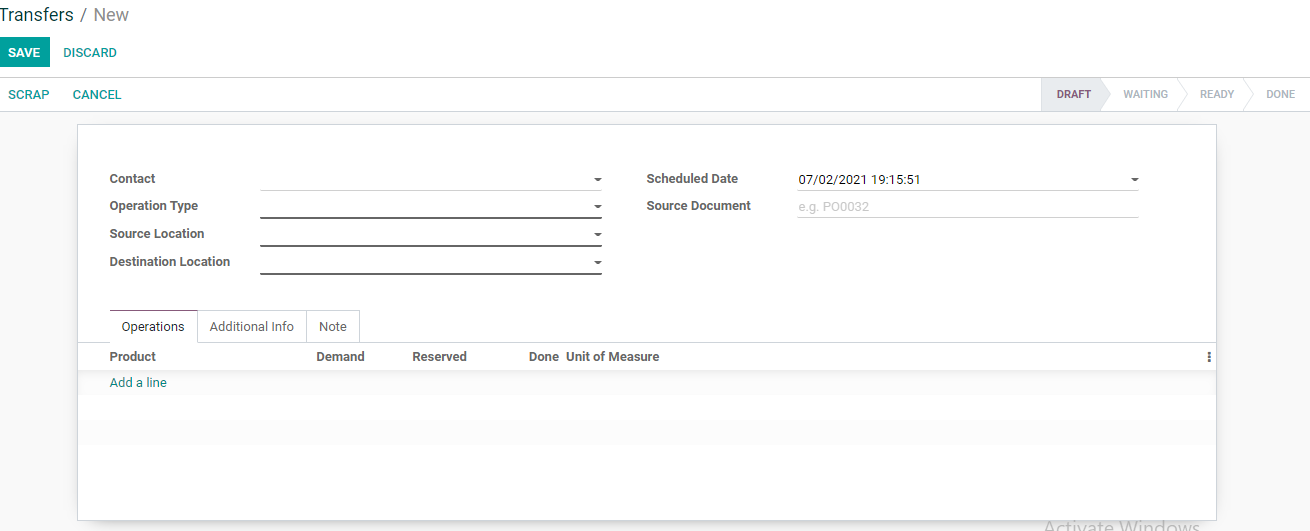

Now we can see how to create a new transfer

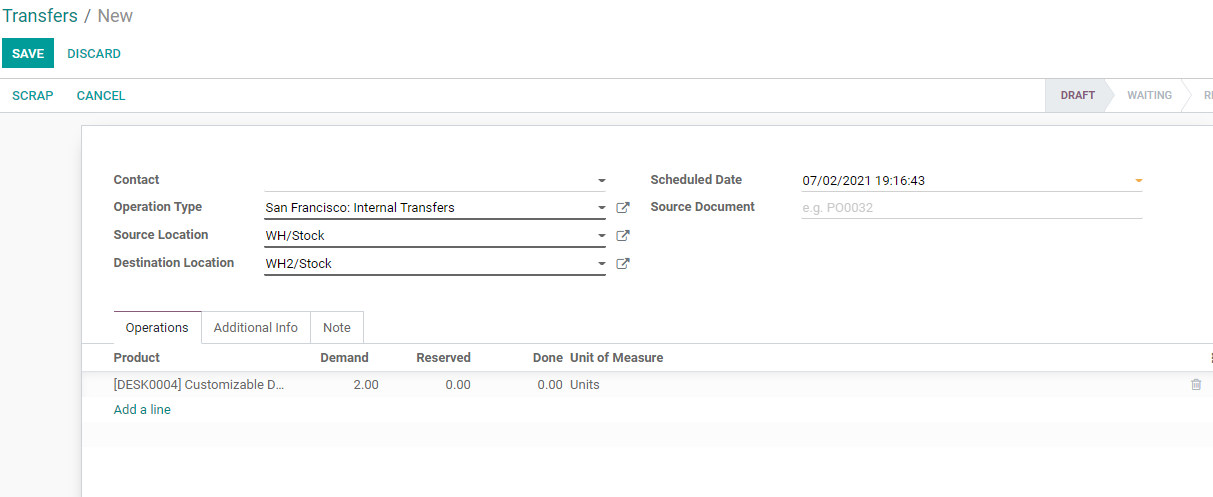

We can set the contact Operation type, Source Location, Destination Location Etc.

We can manage different types of transfers here. The major transfers are Internal Transfer, Delivery Order, PoS Order, Receipts, Manufacturing Etc. First, we can check how to set internal transfers.

We can check availability and Validate the transfer here itself.

Now we can validate the transfer to get the below page.

We can find the transfer here.

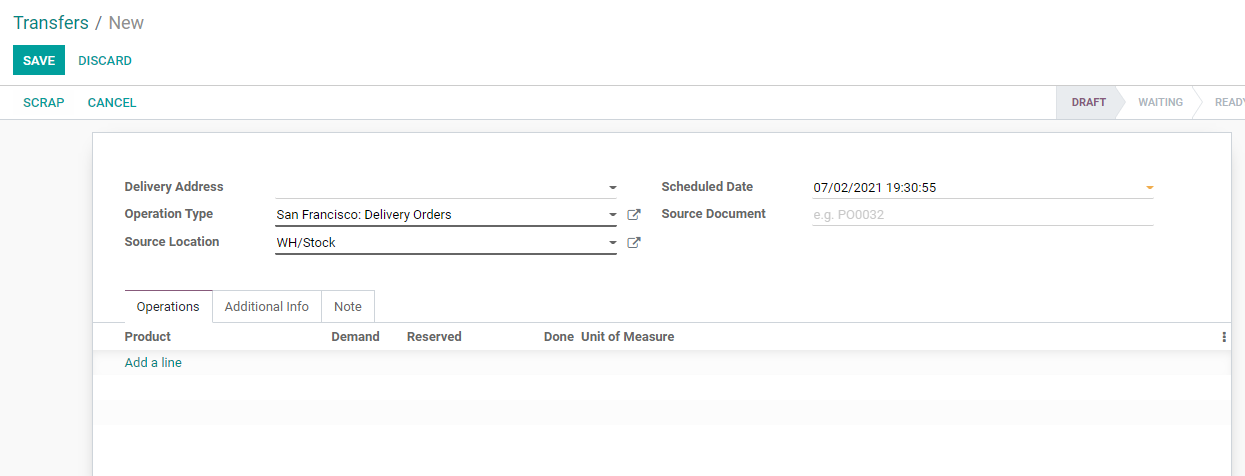

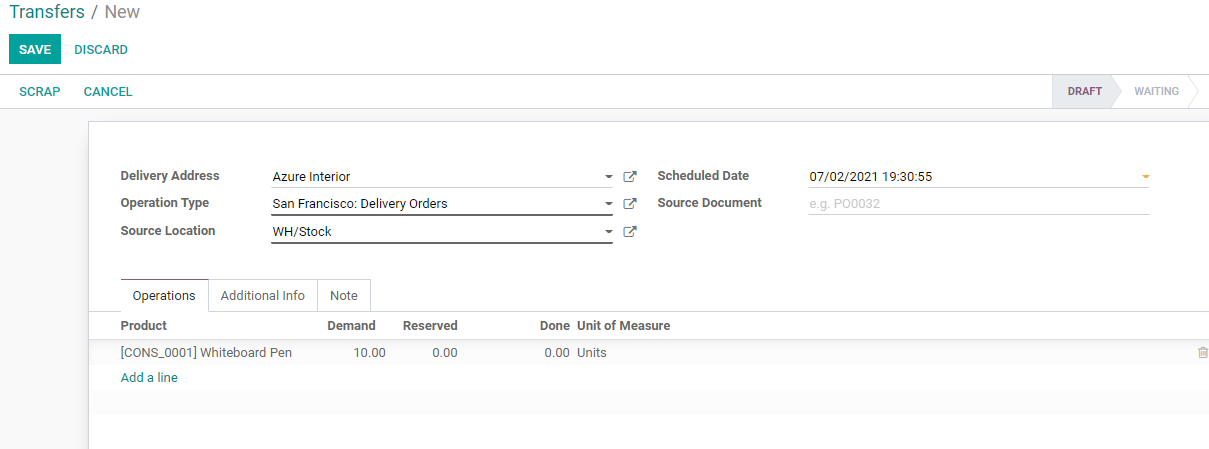

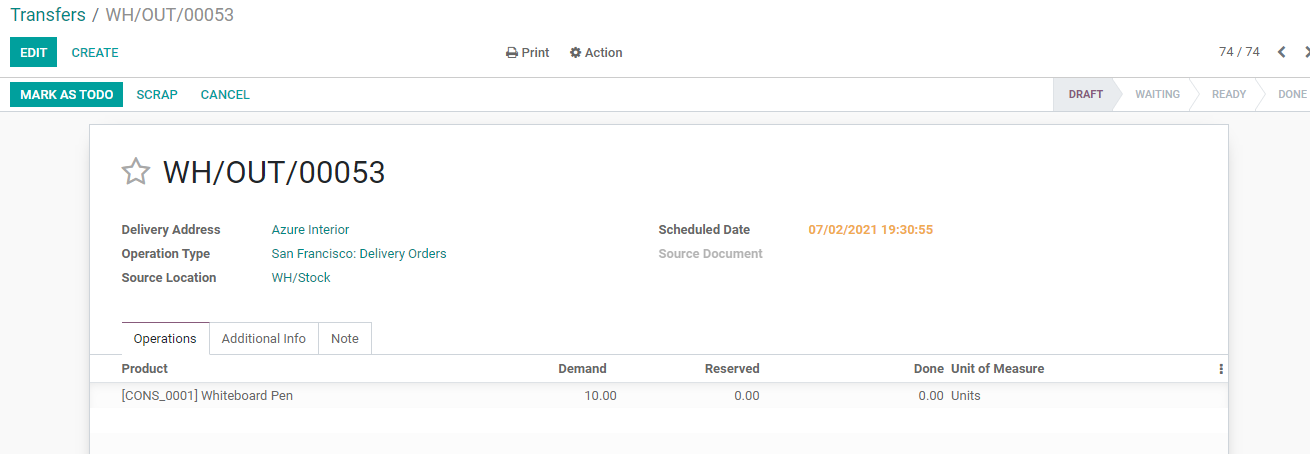

We can also create and manage transfers for Delivery Orders.

In the internal transfer, we don’t have to mention the contact as the transfer is made within the warehouse or between warehouses. We can choose a Source document here based on the requirement for the transfer. Most of the time the internal transfer may be made to meet the requirement of a product or raw material.

But if we are managing a delivery order and we select delivery order as the operation type then we get a delivery address field instead of a contact field.

The destination location also gets removed from the form as the destination location will be the delivery address. All the other fields remain the same.

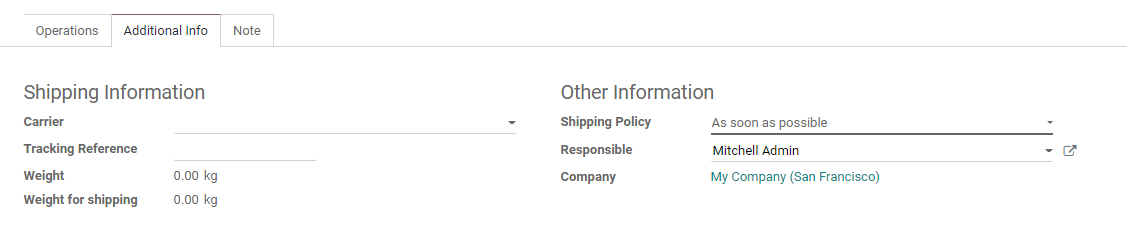

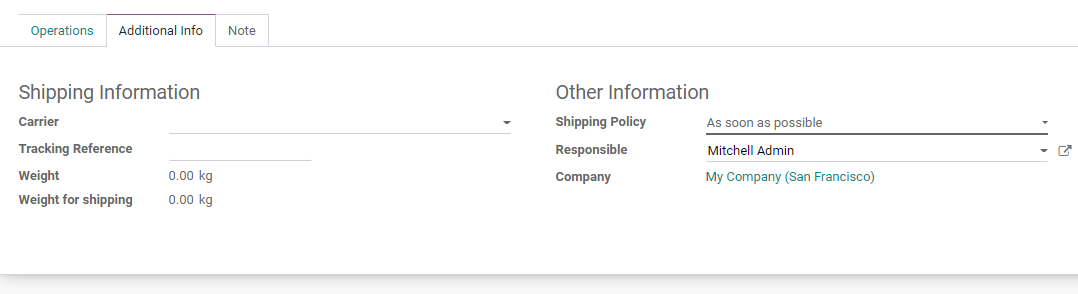

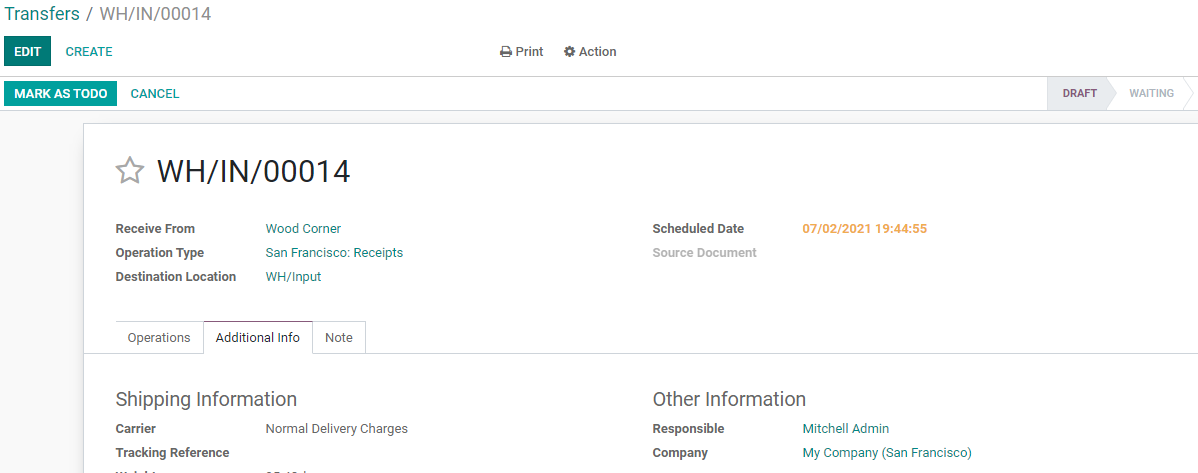

We can also find Additional Information Tab here and below this tab we can find the shipping information

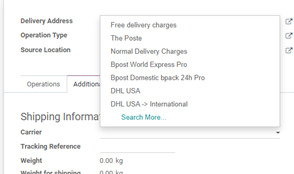

We can find the Carrier field where we can select or add carrier details.

We can also add tracking references, Weight, Weight for Shipping, Shipping Policy, Responsible and company details.

Here, the shipping policy can be “As soon as possible” or “When all products are ready”.

We can also find a Note tab here.

We have created a new transfer for Delivery order management.

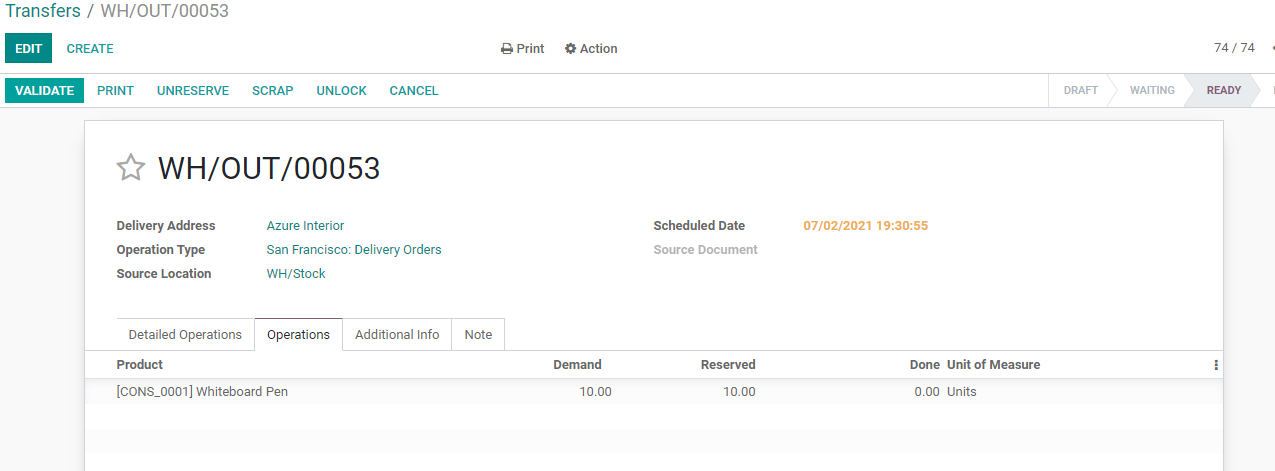

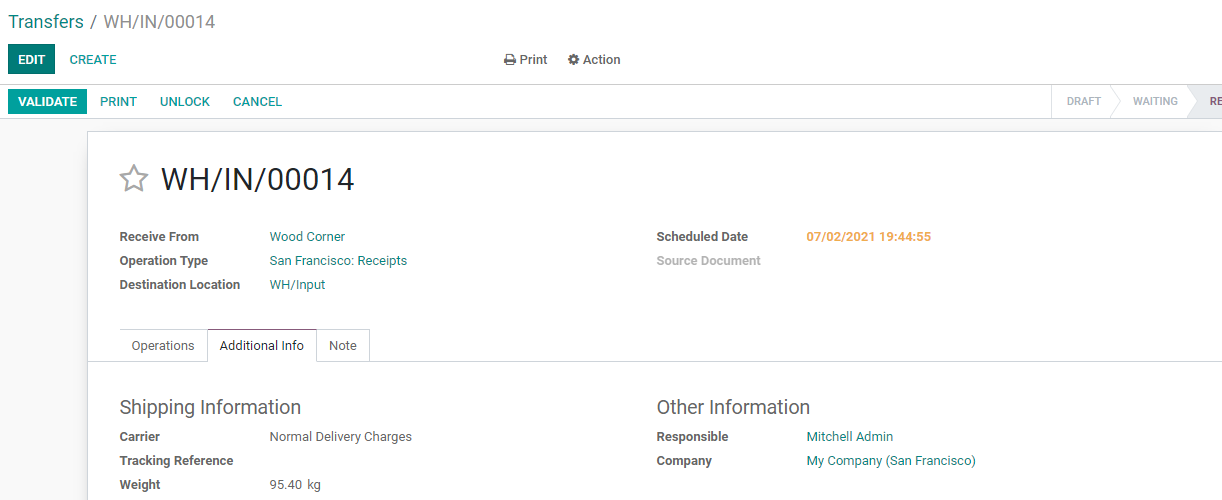

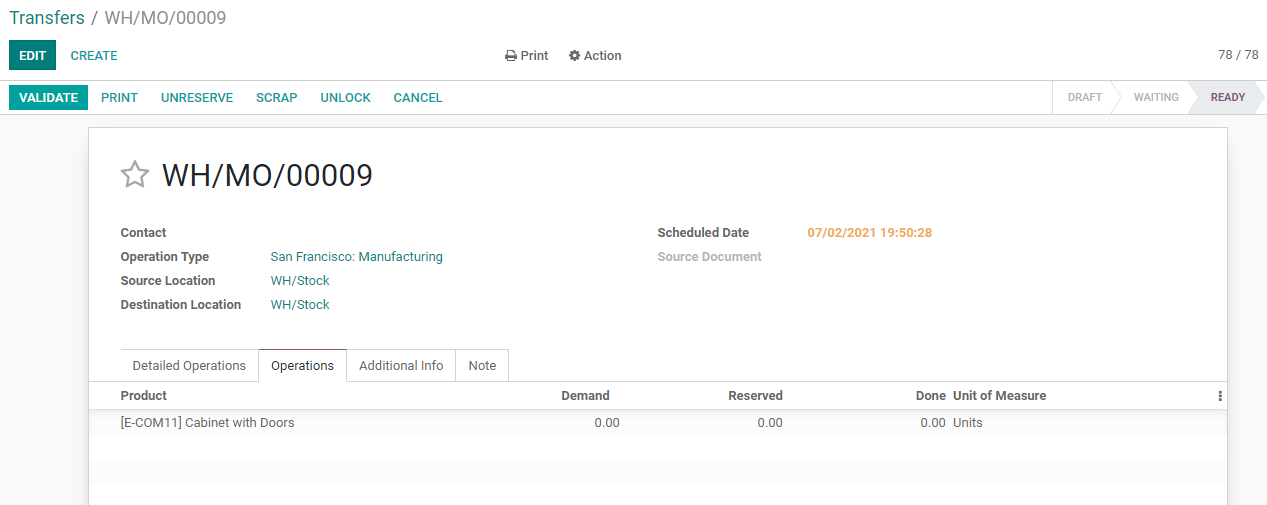

If the changes are saved we get an option to Mark as Todo. On Clicking Mark as TODO we get an option to VALIDATE the process.

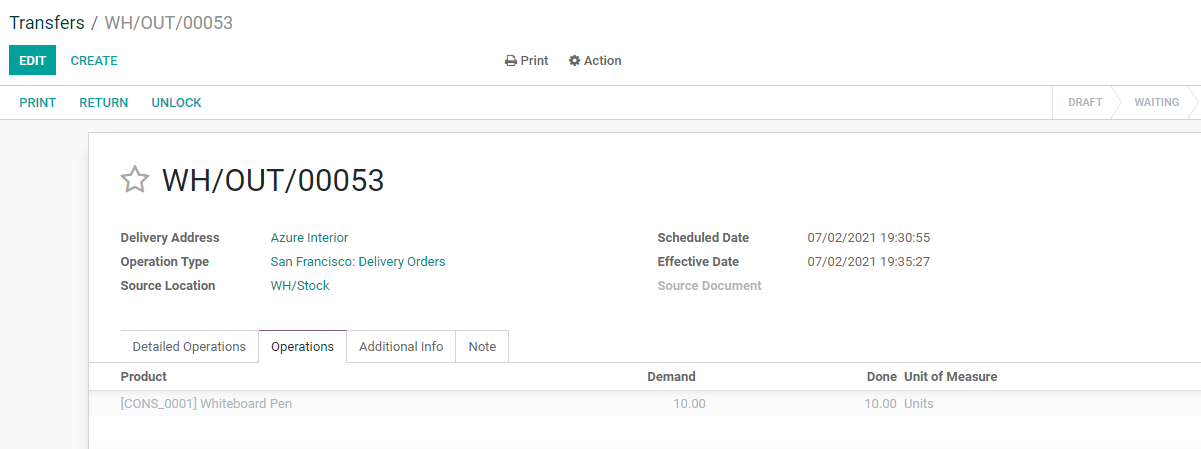

I have clicked on VALIDATE and we have created a new transfer.

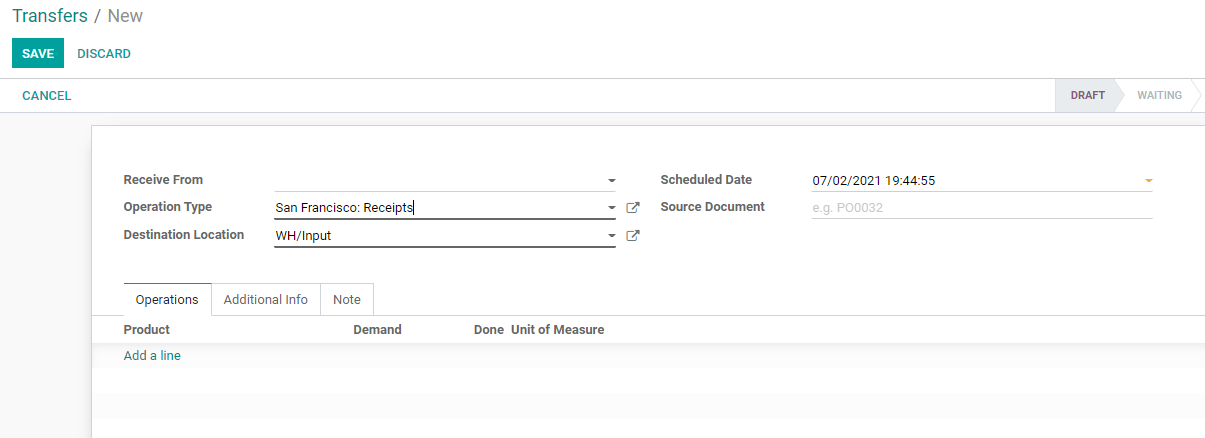

Transfer for Receipts

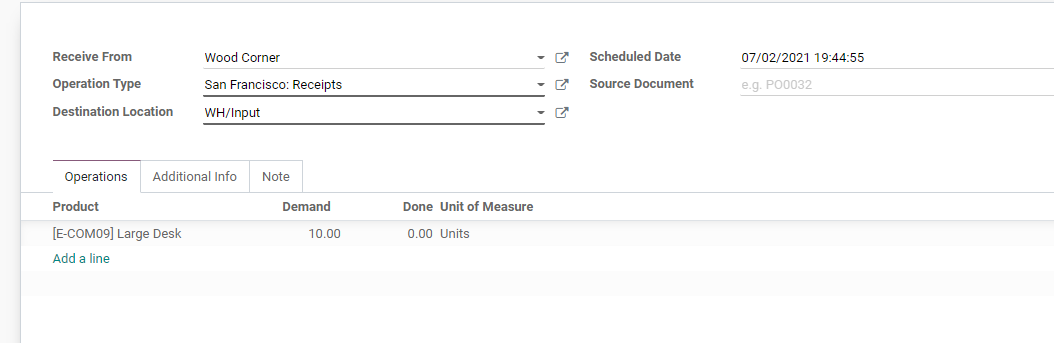

We can select Operation type as Receipt here.

Then instead of contacts or delivery addresses, we get Received from the field here. We can choose the vendor details here. Then we can add the destination location or the location where we want to store the purchased product. Here, the selected location is WH/Input.

Then we can add the product details.

We can save the transfer and then Mark As TODO

The transfer is now in DRAFT state.

We can VALIDATE the transfer

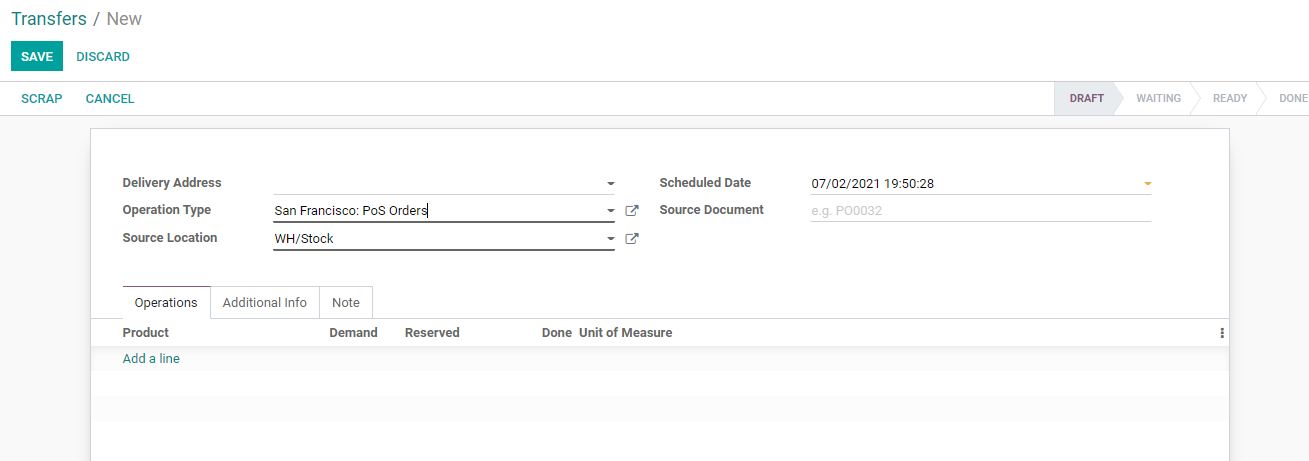

We can manage transfers for managing PoS orders also. Like delivery orders, we will have to add a delivery address, operation type, and source location here. Then we can add product details and continue the process as in the other transfers.

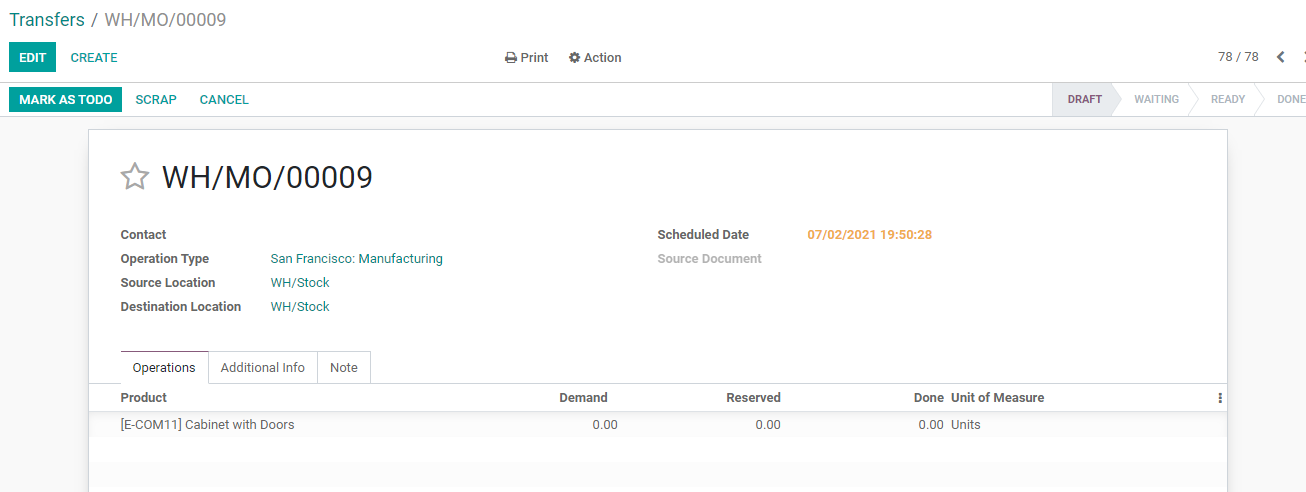

Manufacture

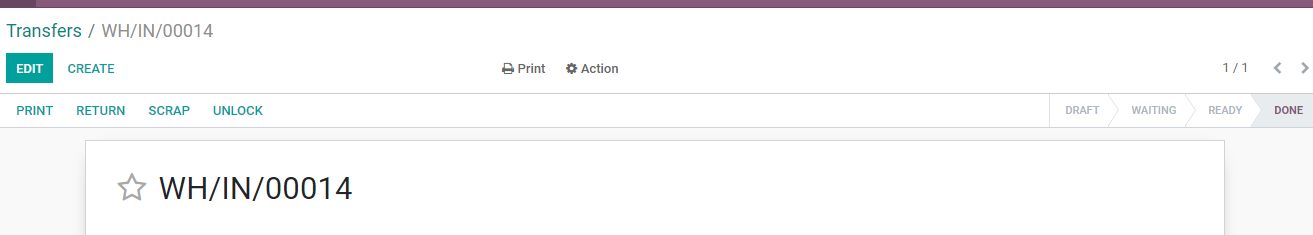

When we VALIDATE the transfer status changes to DONE.

PoS Orders

As in internal transfer, the manufacture also has contact details, operation type, source location, and destination location. We can schedule the date and select the items for transfer.

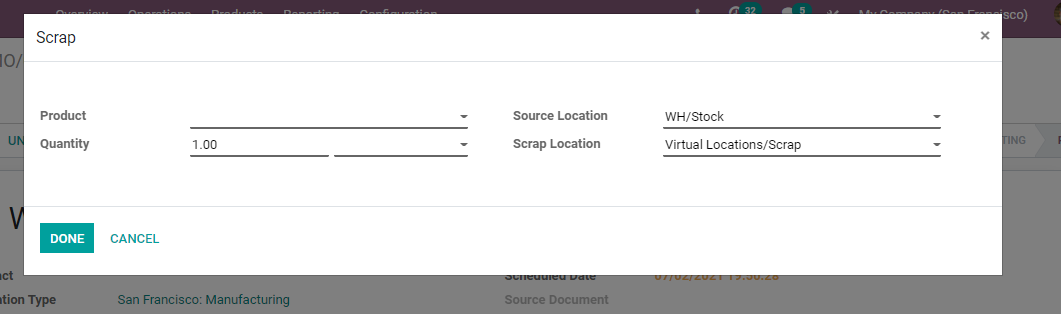

In internal transfer and manufacture operations, we can also scrap the item if it is damaged.

Then the item will be moved from source location to scrap location

Dropship

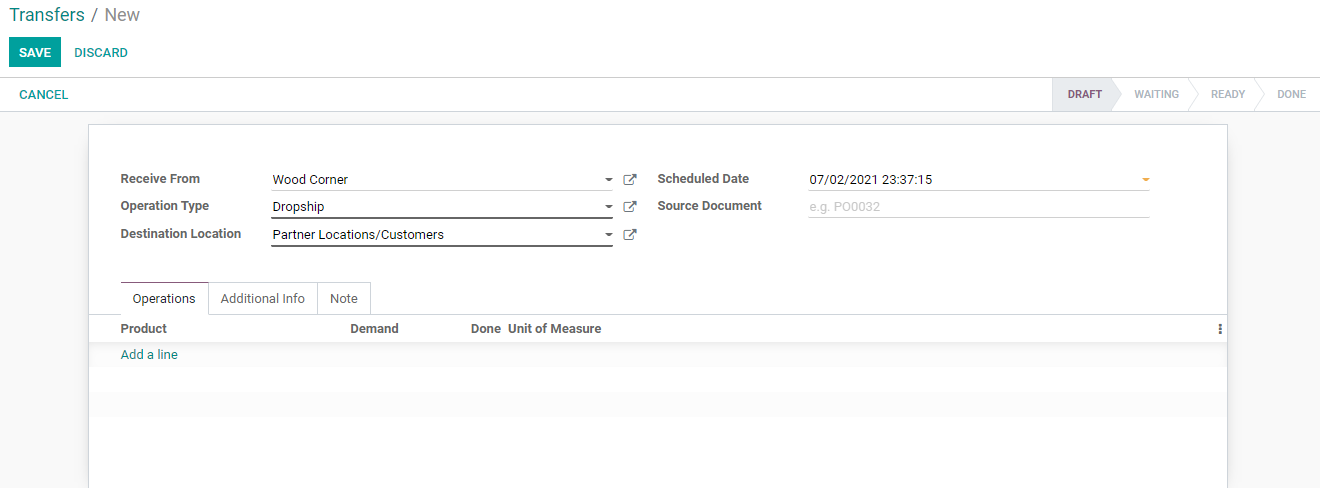

We can also manage transfer for Dropship management.

Dropship operation is managed without managing its own warehouse. In this case we have to add the details of the vendor or partner from whom we are getting the product. This can be added at the Received from field. One fact we have to note is that we have to select the operation type first.

Then choose the destination location. Here it could be partner location or customer location.

This way Odoo Inventory eases all types of inventory transfer.