Lot and serial numbers are key elements that are mostly used to track the products and product movement. This will help to track the product movement within the warehouse and outside the warehouse.

What is a lot? Lot is the unique identification number that is used to identify a group of products of the same type. Usually, we use a lot of numbers when the products are small or cannot be considered individual products. Lots are picked as batches.

On the other hand, all items which can be identified as individual products or items will be assigned serial numbers. Here the unique identification number is assigned to each and every product.

When we discuss in detail, we can say that a lot contains a number of units of a single product. It can also be considered as a batch of products. The batch identification number or Lot can be used to manage sales operation, shipment, and other activities in a business.

Lot and serial number management are important when it comes to a business as it ensures our support to track the product. Increased traceability is the highlight of a lot of serial number management.

Lot and serial numbers are usually set and managed in the inventory of the product. When we manage a product in inventory we can add a lot and serial number so that the product can be traced thereafter. The inventory management tools usually support this lot and the serial number management support system.

Odoo Inventory is a module that is capable of managing all inventory-related operations is best suited for Lot and serial number management also. We can create a unique identification number for an individual product with the help of a serial number and a unique identification number for a group of products using Lot management support. Odoo supports the users to manage a lot and serial numbers for different operations.

In short, a lot number is used to transact bulk quantities of products. This helps to transact the product, track the product and generate reports. Serial number on the other hand smoothens the transaction, reporting, and tracking of individual products. We can detect the damaged product and ease the return activity also with Lot and serial number.

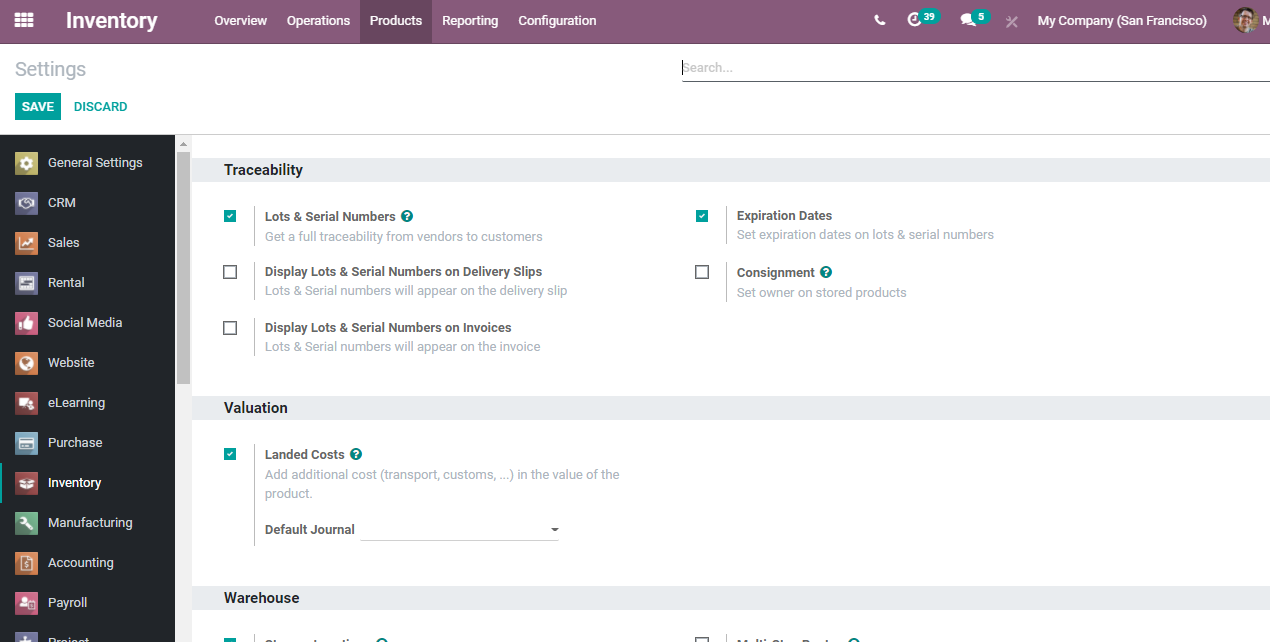

Configuration:

Odoo Inventory module is an easy-to-use module to manage inventory operations. Thus Odoo helps us to configure a lot and serial numbers without any difficulty. Before moving ahead with the management of lot and serial number below the product menu in the module we can check how to enable the lots & serial number’ function in this module.

All the features are enabled with the help of configuration settings. We can manage the operations by going to the Settings of Inventory module. Here we can find a section on Traceability. Below this, we can find the Lots and Serial numbers option and let us enable it. Save the changes that the changes reflect in the menu.

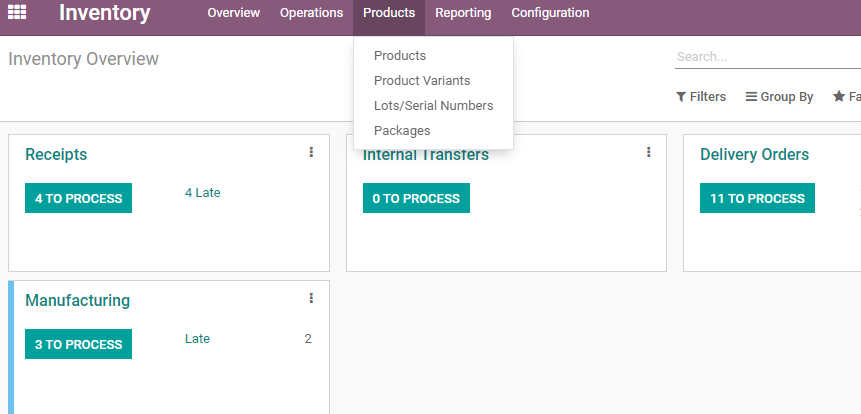

Now we can view the Lot and Serial number below the Product menu.

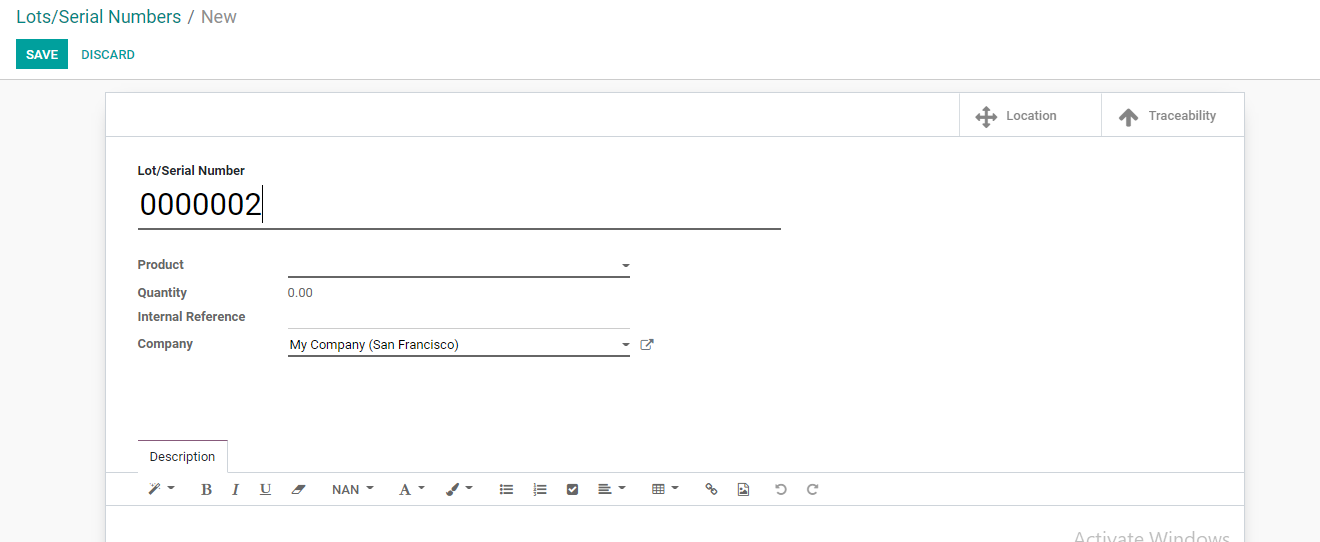

Clicking on the Lots/Serial Numbers option we can move to the page

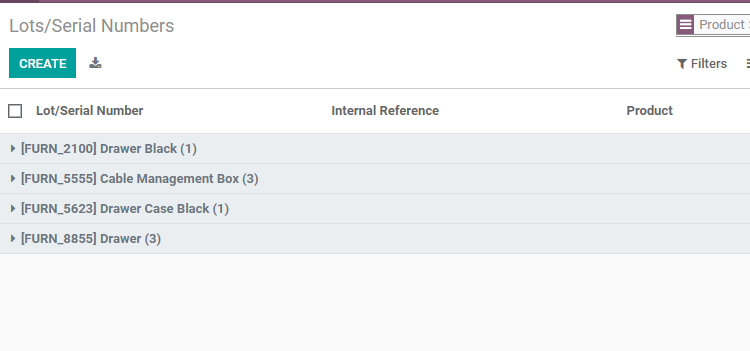

Here we have all the pre-configured lots/serial numbers.

We can find the details of the product and internal reference also here.

It is also possible to edit the lots/serial numbers or create new ones from here.

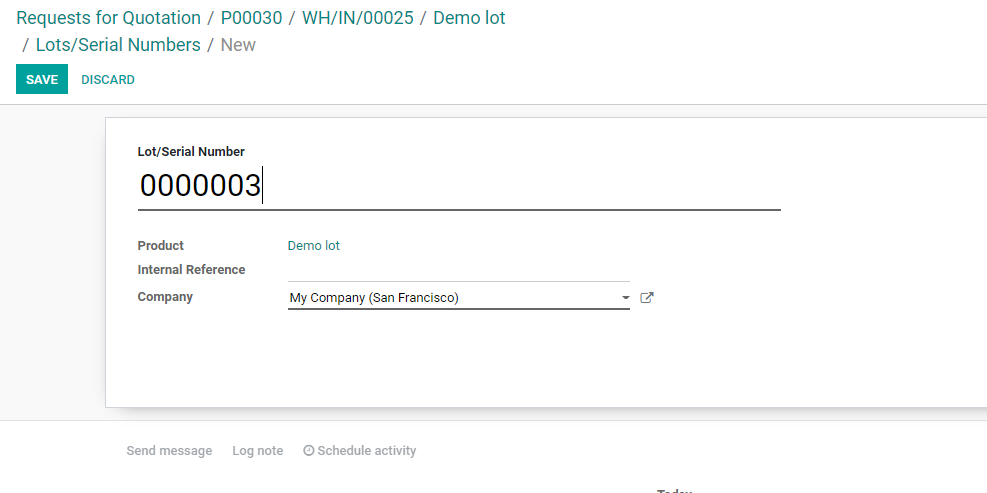

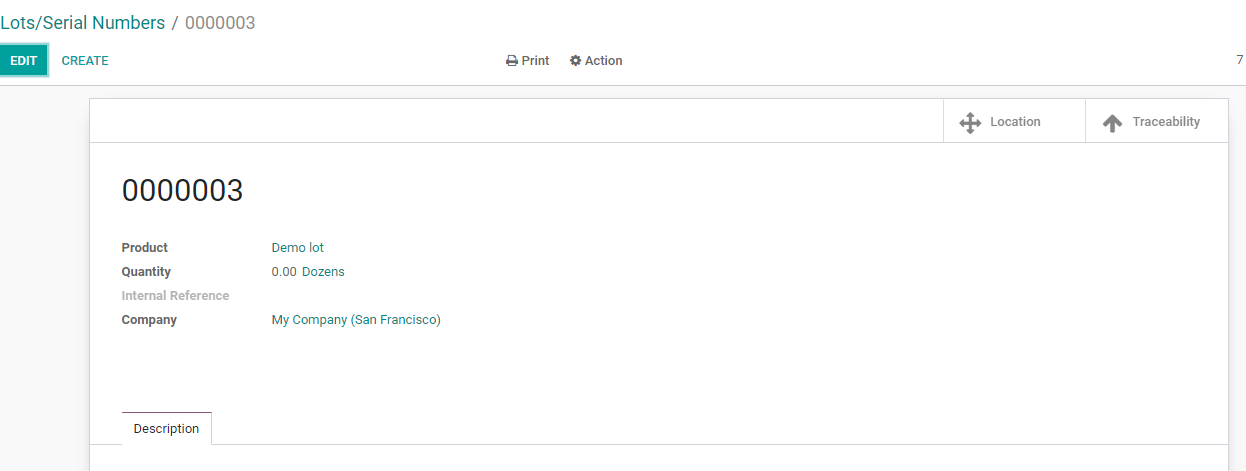

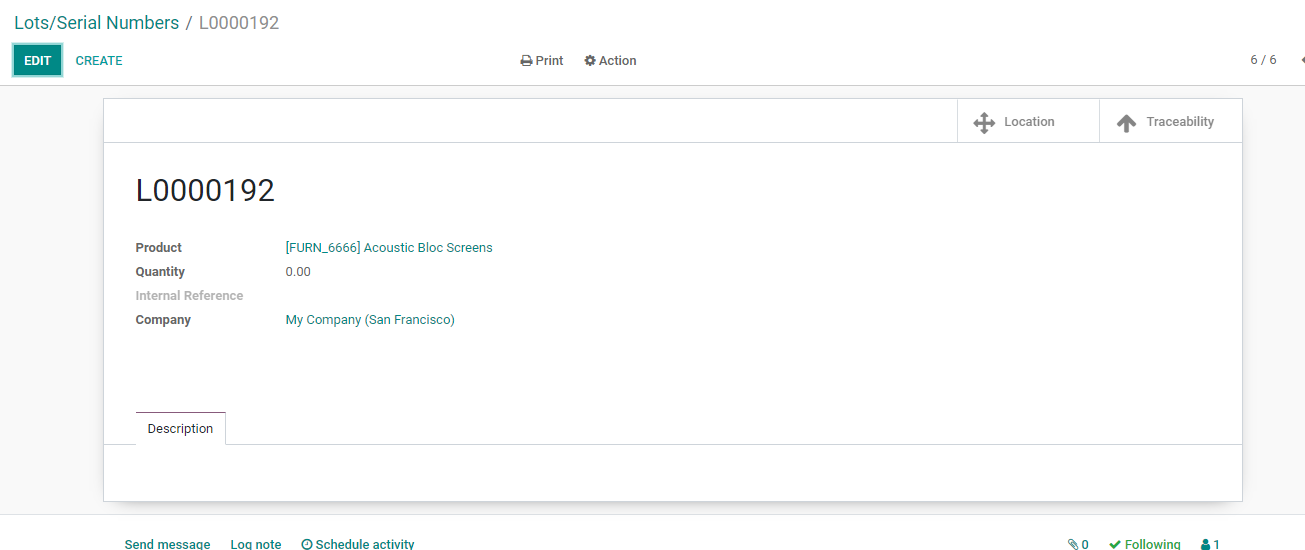

The above-given form helps us to create new Lots/Serial numbers. We can manage the product by selecting the product. We can also set the quantity here.

After entering the values we can change the form. Once saved, we can track the location and traceability.

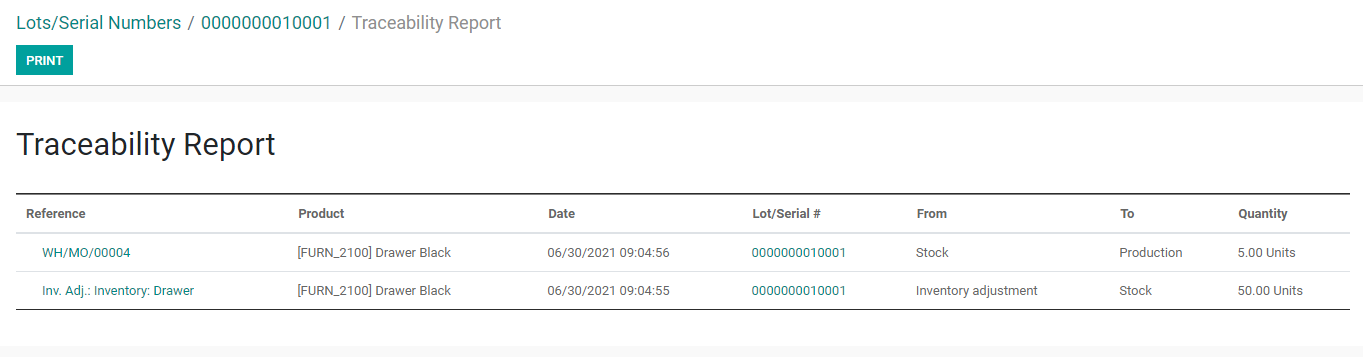

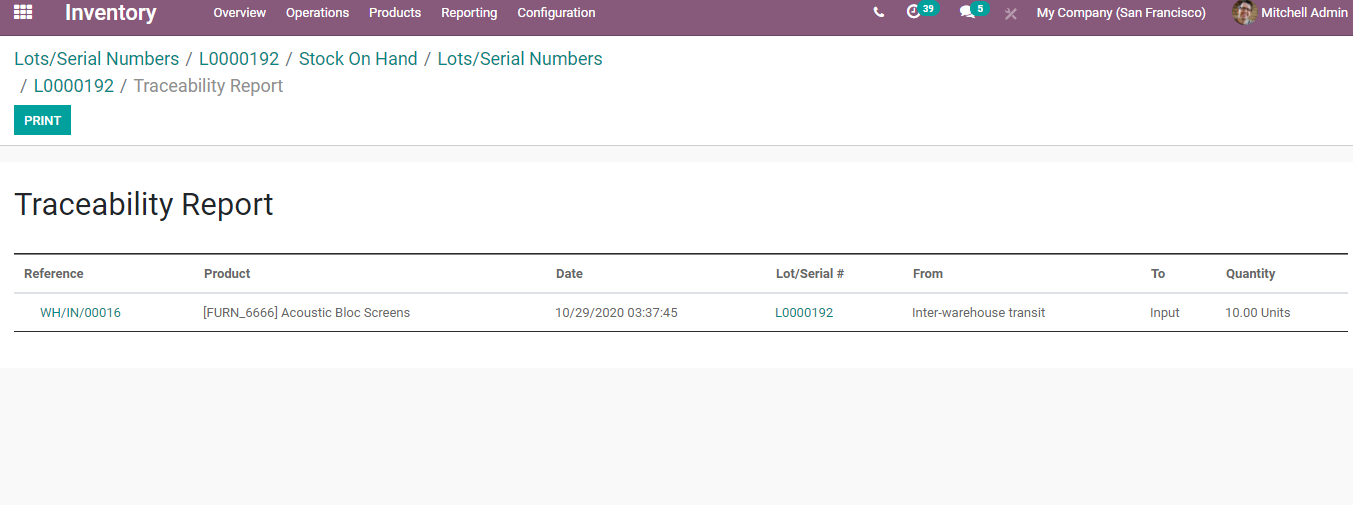

Clicking on traceability, we get this page where we can find the traceability report on the basis of the lot/serial number.

Product Configuration:

Usually, we manage a lot and serial numbers also while configuring a product. Let us check how to do this. We can now manage the product and track the product with ease.

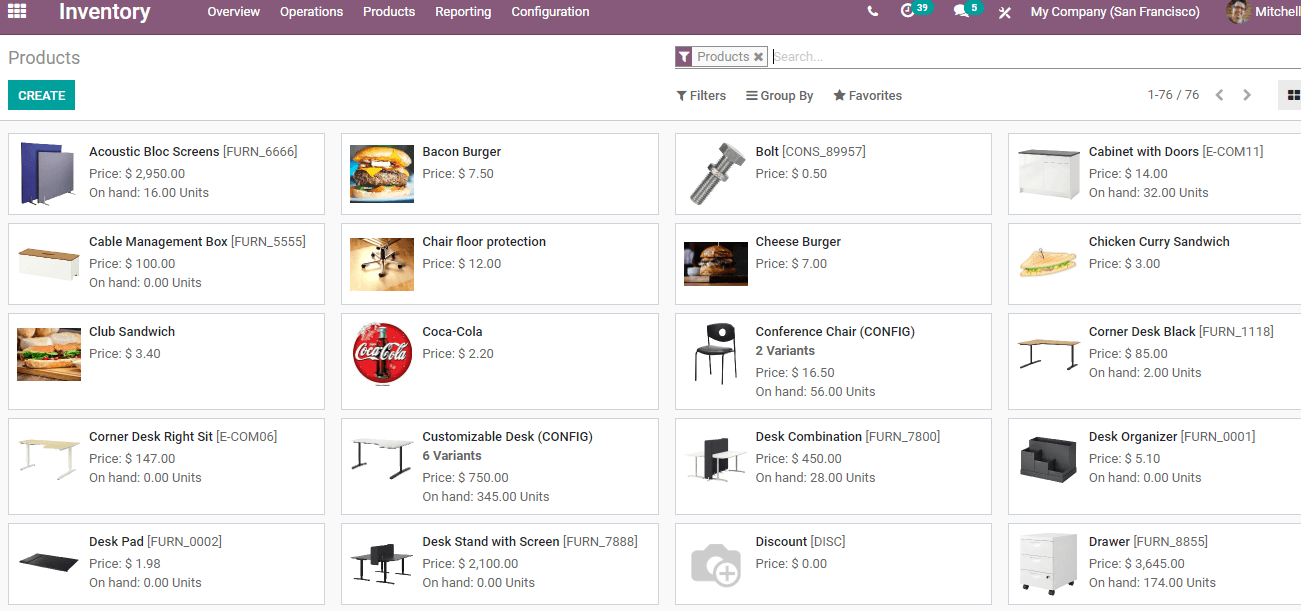

Let us do this at the product menu. First, we can go to the product and find a set of pre-configured products.

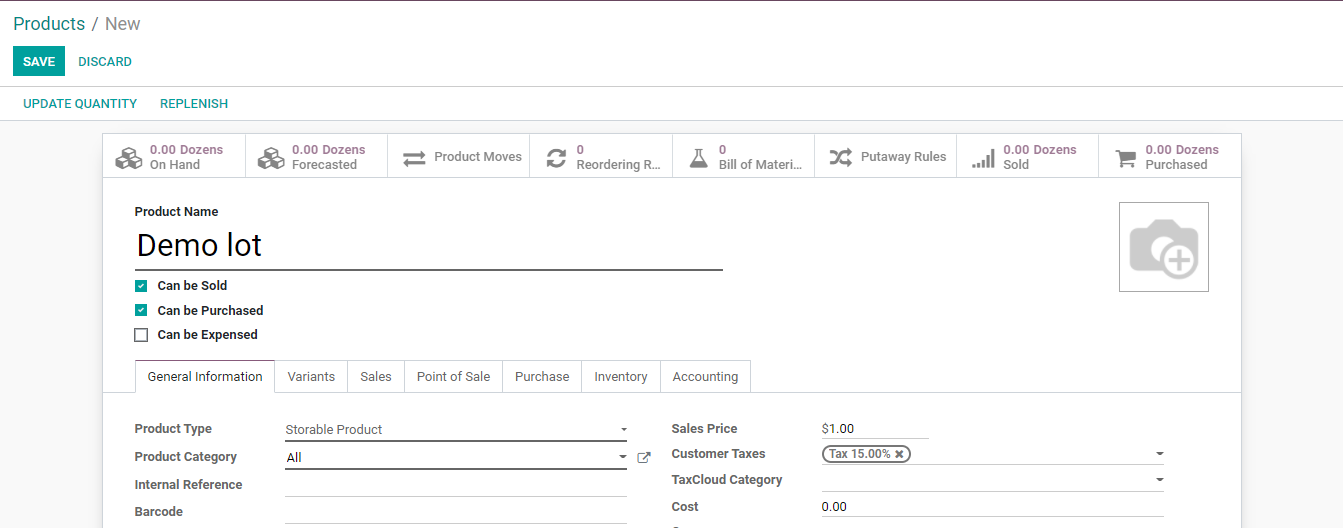

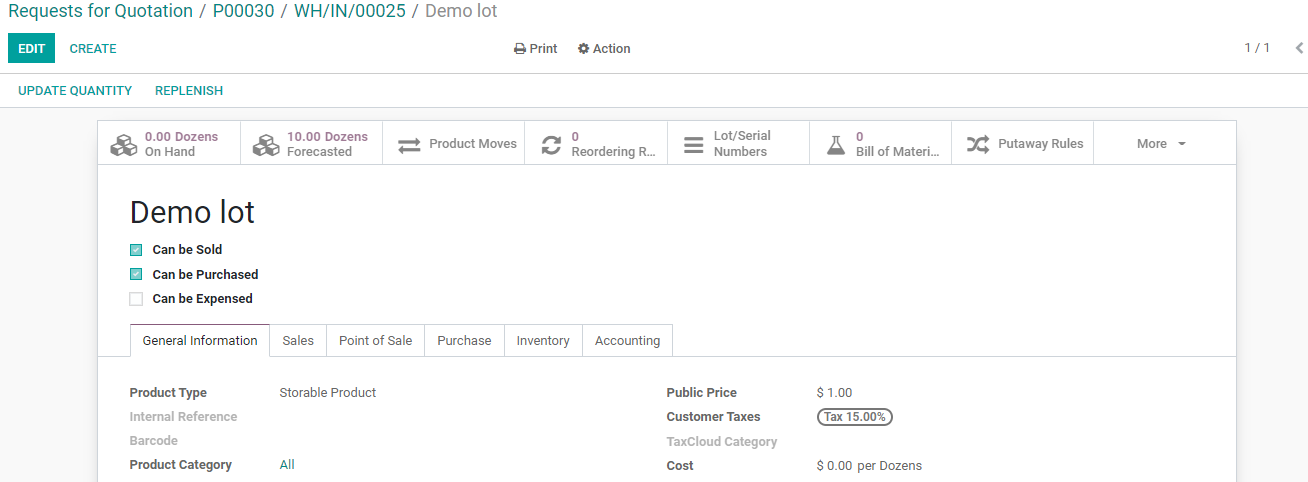

We can choose any of the existing products or create a new product to manage the lot and serial number. Let us create a demo product for the lot and a demo product for the serial number.

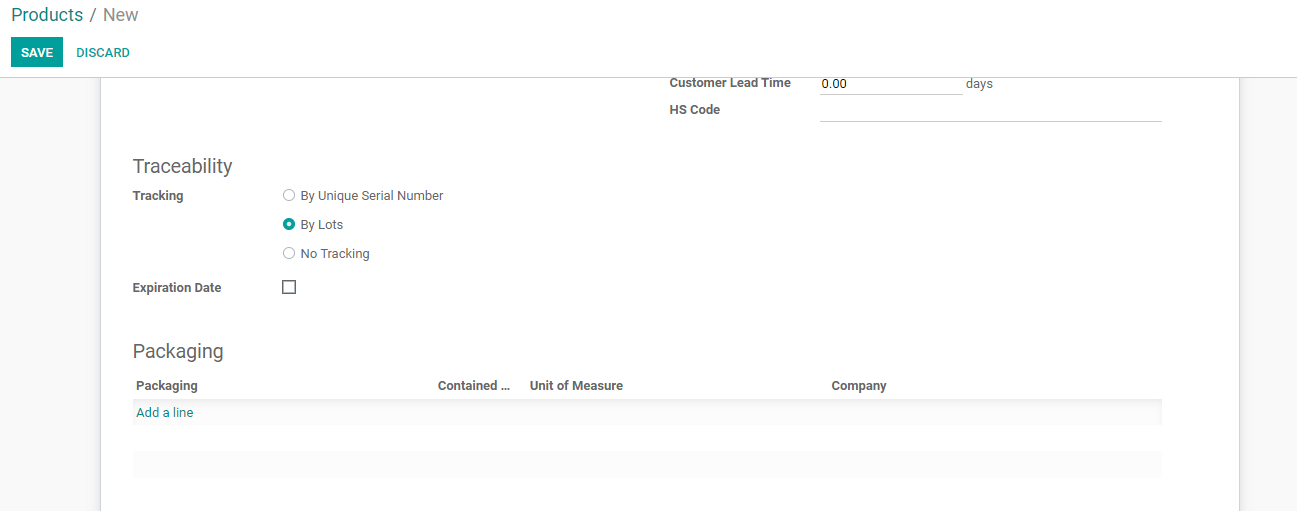

The inventory tab in this form will help us to ensure traceability.

Here there is a section named Traceability below which we can manage the tracking. We have options to manage tracking by unique serial number, by Lots, or enable tracking.

Lot/Serial number Management:

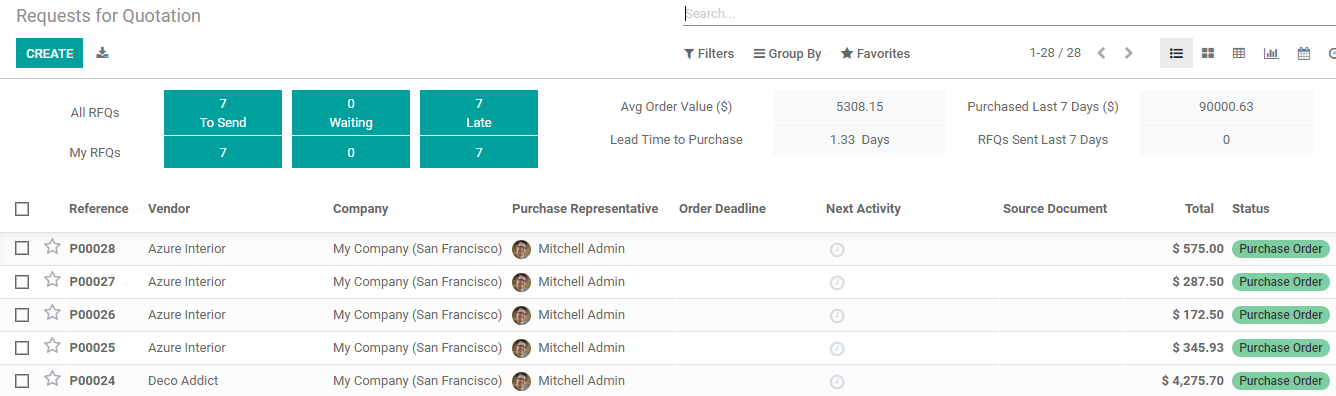

We can manage the lots with the help of a purchase module.

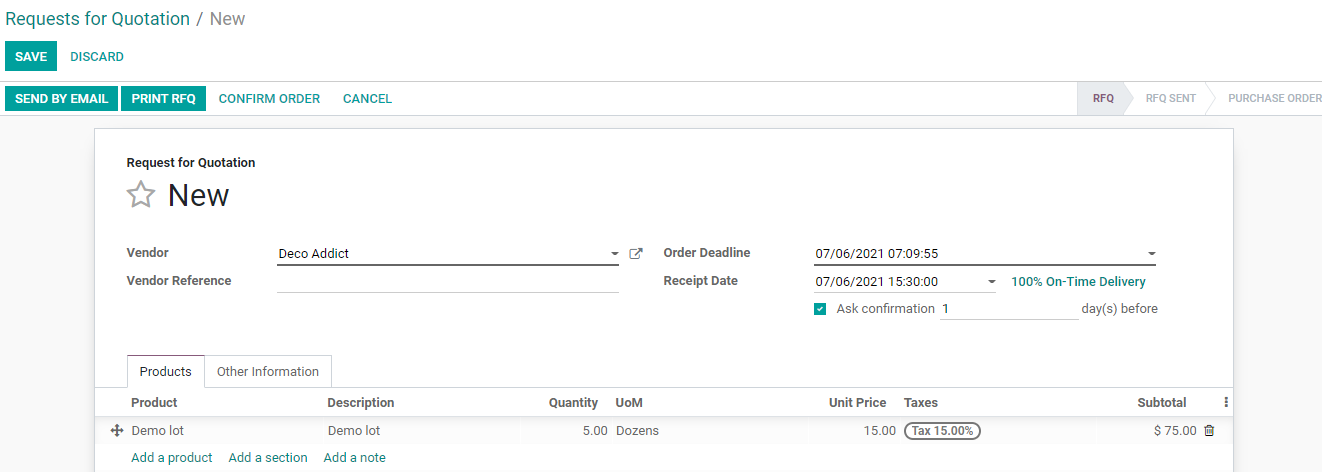

We will create a new purchase order for the product.

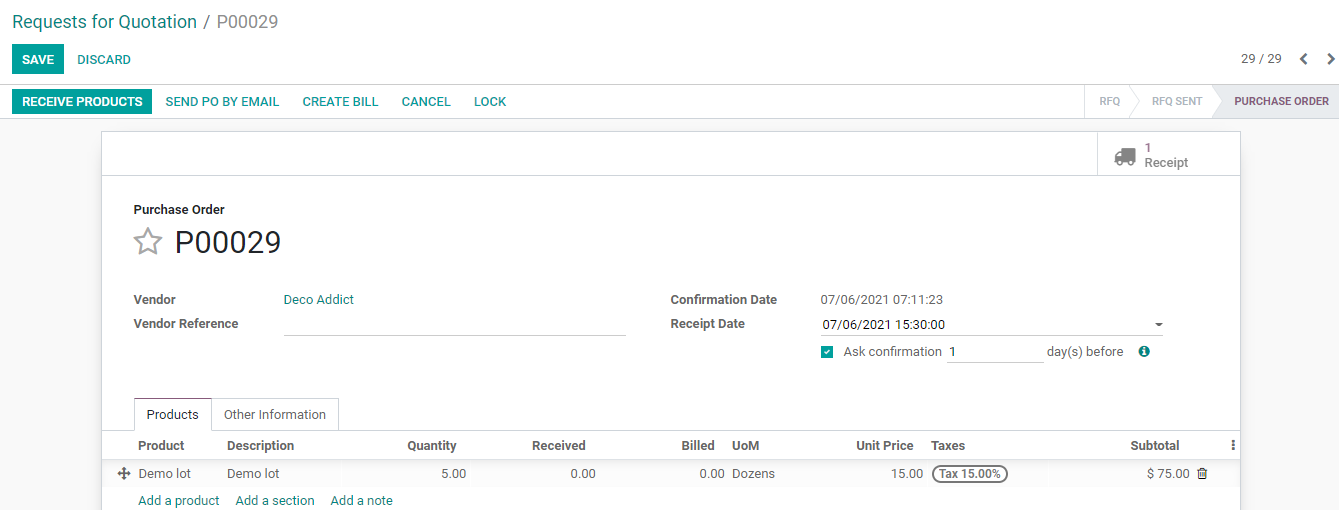

Confirm the Purchase order for the demo lot

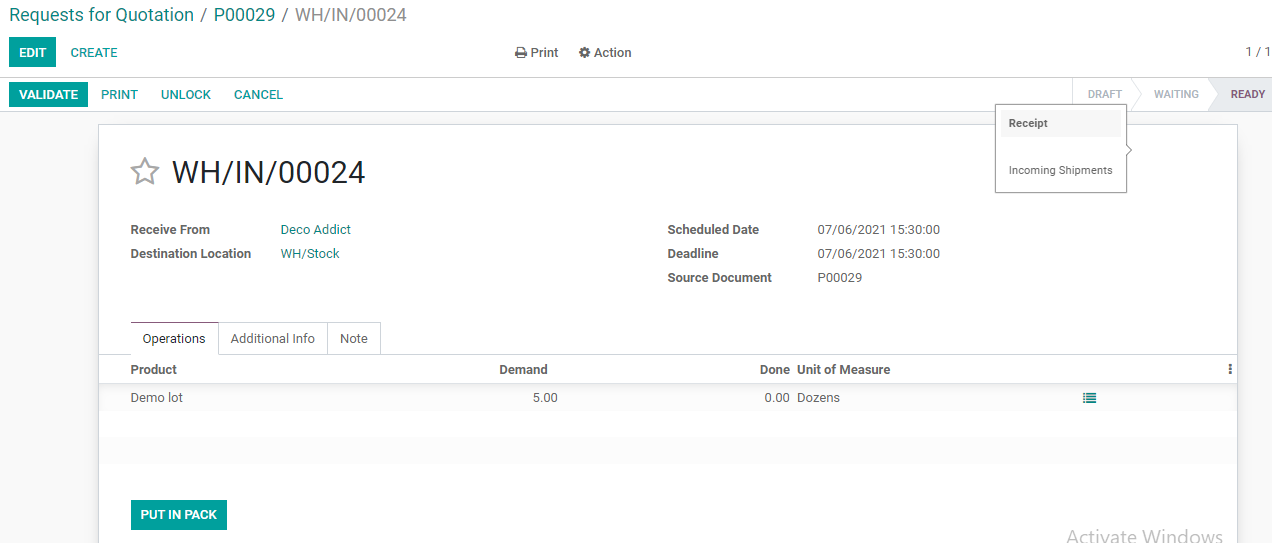

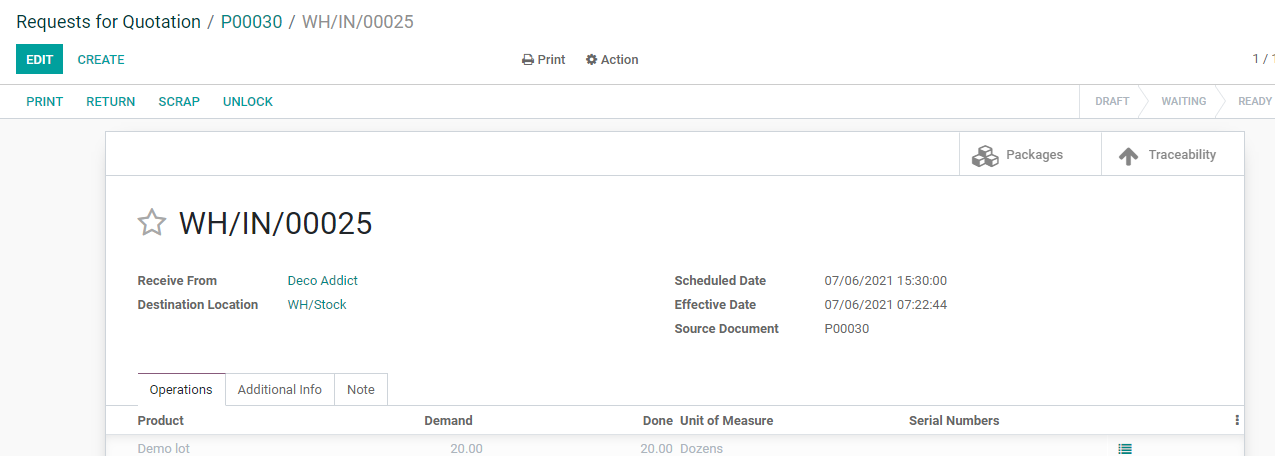

We can check the receipt icon to find the receipt.

We can click on the product and then manage the Lot/Serial number

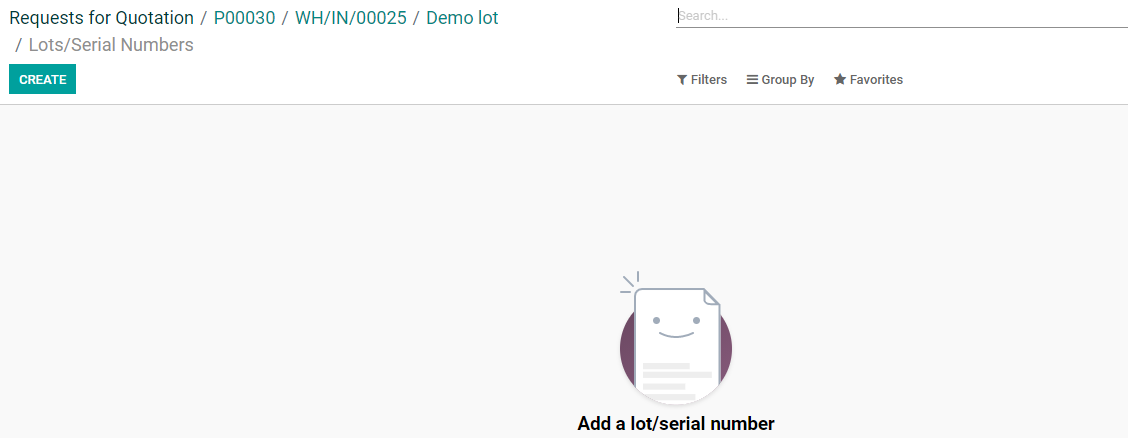

We can find the Lot/Serial number option on the top.

Clicking on it, we get this page where we can create a lot/serial number for the product.

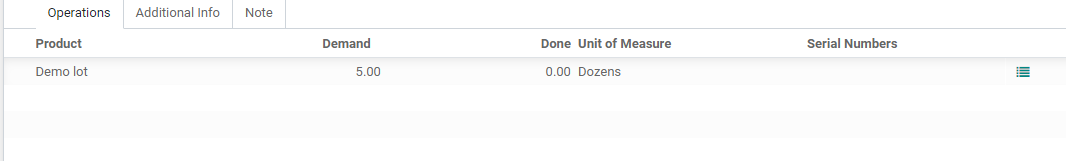

We can manage the same from the receipt page directly

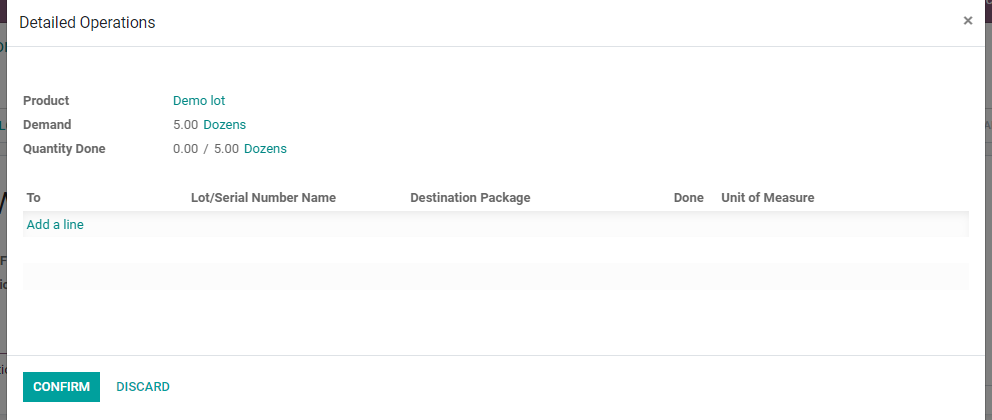

Click on the icon to get a window to manage the Lot/Serial number

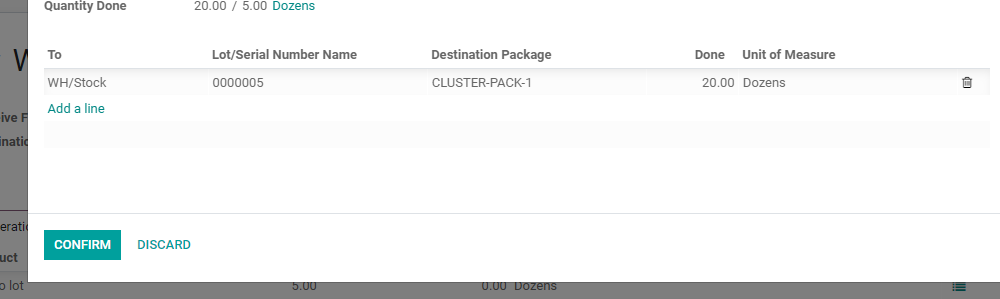

We can add a line to add the lot and serial number.

Confirm the process to see what happens.

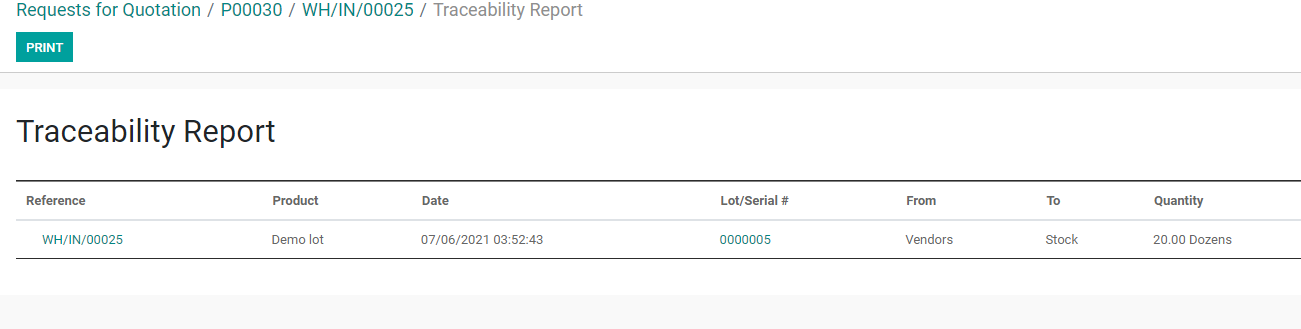

We can validate the process. To trace the purchase operation we can check the traceability button.

The traceability report can be accessed as below.

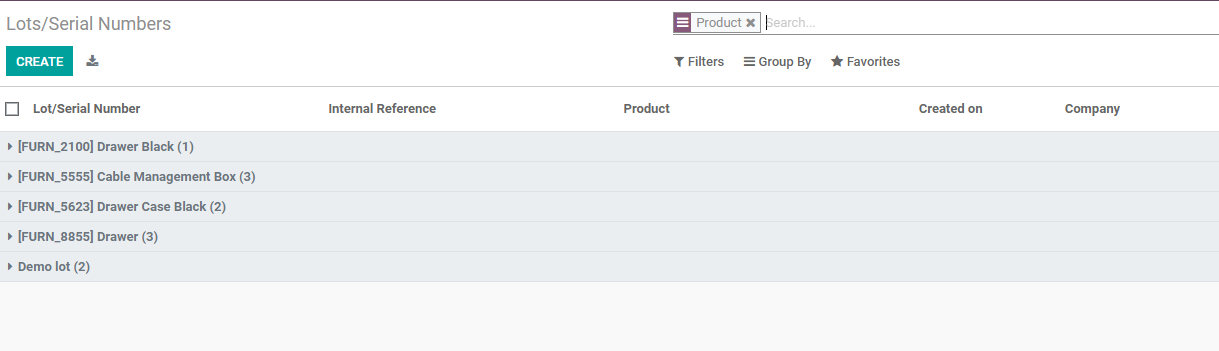

Now let us go back to Inventory> Products> Lots/SerialNumber

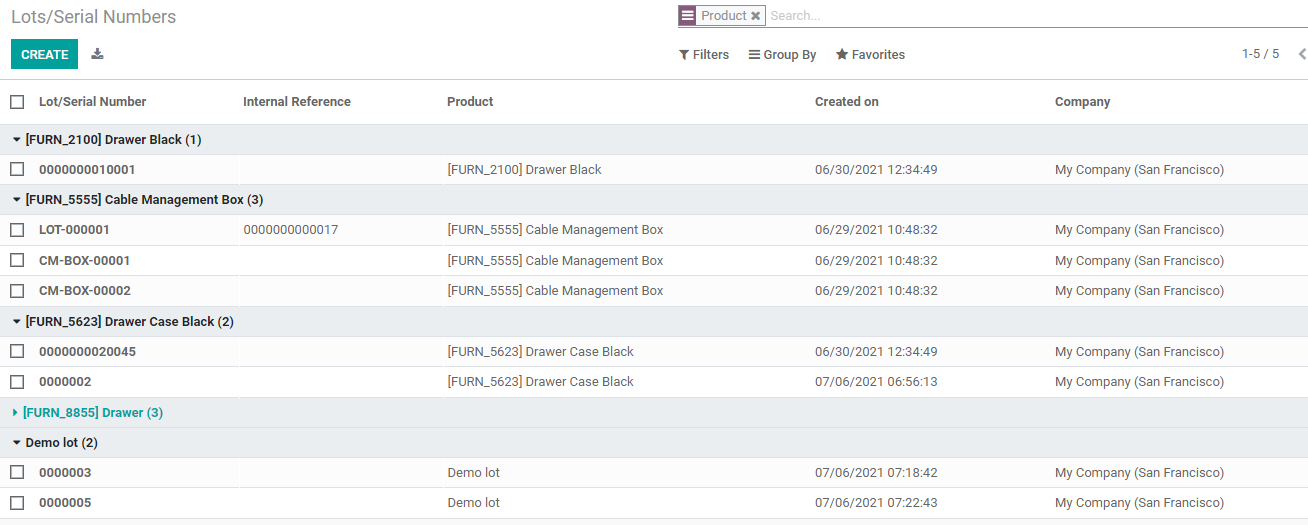

We can find all the products with serial numbers or a lot number

We can find the lot or serial number details here.

We can also ensure the traceability of the inventory using serial or lot numbers. Click on the lot number and check location and traceability

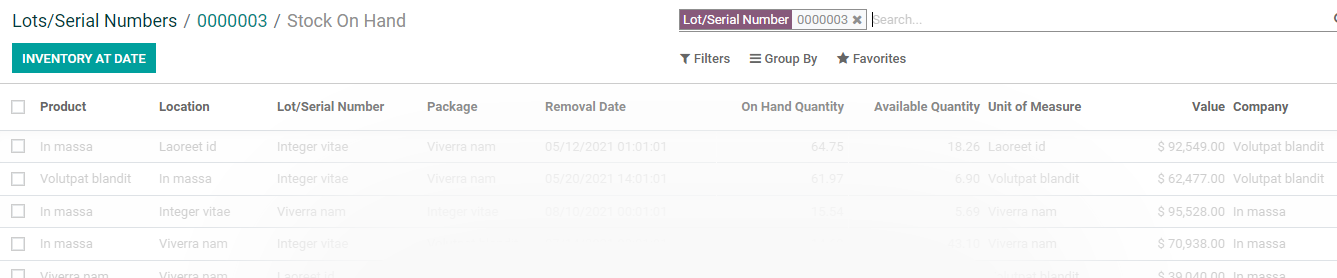

Clicking on the Location icon we get the page below

We can track the product detail location etc from here.

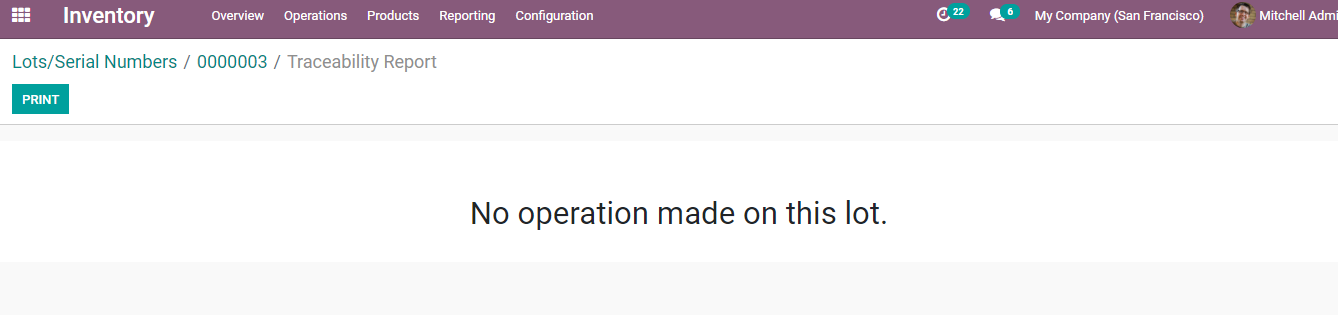

Traceabilityicons can help us track the movement of the product.

We got the above message as no transaction was done on the product.

Can check another product Acoustic block screen.

Inventory Adjustment

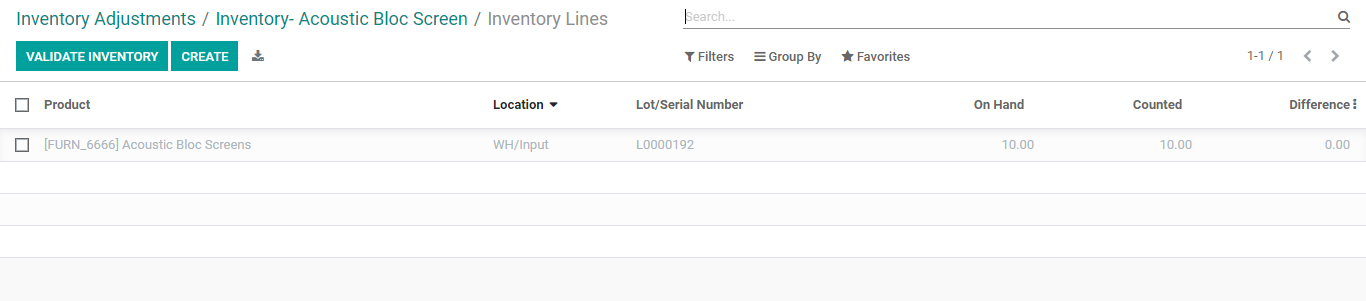

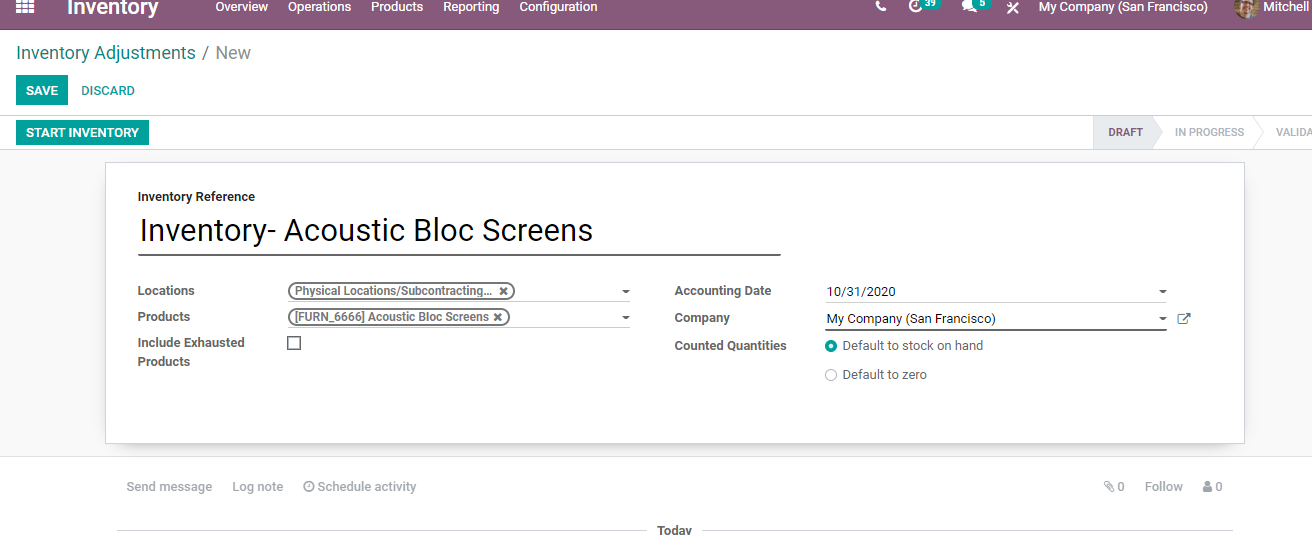

It is also possible to manage inventory adjustments with Lot/Serial numbers.

In inventory Operation, we can check Inventoryadjustments.

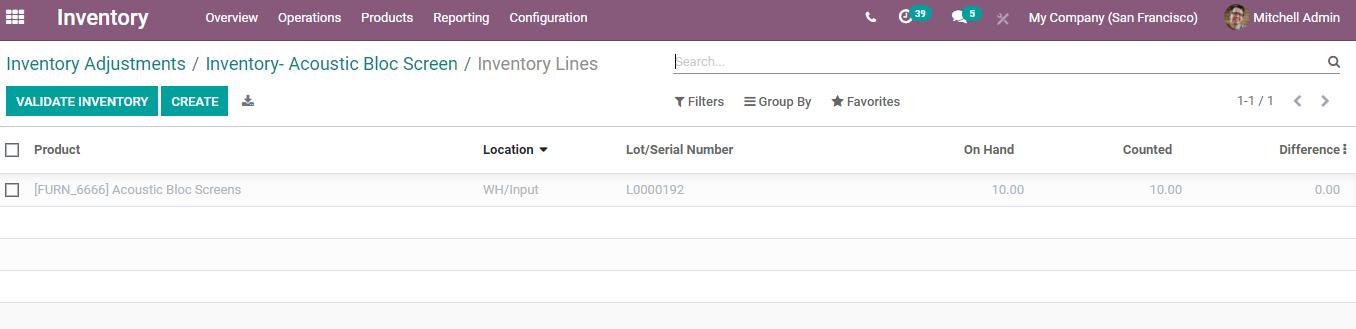

We have added the product and by clicking on START INVENTORY we get this page.

We can manage the location using the Lot/Serial number here.