The most advanced, automated, and productive ERP in inventory management is the Odoo ERP. The pivotal role is warehouse management, which simplifies handling all stocks required for business operation Comparing an enterprise's size, whether small, medium, or large, is a backbreaking task. This automated inventory management software makes your business move with high power efficacy and scale productivity.

Odoo ERP is a user-friendly and intuitive interface that can spontaneously manage a company's stock management. Its modular structure executes the internal operations of a company profitably and systematically.

The absence of ERP software in inventory management mostly fails to activate the real-time information necessary for further development or action. What are the challenges a company faces of the lack of an ERP system in inventory management?

a) Overstocking products may lead to transfer to the manufacturing unit due to their expiration date, and they cannot manage these back orders promptly.

b) Lack of real-time information about the numerous products in stock.

c) Understocking products may cause production and sometimes endure your production system's halt.

d) Inaccurate forecasting of trends leads to fallout during seasonal rises.

e) Lack of centralization leads to the company's expansion without getting prompt data on the inventories from different locations.

In large manufacturing or warehouse executing company must implement an effective ERP system to not coshed the warehouse operations in a company. Odoo ERP comfortably makes your inventory with its advanced features and manages your warehouse processes without complexity. One of the best and most useful advanced features of Odoo 15 is warehouse routing. What is routing in Odoo warehouse management software? Routing is a process where it deals with the order picking strategies in a warehouse management system. In a warehouse management system, the order picking techniques depend on the products gathered from the warehouse to a destination. As the customer orders, the product must plan the pathway where it reaches from the warehouse to the customer's destination. It has to be followed by various rules and regulations in the country. And it can be customized and worked according to the strategies followed by the company policies that can be maintained with the Odoo 15 so that the order picking systems are fulfilled with particular categories like the sales order lines, delivery of orders, collecting orders from the warehouse, etc.

A group of laborers usually handles the routing process. More often, in delivery areas, the use of labor is controlled and managed for the effort to collect the products from the warehouse and distribute them to the customer within the time targeted.

But Odoo stamps out all these factors and tapers the warehouse workflow. In this case, the Odoo routing functions and deal with the procurement rules and push rules to access and make the order and transfer the order to the appropriate locations through various steps and attains orders into proper places.

This blog emphasizes why the Odoo ERP is configured and productively used in warehouse management and routing, customized in Odoo 15, and enhances inventory business.

How is Odoo 15 facilitated in Warehouse Management and Routing?

As the expansion of your company, the warehouse management will also be expanded, where it may find backbreaking to find a solution to tackle. In such cases, the Odoo 15 stands and acts as retrieving towards all those risks. However, with the emergence of multiple warehouses, it would be a rigorous task to cope with controlling and managing the inventories held in the warehouse. This would be a hectic task for the workforce to organize here; the digitally advanced Odoo 15 stands as a regulator in your organization. And that enhances to move your organization into a productive panel with collecting more profitability.

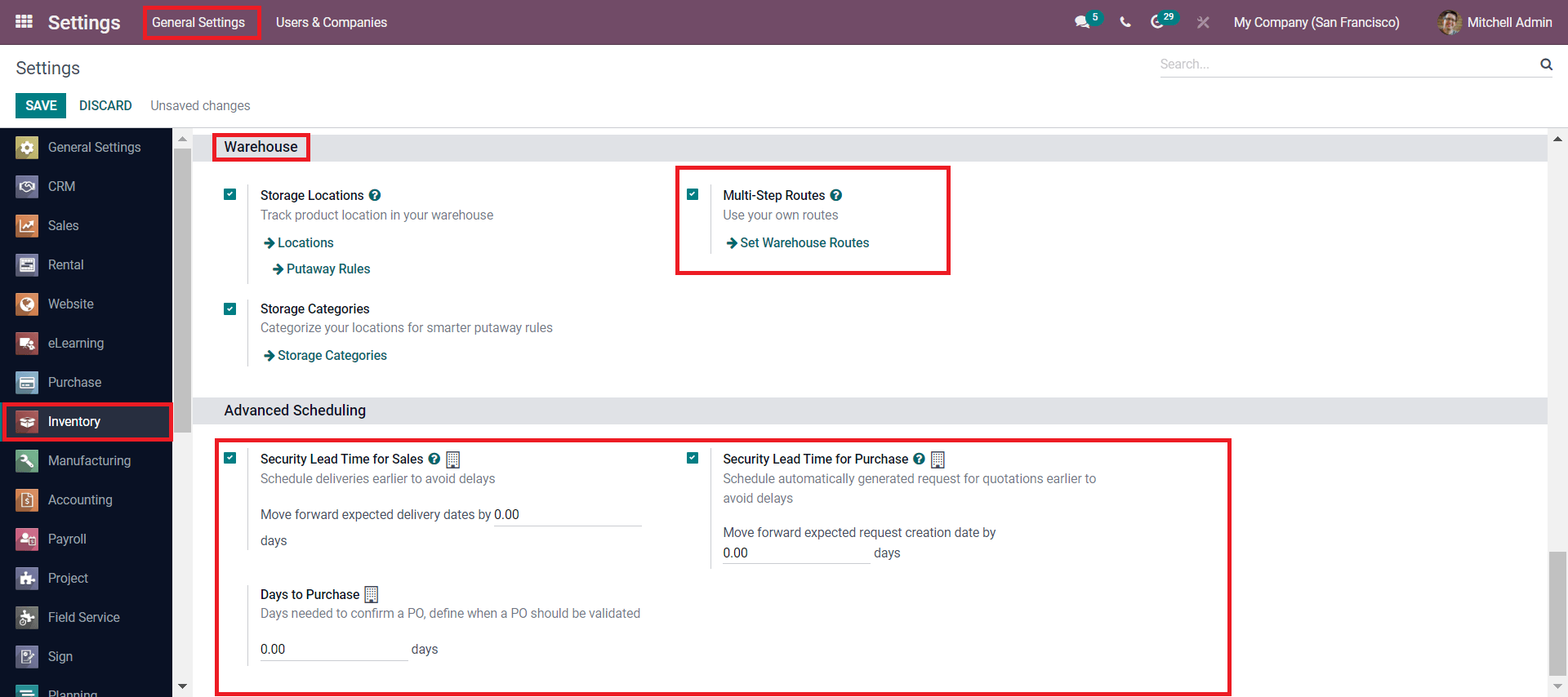

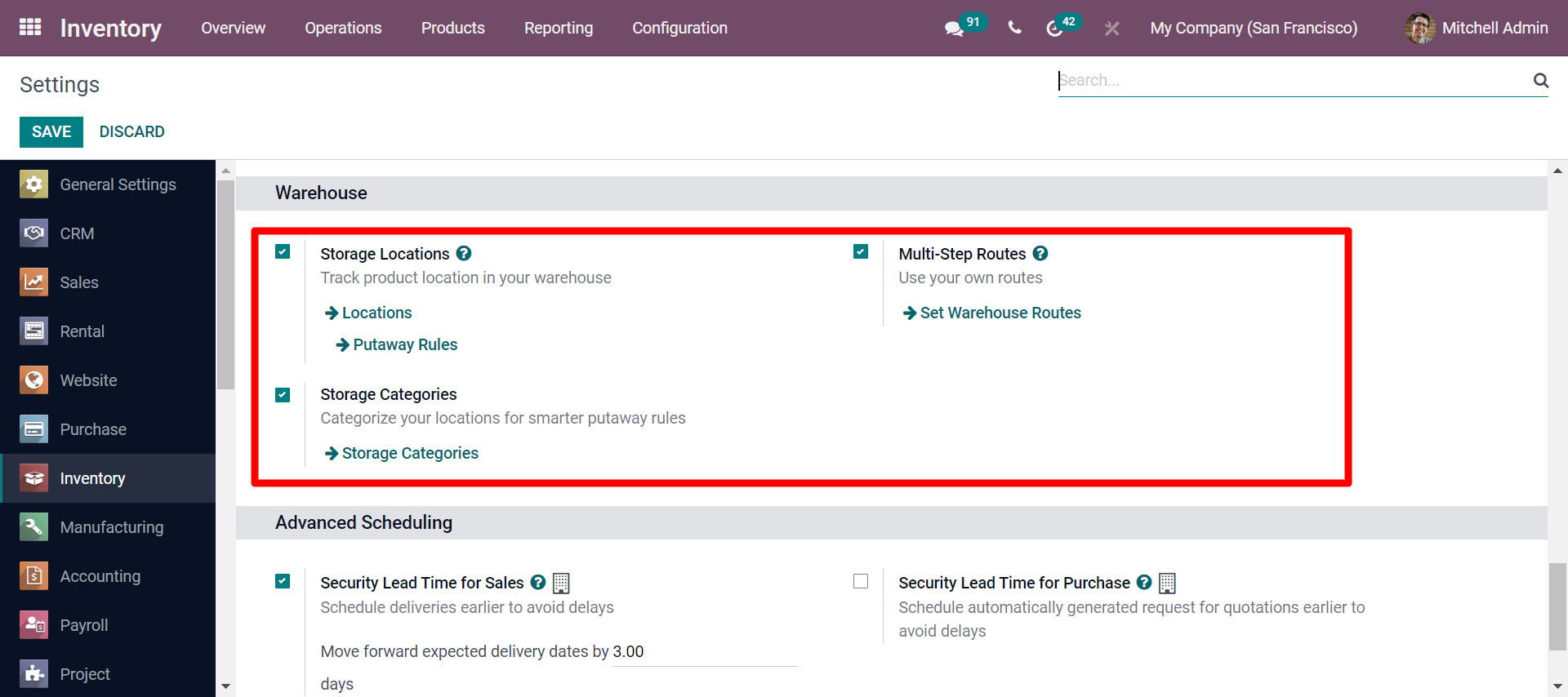

With Odoo 15, let us see how it is managed and regulates all the risks within a few clicks and a fraction of a second. To initiate the process with Odoo 15, you need to go to the General Settings of Inventory module from the Settings and configure the Multi-step Routes from the Warehouse.

Inventory>Configure>General Settings>Warehouse>Multi-Step Routes

As the above screenshot shows, you need to enable the Multi-step Routes to pick and drop the parcels from multiple locations and place them in the warehouses. Also, you need to enable Advanced Scheduling to avoid delays during deliveries and for earlier deliveries. And you can even set the time for the expected delivery within 4-5 days, or you can configure the Purchase order by validating a period in days that can be margined under the Security Lead Time To Sales. And even you can enable the Security Lead Time To Purchase for generating the quotations to avoid delays. You can also define the period within the days and how much it covers.

In the above screenshot, you can customize and set the route operations inside your warehouses if you have multiple warehouses under Multi-step Routes. By adding this unique feature, you can manage the quality control, unloading of products, picking and packing of products, and so on.

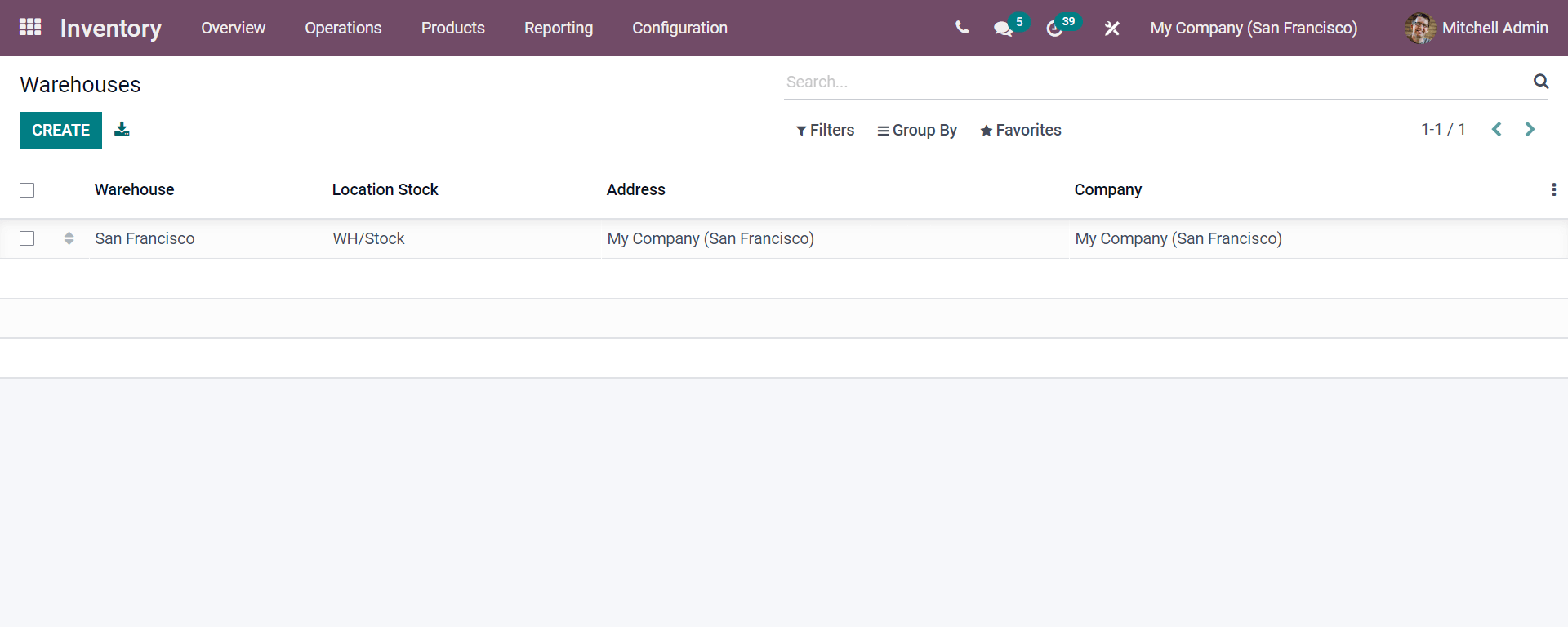

Now, if you require to observe the Warehouse menu, you will move to the Configurations tab and click on the Warehouse, or you can click on the Set Warehouse Route option and view the warehouse menu.

Now, as depicted above, we can click on the CREATE button and see how to obtain a warehouse menu with all specifications.

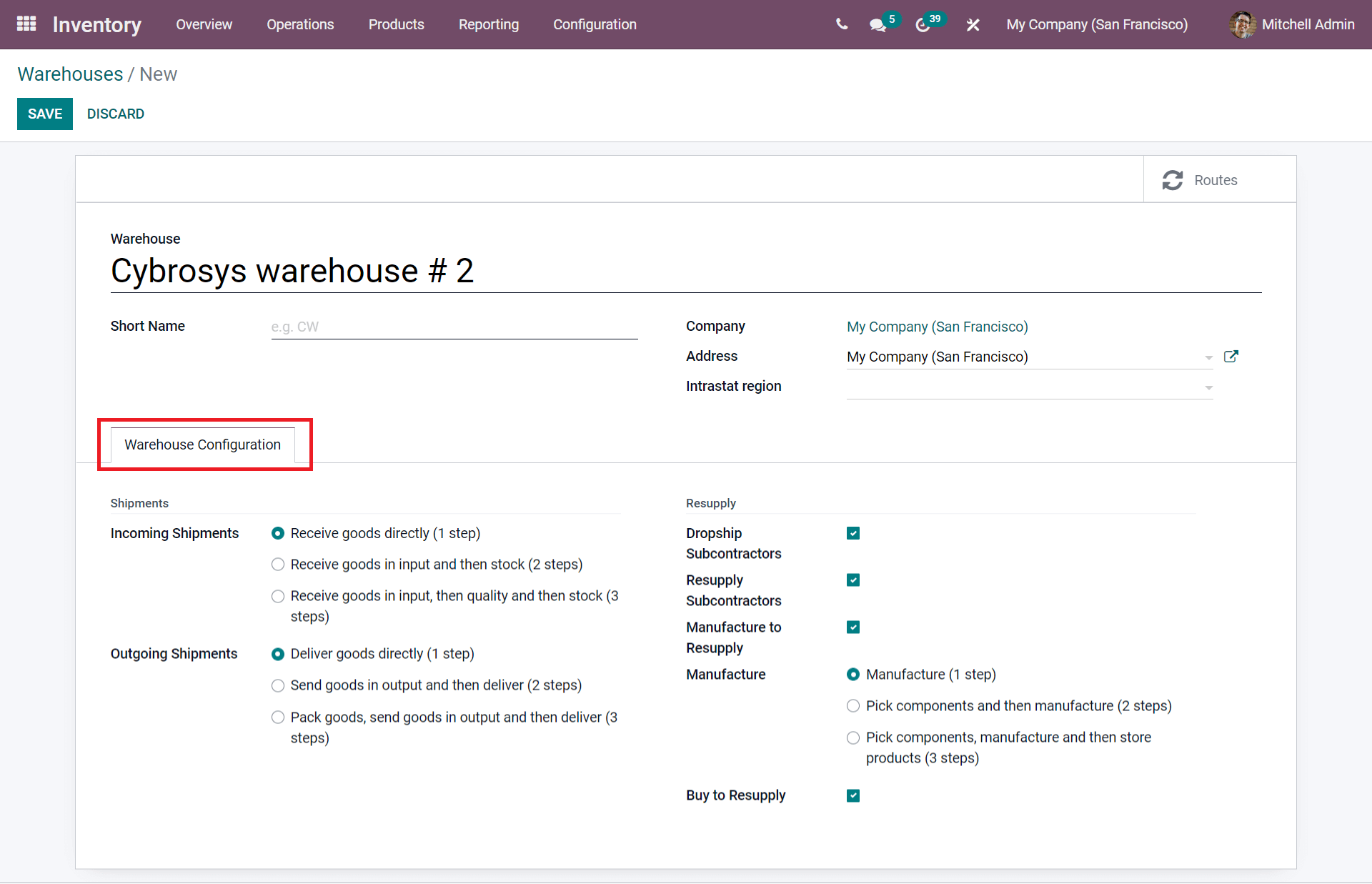

To create the warehouse, you have to enter the basic details above the Warehouse Configuration tab. The warehouse configuration is differentiated into two steps Shipment and Resupply. In shipment, the Incoming Shipments are classified into three steps which means in the first step, and only one process is undertaken where the products are received directly to the warehouse. And in the second step, two processes are followed: input and stock. The last step is the three-step, where three processes are involved in receiving the products in inputs, quality, and stocks. These are the same features engaged in the Outgoing shipment process. Here you can enable the feature to manage the shipments in each warehouse of your company. Next is, the Resupply feature in the manufacturing process it is dealt with. Here this feature is dependent on the multiple warehouses a company manages. And it is considered a beneficial feature since if a warehouse deals with the out-of-stock, the stock can be managed with the next warehouse. The resupply in manufacturing is also a one-step, two-step, and three-step process. Under a one-step process, the products are moved directly to the production unit for manufacturing. In the two-step process, the products are picked from the stock and sent to manufacturing. And in the three-step process, pick the components, manufacture, and store the goods.

In the Resupply field, you can enable many other options required for your warehouse, as seen in the above screenshot. And you can additionally add the ROUTES as the smart buttons if necessary for your warehouse. With this smart button, you can easily manage the route track of your warehouse operations.

To know more about the reordering and replenishment in Odoo 15

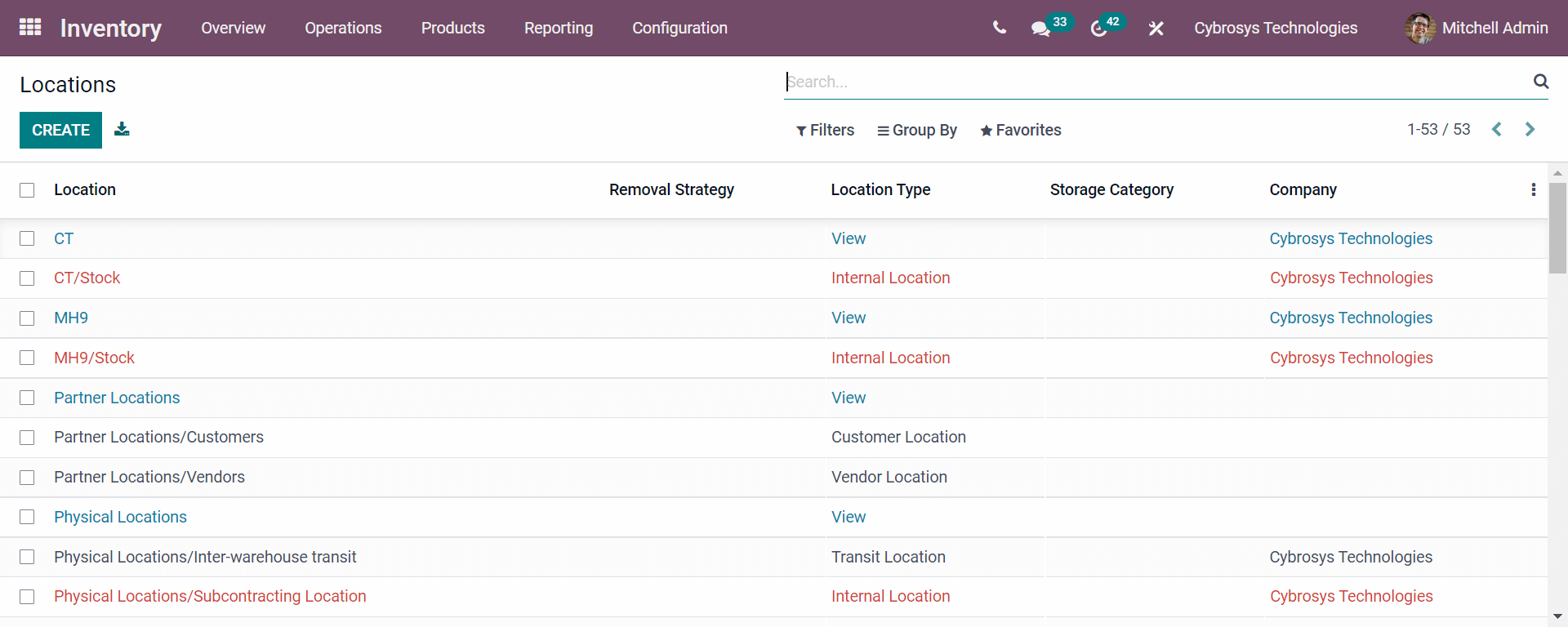

Locations

With Odoo, you can manage the stocks around your warehouse, which are arranged in different sections. Under the Locations, you can manage and control the stock operations held in your warehouse.

Odoo manages three types of locations in your warehouse. It can be classified accordingly;

Physical Locations:-It is considered as the internal locations in your warehouse (stuffing, de-stuffing area).

Partner Locations:-The area where the customer’s or vendor’s warehouse, with the only difference from to physical location, is that it is not the owner’s warehouse.

Virtual Locations:-The location is described as where the product's physical existence may not occur and occurs at the time of your need. It is found in the period of procurement.

You can refer to the link given for the analysis of location types in Odoo 15, Now let us see how the configuration is managed in a location with Inventory.

Here is an image showing the Locations with their details specified under each category depicted above. You can add the Filters, Group By, and Favorites options to customize and get the details per every location with Odoo.

To form a location, you need to click on the CREATE button, and a window will emerge as follows.

Now while you open the creation window, you will be getting a list of options to select, and entering you have to enter all the details based on the locations of your warehouse. Under Location type, there will be a drop-down menu where you must select the desired location type as your requirement. The list of options under location type can be described as follows:

1) Vendor Location

2) View

3) Internal Location

4) Customer Location

5) Inventory Loss

6) Production

7) Transit Location

To know more about the Analysis of Location Types in Odo 15

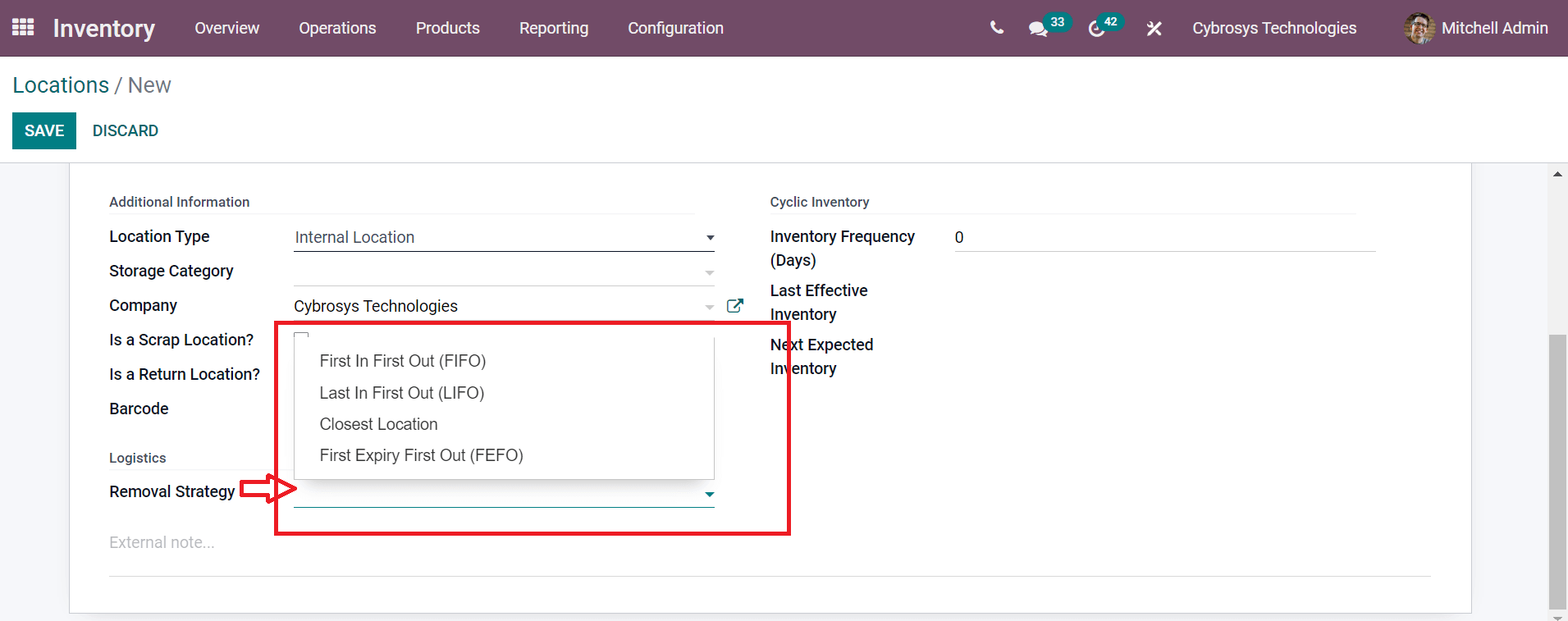

Then as seen in the above screenshot, you can enable the scrap location and return location and enter the product's barcode. And also, the Cyclic Inventory can be entered with your specific location. Now comes the Removal Strategy, as highlighted in the above screenshot. In that, you can see four types of removal strategies by clicking where a dropdown menu emerges such as

1) First in First Out (FIFO),

2) Last in First Out (LIFO),

3) First Expiry First Out (FEFO),

4) Closest location

First in First Out (FIFO)

In this the products which are kept at stock, the old stock is first used and then the latest products which are kept is used. This system is beneficial and effective for a company due to the products can be moved apart and segregated with their expiry and can be arranged with the old products first and then the new ones.

Last in First Out (LIFO)

It is just contrary to the first option which is the FIFO, which means the new products or fresh products must sell first and other old products later. This makes the old stock if its expiry got diminished making the owner a remarkable crisis in their business. But often there are certain products eg:- meat, fish and edible products can opt with this option only.

First Expiry First Out (FEFO)

Here FEFO as the name indicates the products which decomposed are removed first and then the others are used.

Closest Location

As compared to other editions in Odoo 15, this is a new feature where the products are sent out to the which are brought from the closest location.

Now let us discuss the Rules and Routes in Odoo 15.

Rules & Routes

Before configuring the rules and routes in the Odoo Inventory module we need to move the Settings and enable certain options as follows.

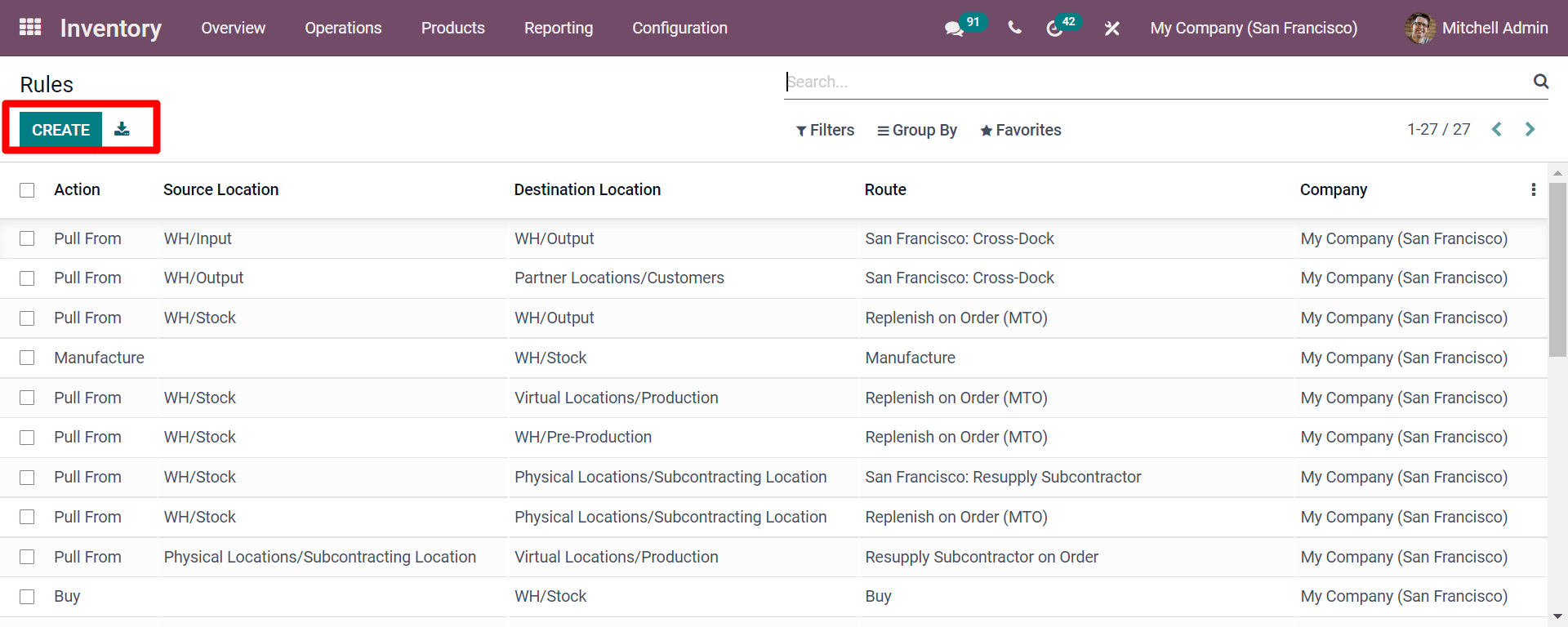

Now from the Configuration, you need to select the Rules where your operation of the push rule and pull rule can be managed.

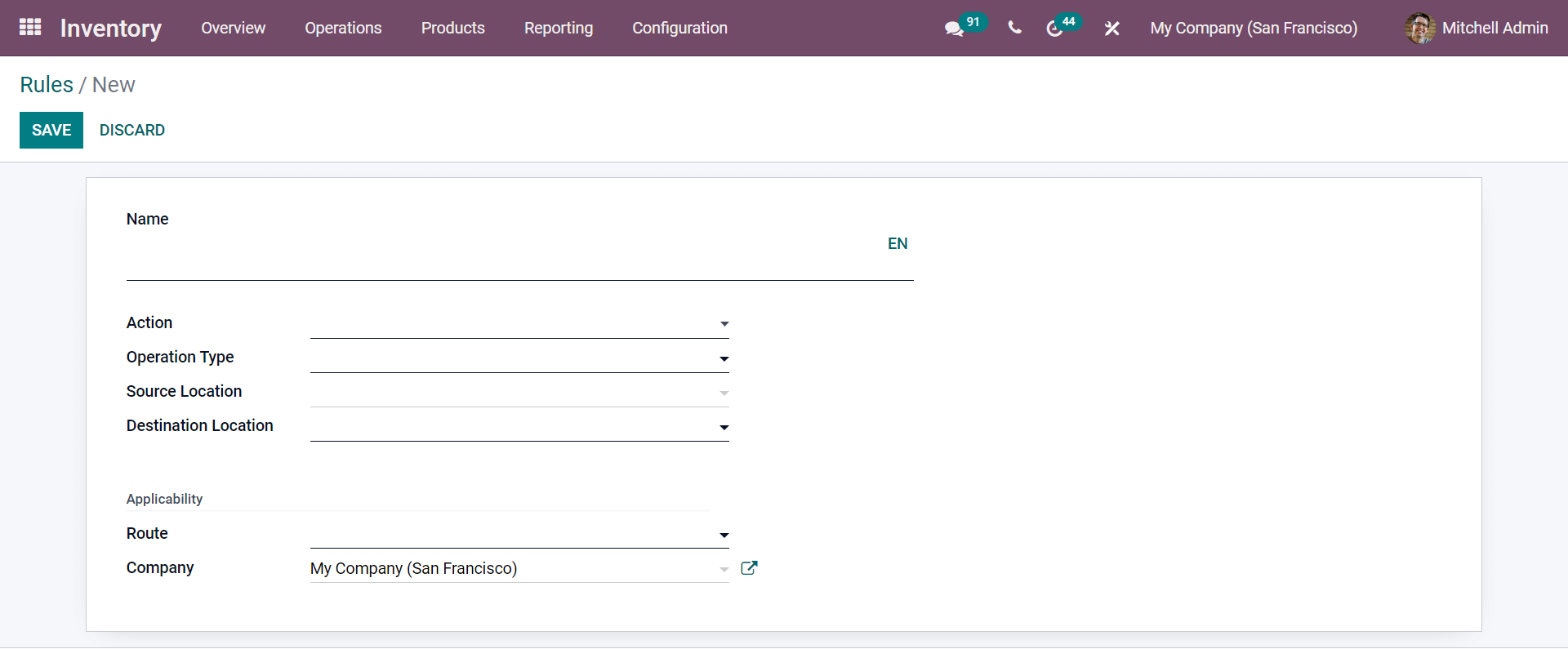

Now as seen in the above screenshot, you can see different areas displayed under rules that are managed with your routing. To create a rule you have to click on the CREATE button where the creation window will appear.

Here in the creation window under the Action, you will get a drop-down menu with options Pull From, Push to, Pull and Push, and Manufacture And Buy.

To know more about the configuration you can move on to the video link as follows

How to Configure Route and Rule in Odoo15 | Odoo 15 Inventory | Enterprise Edition

And to know more about the Operation types in Odoo 15 you can move to the blog.

By concluding this blog, the blog gives you a detailed overview of managing warehouses and routing with Odoo 15. The blog studies how effectively we can perform warehouse management with different steps of features and performs your inventory business within less span of time even if you manage with multiple warehouses.