Lead times are nothing but the time expected to receive, deliver, or manufacture products. One can configure the lead time for purchase, sales, and manufacture. The vendor lead time is the time demanded by the vendor to deliver a product. On the other hand, customer lead time denotes the time needed for delivering products to customers and the manufacturing lead time- the time you needed to manufacture a product.

Purchase Lead Time:

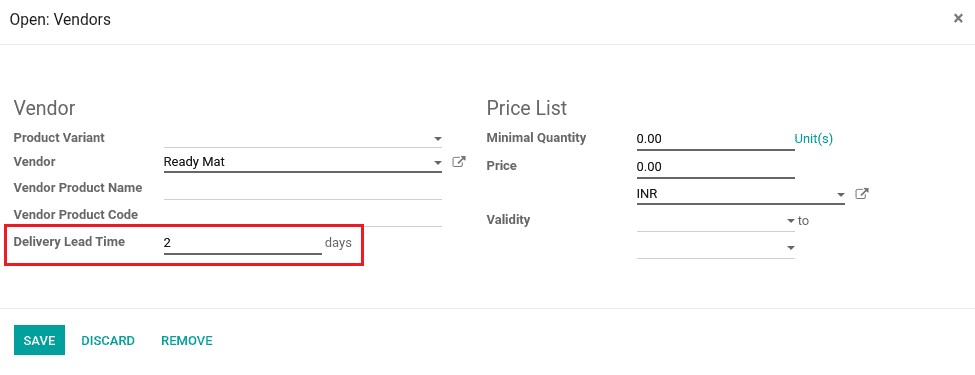

In order to configure delivery lead time, one has to go to Product and under the product purchase tab, need to click a vendor. The delivery lead time for both vendors and products can be changed here.

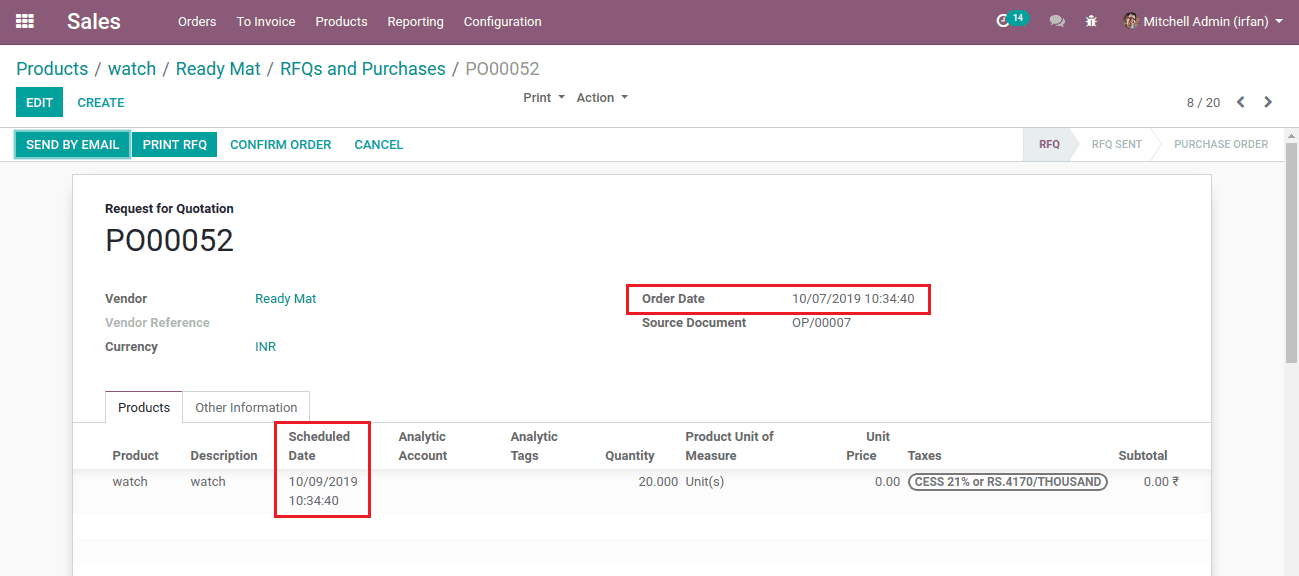

Since the delivery lead time is 2, when you make a purchase order, the order date will be two days before compared to the scheduled date:

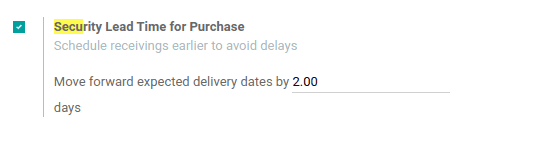

To configure security lead time, go to settings > security lead time & set a lead time.

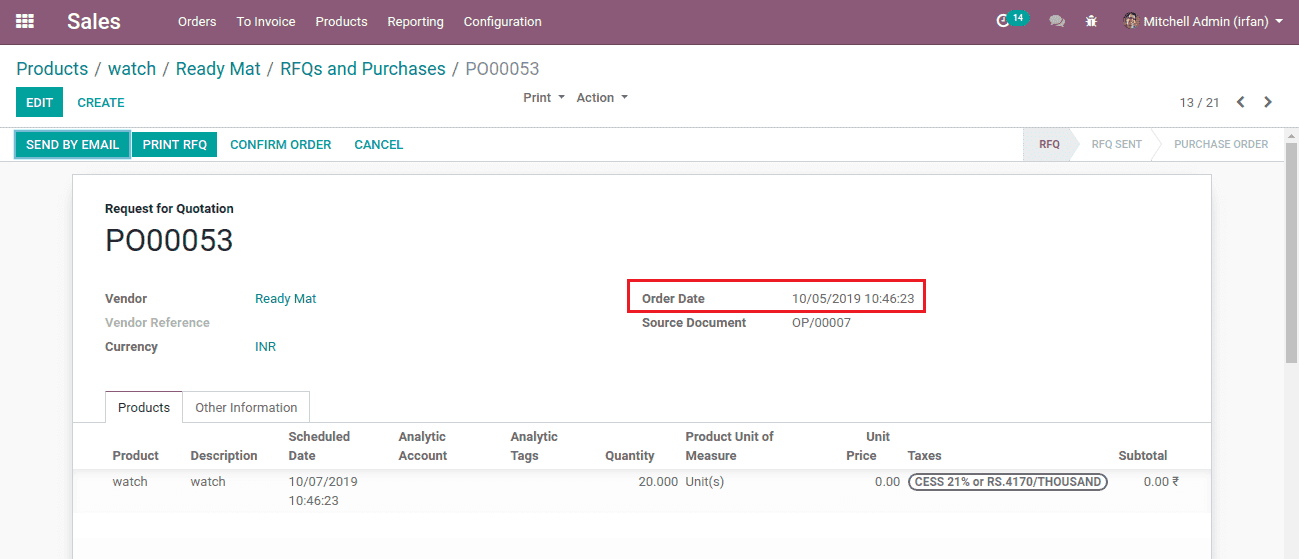

Then trigger the Run Scheduler, the RFQ will be sent to the corresponding vendor if the quantity on hand is the min that set in the scheduler. Since the security lead time is 2, the order date will be 2 days before the current date.

Sale Lead Time:

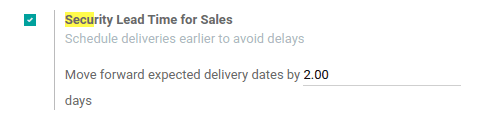

To configure security lead time, go to settings > security Lead time for sales, & set the lead time.

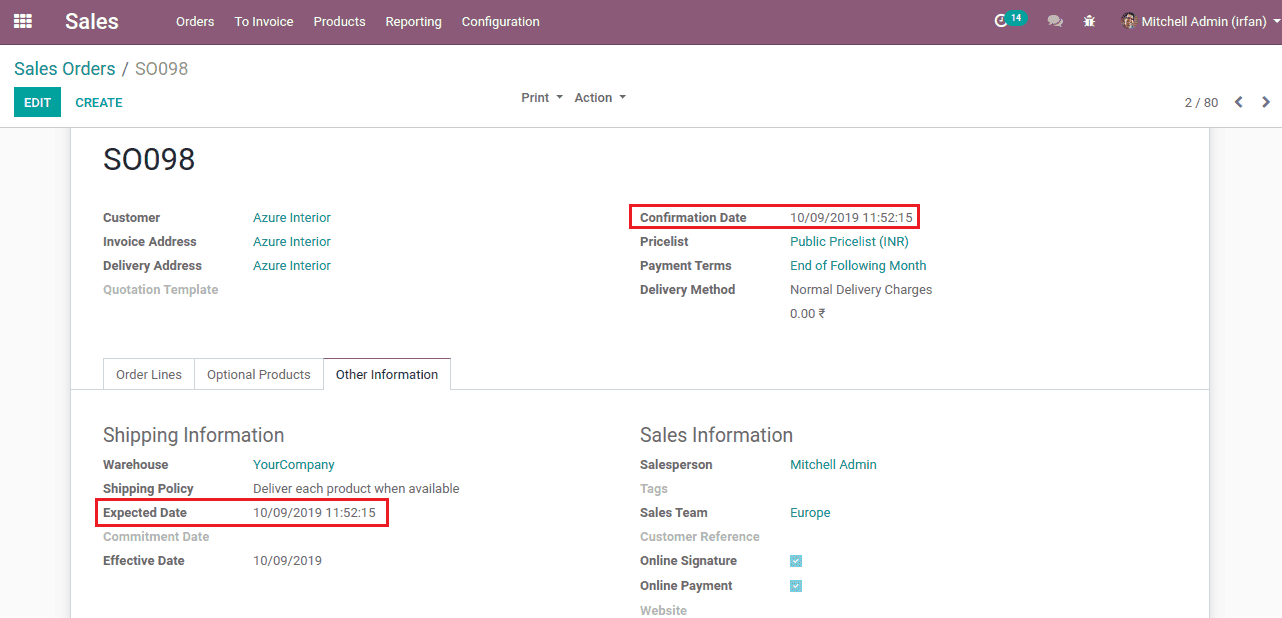

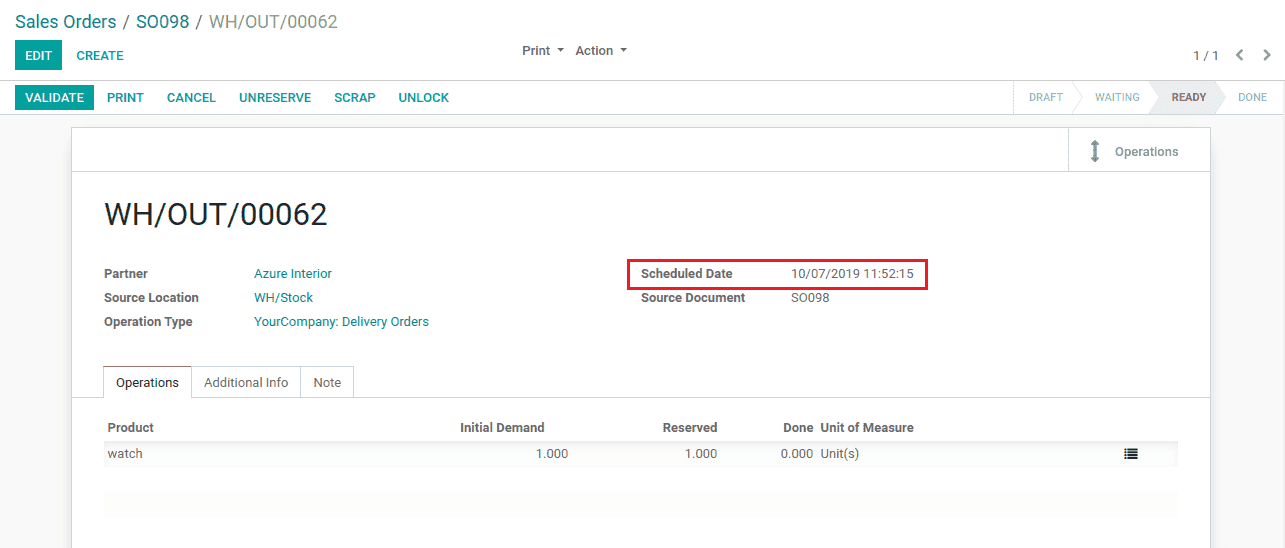

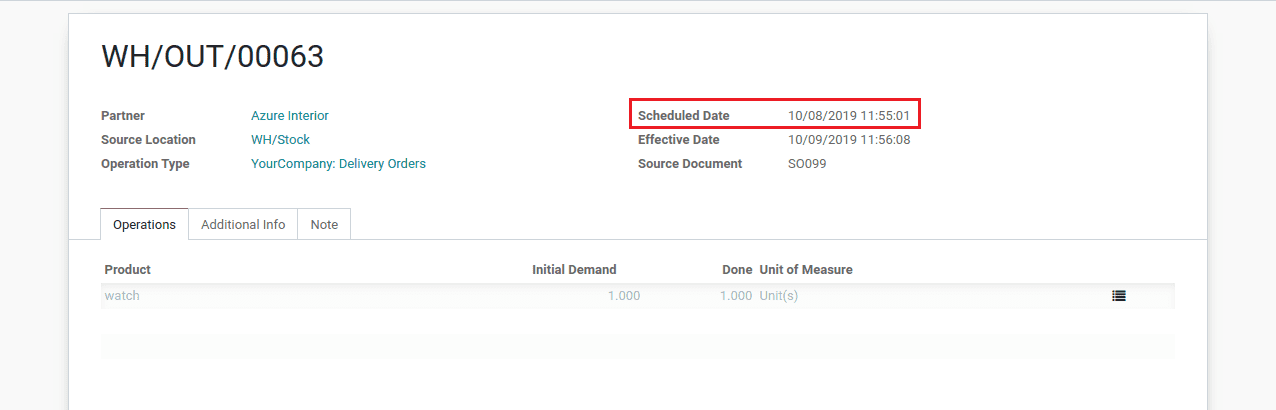

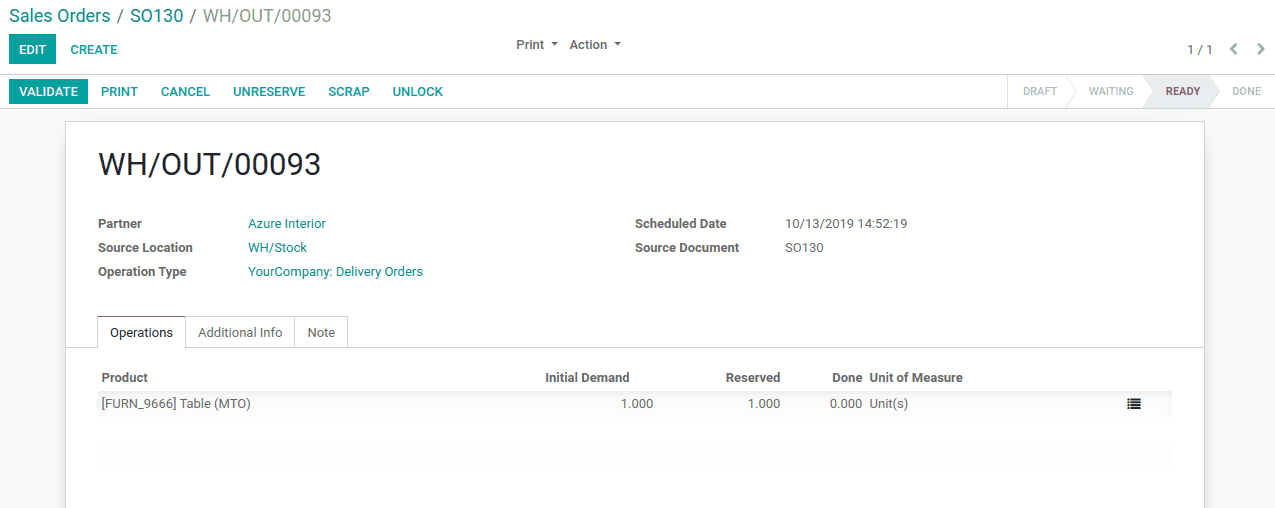

Then make sale order, here lead time is 2 so while making delivery, the scheduled date will be two days before the expected date. It is shown below:

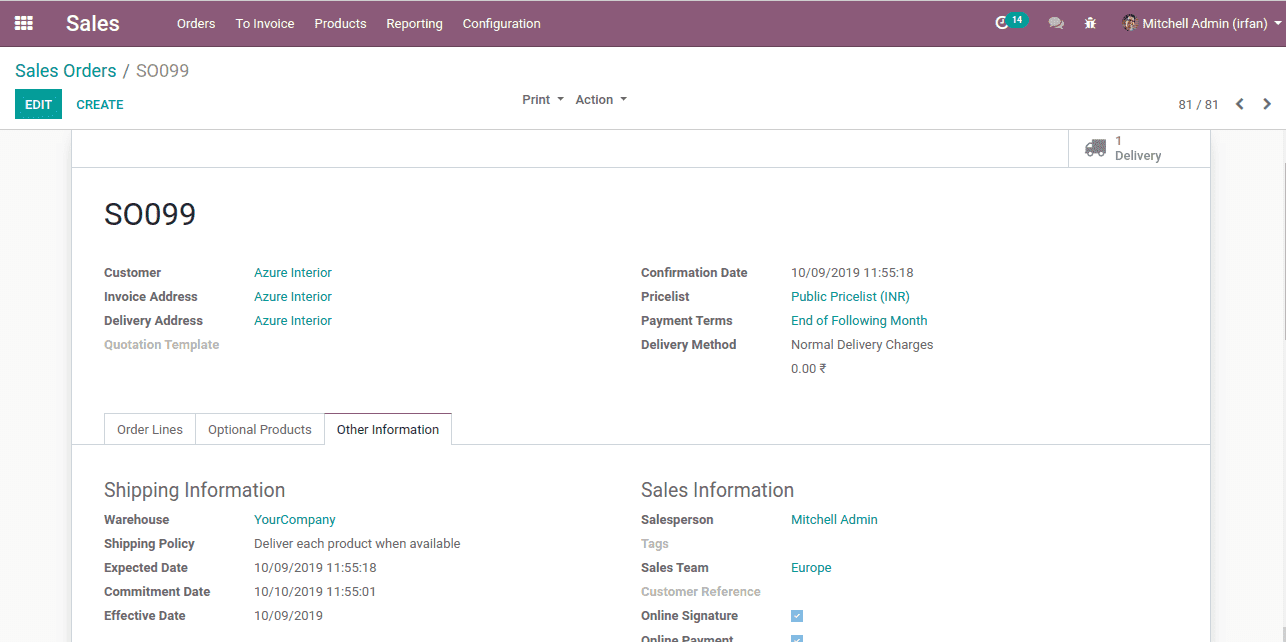

When we give a committed date in the sale order, here security lead time is 2 then the scheduled date will be two days before the committed date.

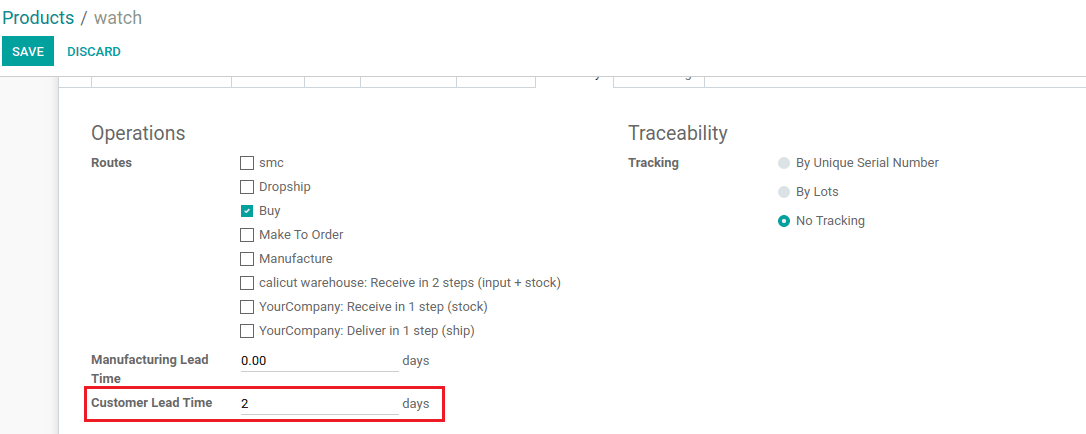

Customer lead time: go to products > inventory tab, here set customer lead time

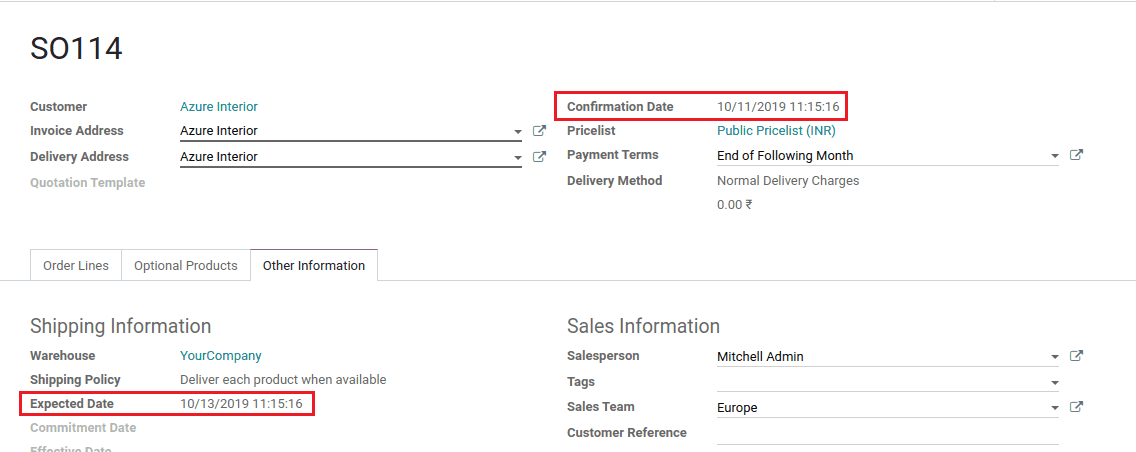

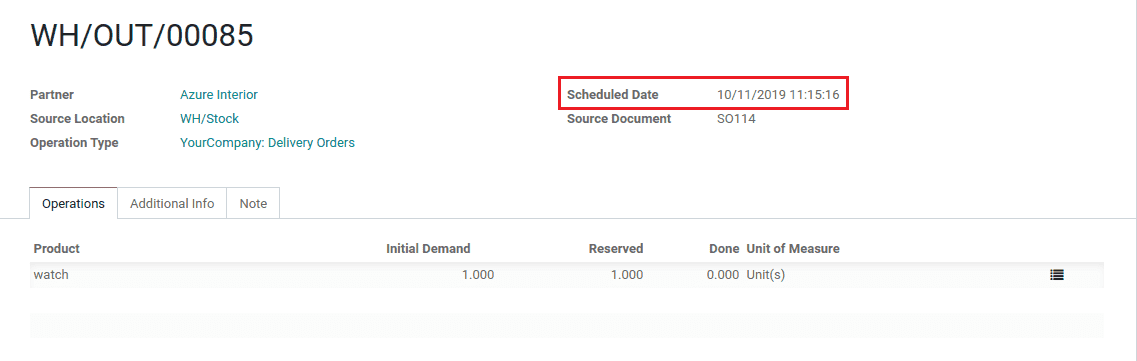

While making a sale order, here customer lead time is 2 so the expected date will be two days extra of confirmation date and the scheduled date will be the same as discussed above.

While selling two products with different customer lead time, for example, one product with customer lead time( it is created above and the other I will be shown below), when you make a sale order for those products, there comes two shipping policies.

1. Deliver each product when available.

2. Deliver all products at once.

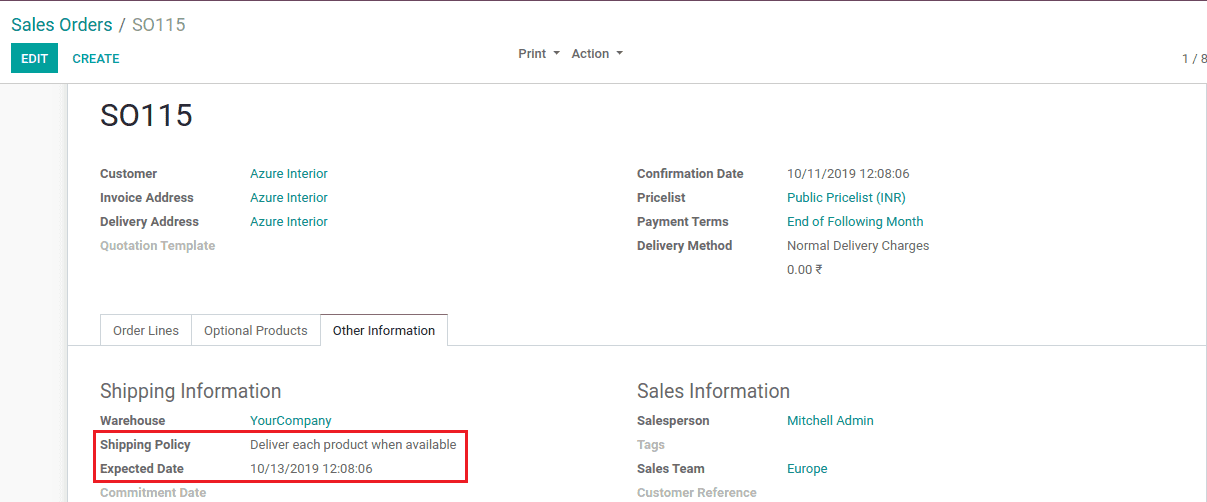

In the 1st case, according to customer lead time for each product, the expected date will be changed.

that is shown below:

Here expected date will take a minimum date compared with those two product lead times. In these cases for watch lead time, it is 2 and for water bottle lead time it is 5. So the expected date will be according to the watch.

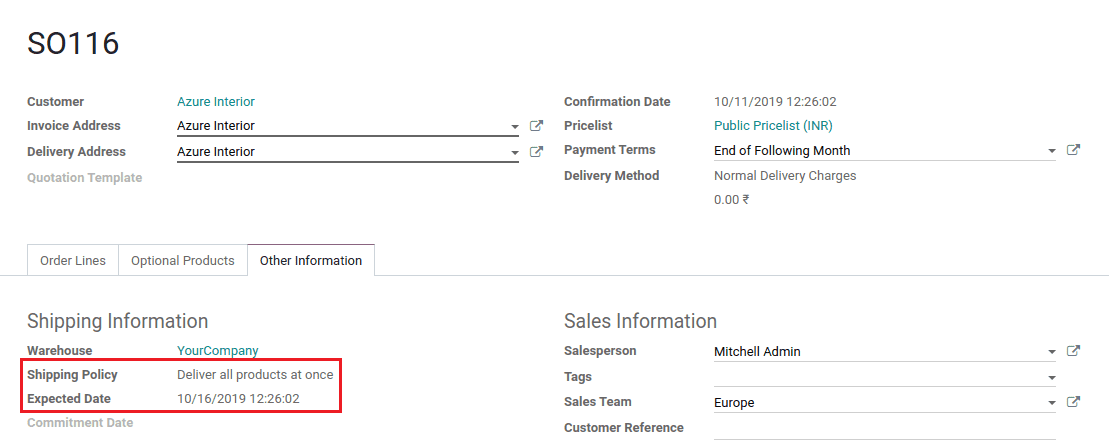

In the 2nd case, the expected date will be the maximum date compared with the product lead time.

Here the water bottle lead time is more, so the expected date is taken 5 days extra.

Manufacturing Lead Time:

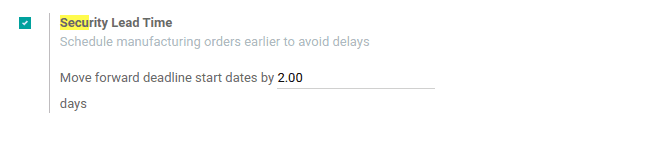

To configure security lead time, go to settings > security Lead time for sales, & set the lead time.

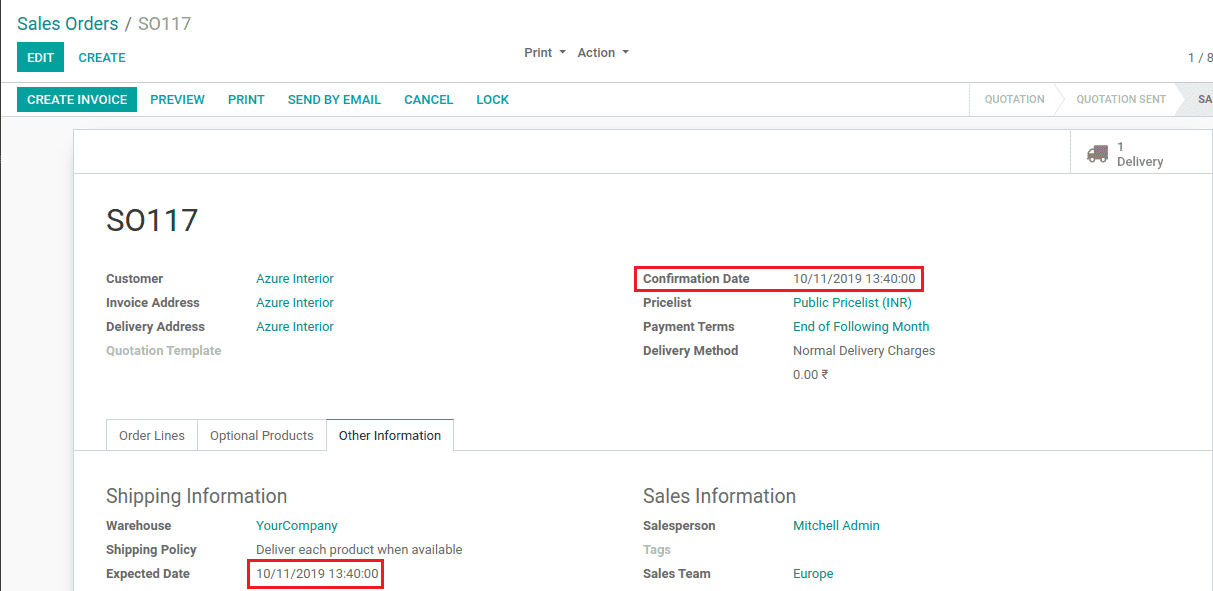

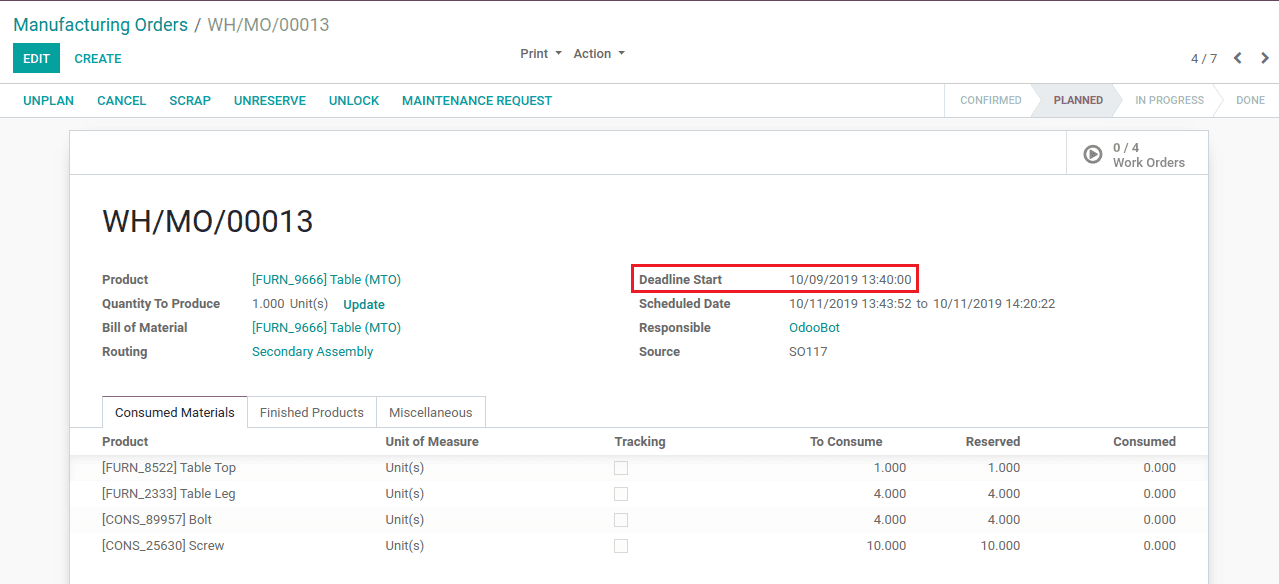

While making a sale order for the product to manufacture there will be a change in the deadline start in manufacture order.

Here there is no change in expected date and conformation date, the security lead time is 2 so the deadline start will be two days before the expected date.

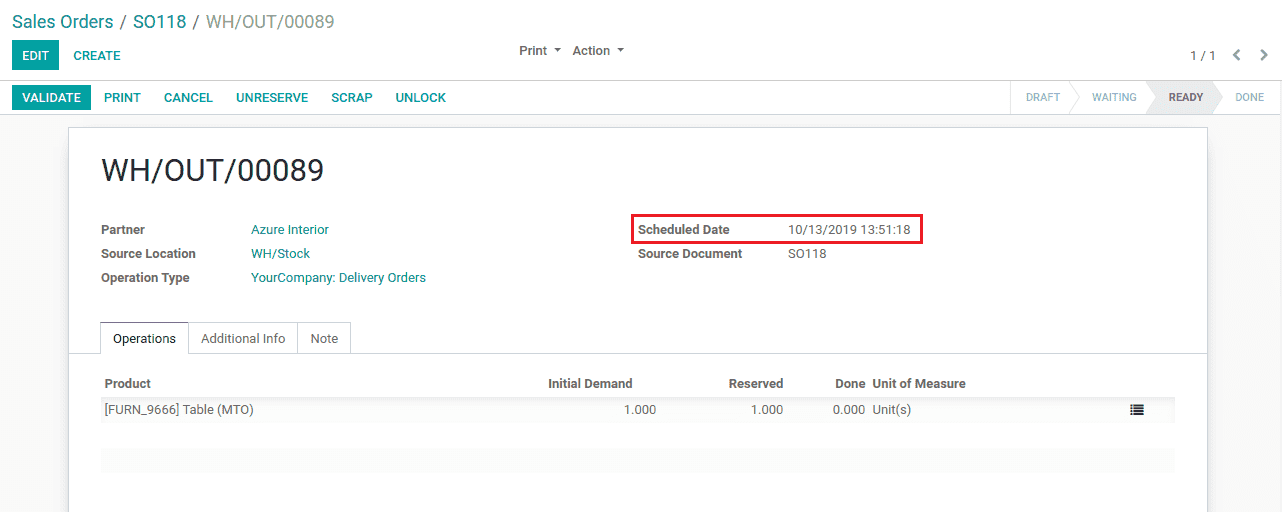

After finishing the manufacturing order, the delivery date will be changed to 2 days extra of the expected date. That is shown below:

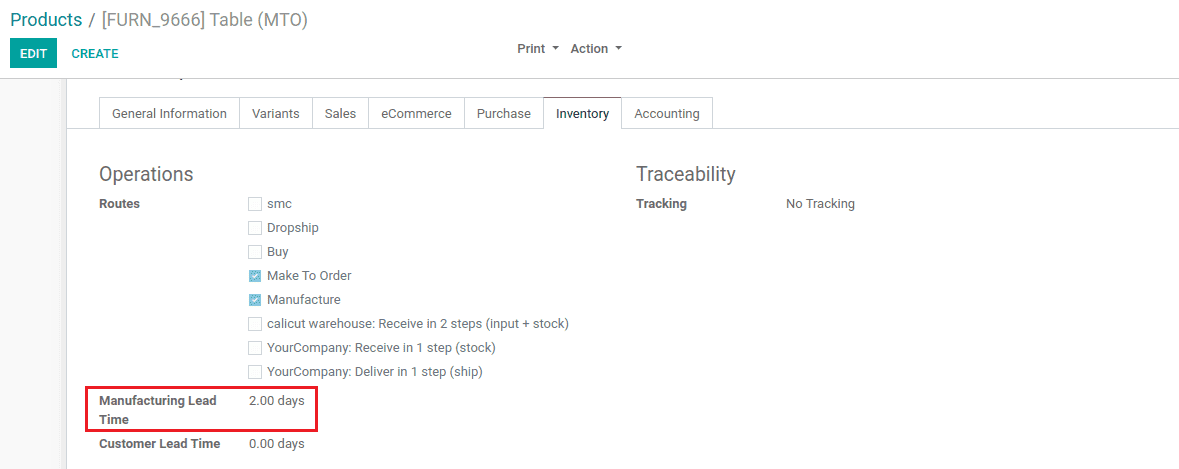

Same case for manufacture lead time. For that go to products > inventory tab, set lead time.

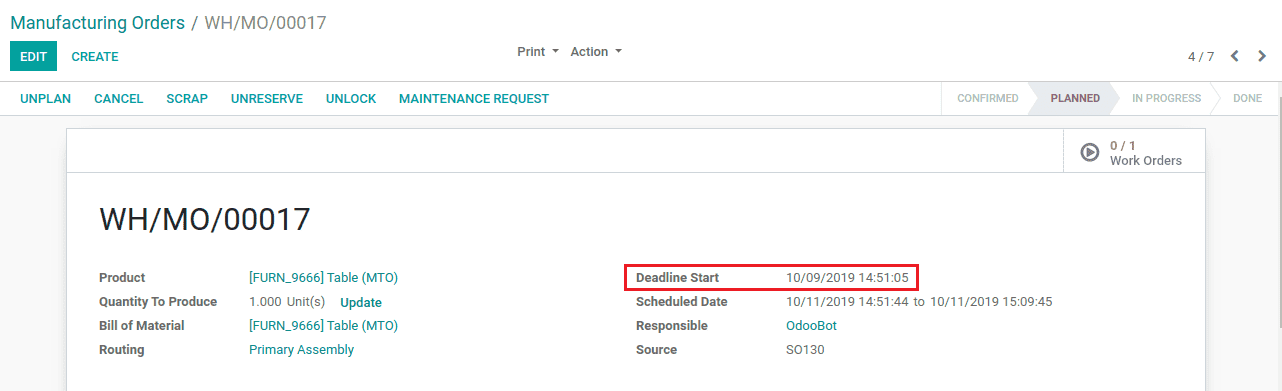

The manufacturing lead time is 2 so the deadline start will be two days before the expected date,

that is shown below:

After finishing the manufacturing order, the delivery date will be changed to 2 days extra of the expected date. Thus we can give the different lead times in odoo.

Above shown are the different ways through which we can make the lead time and how it affect sales, purchase, and manufacture.

You can also have look Lead Time in Odoo 13