A Bill of Materials (BoM) in Odoo 16 Manufacturing is an extensive inventory of the components, raw materials, and manufacturing guidelines needed to produce a product. It describes the precise steps in the production process as well as the amount of each item that is required. This bill of materials (BoM) offers a clear process for producing final goods, which guarantees effective inventory management and production scheduling.

Three primary Bills of Materials (BoMs) are available in Odoo 16 Manufacturing: Manufacturing BoM, Kit BoM, and Subcontracting BoM.A Manufacturing Bill of Materials (BoM) is used for products that will be produced internally. It includes a list of all the components and their quantities. Items that are marketed as kits but not constructed are categorized as kit BoMs, whereas items that are assembled entirely or partially by an outside subcontractor are classified as subcontracting BoMs. So let's discuss the Bill of Material Type Kit.

Manufacturing kits are viewed as packages that provide a variety of materials, tools, etc to assist effective manufacturing. This aids several sectors by lowering the difficulty of assembly, improving business productivity, and simplifying operations. A Kit Bill of Materials (BoM) is used by Odoo 16 Manufacturing for products that are offered for sale in bundles but are not put together physically into a single item. This kind of bill of materials describes a set of separate parts that are packaged and sent as a set. It is perfect for companies that sell product bundles since it lets them sell several things together in one package without having to pre-assemble them. The system selects the required parts from stock and assembles them for shipment when a sales order for a kit is processed. This approach expedites the sales process for packaged items and improves inventory efficiency. So in simple terms, in Odoo 16 manufacturing, a kit is a concept that combines several goods into one but is still thought of as a single product. This concept streamlines the manufacturing process.

Check out how Odoo16 handles kit development and management.

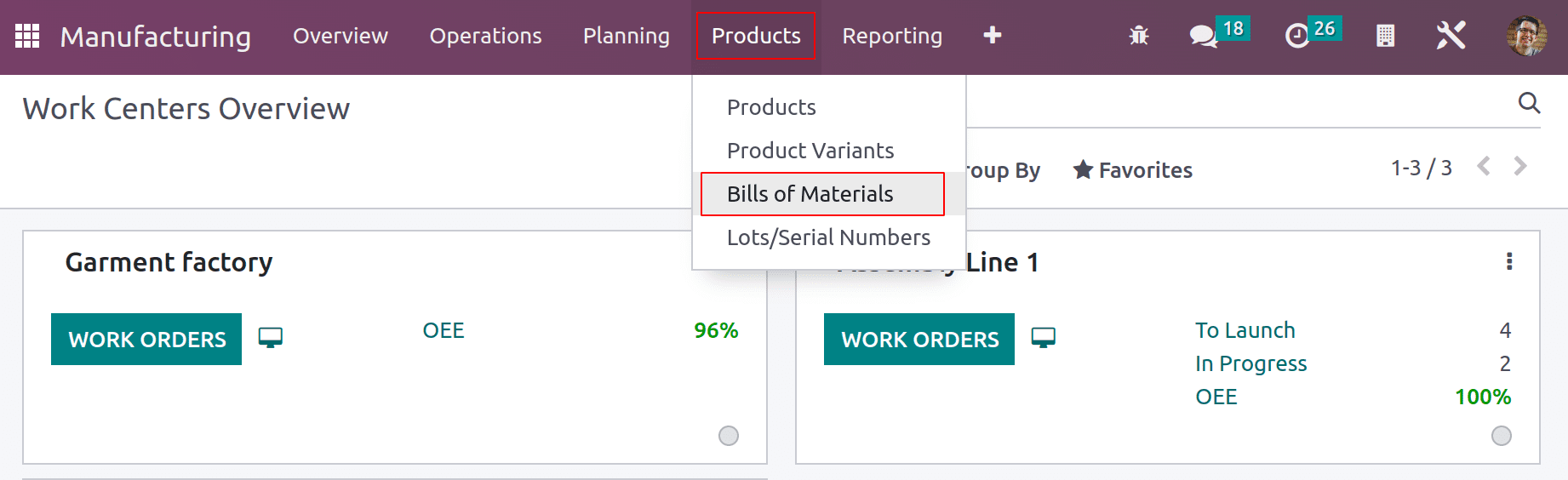

Before making a new kit, the user must produce a new bill of material. To do this, select Bill of Material from the product tab.

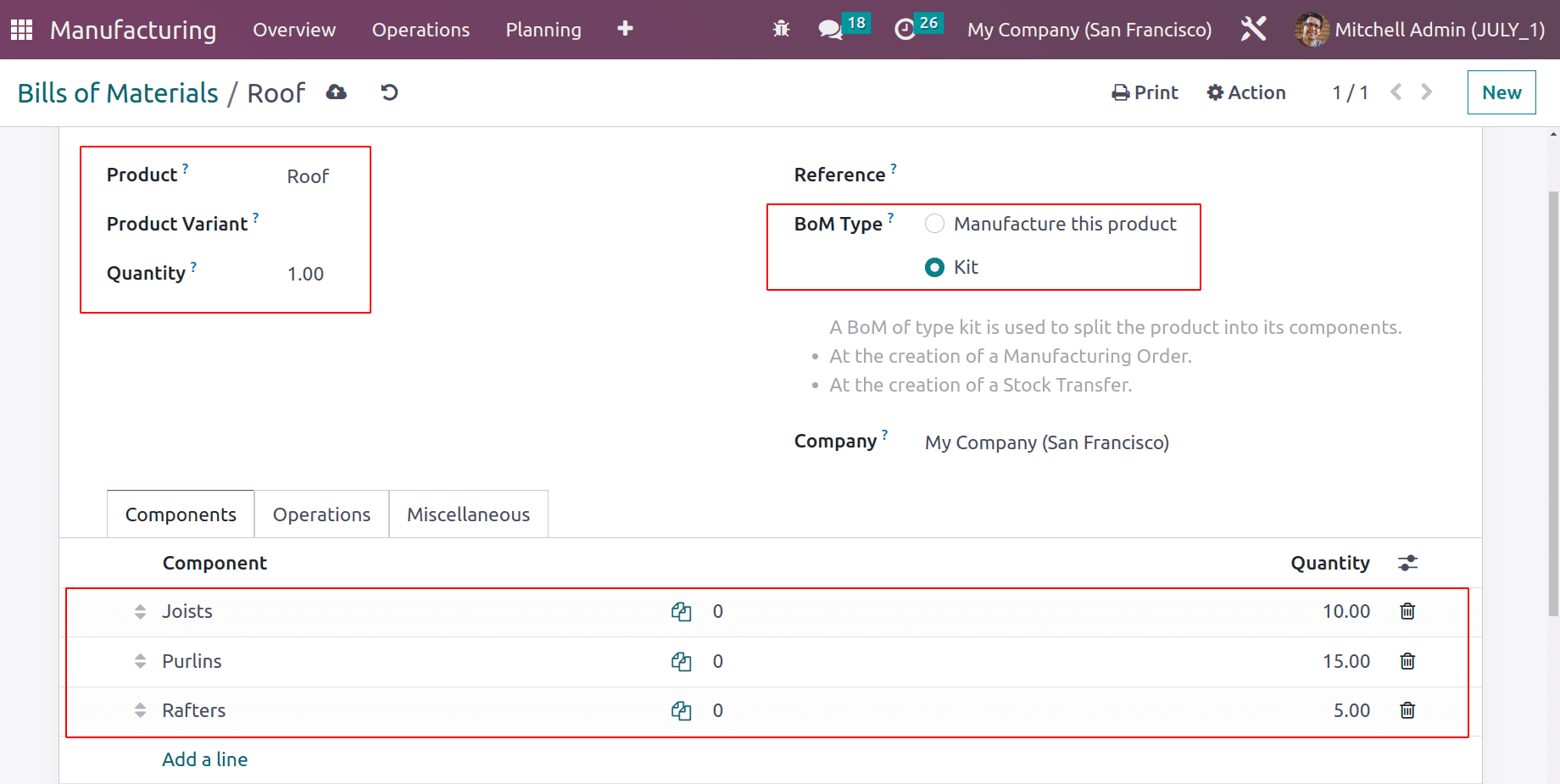

Select the item from the product list. Components are products that are combined to create the final product. Rafters, Joists, and Purlins are combined to form the Roof in this instance. Here, the product Roof is a storable product and all the components are set as consumable products.

Select Kit as the BoM Type. Hence, save the Kit Bill of Materials.

When a customer needs a Roof, he receives a kit that includes every part needed to make a Roof. Customers can create the product Roof by combining all these parts.

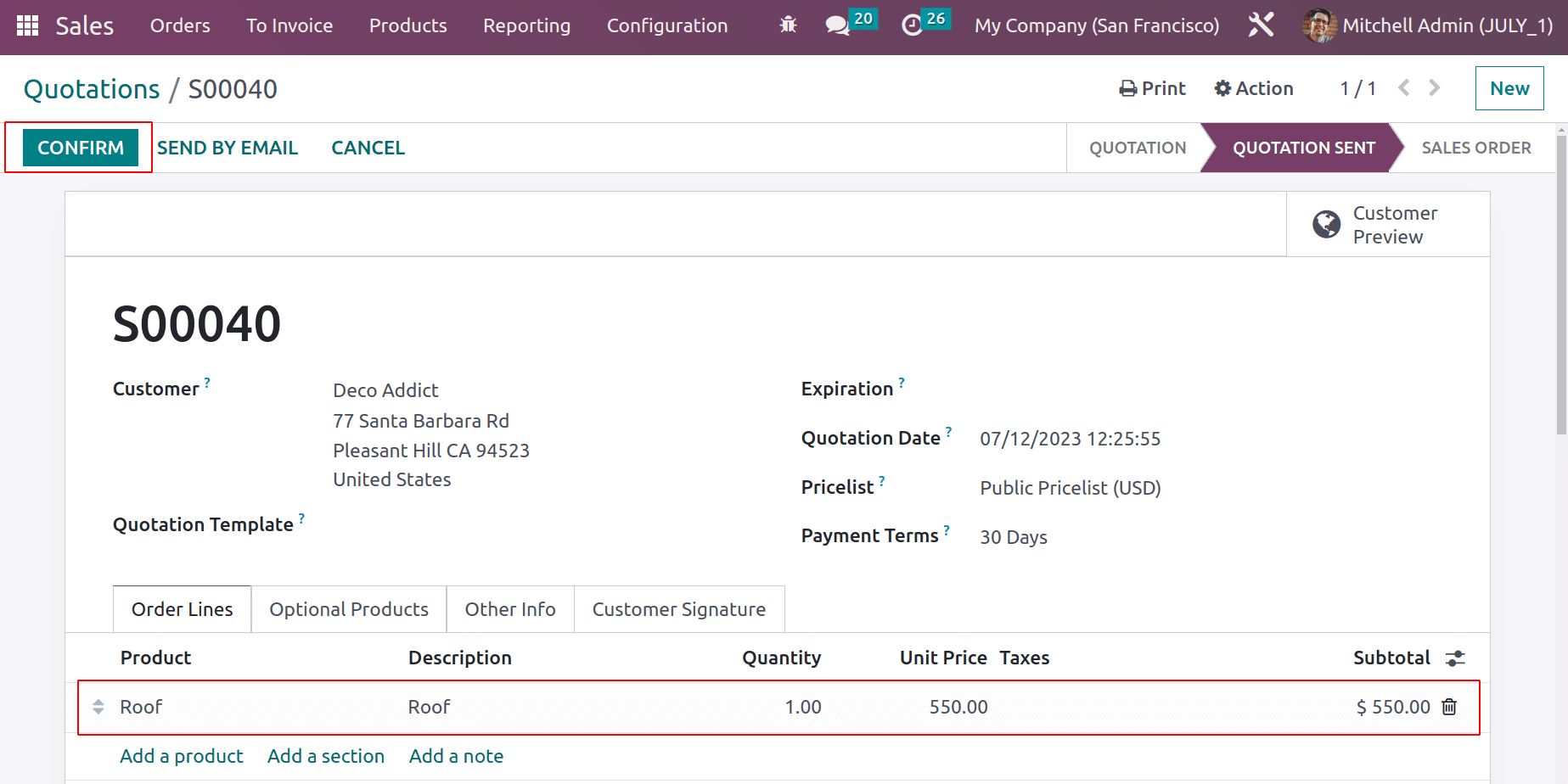

Let's use the sales module to create a sales proposal for the item Roof. merely because the goods are being sold by the user here. The Sales module can be used to accomplish that. Navigate to the Orders option in the sales module. Users can select the Quotation with ease from that point on. A list of previously made quotations will appear while selecting the quotes; click the New button to create a new quotation.

Users must include the customer's name, the quotation expiration date, the price list, and the terms of payment when making a new quotation. Next, include the product's quantity and price inside the Orderlines. Deco Addict, the client in this instance, selected 1 quantity of the product Roof. Verify the sales proposal by clicking on the Confirm button.

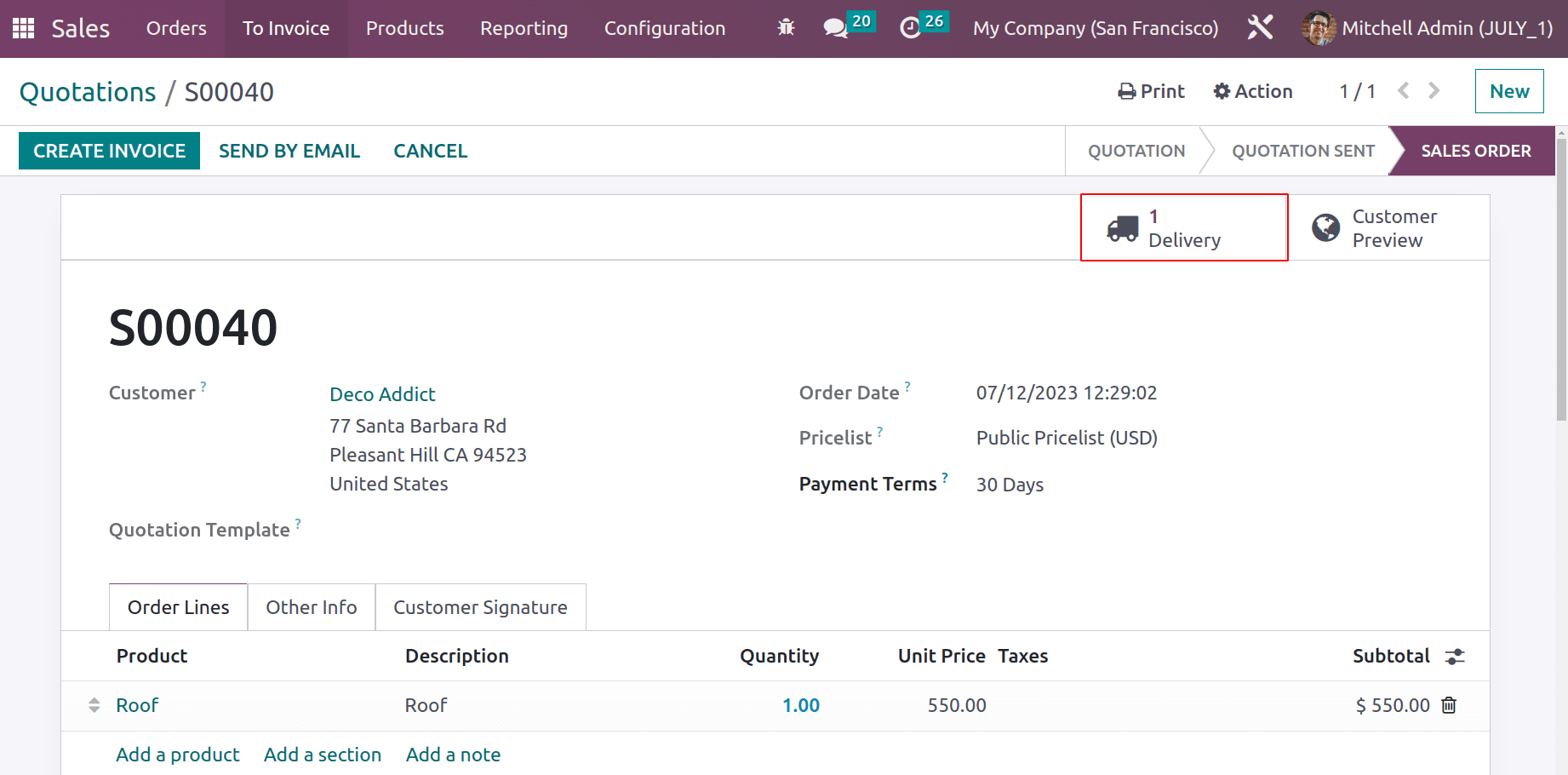

Following confirmation, the quotation becomes a sales order, and then the user can move to deliver the required product. For that, a smart tab named Delivery is added.

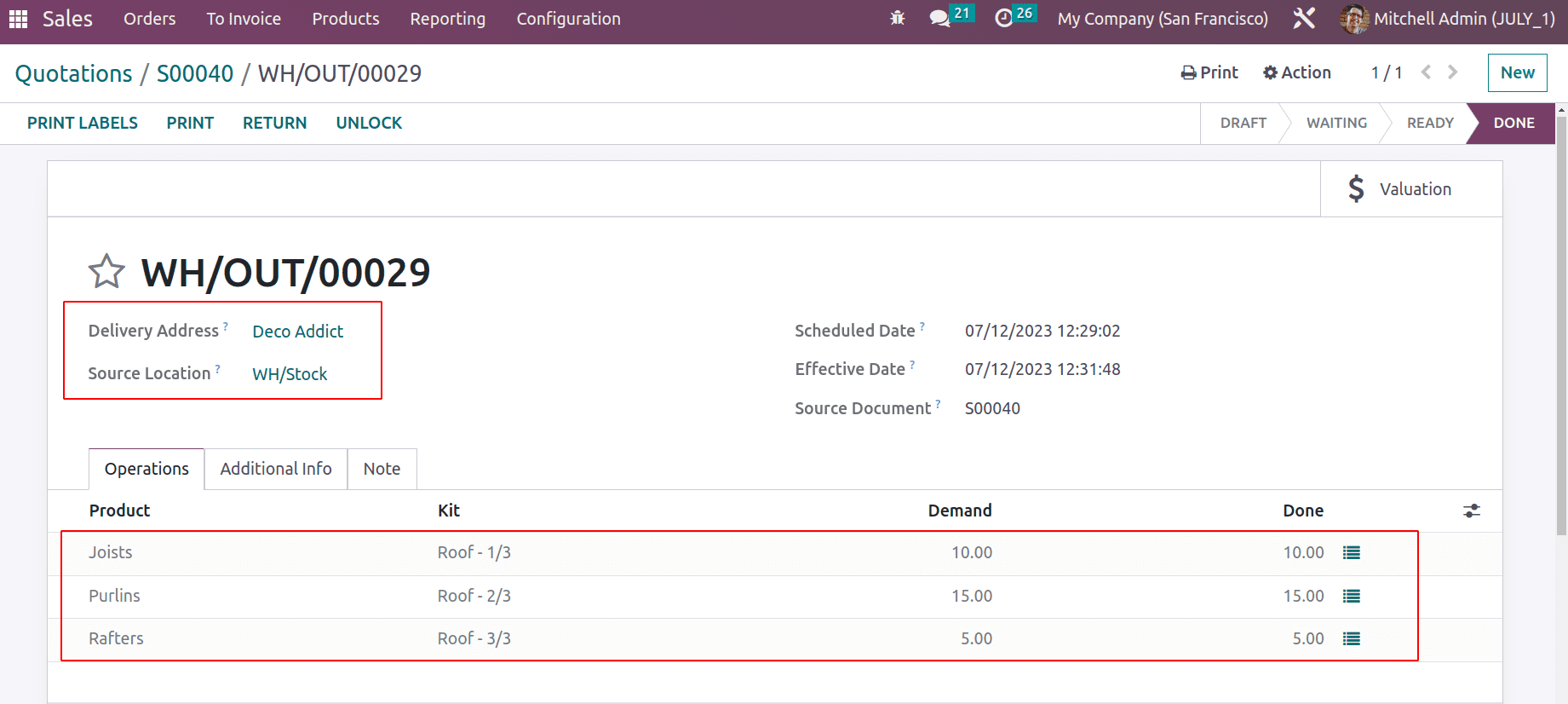

Open the smart tab Delivery. Here inside the slender, our client requested the product Roof. But while checking the Operation tab of the Delivery, instead of the product Roof the three components added inside the Bill of Material are included in the delivery along with the specified quantity. Which means here the products Joints, Purlins, and Rafters are reserved for delivery. To complete the delivery, users need to validate it. So click on the Validate button to deliver the kit from company stock to the customer's location.

Instead of the desired good Roof, the three components, Joints, Purlins and Rafters are sent to the customer's location when the delivery is validated.

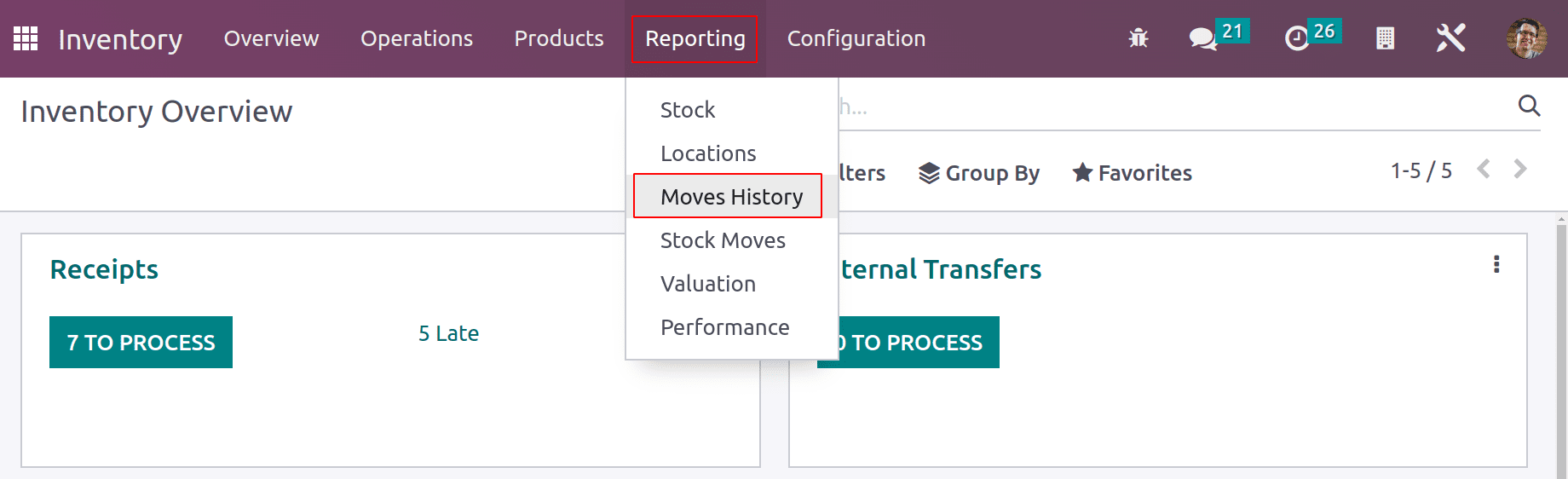

Let's check how these products are moved from the stock. This can be viewed from the inventory module. So to check the stock details of the product open the Inventory module. Go to the Reporting tab and select Moves History to view the stock movement.

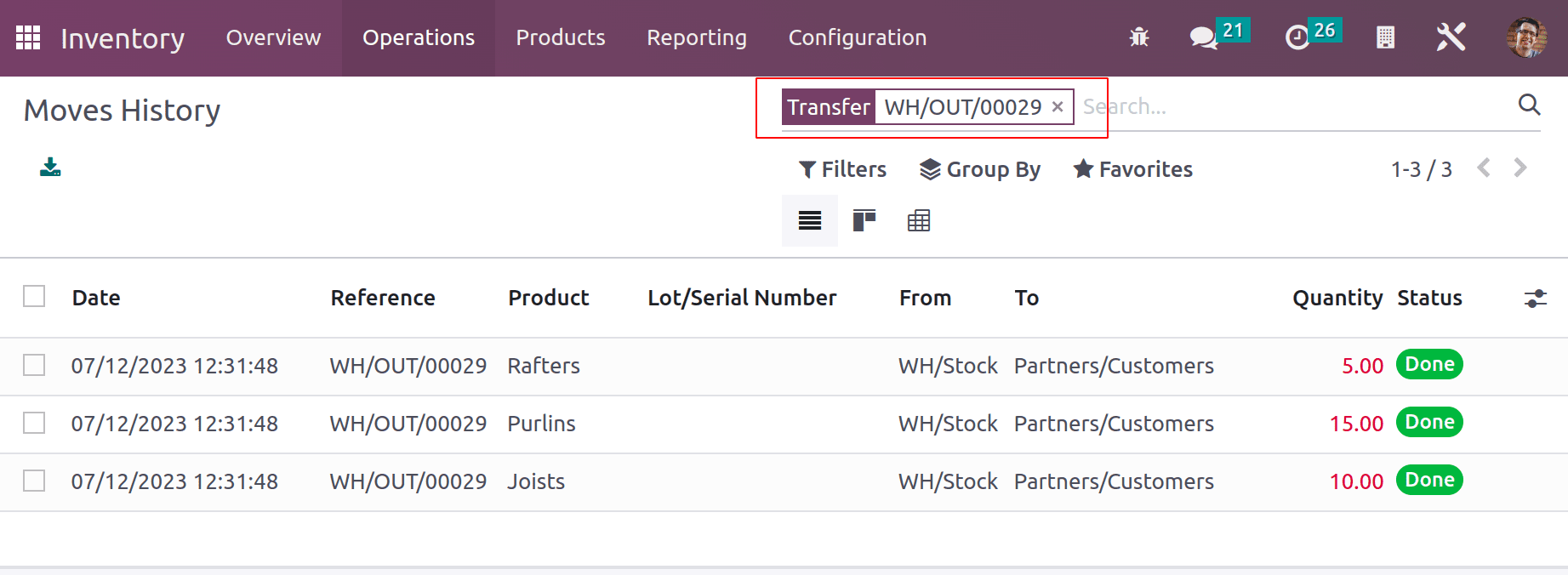

A lot of previous transaction details are shown together there. So to simplify the checking process, users can use the search option. Paste the sequence number of the last transaction inside the Search bar and make a search for the same transfer. Only the components are moved from there, not the finished product.

It is quite challenging to move the finished product in such vast companies, possibly due to the size of the product. In some instances, a product must be created by mixing several parts. The Manufacturing kit option can be used in these circumstances. For connecting extra components, a kit is quite helpful and is utilized in numerous industries, including the manufacture of automobiles and roofing, etc.

In conclusion, the functionality of Kit in Odoo manufacturing offers a practical way to manage several components simultaneously and makes it easier to put those components together.