Modern-day manufacturing requires us to develop an efficient maintenance system. The maintenance has to be managed effectively and delivered satisfactorily. For any manufacturing enterprise in the current industrial phase, maintenance is inevitable to remain in the game. The adoption of new technologies for better maintenance has successfully reduced maintenance cost. A well-planned and proper maintenance scheduling can cut down the downtime to almost nil. This can be highly beneficial for companies not only to improve client satisfaction but also to reduce the maintenance expenses of the company.

Downtime and expenses rise with lofty maintenance and for highly functional manufacturing units, machine failure can cause huge losses. Most manufacturing companies have alternative work centers and back-ups for the time of unexpected machine failures. But this does not provide the long-term solution and can only be reserved as the support system while the other is under maintenance. Though inevitable, the maintenance cost has always been heavy on the pockets. And if one goes lazy on the maintenance, the end result can cause more than money.

Combining various maintenance types in manufacturing, a manufacturing company can create commendable changes in their expense tab. Manufacturing automation has revolutionized the industry to be a highly efficient system. Integrating a technology-dependent maintenance system would make the process of maintaining a highly effective system that does not weigh too heavily on the expenses of the company similar to manufacturing.

The classic form of machine maintenance has been reactive maintenance or corrective maintenance. It simply reacts to any kind of machine failure or malfunctioning. The restoration process of malfunctioning machinery involves not-so-complex planning. It merely involves the rectification of the problem at hand through quick and immediate response. But this kind of maintenance would cost more to the company as the shortage in production would be more impactful. The contingency of the repair can affect the work centers. This would require reallocation of work and orders as required, which would increase the load on other centers.

We can reduce the probability of machine failures through preventive maintenance. Preventive maintenance is a calendar or time-based maintenance system. The regular interval or the time is determined by the manufacturer especially for machines used on a regular basis with foreseeable wear and tear. This involves a lot of planning and assessment of machine history and pattern to schedule the maintenance before the equipment gives up. We can plan the downtime and schedule and manage orders beforehand, causing very little downtime. We can tackle the shortage in production almost to null through effective planning of preventive maintenance.

An effective maintenance planning of equipment would ensure the benefits of

> Lower maintenance costs

> Stabilised workflow

> Reduction of unmet deadlines.

> Reducing scrap

The maintenance planning is now easier with the Odoo Maintenance module offered in the Odoo ERP software.

Odoo maintenance

The Odoo maintenance is designed as an organized automation solution to run maintenance of a company with simplicity and efficiency.

The module has both a calendar and kanban view to organize and overview the requests inconvenience. it is also optimized to facilitate better communication between the manufacturing unit and the maintenance team, reducing downtime. We can level up to the best of maintenance with timely maintenance made possible automatically computed maintenance statistics in Odoo.

Maintenance Configuration

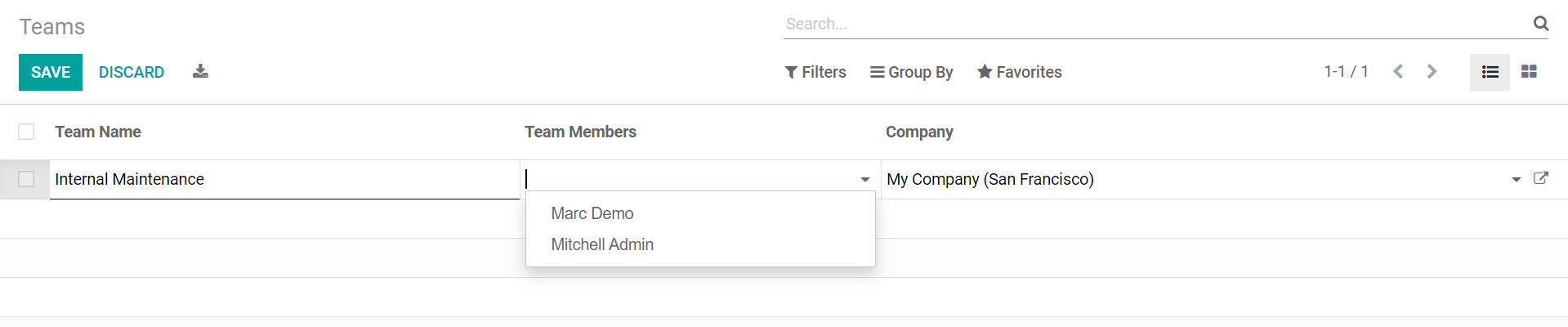

In the configuration of the maintenance module, we can create maintenance teams and configure equipment categories. From the app drop-down menus select configuration to add the teams and equipment categories.

The maintenance teams will be displayed as a list and we can modify details or create new teams.

Here, the maintenance team ‘internal maintenance’ is created and we can add the team members. In the case of multi-company operations, we can choose the company for the specific team.

After creating the team, the dashboard will display the teams and we can add maintenance requests to each team.

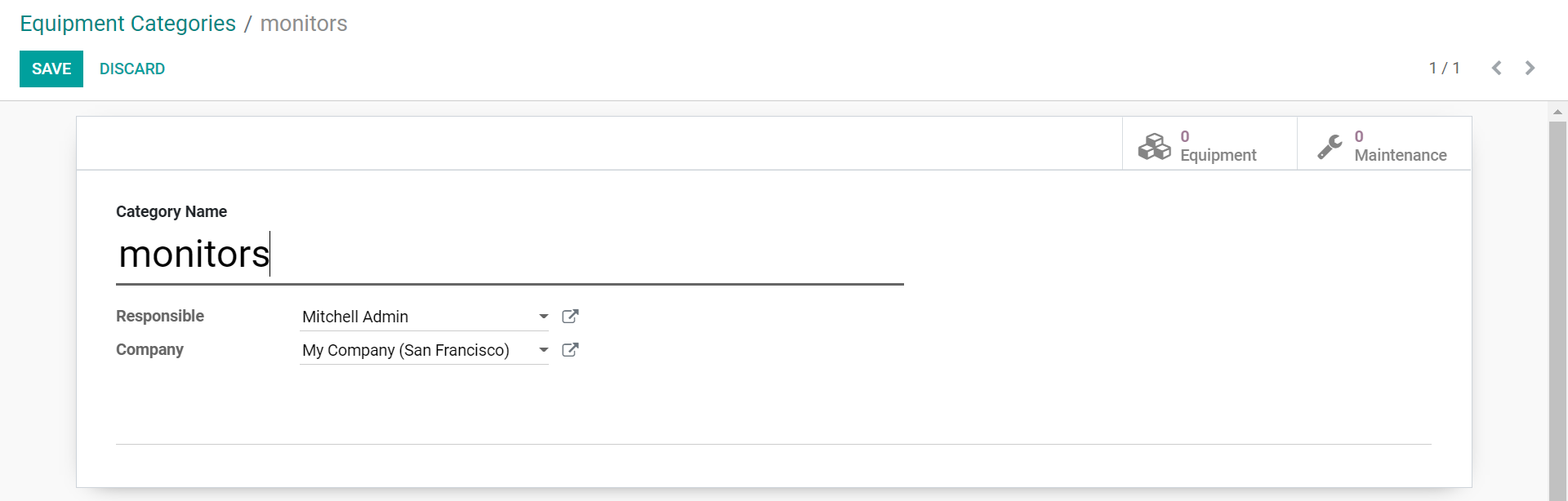

The other menu available in configuration is for the equipment category. The menu lets you create categories of the equipment and assign persons responsible for its maintenance. This would organize the details of equipment that are created under the category and their maintenance history.

Equipment in Maintenance

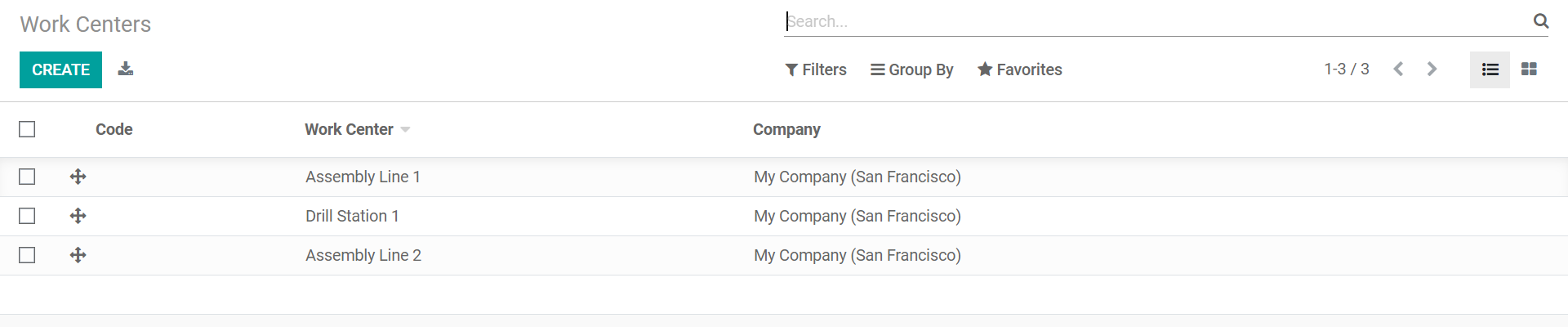

We can create both a list of work centers and machines & tools in the Odoo Maintenance module. The work centers created in the manufacturing module will automatically be imported into the maintenance module. We can create new work centers if necessary.

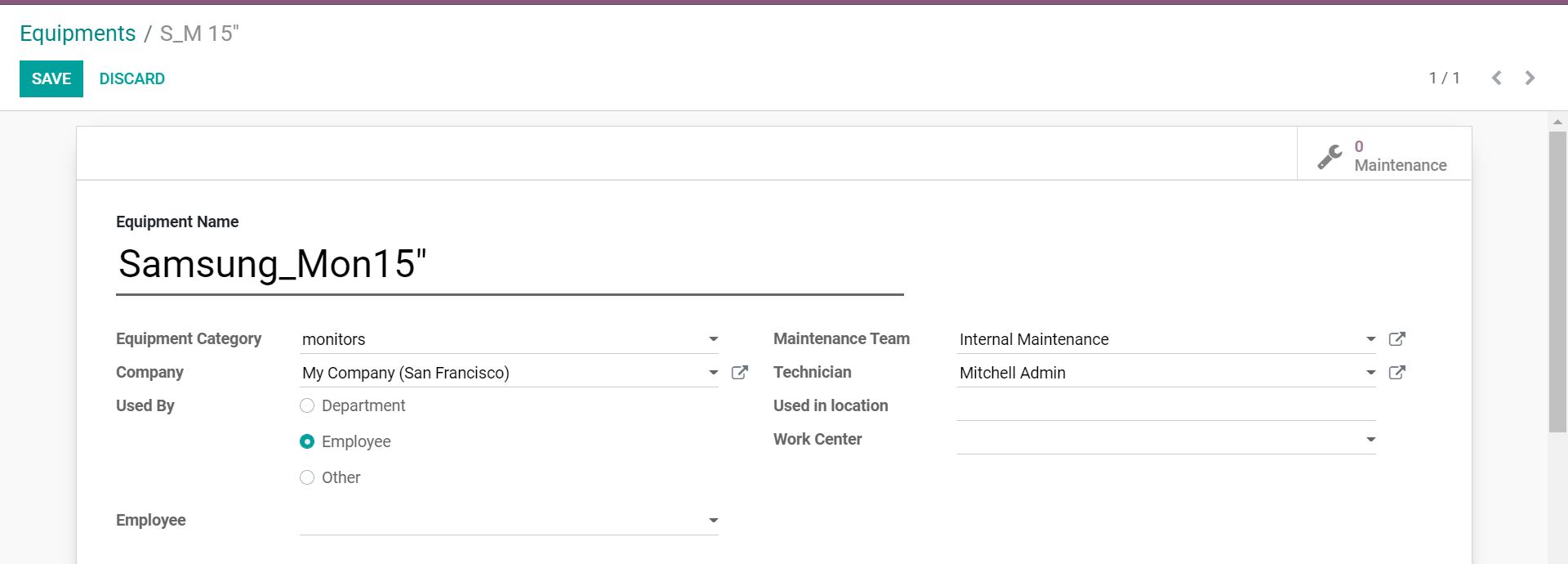

The other option lets you create the various equipment used by the departments, employees, or others. We can create new equipment and assign a category. It will automatically update the person in charge of the maintenance. We can also select a user for the equipment and fill in the corresponding details.

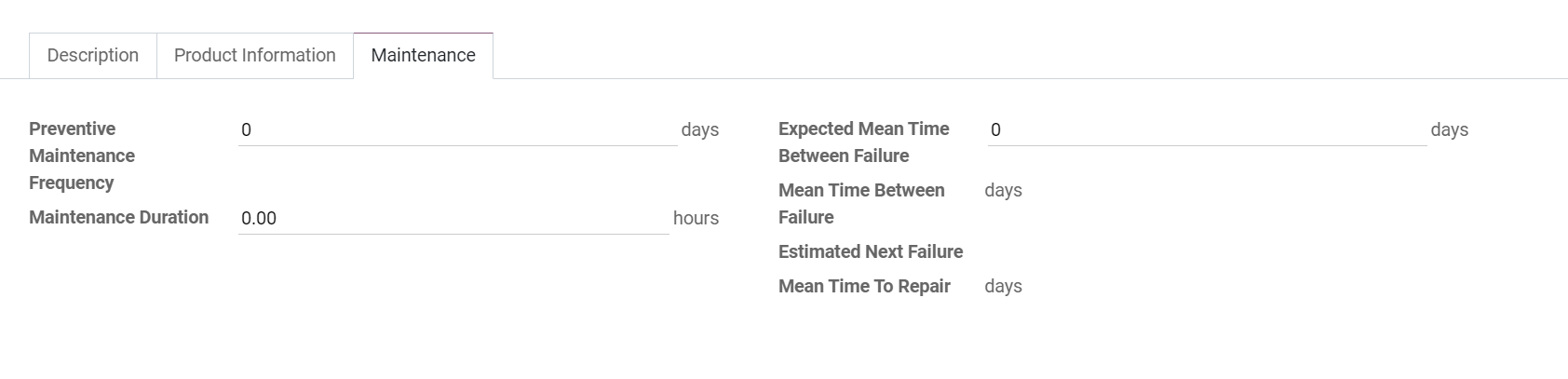

The maintenance tab of the equipment would display automated statistics like the mean time between failure (MTBF) and the meantime to repair (MTTR). The estimated next failure is also displayed in the tab.

For a more detailed overview, read equipment management in Odoo 14.

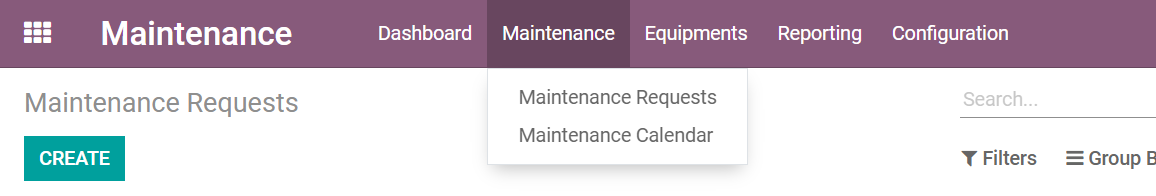

Requests and calendar

The maintenance requests created in the manufacturing module are updated in the requested dashboard.

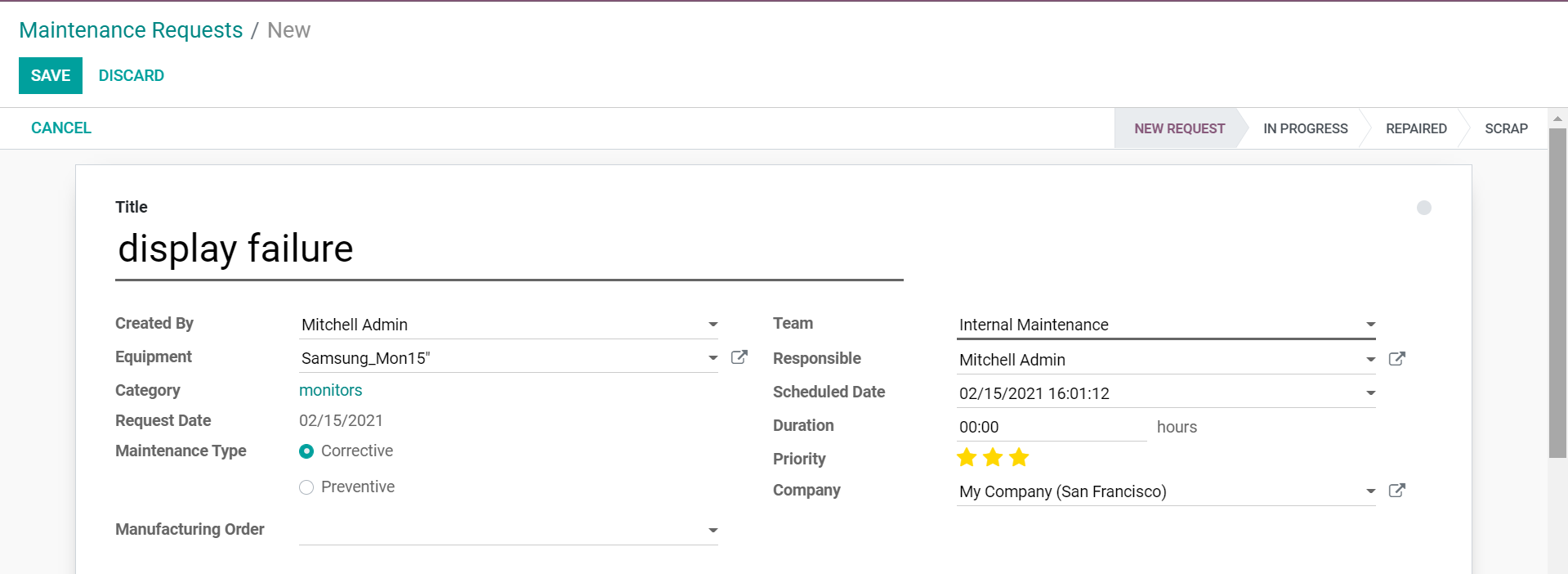

We can create new requests for maintenance in the window. We can add the equipment that has to be repaired along with the maintenance and other details that have not been configured for the equipment. We can mark the maintenance type as corrective or preventive. We also have the option to prioritize the request as deemed necessary.

Once the maintenance is done, we can either mark it as repaired or scrap the equipment.

Shifting to a calendar view would enable us to create maintenance requests for particular days. This can be helpful in scheduling preventive maintenance. It is easier to create and schedule preventive maintenance requests in Odoo as the calendar view would provide a more comprehensive view of the upcoming requests.

Reporting

The reporting would display the details of the repairs done measured by the count or color index or the duration.

The module is fully integrated with

> Odoo Manufacturing

> Odoo PLM and

> Odoo Quality

You can also know more about maintenance modules with a detailed overview and functionality of the module through the video from Cybrosys Technologies.