In Odoo we have routes for which we can give the path of a product to move in accordance. We have to specify the rules to satisfy the conditions that we want. For that, we need to configure the rules inside the route. In this blog, I am going to write about the application of rules in manufacturing. In Odoo manufacturing we can specify the rules in which the products should move on. For example, if we want to manufacture a product via multiple locations such as pre-production, post-production, quality etc, for that we need to add certain rules. Let’s see how this can be done.

If you are totally unaware of rules and routes, you can refer to our previous blog How to Use Push and Procurement Rules in Odoo.

To show you how to configure a route, here I am citing a small example.

Imagine I have four locations such as Raw Materials, Pre-production, Post-production, Quality, and Stock. I am going to create rules for which I have to take the raw materials from WH/RawMaterials (location where my raw materials are stored) and then WH/Pre-production (location for pre-production) then Manufacture the product. After manufacturing, the product will be present in the WH/Post-production. After manufacturing, I am doing a quality check for my newly manufactured product. So I am passing the product to the Quality location that is WH/Quality. When all these operations are done, finally I am going to keep the product in my Stock(WH/Stock).

How to create a rule for an odoo manufacturing order

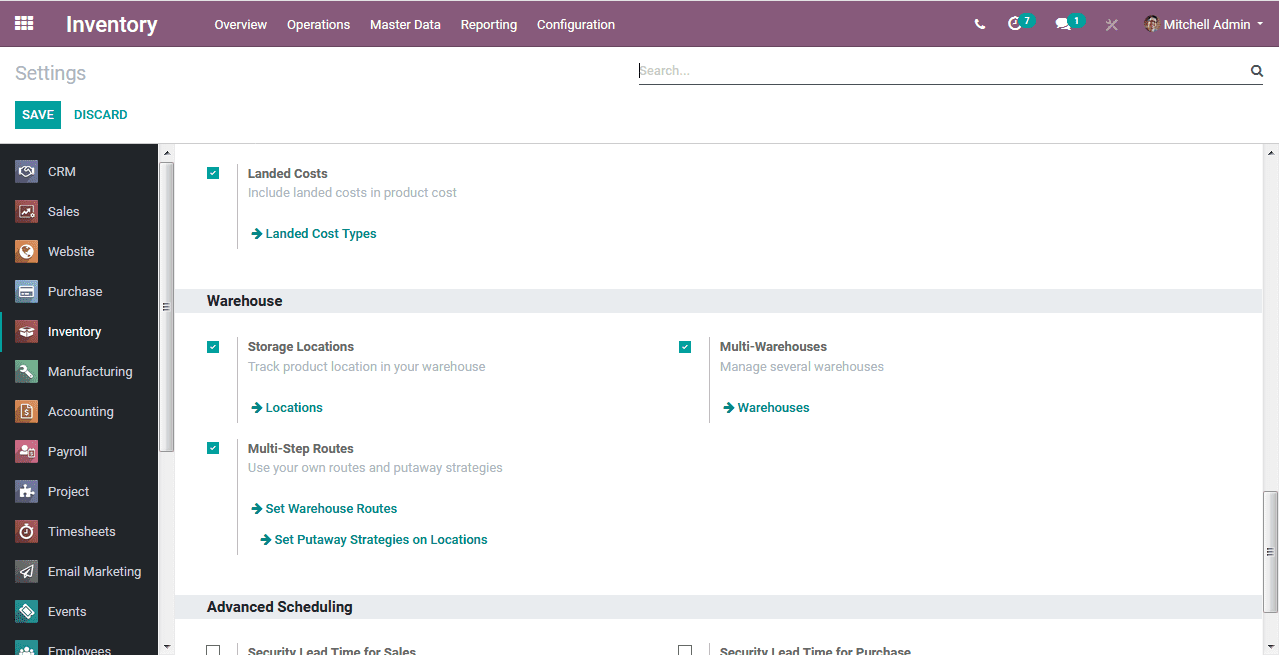

Firstly you need to activate the Multi-Step Routes.

For that Go to Inventory -> Configuration -> Settings -> Multi-Step Routes

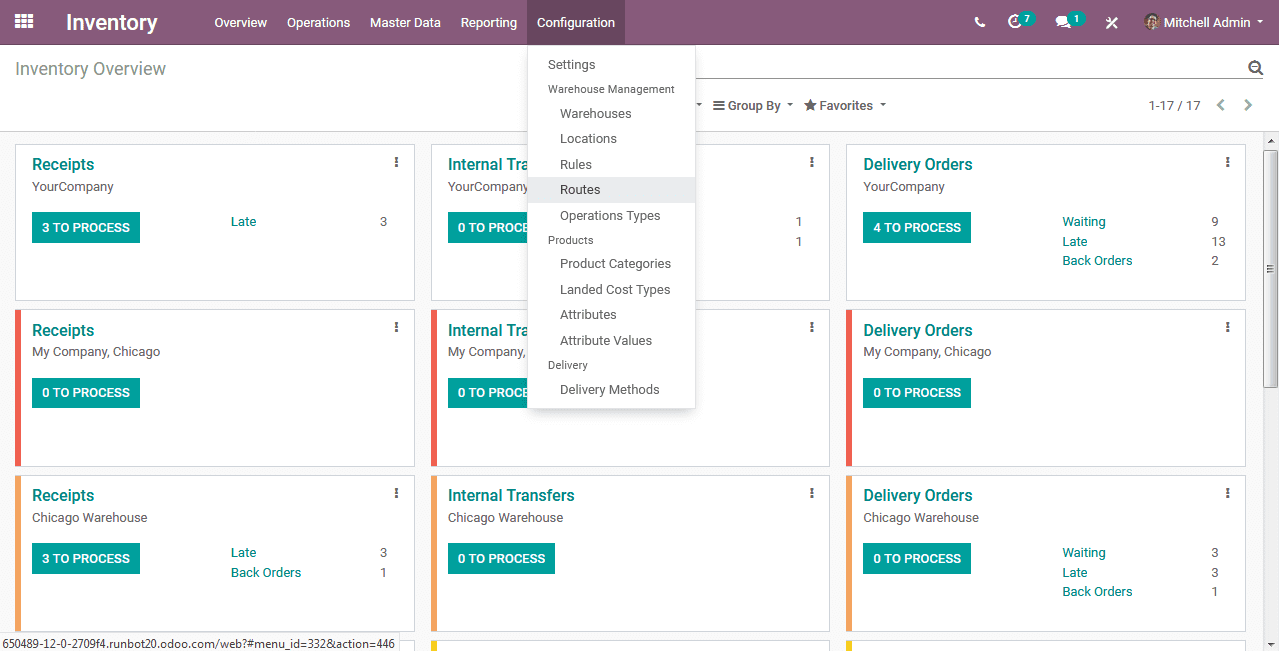

After that, you need to create a route.

For that go to Inventory -> Configuration -> Route

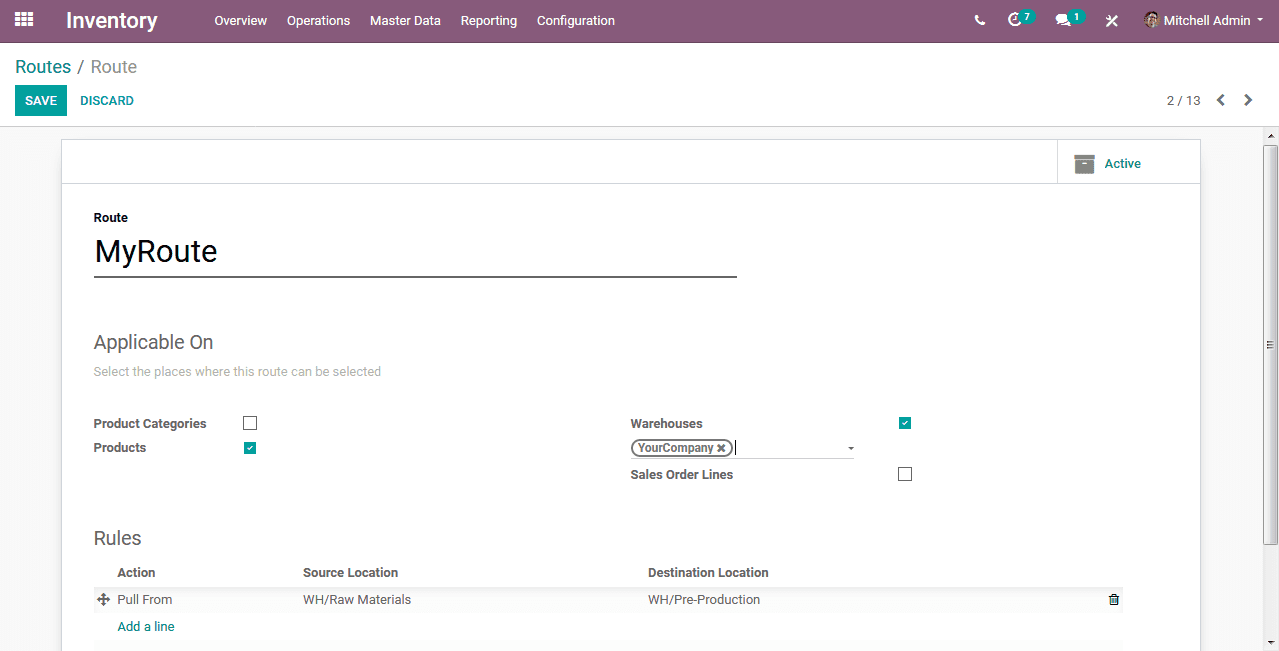

Click on create.

Give any suitable name to the route. Then we have an option called applicable on, i.e. where you want to apply this route. We have four options for it. We can apply this route on product categories, warehouses, products as well as sales order lines. You can choose as you wish. Here, I am going to choose warehouse and I gave my warehouse name so that I don’t need to go-to products or product categories and select this route.

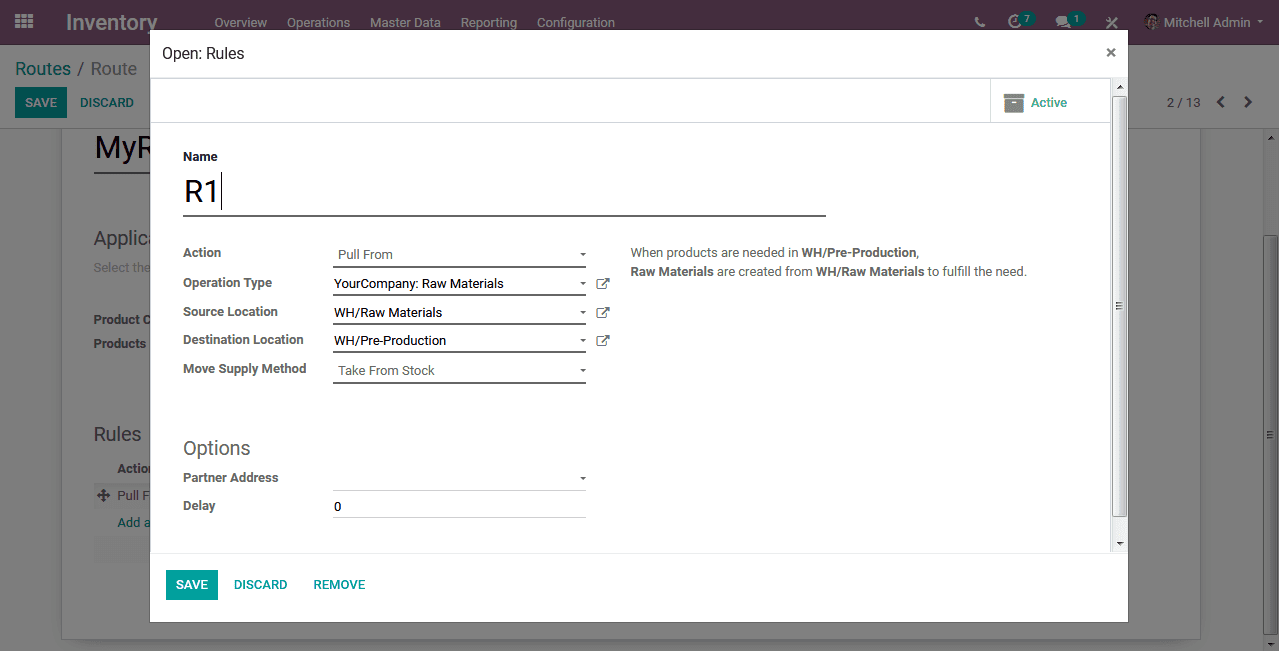

Now coming to Rules. The first step is we need to move our Raw Materials to the Preproduction Location. Since there is a need we are going to use the pull action.

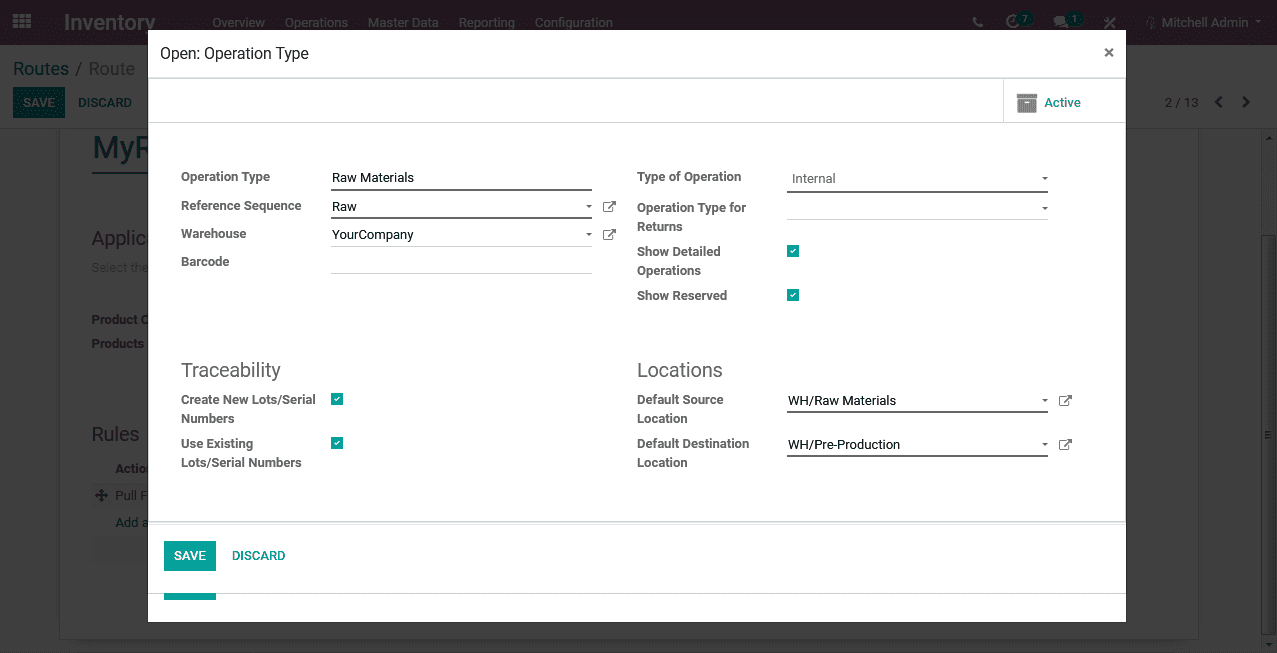

We need to give a suitable name for the rules. As I mentioned the action pulls from. Select the operation type.

Since this is the first rule we are going to select the Move supply method as Taking from Stock.

So our First Rule is done. Our Raw materials have now reached the Pre-Production Location.

Now we are Manufacturing the product.

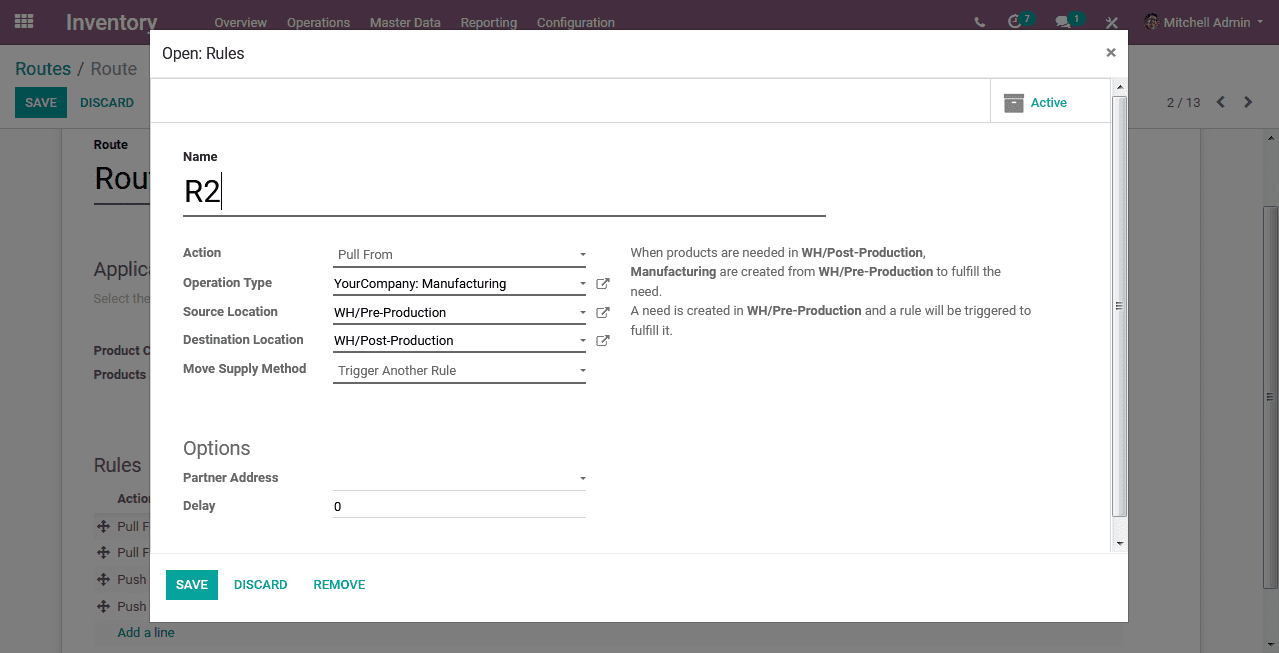

So our second Rule is

Here also we have to give a suitable name for the rule and I going to choose the action as Pull from. I selected the Operation type as YourCompany: Manufacturing and since we are depending on this rule from rule 1, I am going to give the Move Supply Method as Trigger Another Rule.

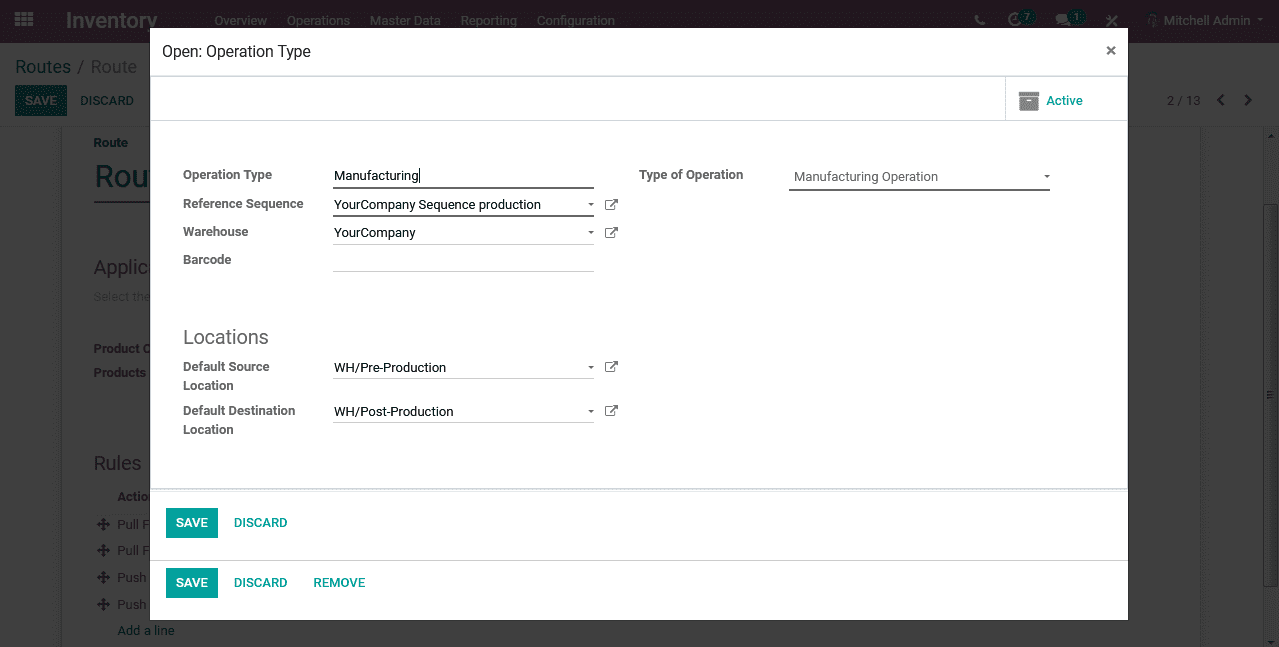

This is the operation type YourCompany: Manufacturing

Now Our Product is manufactured and right now our product is in the Post-Production Location.

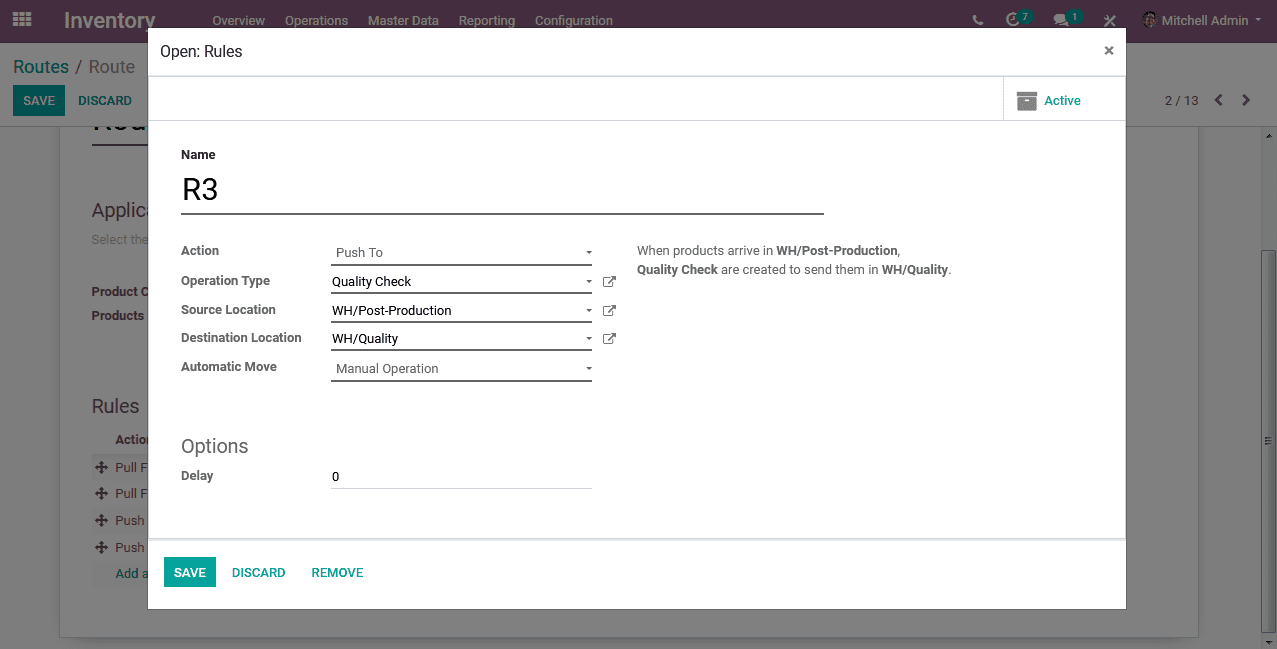

Now I need to check the quality of the product. So I am going to push this product to our Quality Location and get the quality check done. For that, I am going to add another rule. Since the product arrived in the Post-Production we just need to push it to Quality.

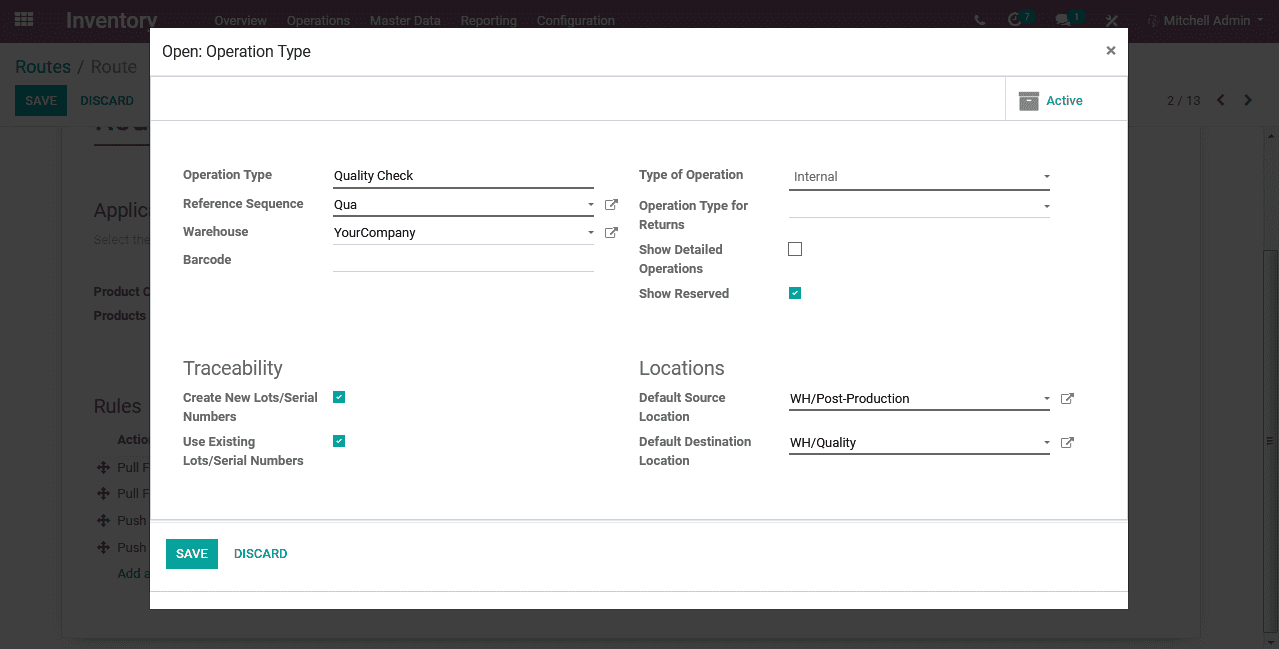

This is Rule 3. As I said we are going to push this product to location quality, I gave the action as Push to. Select the operation type.

This is the operation type Quality check.

Now our product arrived at the Quality. In Quality Location I am performing a quality check and after quality check, we can now send our main product to the Stock.

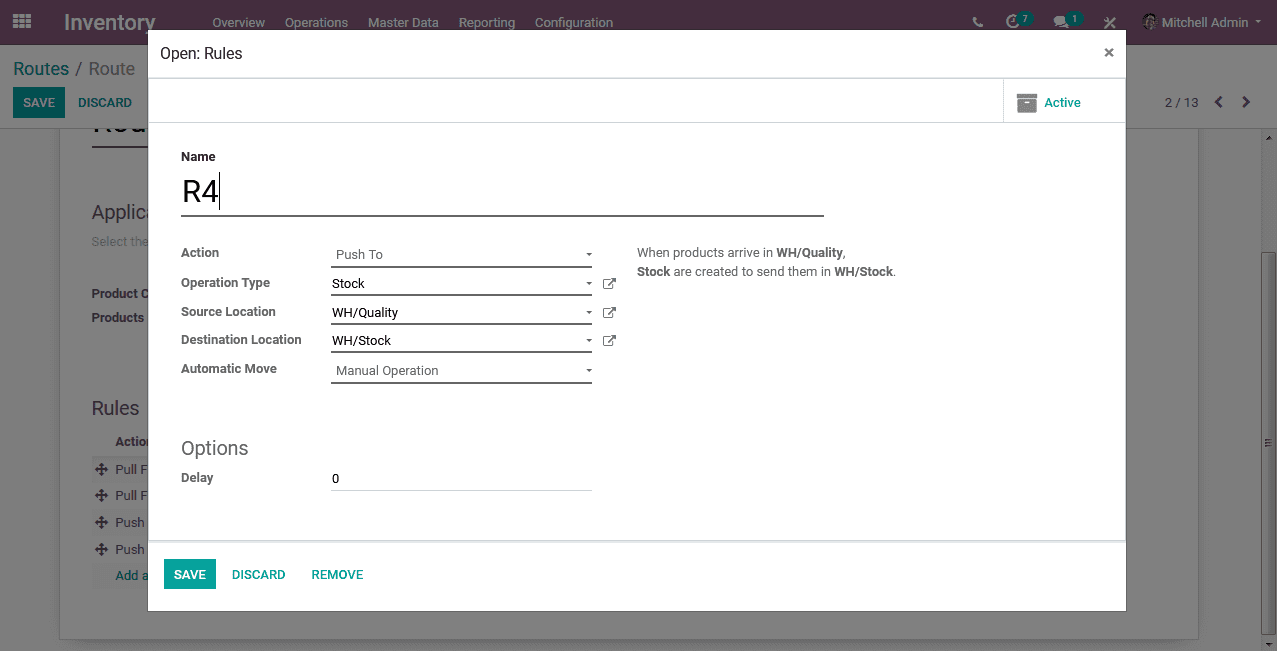

Lastly, I am going to add Rule 4. In this rule, I am pushing my product to Stock location from Quality.

So our Route is finally done.

Now I will show you how this will work.

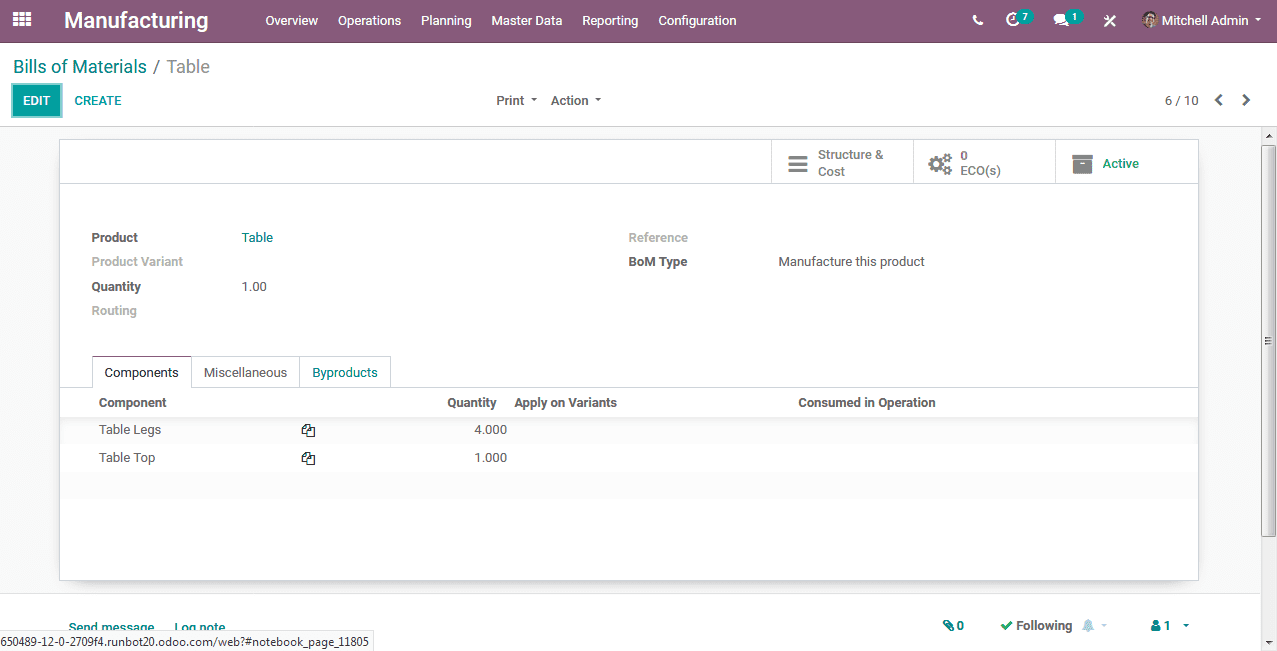

I have already created the product and Bill of Materials for the product Table. The Raw materials Table Top and Table Legs are presented in the location WH/RawMaterials.

After that, I am going to create a manufacturing order for our product Table.

Go to Manufacturing -> Operations -> Manufacturing Orders -> Create

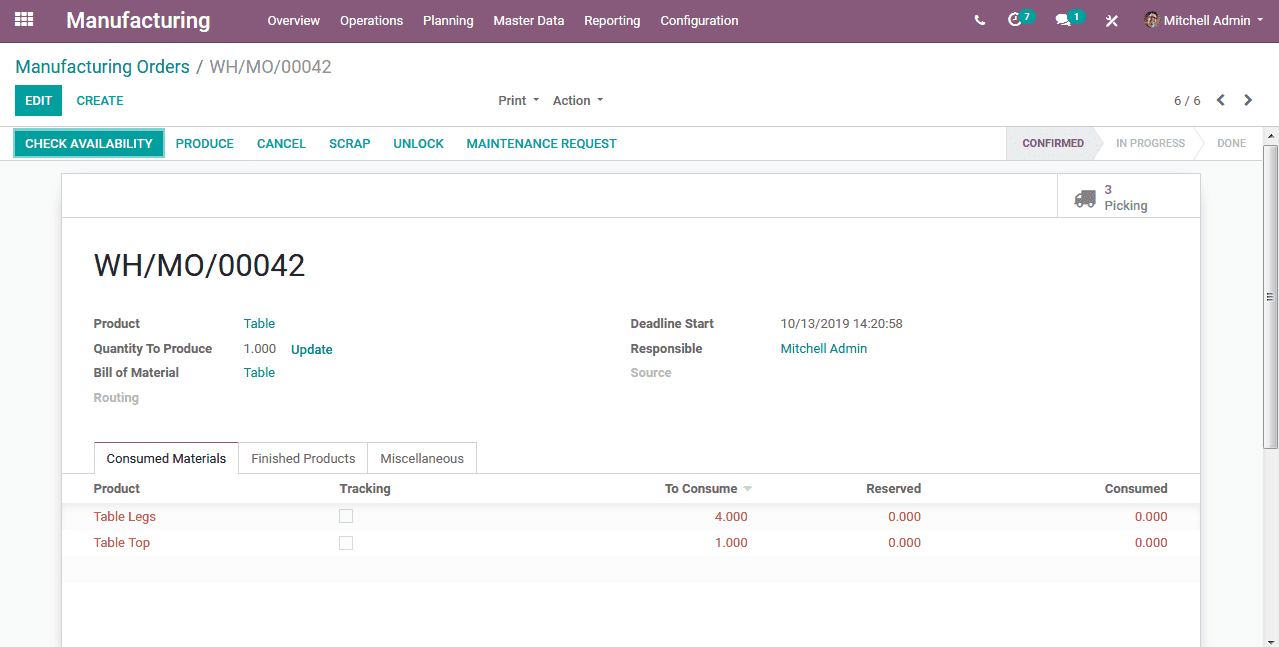

Select the product. Here my product is Table, So I selected Table and click save.

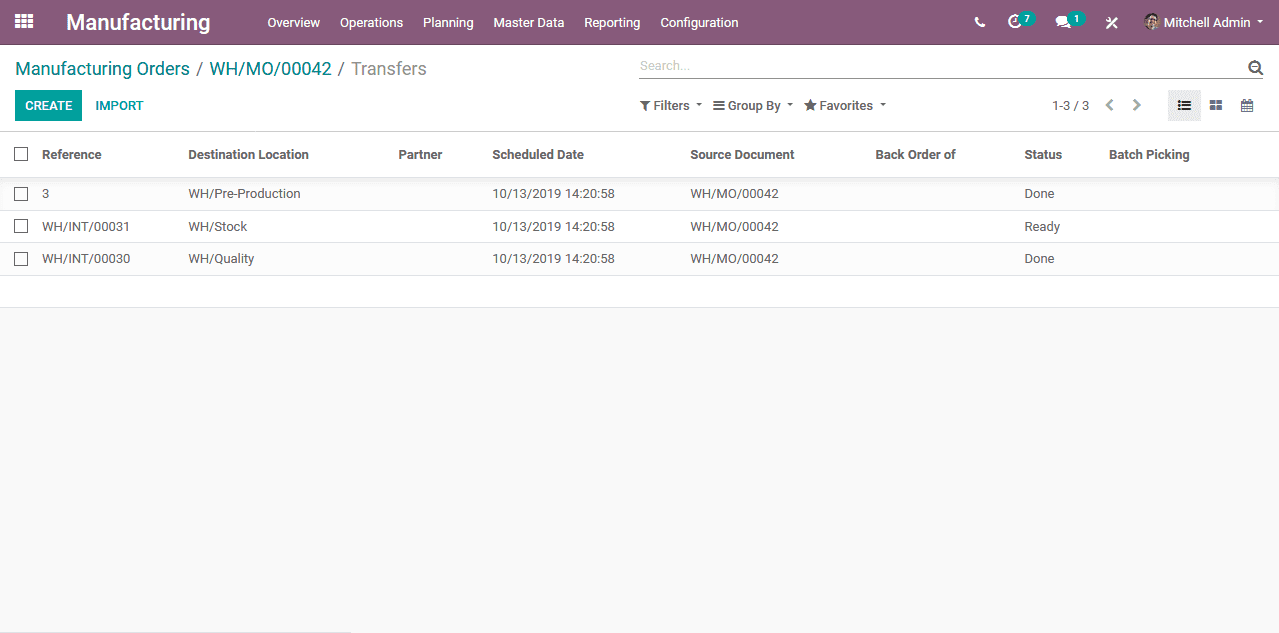

Here we can see the products are not reserved. That is because our Table Legs and Table Top are in the location WH/RawMaterials. We have to perform our first operation that is pulling the raw materials to the pre-production. We can also see on the right side we have 3 pickings.

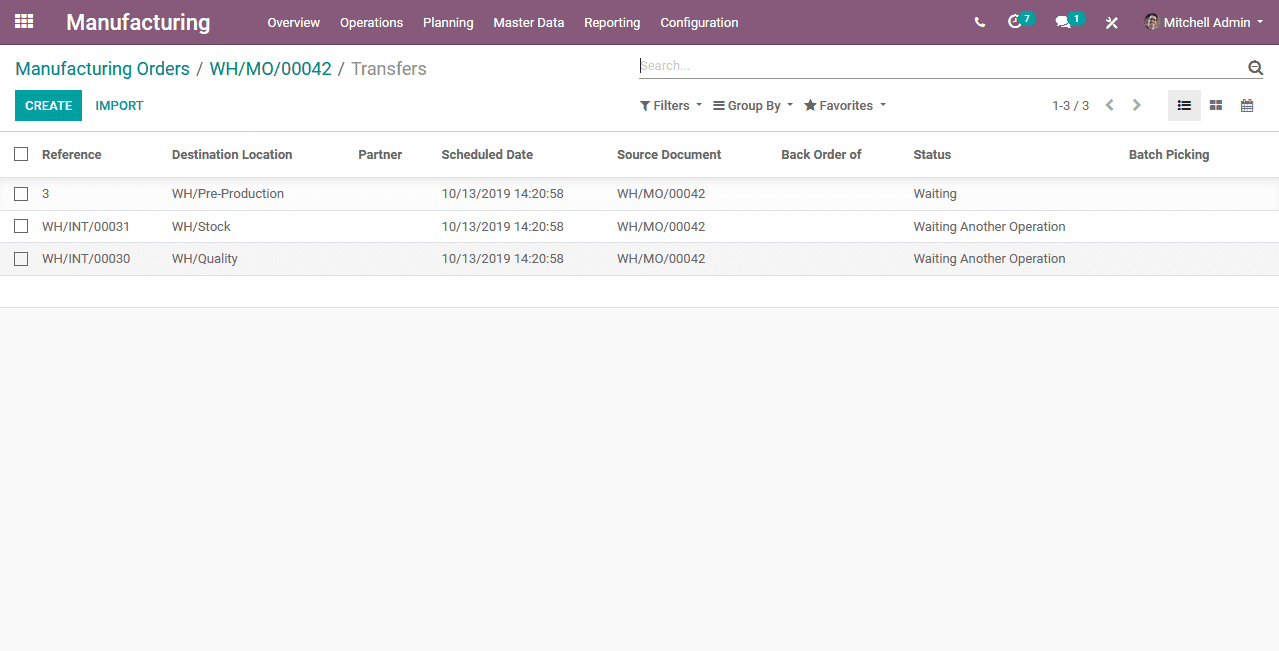

Here we can see our operations. Just click on the first operation. It shows the status of waiting.

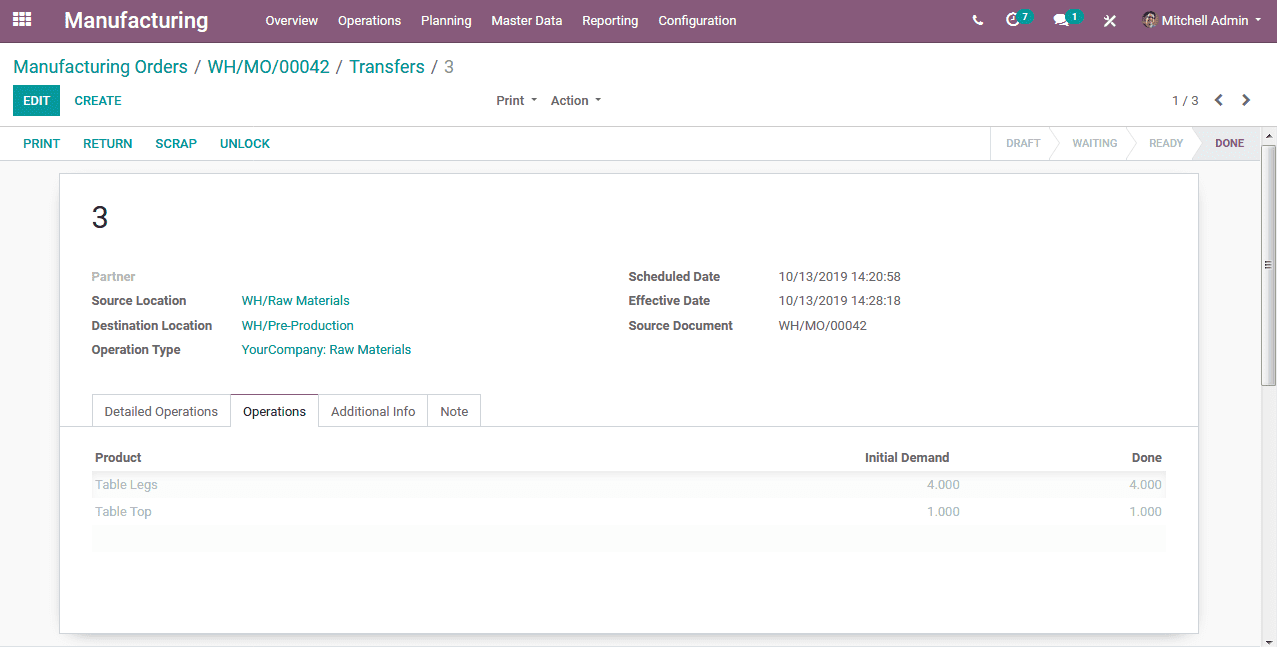

Just click on to check availability and validate. Here we can see the source location and destination location. As you can see our raw materials now arrive at Pre Production Location. Now We can manufacture our product.

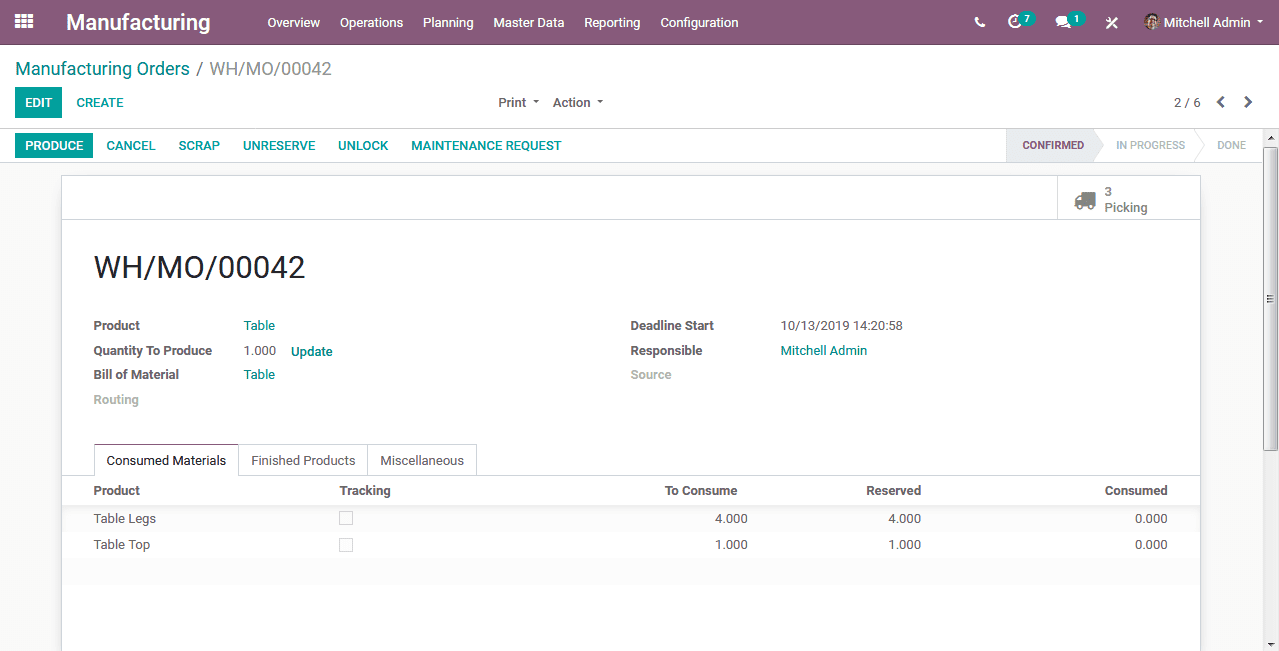

Go back to the Manufacturing order and you can see that the products are already reserved.

Now Click on Produce and Mark as Done.

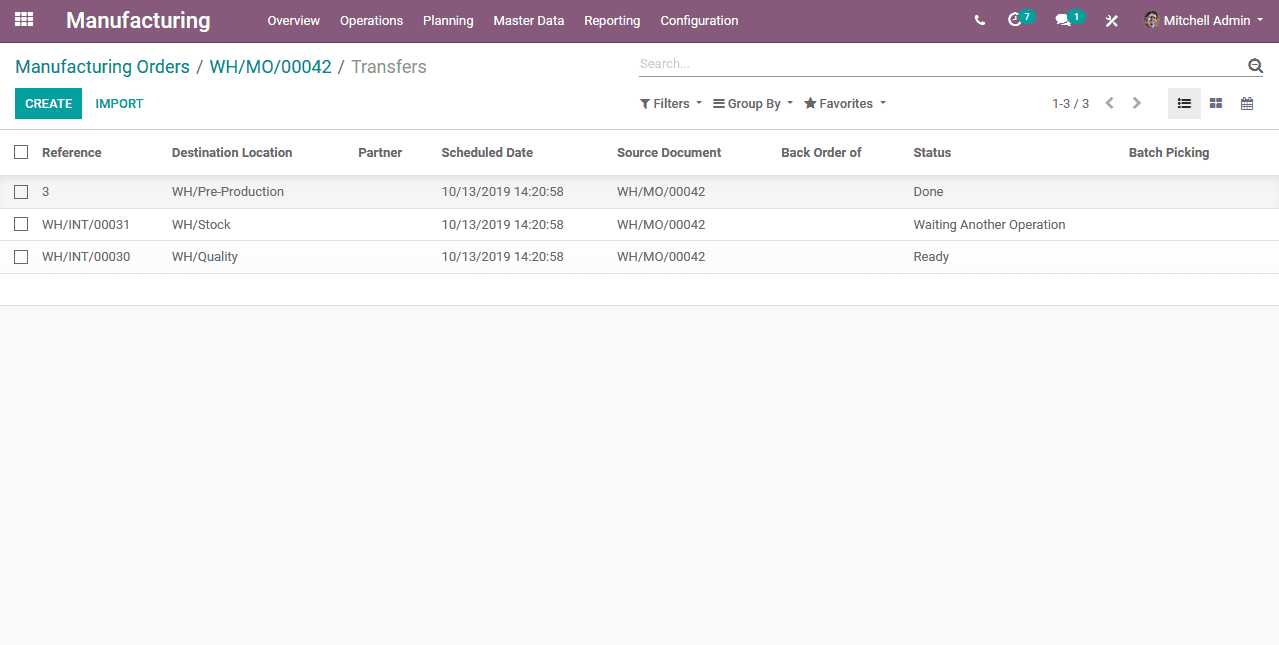

Now our Table is manufactured and it is currently present in the Post-production location. We need to move this product to Quality. Now again click on to Picking and you can see another operation getting ready.

Just click on to that transfer and validate it.

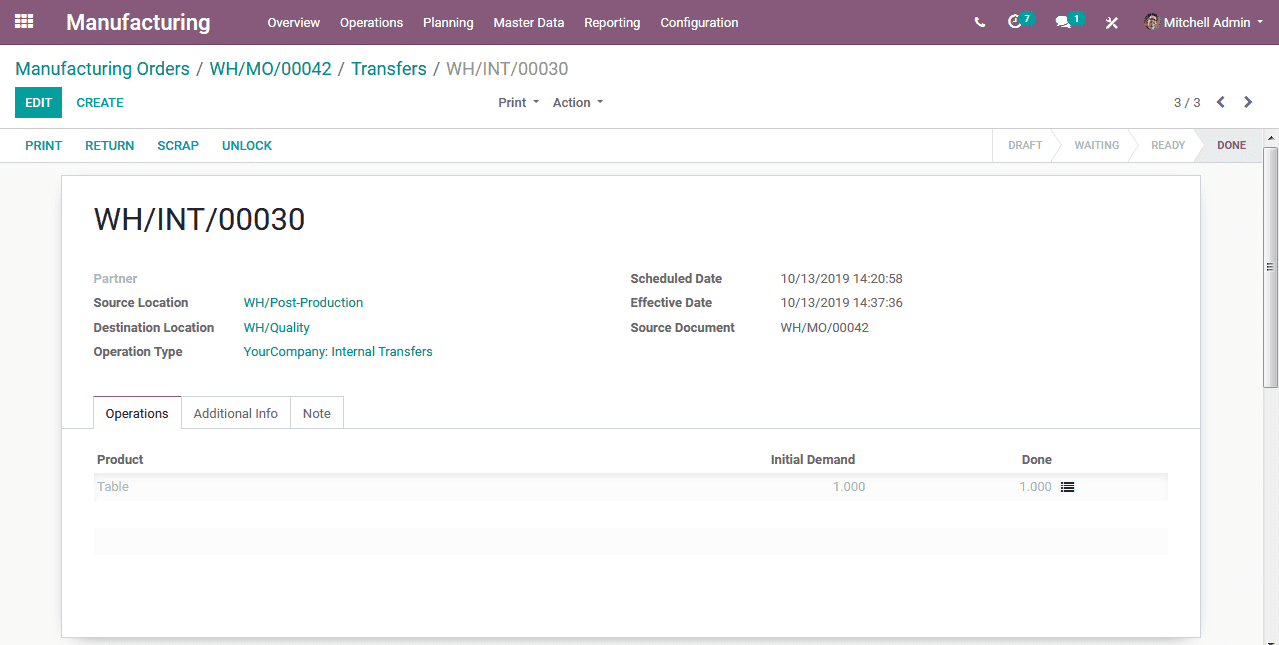

After clicking validate, our product just transferred to the location Quality from Post-Production.

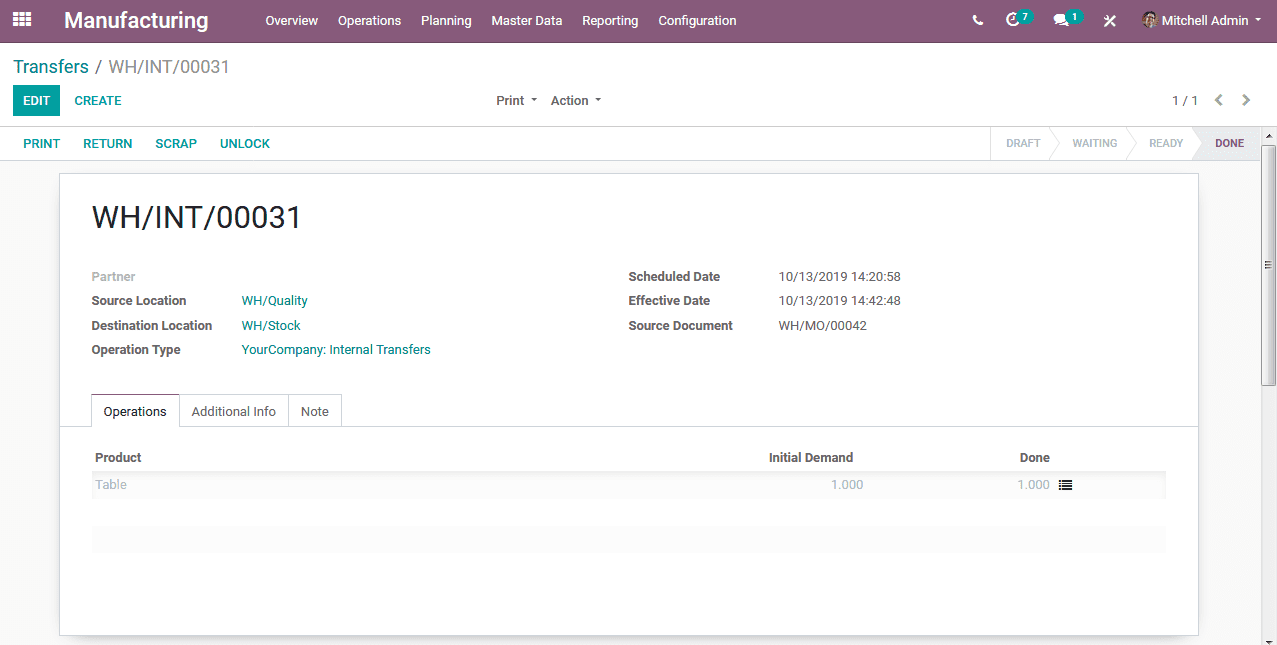

Let’s assume that I performed a quality check for this product and it is successfully passed. At last, we need to move this product to our stock. Go back to the transfer we can see status changer to ready.

Click on to the transfer and validate the transfer.

Finally, our product is in the stock location. If you want you can just check the current stock in the warehouse. This is how we can configure the rules in manufacturing. We can add any number of rules as per one’s need.