The manufacturing industry deals with the manufacturing of different types of products. Key manufacturing industries are the apparel industry, footwear industry, furniture industry, telecommunication industry, electronic industry, petrochemical industry, food processing industry, etc.

All the industries depend on a number of machines and other equipment for completing the manufacturing process. Apart from controlling production and managing the raw material purchase and product sale, the investors will have to pay attention to the maintenance management of the machines used in the industry.

For an investor who is running a manufacturing business, the major share of investment is that of machines. Hence, we have to make sure that our machines function properly and for a longer period of time. For this one has to carry out the timely maintenance of the machines.

Odoo Manufacturing

Odoo open source tool has dedicated modules for managing manufacturing and maintenance operations. Odoo also allows the easy integration of the manufacturing module with the maintenance module. IF you are using Odoo support for managing manufacture you can also depend on the maintenance protocol prepared for your business. This is aimed at assuring the quality of your products. Odoo supports you to track the equipment, scheduled maintenance, and create and resolve maintenance requests. With Odoo, the users can manage maintenance operations in the Preventive way and the Corrective way.

What is preventive maintenance?

How can we explain preventive maintenance? We can consider preventive maintenance as the maintenance measures carried out on a routine basis, especially in advance, to avoid unexpected mechanical failure. We can carry out the preventive maintenance task when the machine is in perfect shape. Usually, equipment notifies failure when it is defunct. Preventive maintenance is done before this failure occurs.

What is done in Corrective Maintenance?

We can say, corrective maintenance means correcting an error. As it is all about machines, corrective maintenance aims at correcting the mechanical error of a machine. We depend on corrective maintenance when we experience some mechanical errors and machines stop functioning. This kind of maintenance operation helps to distinguish the issue. IT supports identifying the core cause and address the issue at the earliest to reinstate the operations of the machines and reinstate the operations of the work centers.

Equipment maintenance will help the business to perform more proficiently with efficient machines. Corrective and preventive maintenance at regular intervals will help the business to avoid the failure of equipment.

Equipment management plays an important role for managing the overall productivity of the industry. The key benefits of maintenance management are

- Avoid production loss

- Efficient use of work centers

- Reduce the wastage of components

- Reduce downtime

- No wastage of labor force

- Maximum utilization of machines

How to use maintenance management in manufacturing?

How can we make use of the Maintenance module in the Manufacturing module? We first have to install the module.

And yes. Now we can use it to manage different types of maintenance activities.

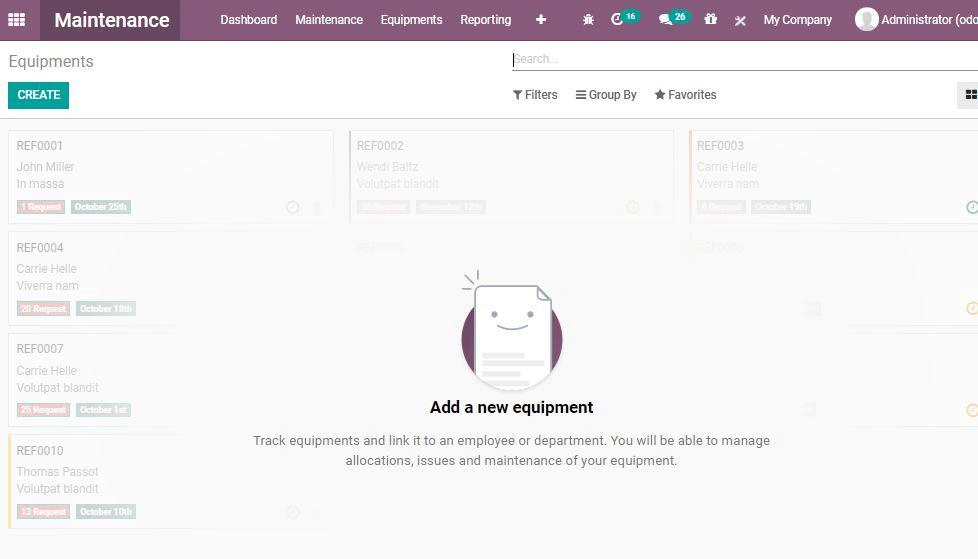

Create Equipment

Using this maintenance module we have to create an equipment list by going to the Equipment menu. Underneath this menu, you can find an option for Machines and tools. Here we can create new equipment.

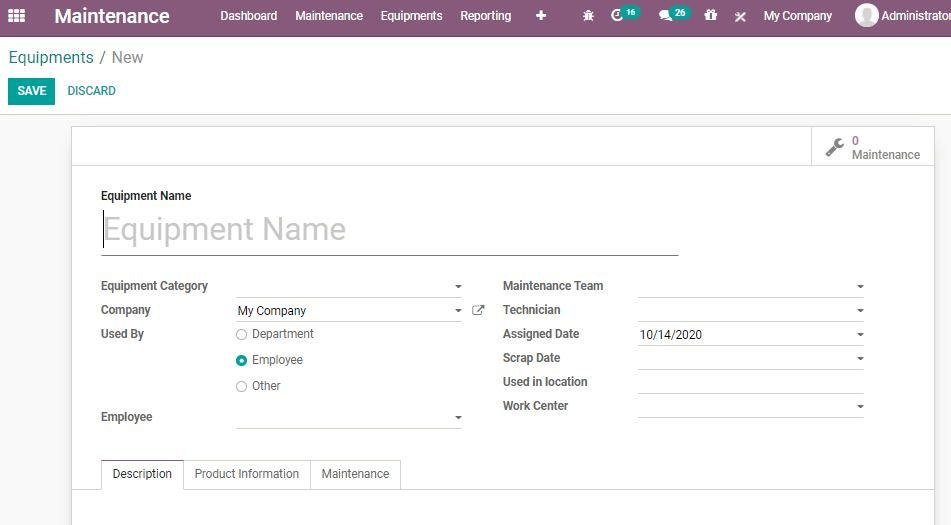

The page below will help you to create equipment.

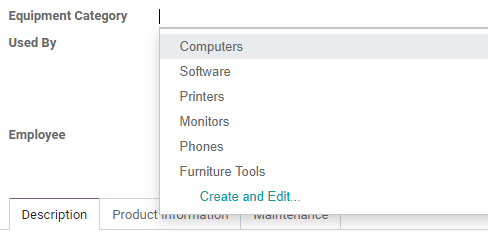

Here we have different fields like Equipment name and Equipment Category.

We can also find columns to fill in details like department, employee, other, maintenance team, etc.

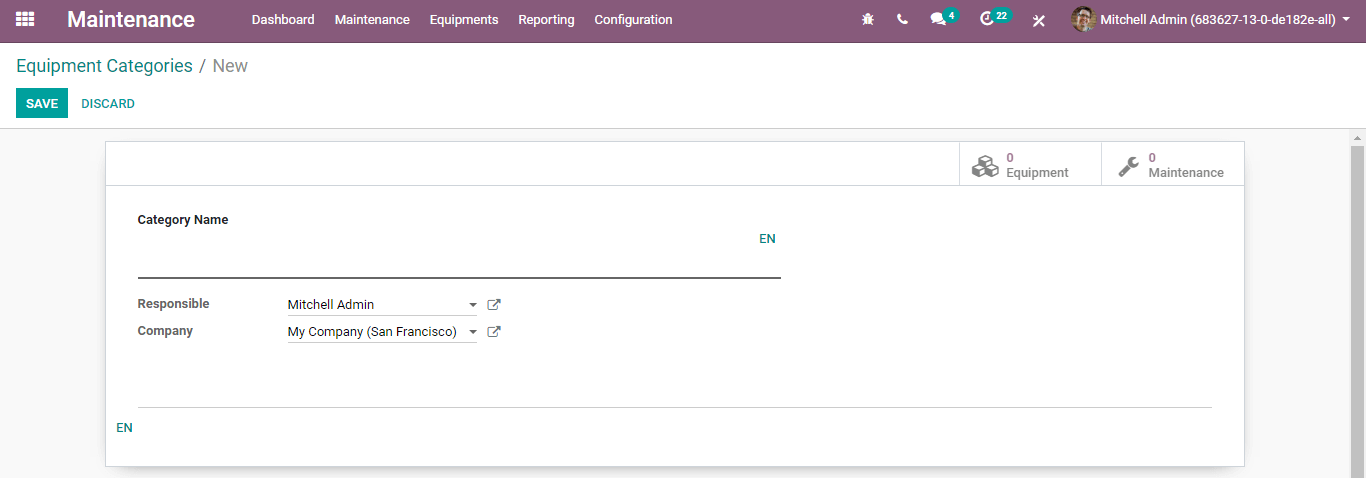

Create Equipment Category

Before going ahead with maintenance we have to create an equipment category.

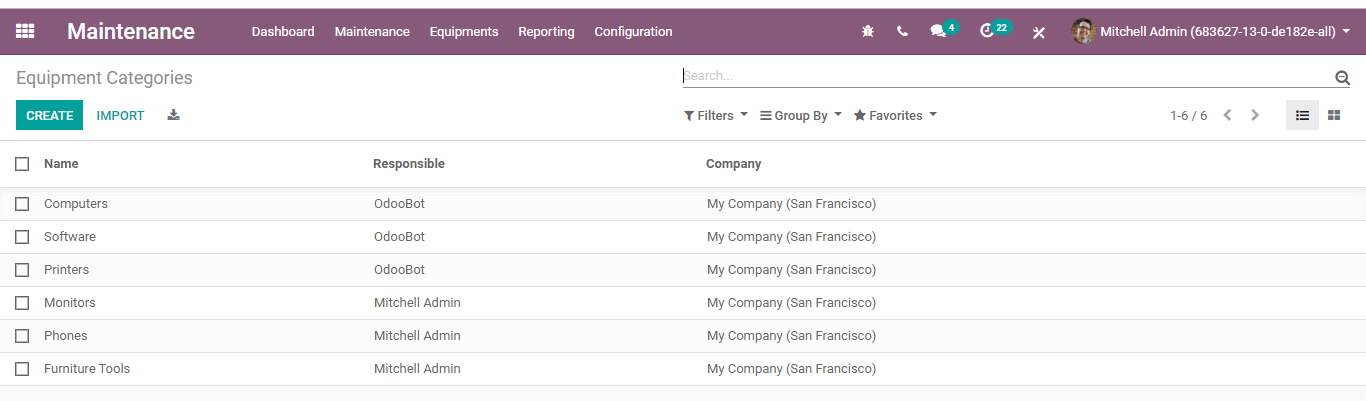

Let us see how. In the Maintenance module, we have a Configuration menu below which we can find Equipment Categories

We can just pick CREATE option to create the category.

We can fill in the details like category name, persons responsible, and the name of the company here.

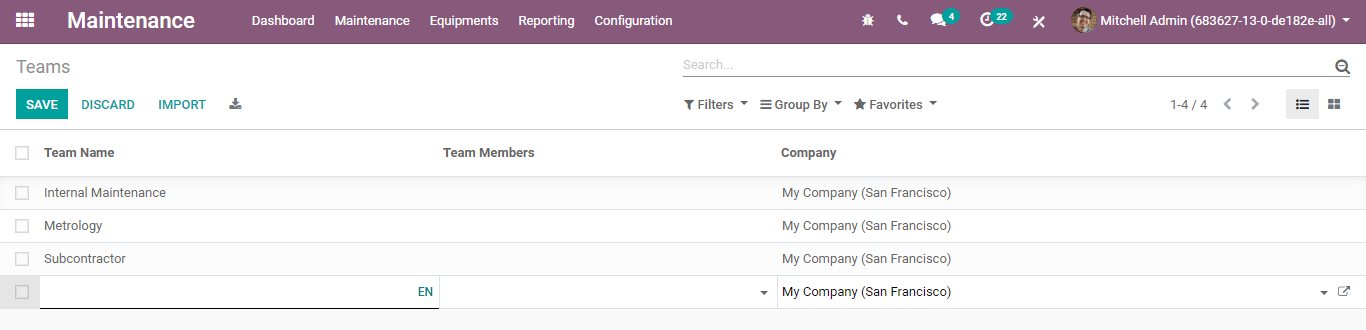

Create Maintenance Team

To create a maintenance team we have to go to configuration again and choose the Maintenance Teams option. Here we have to Create an option for the purpose.

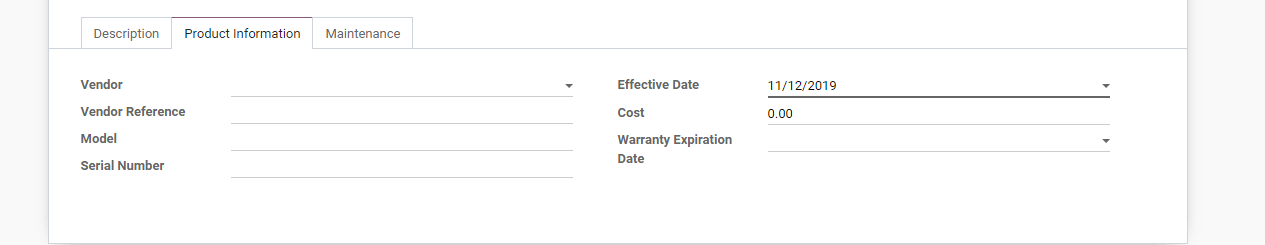

Fill in all the details here under the General Information and then move to Product Information tab

We can give the details of the equipment here.

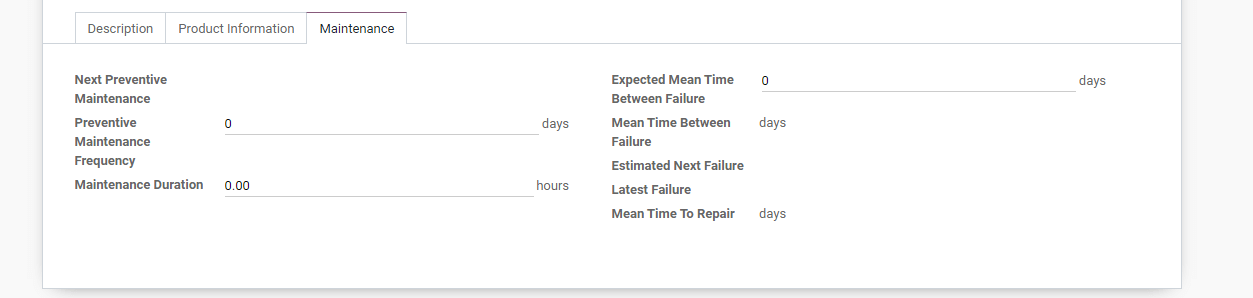

Then choose the Maintenance tab to give details of maintenance

Below this tab we can set Preventive Maintenance Frequency, Next Preventive Maintenance, Maintenance Duration, Expected Mean Time Between Failures, Mean Time Between Failures (MTBF): Estimated Next Failure, etc.

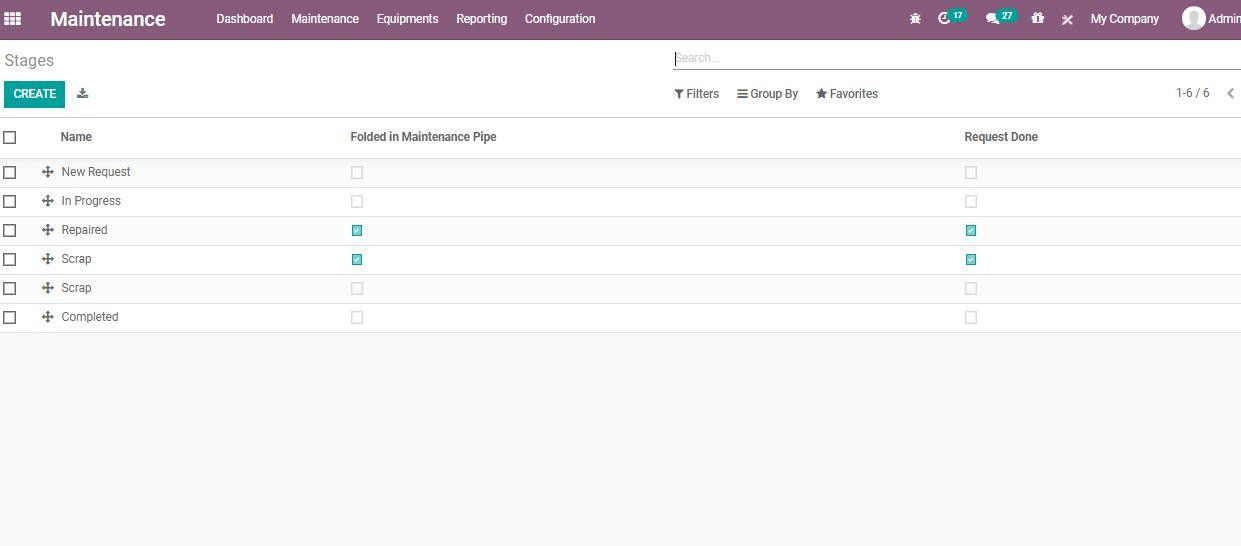

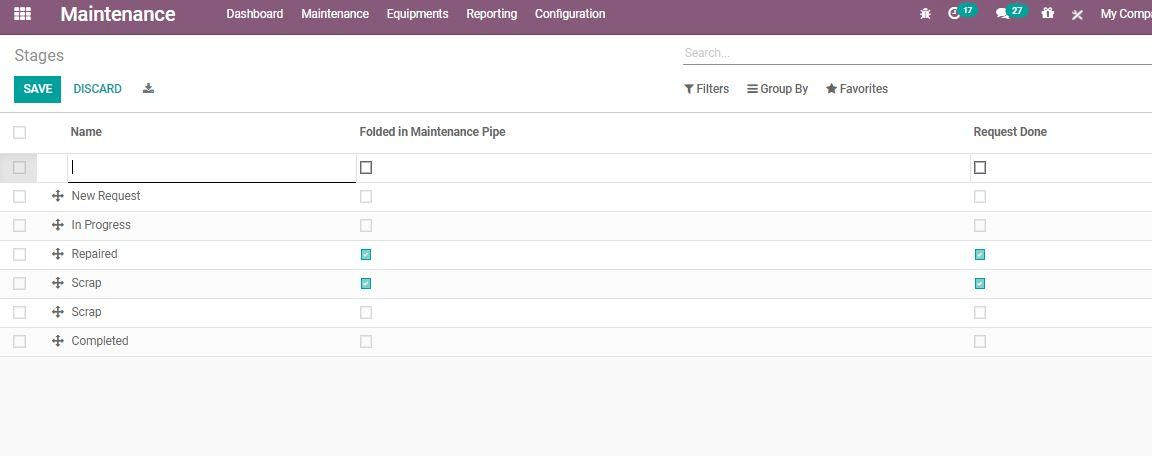

Create Maintenance Stages

We need to review the progress of maintenance work and for this, we have to create a maintenance stage. This can be done using the Maintenance Stages Configuration option below the Configuration menu.

Use Create button to get create a form

We can name the stages and manage them.

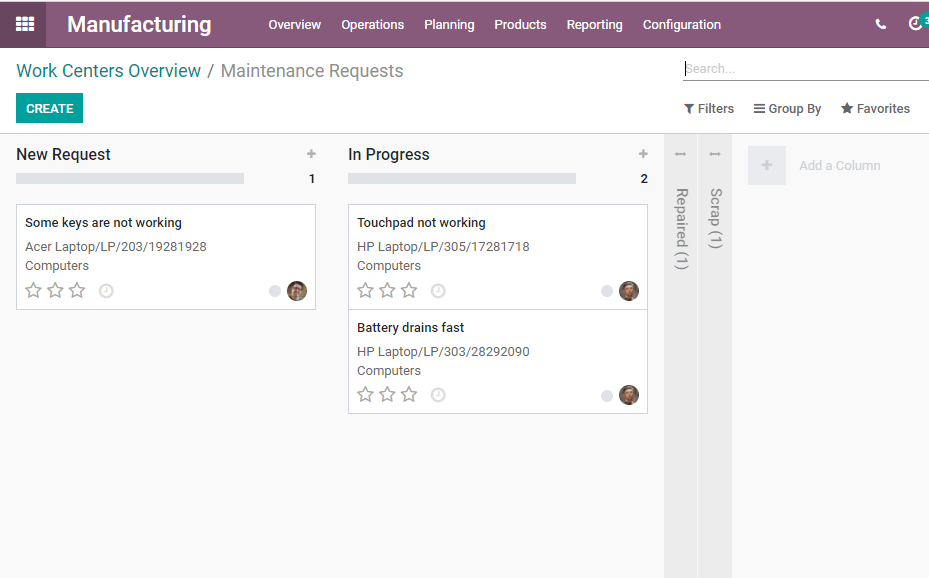

Create Maintenance Requests

In a manufacturing industry, we can raise maintenance request from the manufacturing module or maintenance module

In the Maintenance module, we can go to Maintenance request and create a new request directly.

In the same way, we can create maintenance requests from the Manufacturing module also. This can be done from Manufacturing Order, Work Orders, or Work Center.

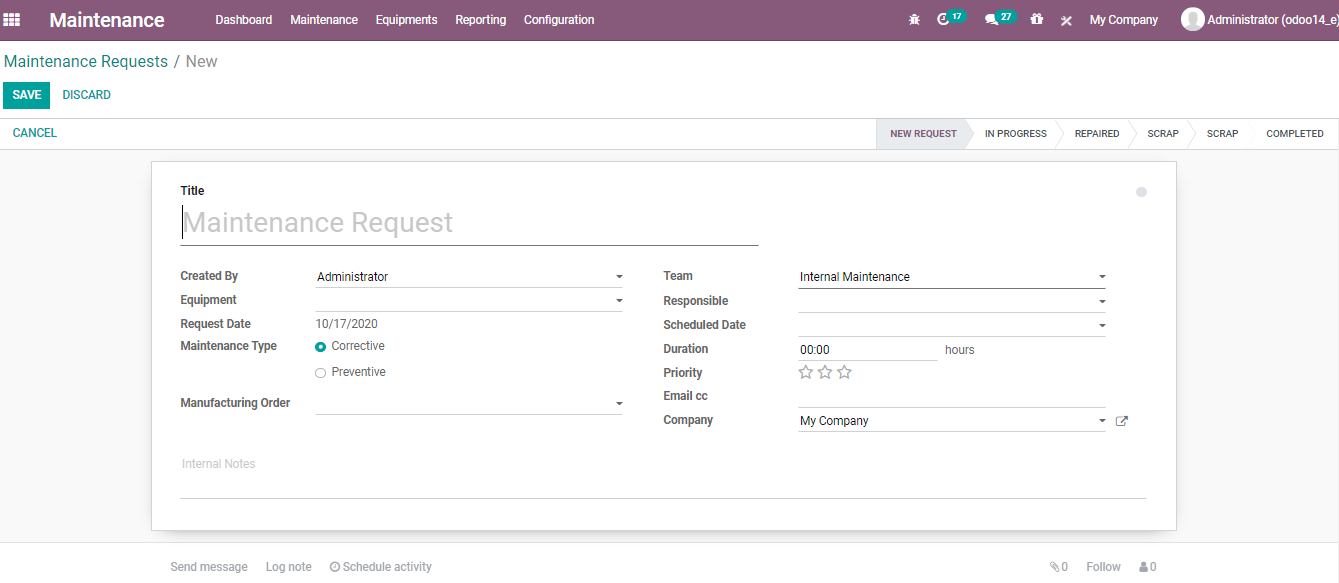

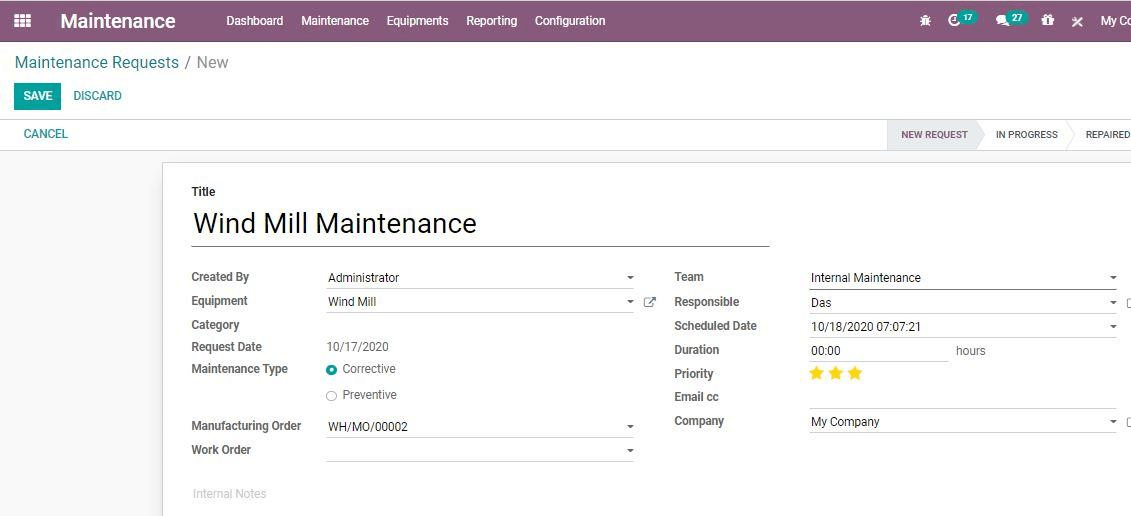

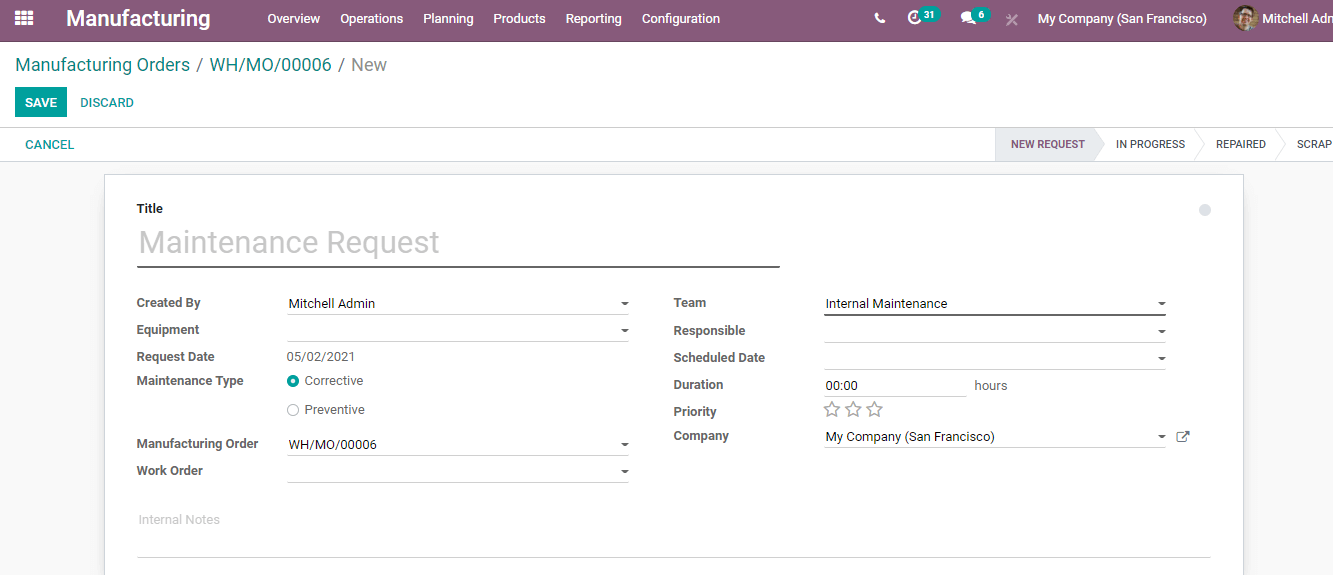

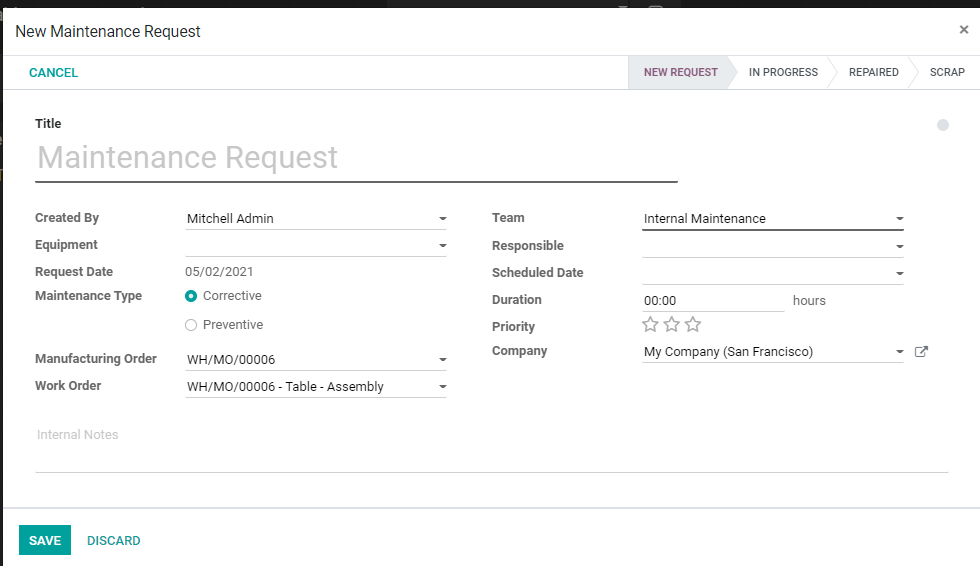

How to fill in the Maintenance Request form

We have many fields here.

Title: A name to identify the request

Created by: The person who raises the request

Company: Info of the company

Equipment: Machine that requires maintenance

Request date: When the request is created

Maintenance type: Choose between Corrective and Preventive

Manufacturing order: In case machine failure occurs when the manufacturing process is progressing ad MO

Teams: The maintenance team detail

Scheduled date: Planned date of manufacturing

Duration: Maintenance duration

Priority: choose to manage priority

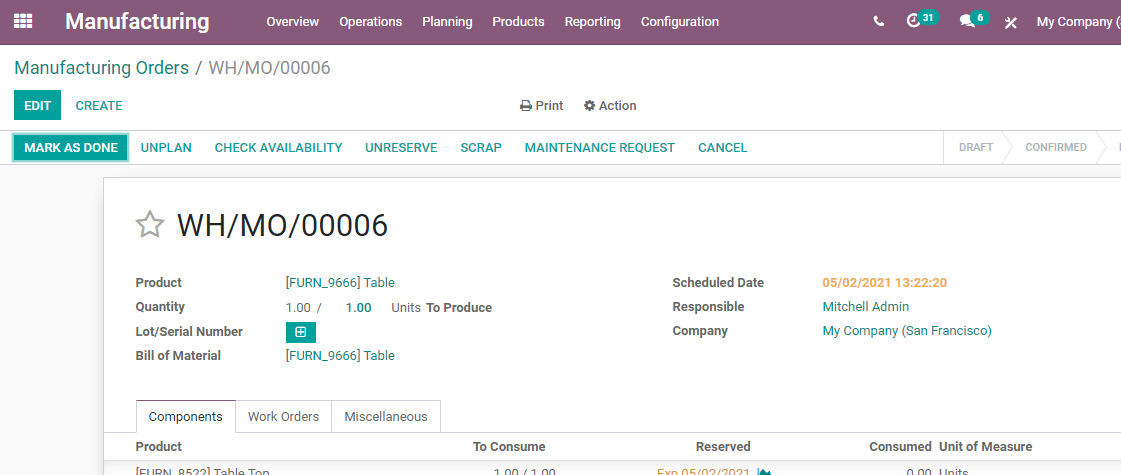

Maintenance Request from MO

Let us check the different ways to create a Maintenance Request

First, we can see how to create a Maintenance Request from MO.

This type of maintenance request is created when we experience a mechanical error during the progress of a manufacturing process.

To raise this request we have to go to the manufacturing module

Then go to Operations> Manufacturing Order

Open the MO and we can find the Maintenance request option.

Choose the Maintenance Request button and we can find the maintenance request form

Filling the fields we can manage this.

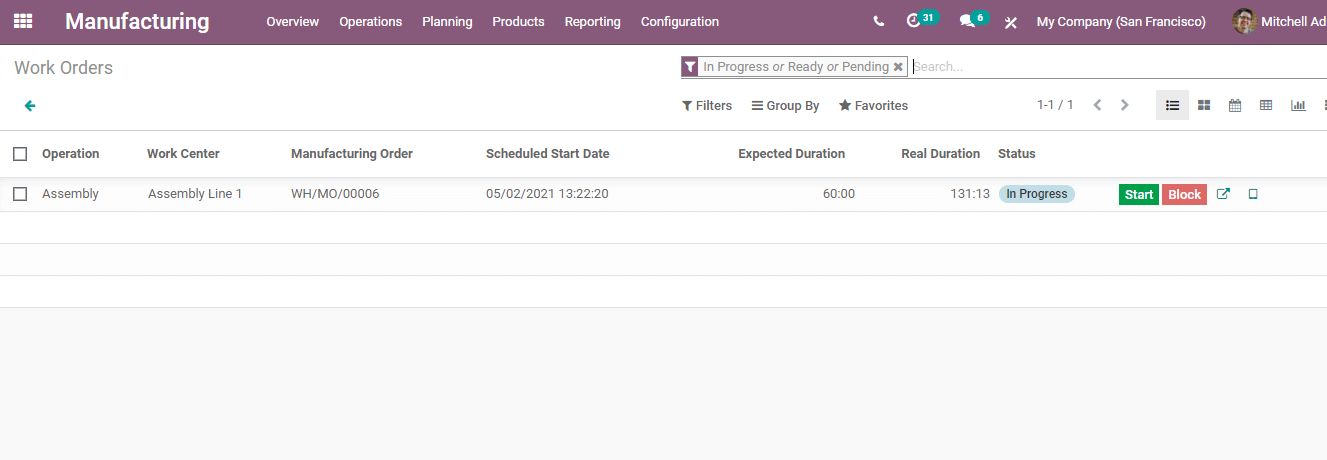

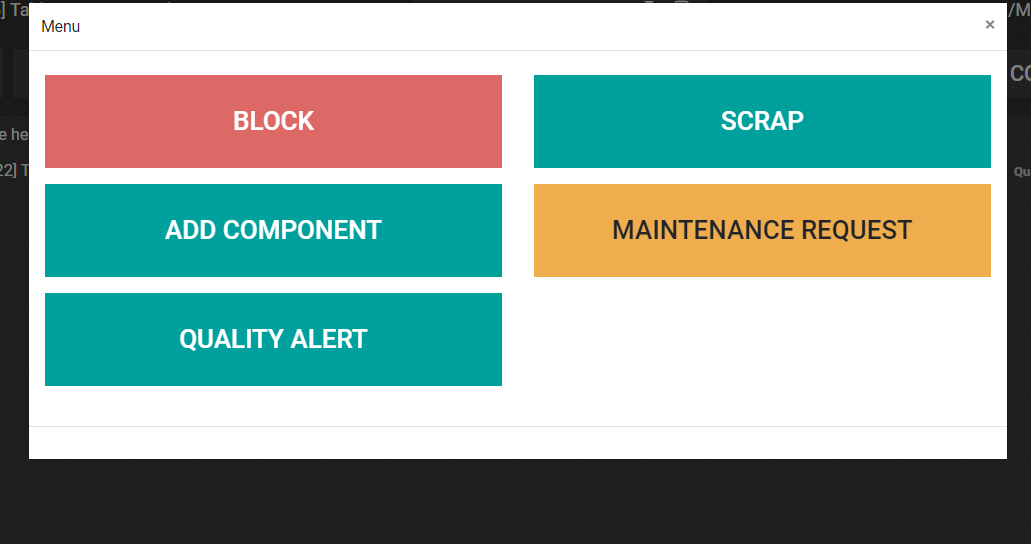

Maintenance Request from Work Order

We can raise maintenance requests from the work order which can be found below the Operations menu.

Here, we have an icon on the extreme right. Clicking on this we will get a page. The menu of the page helps us to raise maintenance requests.

Clicking on It we get the same maintenance request form

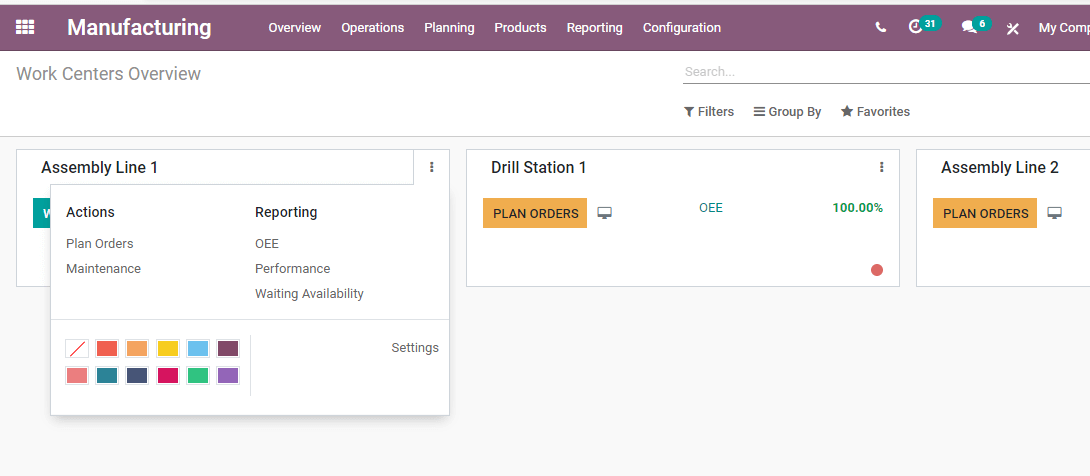

Maintenance Request from Work Center

In the Manufacturing module, we can find the work centers in the Overview itself. There we can find all the work centers.

In each work center, we can find three dots. Clicking on it we will get many options and one among them is maintenance.

In the above image, we can view Actions and Reporting. Below Actions we have maintenance.

We can find the status of the maintenance requests and create new ones here.