In the world of manufacturing, efficient tracking of components and finished products is crucial for maintaining quality, ensuring compliance, and managing inventory effectively. Odoo 17, with its comprehensive manufacturing module, offers robust features for managing lot and serial numbers throughout the production process. In this blog, we'll detail how Odoo 17 facilitates tracking components and finished products using lot and serial numbers, enhancing traceability and accountability in manufacturing operations.

Effectively managing manufacturing operations necessitates orchestrating a series of production stages, wherein the end product undergoes refinement across diverse machinery until its fruition. From the initial machinery installation to the retrieval of raw materials from inventory, meticulous oversight is paramount. This entails structuring manufacturing workflows meticulously, guaranteeing uninterrupted operational flow across every work center.

In Odoo, meticulous tracking is facilitated via lots and serial numbers, which furnish each product with a distinct identity, thwarting any potential data redundancy. Furthermore, these assigned lot or serial numbers are meticulously managed and seamlessly integrated across the platform, empowering users to customize them in accordance with specific needs as they navigate through the system.

Importance of Lot and Serial Number Tracking

1. Quality Control: Lot and serial number tracking enables manufacturers to trace products back to their source in case of defects, facilitating targeted recalls and quality control measures.

2. Regulatory Compliance: Many industries, especially those dealing with pharmaceuticals, food, and electronics, are subject to stringent regulations mandating lot and serial number tracking to ensure product safety and compliance.

3. Inventory Management: Tracking lot and serial numbers allows for precise inventory management, enabling manufacturers to monitor stock levels, expiry dates, and product movements accurately.

4. Customer Satisfaction: With lot and serial number tracking, manufacturers can provide better customer service by quickly addressing warranty claims, tracking products in transit, and offering detailed product histories.

Here's a step-by-step guide on how to track components and finished products with lot/serial numbers in Odoo 17 Manufacturing:

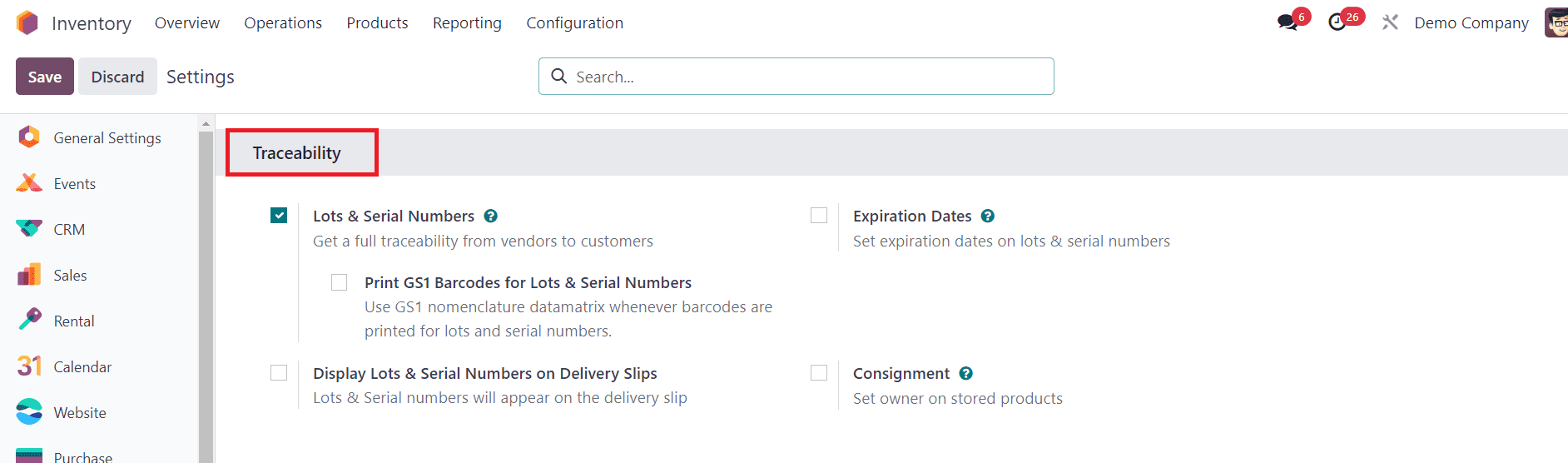

Activating the Traceability feature in Odoo involves a few steps to ensure that the necessary settings are configured correctly. Go to the 'Inventory' module and access the Settings menu.

In the Inventory settings, ensure that the 'Traceability' option is activated. This setting allows Odoo to track components and finished products using lot or serial numbers throughout the production process. In order to enable the traceability for a specific product, go to Products.

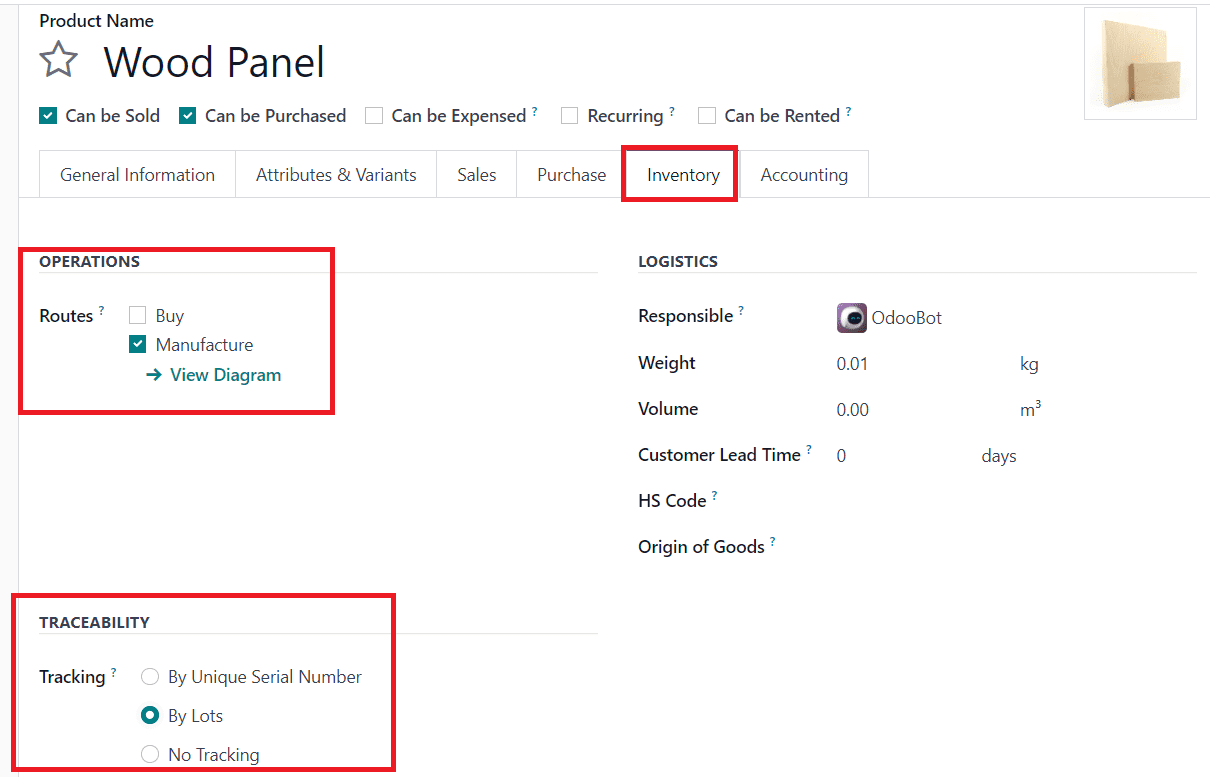

For each product, enable lot and/or serial number tracking as required. Go to the product form, click on 'Edit', and under the 'Inventory' tab, select the tracking options (lot, serial, or both). To activate traceability for a product undergoing manufacturing in Odoo, ensure that you enable the "Manufacture" route and select the "Traceability" option for the respective product. By activating traceability for a specific product, you signify that it will be monitored using lot and serial numbers, enabling comprehensive tracking of its movement and history within the Odoo platform.

Once the traceability feature is enabled in Odoo, users gain the capability to assign unique serial numbers or lots to the finished manufactured products of the company. This empowers users with the flexibility to update the quantity for each product and provide detailed information, including allocations of serial/lot numbers.

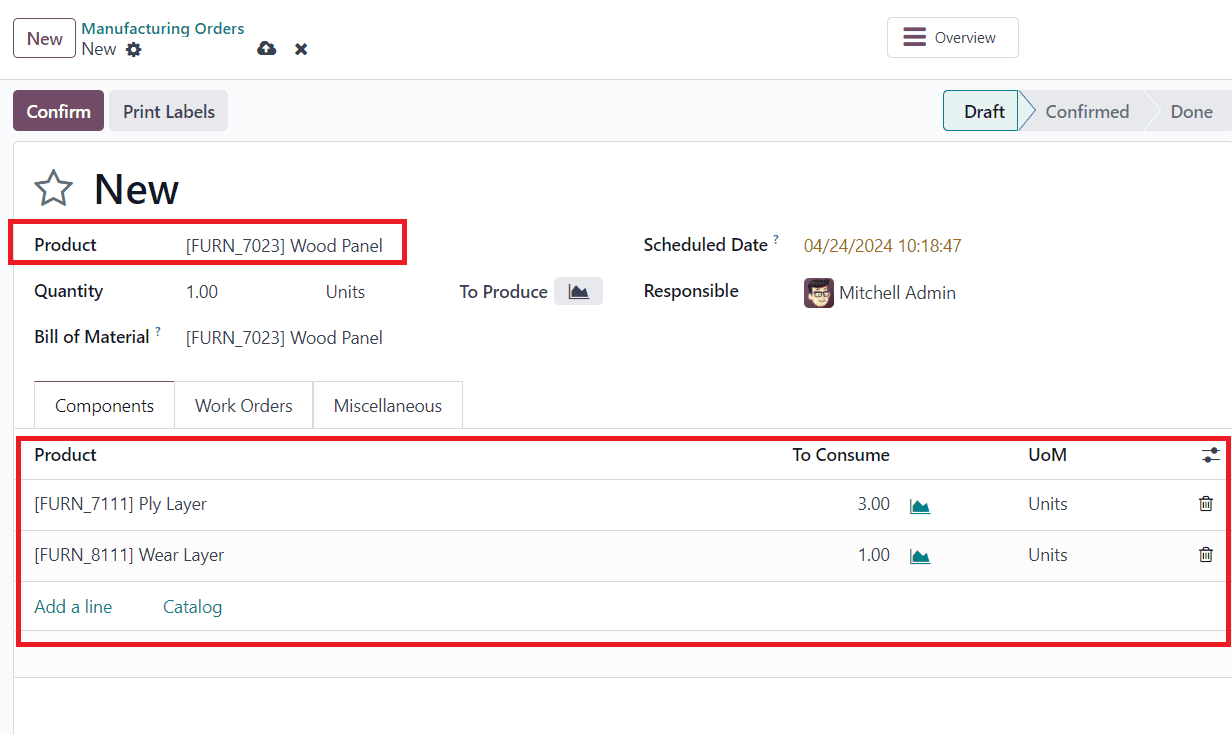

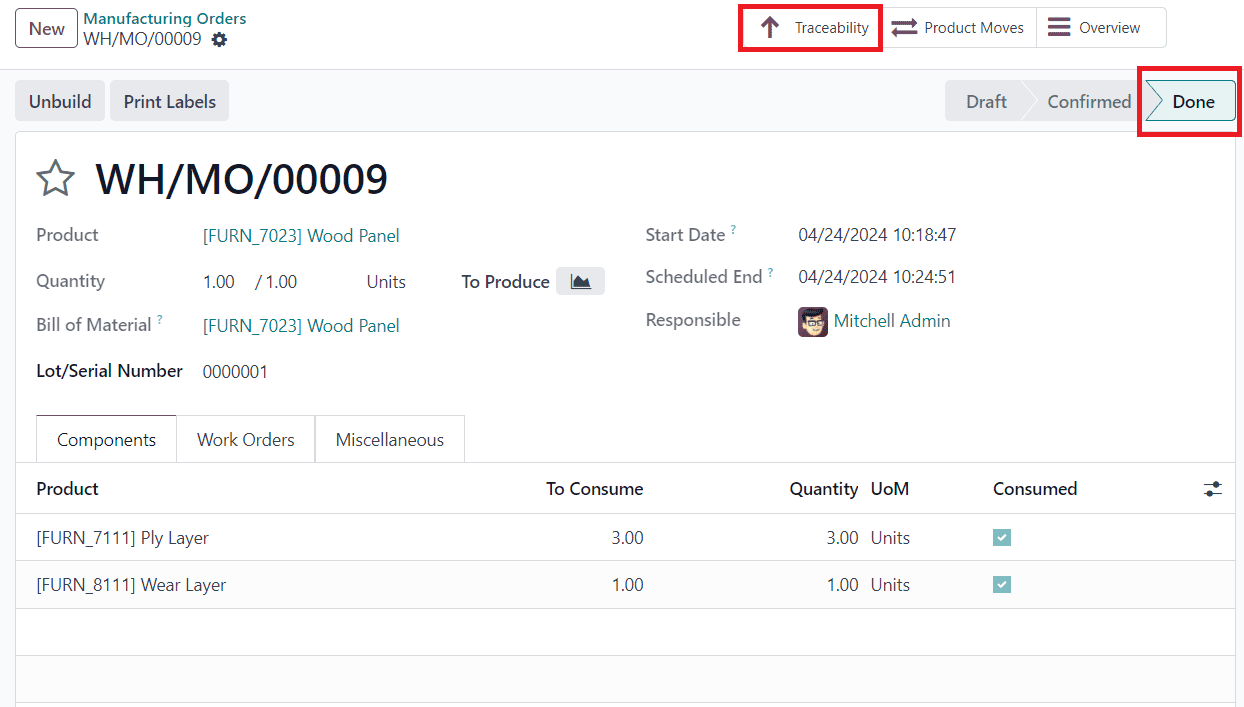

Let's proceed with the manufacturing order for wood panels. These panels consist of two main components: the ply layer and the wear layer. The ply layer provides structural support, while the wear layer offers durability and aesthetic appeal.

With the Bill of Materials (BoM) in place, the order will automatically include the required quantities of ply layers and wear layers for the specified number of wood panels. Once we've confirmed the quantities and details, we'll save the changes and proceed to confirm the order by clicking the designated "Confirm" button. This action will set the production process in motion, ensuring that all necessary components, including ply layers and wear layers, are available for manufacturing the wood panels.

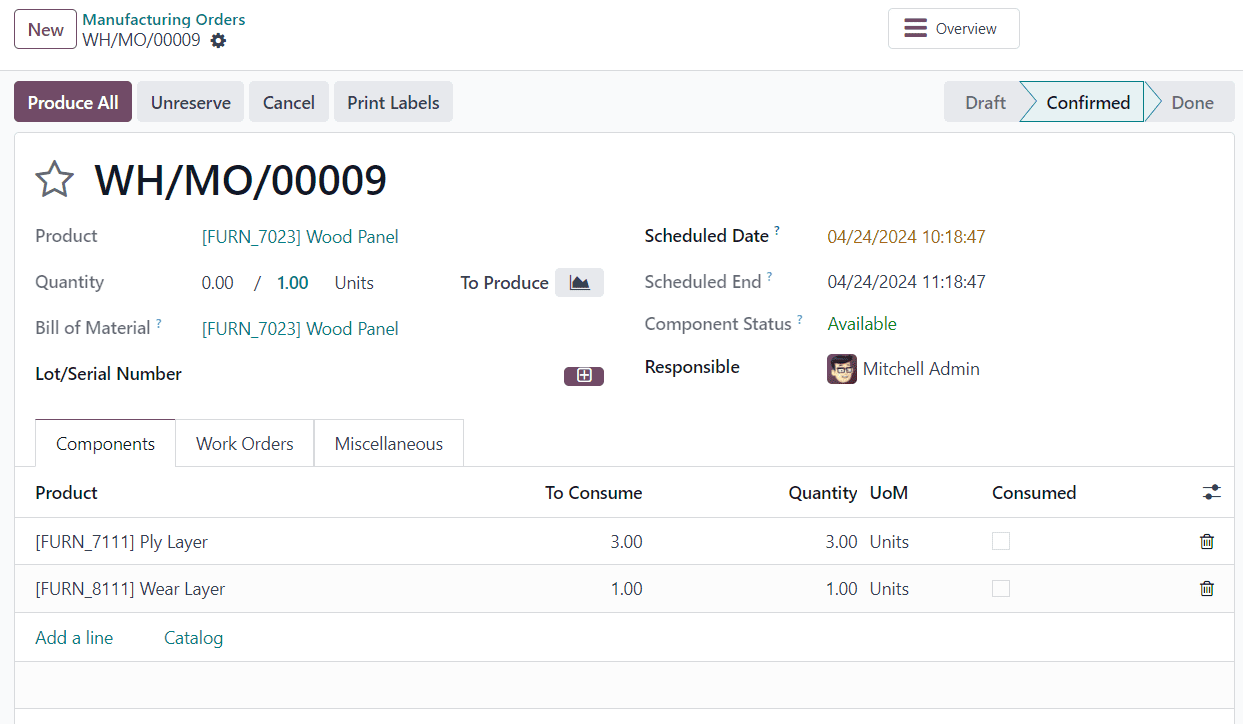

After confirming the order, you'll be presented with two lot/serial number assignment options:

1. Manual Assignment: With this option, you have the flexibility to manually assign lot/serial numbers to each product. This approach allows for precise tracking and customization according to specific requirements or customer preferences.

2. Automated Assignment: Alternatively, you can streamline the process by selecting the "Produce All" button once all operations are completed. This triggers the system to automatically assign lot/serial numbers in accordance with the predefined sequence order. This automated approach enhances efficiency and reduces the potential for human error during the assignment process.

Whichever option you choose, rest assured that the system is designed to facilitate seamless lot/serial number management, ensuring accurate tracking and traceability throughout the manufacturing and distribution processes.

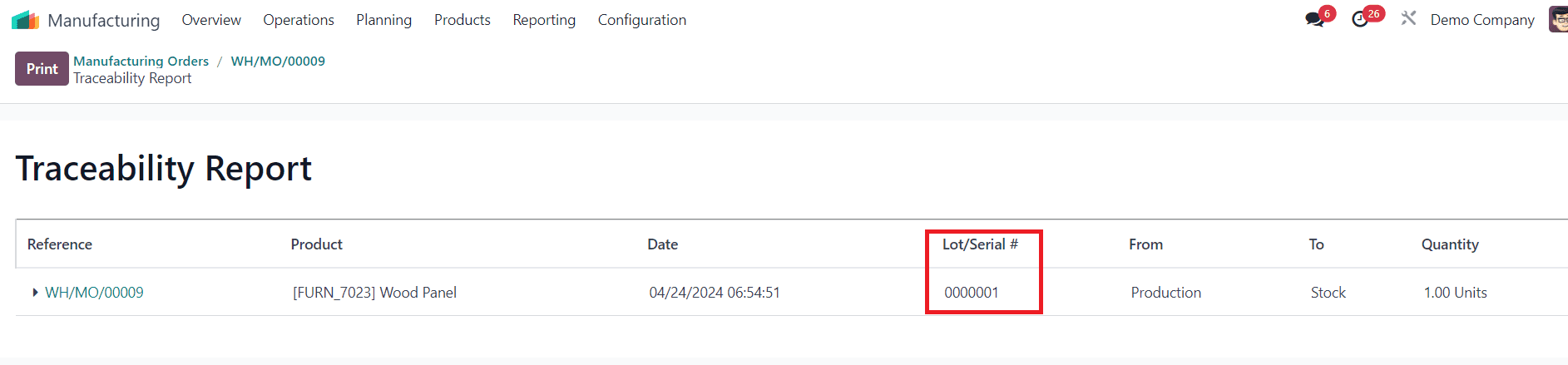

Upon completion of manufacturing, you can utilize the Traceability smart button to generate a comprehensive traceability report for the newly manufactured product. This report will provide valuable insights into the production journey, including details on each stage of manufacturing and the associated components used.

Furthermore, the traceability report will prominently display the lot/serial numbers of the newly finished products. This ensures transparency and facilitates easy identification and tracking of individual units throughout the supply chain.

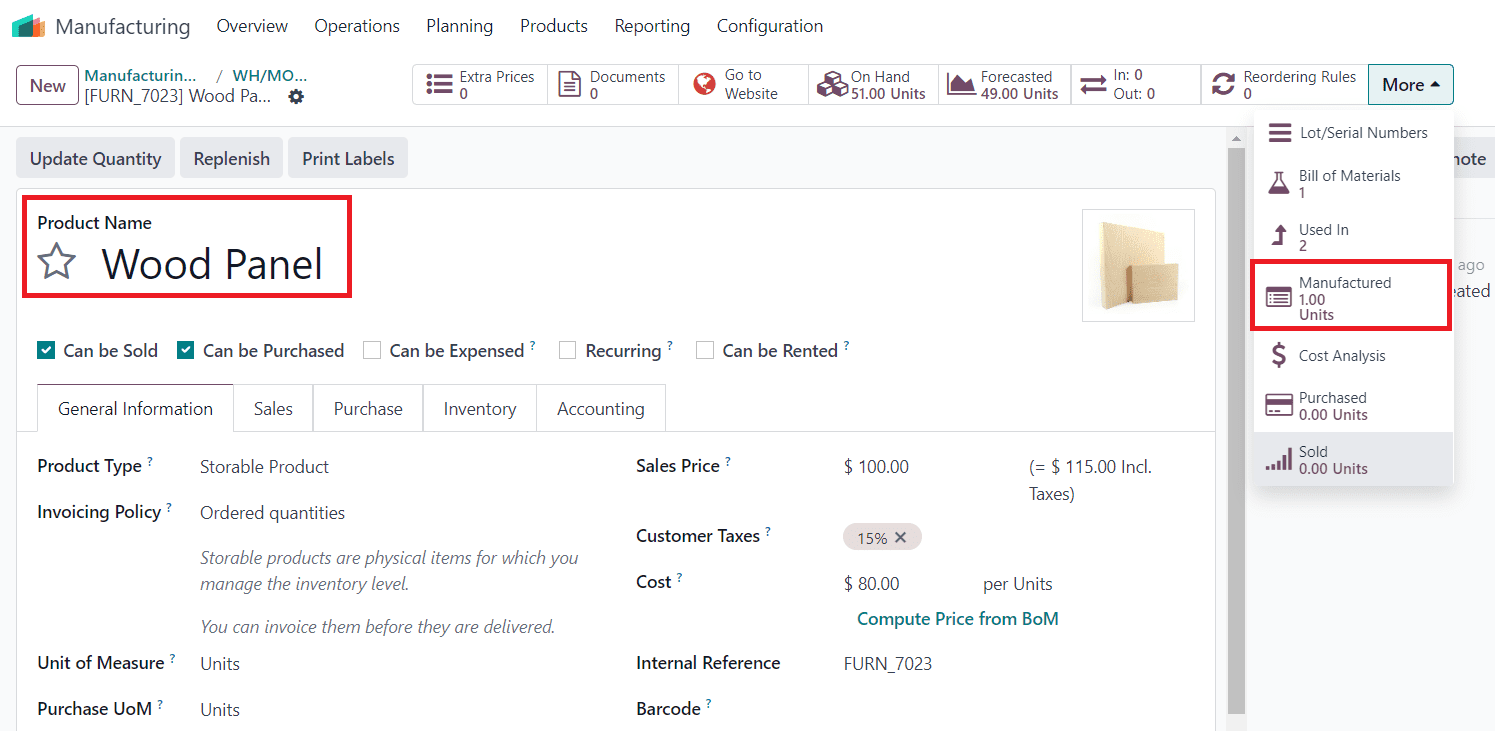

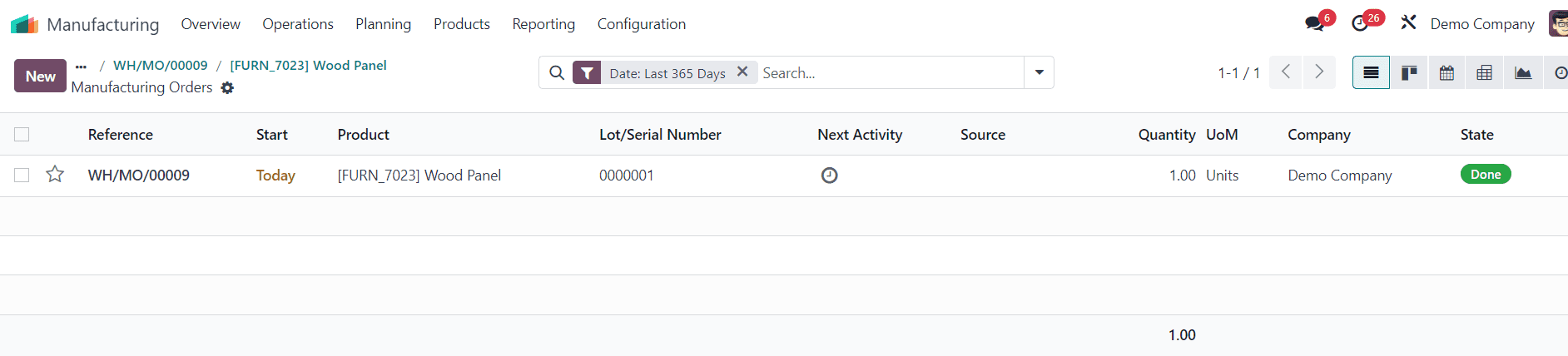

Upon accessing the product form, you'll discover comprehensive information regarding the manufactured units of the product wood panel.

This includes essential details such as the total quantity of units produced, their current status, and any associated lot/serial numbers.

By following these steps, manufacturers can effectively track components and finished products with lot/serial numbers in Odoo 17 Manufacturing, ensuring traceability, compliance, and efficient inventory management throughout the production process.