In the manufacturing industry, we have to carry out different processes to complete the production of a product. For completing different processes, we will need different workspaces. These workspaces where different types of tasks are completed may have to follow different protocols.

Such workspaces where we perform different tasks following different protocols are called work centers in the manufacturing industry.

Odoo Manufacturing Module offers assistance to the clients to configure and manage different work centers in a hurdle freeway.

Let us see how.

We can directly dive into the work center details

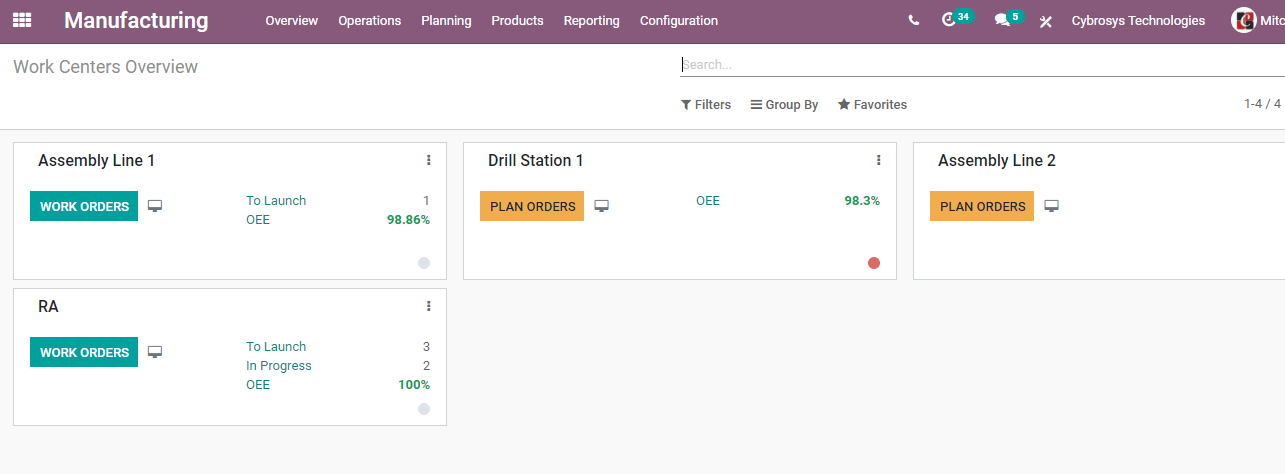

Work centers play a critical role in the manufacturing industry. If we are using Odoo, we will be getting a view of all existing work centers when we enter the module.

As these work centers perform different specific tasks we will have to configure the work centers based on our requirements.

We can also manage different work orders at the work centers.

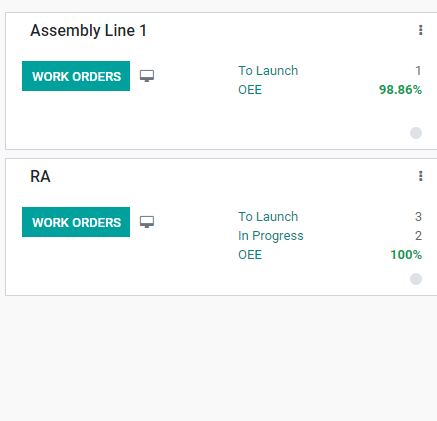

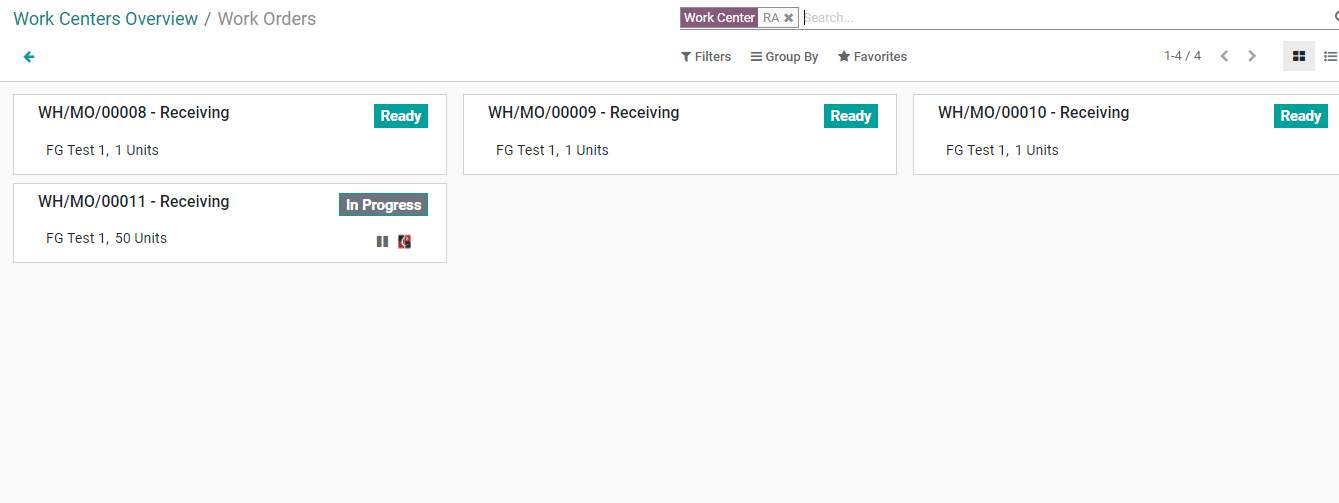

Here, we have different work centers Assembly Line 1, Drill Station 1, Assembly Line 2 and RA.

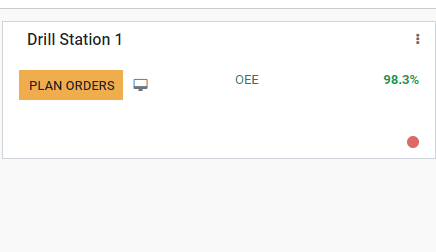

Here, we can see a button Plan Orders.

This means these work centers are not engaging in any activity and we can schedule work orders. The tab can be used to plan new work orders.

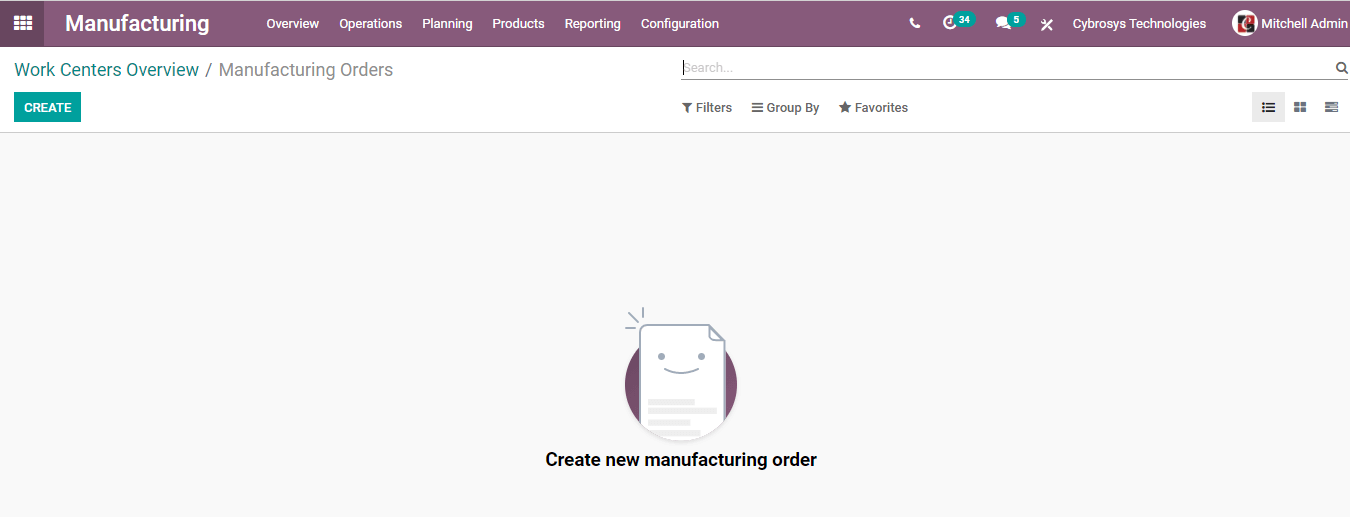

Planning a work order using the Create button is not a difficult task.

Then we can also see the Work Orders tab on some assembly lines. This means some work orders are already in progress in these work centers. We can also view the details of the work orders in progress.

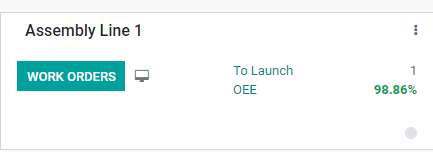

We can view the Work Orders in Progress, Work Orders to Launch, and Overall Equipment Effectiveness (OEE) from here.

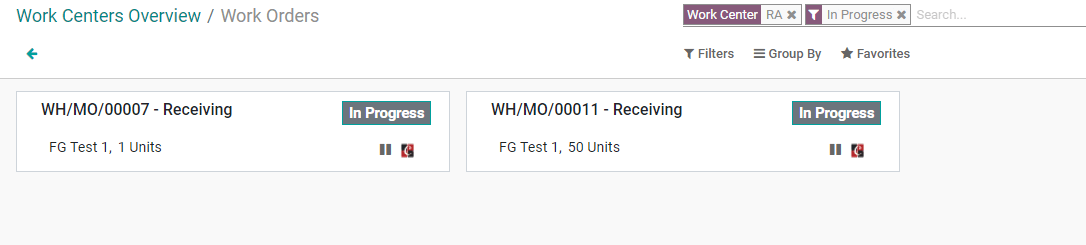

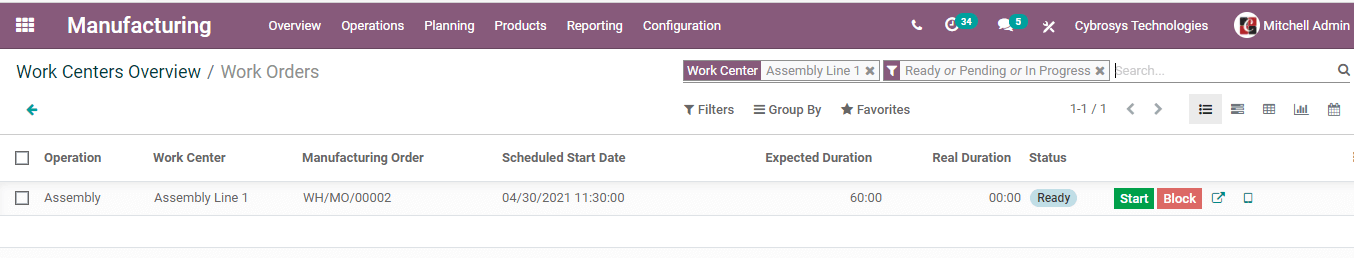

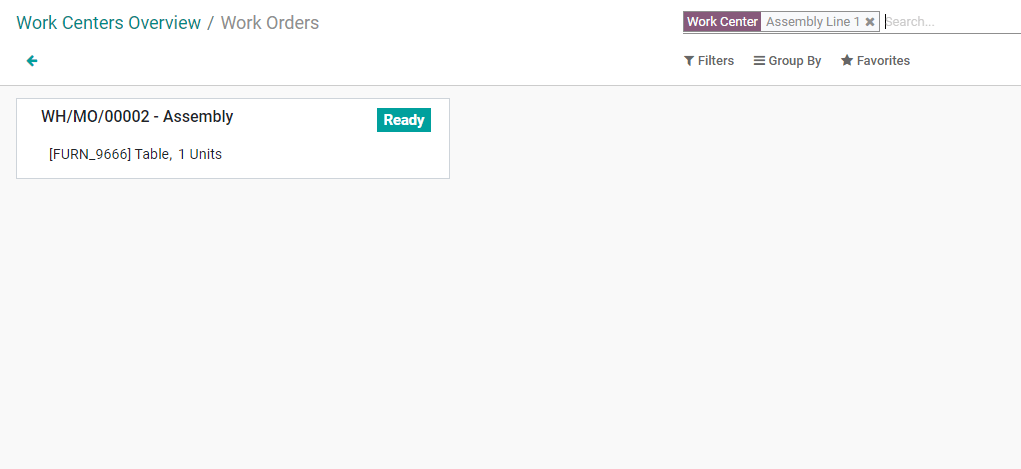

Clicking on Work Order in progress I got

We can see we have two work orders in progress.

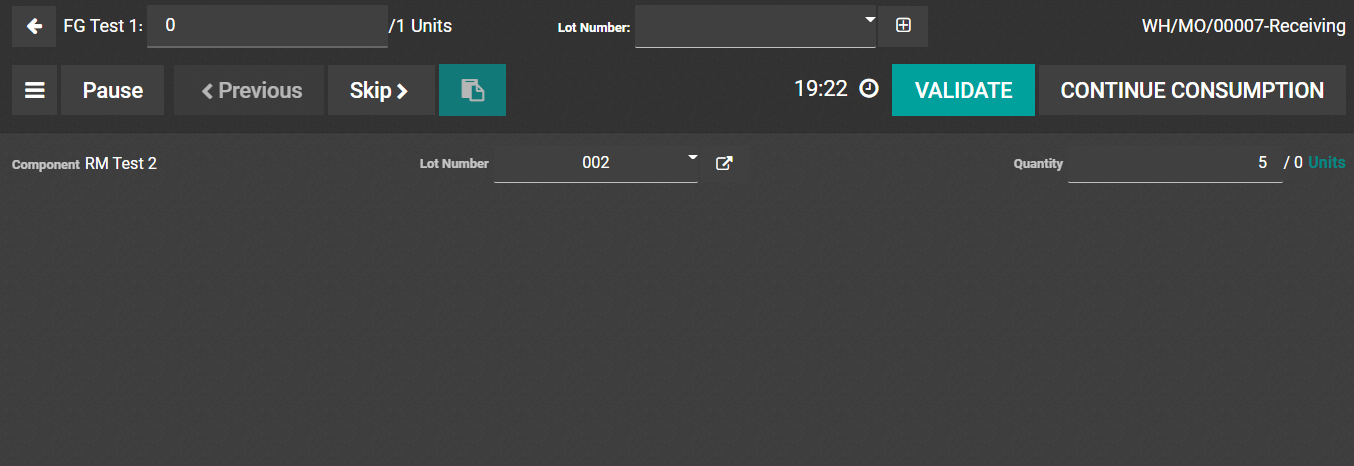

Let us click open one work order.

We can see an icon next to the Work Orders tab.

Clicking on this we will be taken to the work orders page.

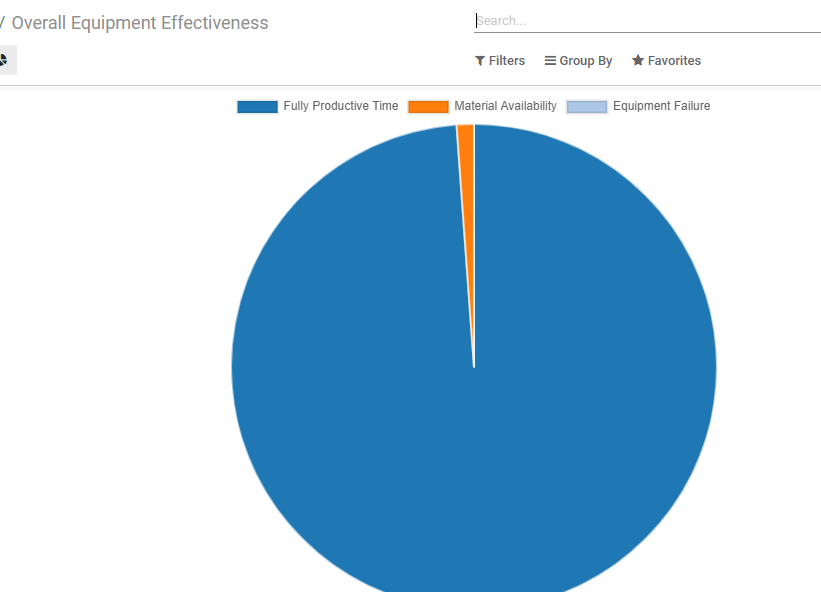

Another fact we can find in the work center is OEE or overall equipment effectiveness.

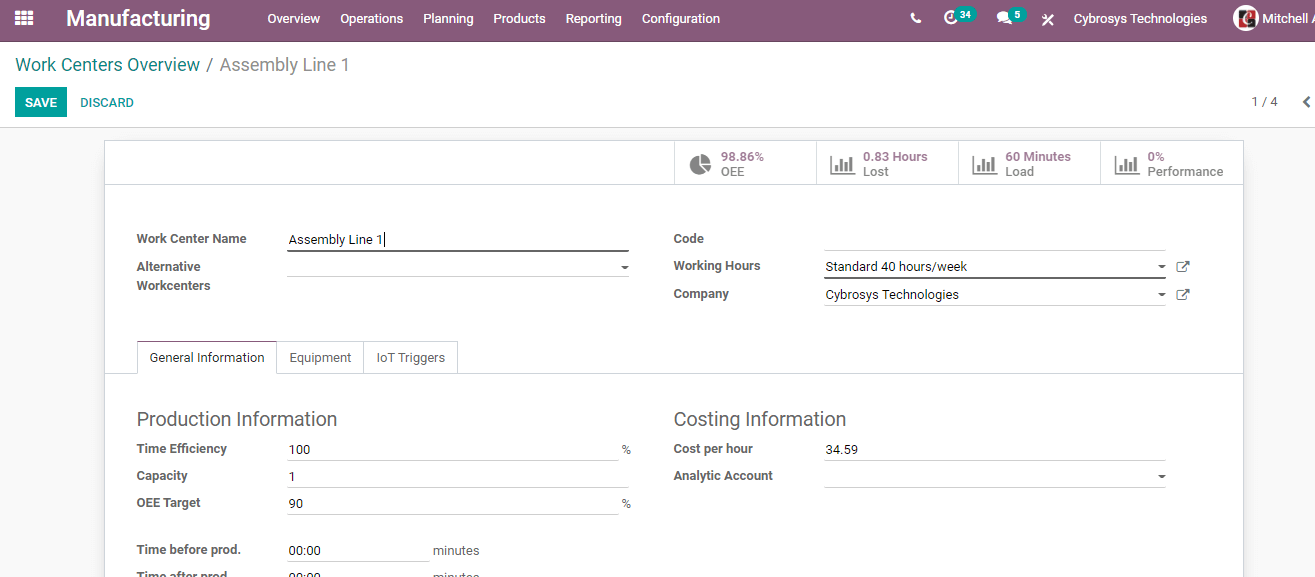

Here, OEE is marked as 98.86%.

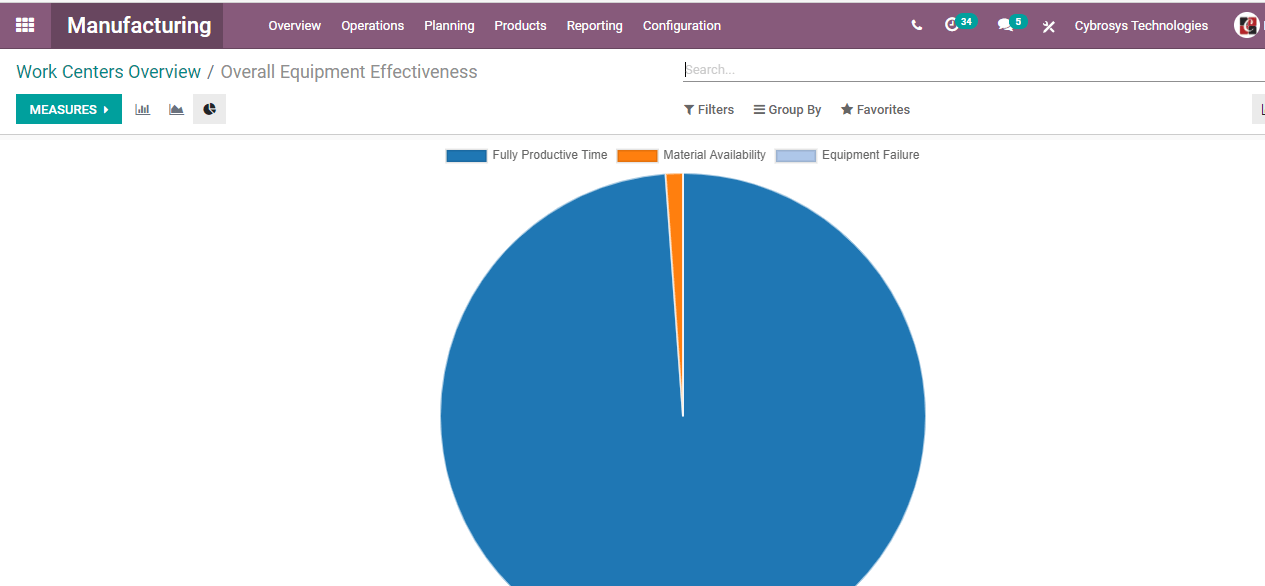

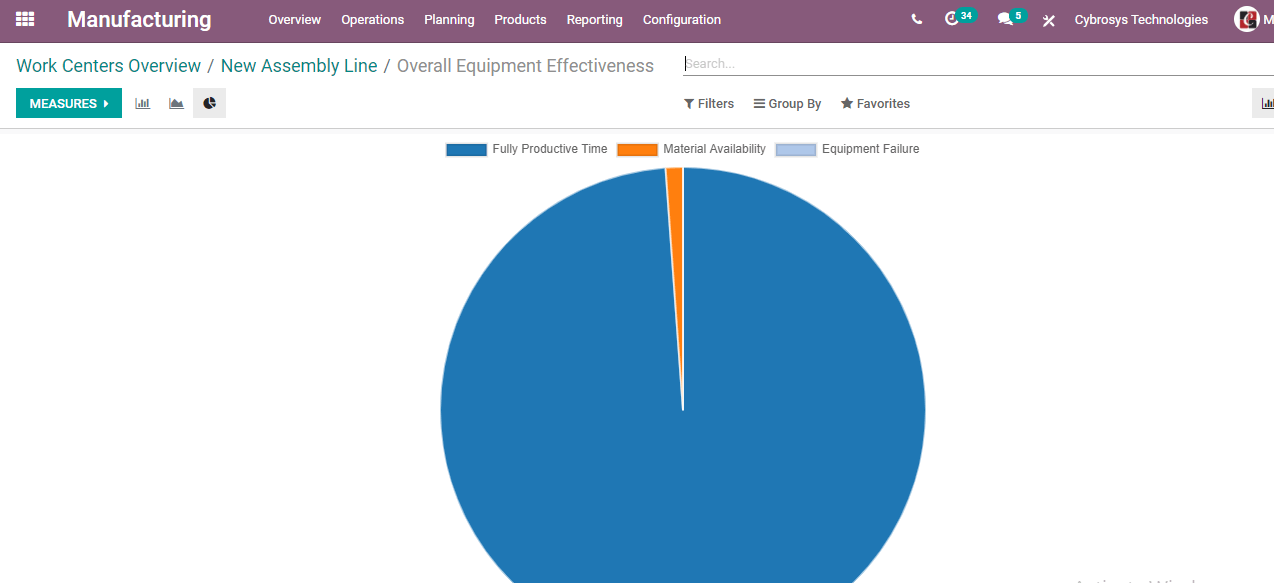

Clicking on it we will get the graphical image

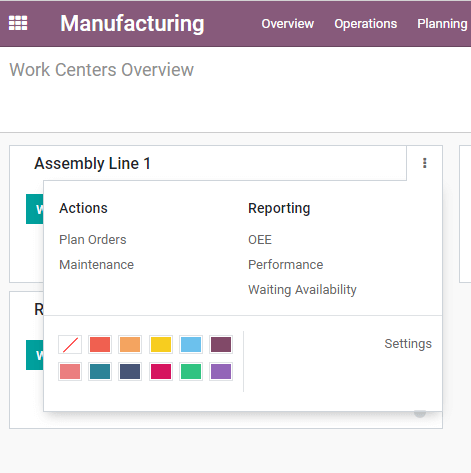

Now we can use the three dots on the right side of each workstation to view other information.

On clicking it we get a new window we can see Actions and Reporting

Below Actions, we can find Plan Orders and Maintenance.

Below Reporting, we can find OEE, Performance, Waiting Availability.

Let us see what this indicates

Plan orders

When we click on the option we get a page where we can find all Worker's orders to be launched.

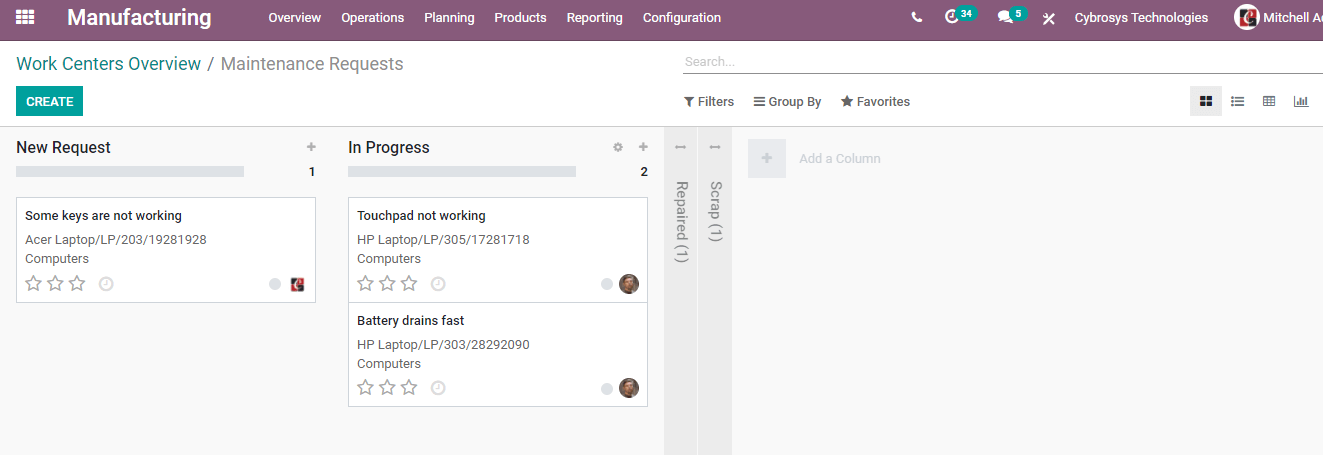

Maintenance

Here we can view the details of all maintenance requests raised from the work centers. We can also view the status of the maintenance request and create new requests here.

When it comes to reporting we can see the analysis of different facts.

OEE

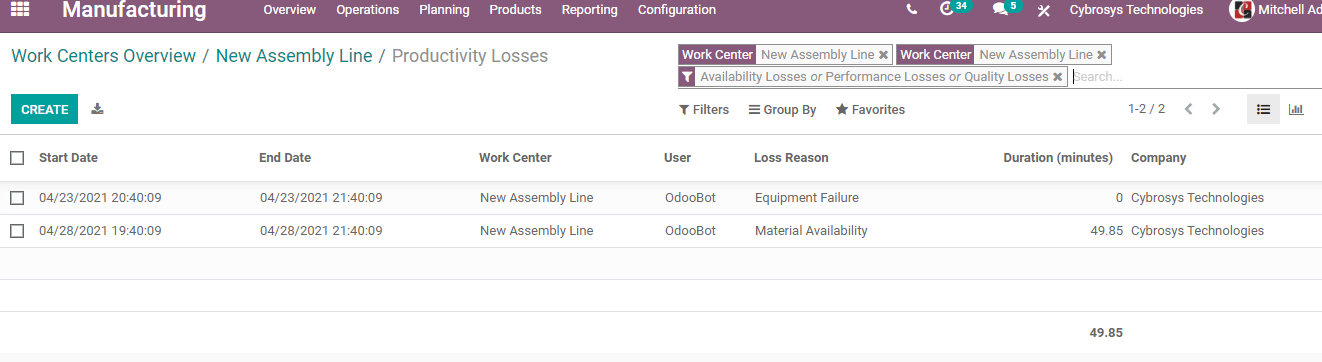

Here, we can find fully productive time, material availability, and equipment failure.

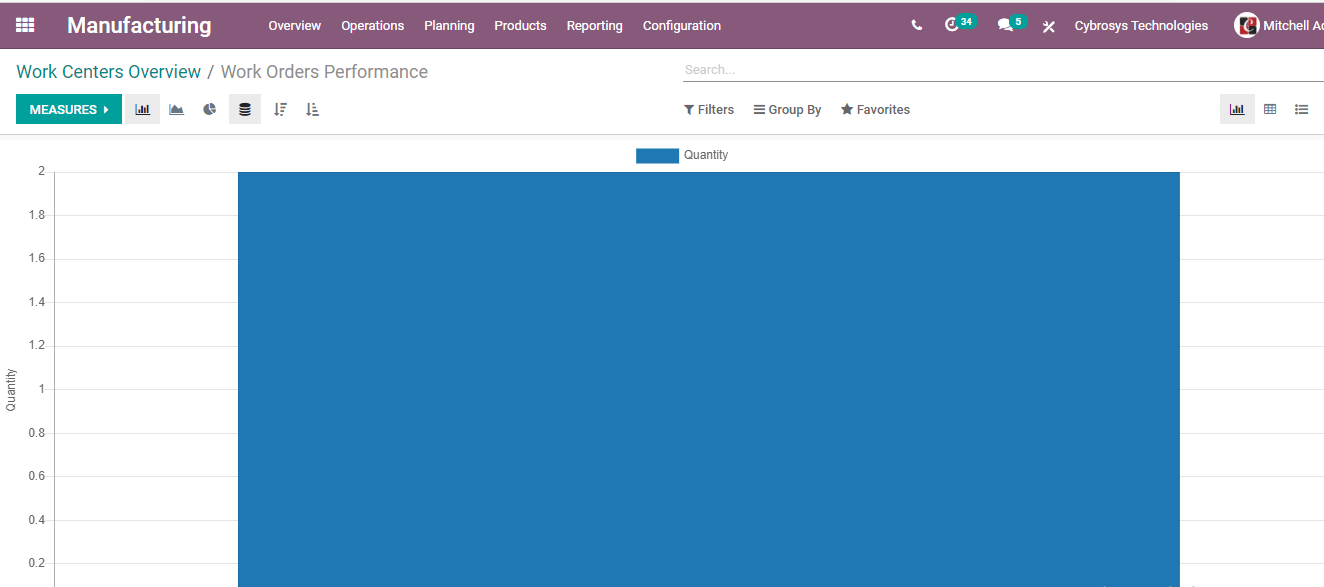

Performance

This helps us to examine the performance of the workstation based on different measures.

Waiting Availability

On clicking this we can view the work orders waiting for the availability of the work station.

Color

Using the color boxes we can change the color of our work center.

Settings

The settings option will help us to create new work centers.

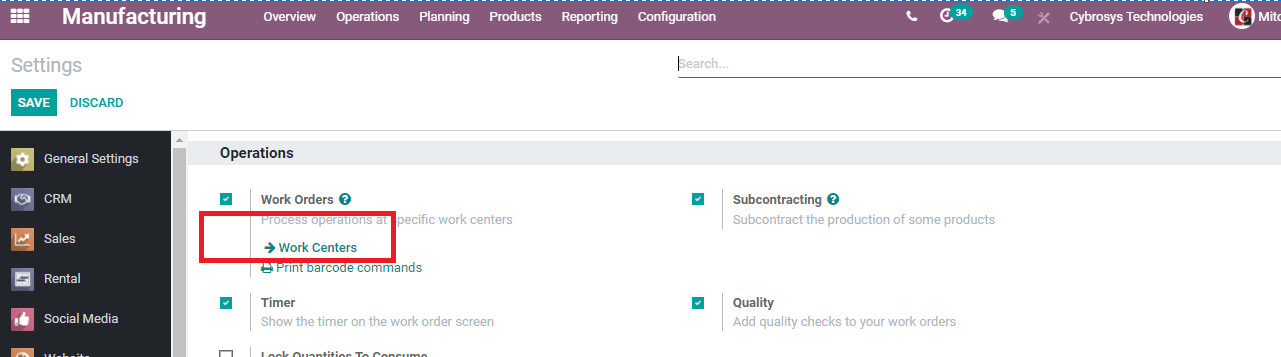

But before making use of this feature we have to go to Configuration and go to settings.

We have to enable Work Orders to enable Work Centers.

Save the changes and return to Overview and continue with the work center creation.

Create a new work center

Click Settings and then we get a new form for creating a work center

Here we have different fields

WorkCentre Name: The place where we can add the name of our new work center. I am adding the name as New Assembly Line.

Alternative Work Centers: The work center can be used to carry out the functions scheduled for this work center in case New Assembly line experiences any technical failure or work overload.

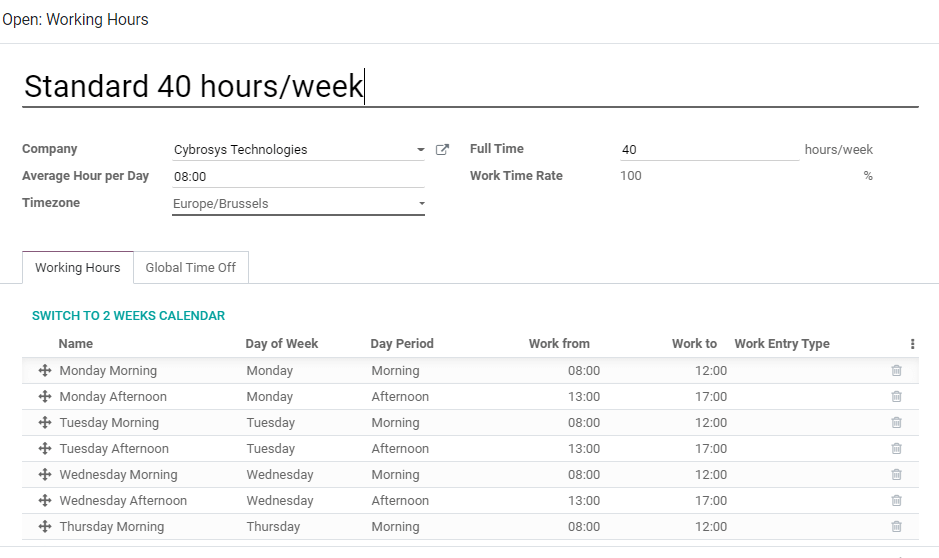

Working hours: Standard working time. On clicking the external link we get a page as given below.

Here we can set our timing and manage shifts easily.

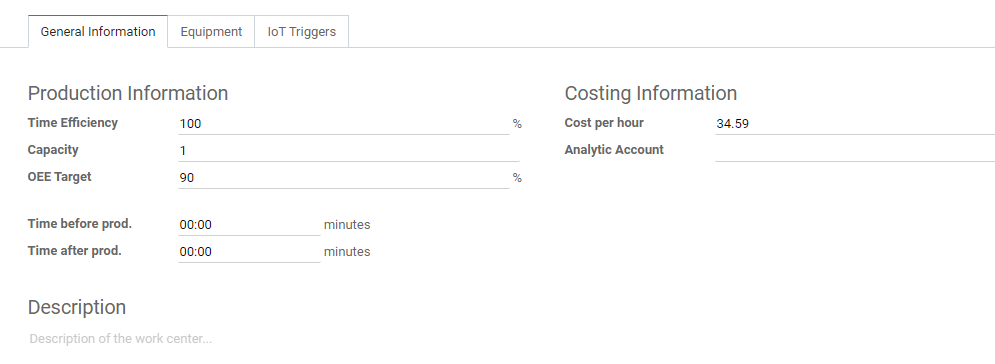

General information tab

Here we have production information including time efficiency, Capacity, OEE Target, etc. We can also set a Time Before Production. This helps us to provide the preparation time. WE can also add Time After Production or the time required to clean the work center after production.

Cost information helps us mention the cost per hour.

We can also add Analytic Account details here.

In the above image, we can view many icons.

OEE:

Loss hours: Time lost due to equipment failure or other reasons. We can change this or create new Productivity loss reasons

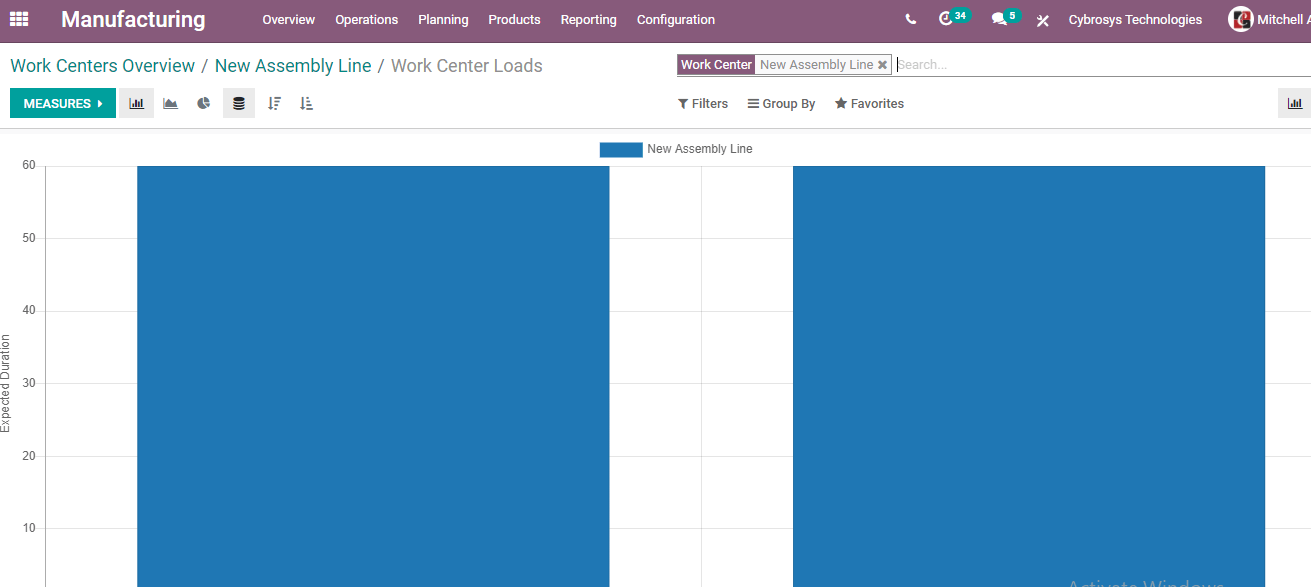

Load: We can find a load of our work center based on different measures

Performance: We can analyze the performance of the work center based on different measures.

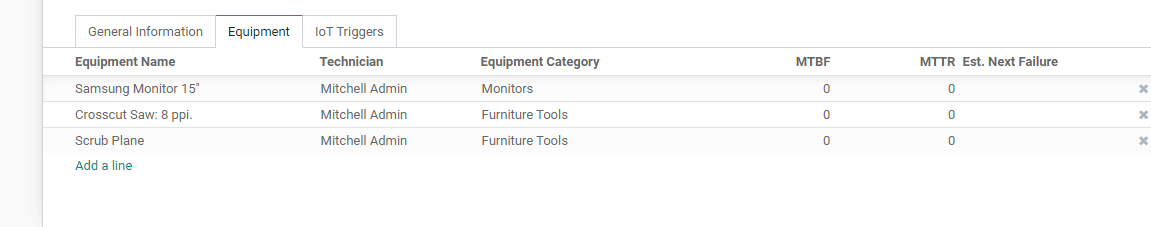

Equipment Tab: This tab enables us to attach equipment to our work center.

Here we can add equipment name, technician name, equipment category, MTBF (mean time between failure), etc.

This is how a new work center can be formed.

After the creation of a work center, we can make use of this work center for performing different tasks.

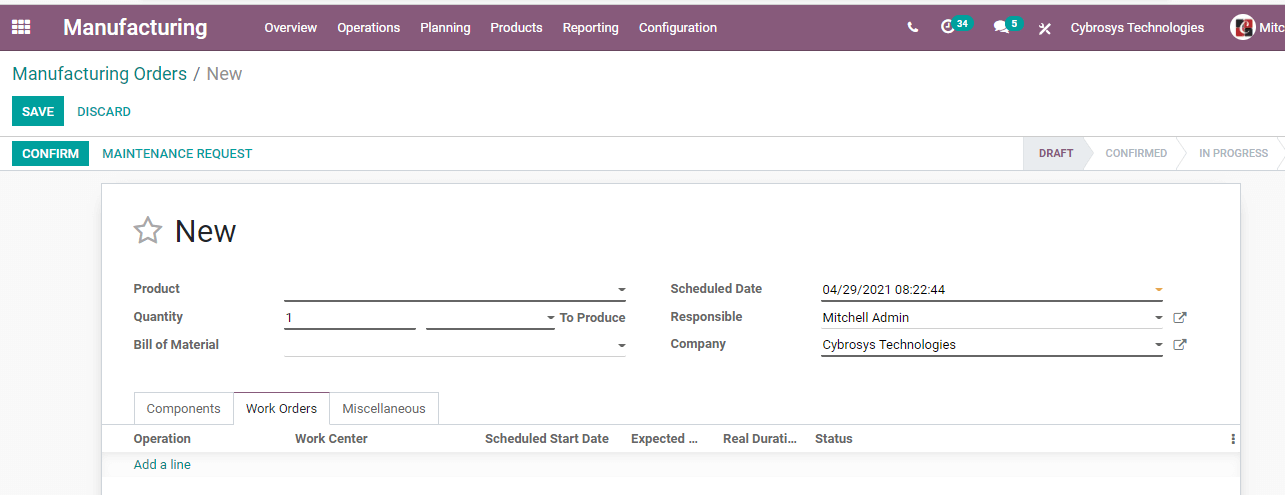

This can be done at Operations. When we create a manufacturing order we will have a Work Order tab where we can add the details of the work center.

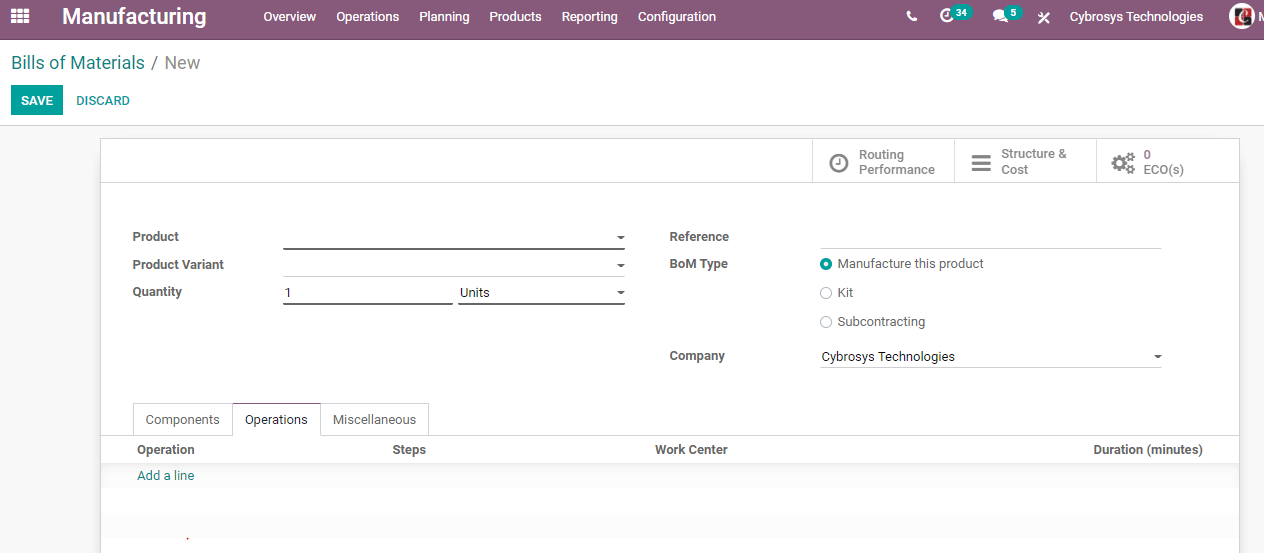

We can also add the work centers while creating a Bill of Materials

Here we can set operations if we want and there we can add the work center detail.

This is how we create and manage work centers using Odoo 14 Manufacturing.

Odoo 14 manufacturing is surely a tool that can ease your work center creation and management tasks. And help you to complete all tasks efficiently. Work center management will not be very difficult if you are using Odoo. You can manage any number of work centers with this tool.