Managing the WorkCentre in the manufacturing plant of a company should be precisely planned as executed since a disruption in the plan can cause catastrophic losses to the company in terms of money and commodities. The work centers for each process should be properly planned and allocated for the smooth process. The need for substitute or alternative WorkCentre’s is always needed since at some instances one of them may detect certain faults and may become non-functional. The alternate work center situation can also be used when the load on one is much more and needs to be distributed equally.

The alternate work center can be set up in the Odoo platform allowing the users to set up alternate work center sites for the same manufacturing operation. The alternate work centers in Odoo allow the users to create various work centers for the same product being manufactured. A single manufacturing line can be used for multiple products to be manufactured. The ability to customize the various work center sites allows the user to run the manufacturing operations of the company uninterrupted.

This blog will describe how to create a work center? Assign an alternative work center? How alternative work centers settings operate in a manufacturing order?

How to create a work center

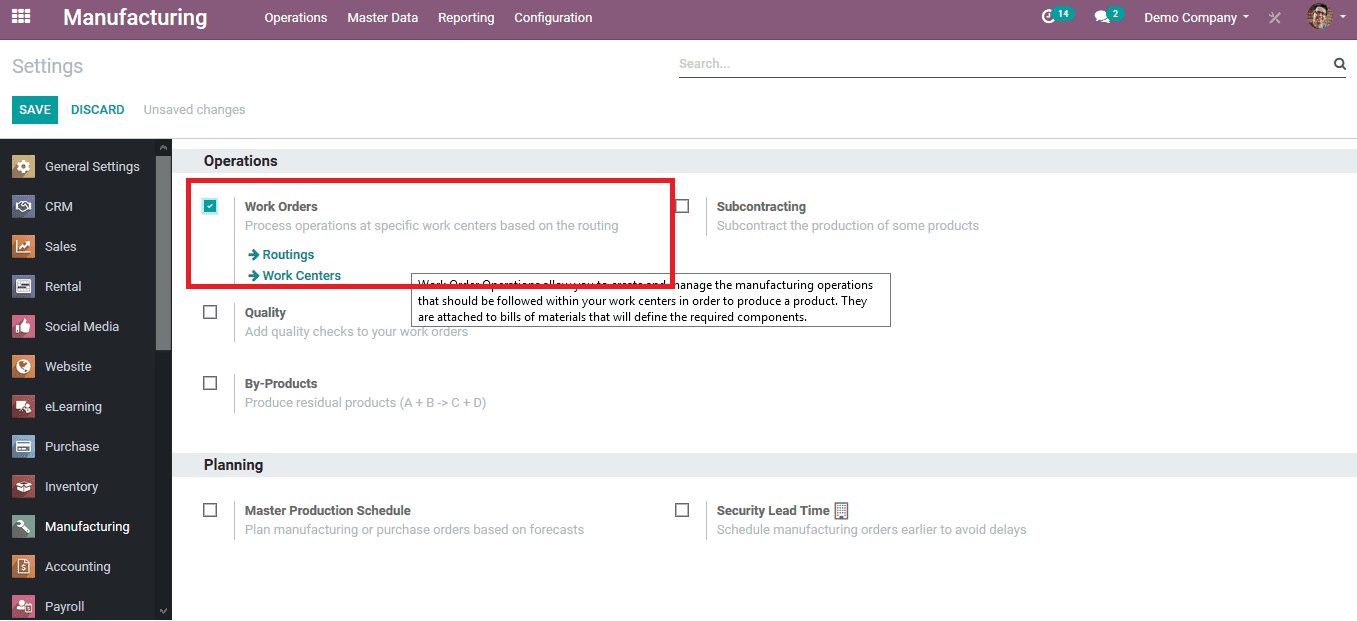

To create multiple worksites for a project the user should initially enable the work orders option in the settings menu of the manufacturing module. Upon enabling this option the user can create the work center and routings and allocate them to various processes.

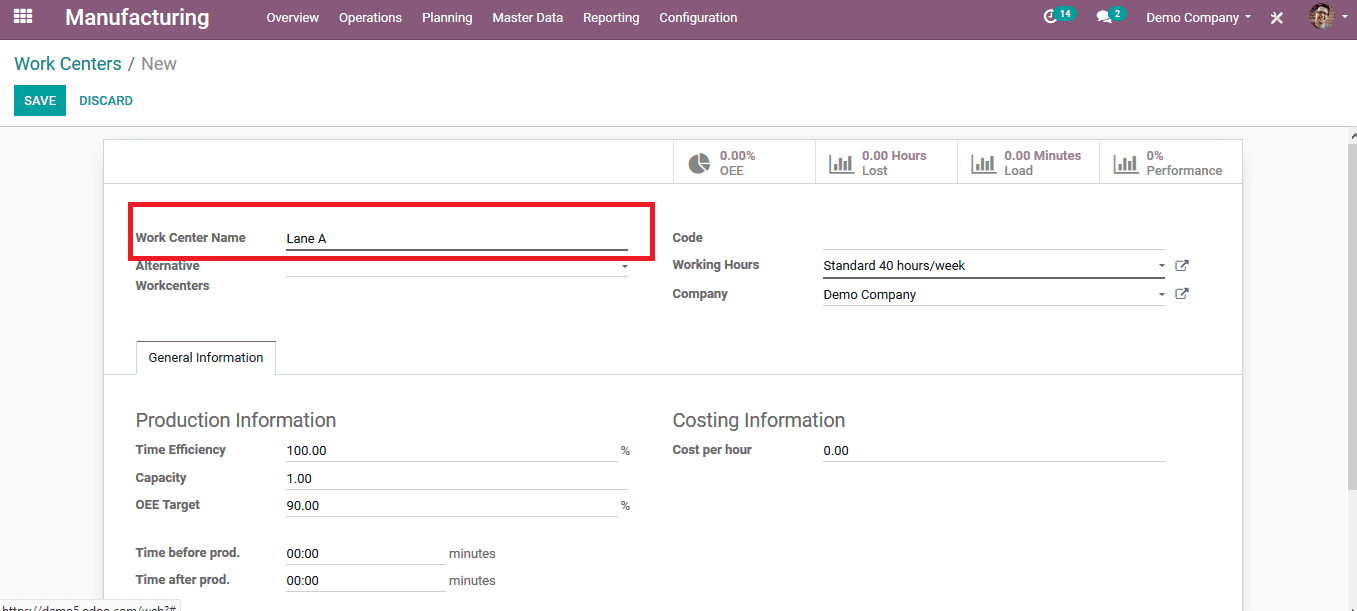

Upon enabling the work center option the user can create work centers from the work center menu available in the master data dashboard of the manufacturing module. The user can create or edit the work centers available in the menu, upon choosing to create a work center the menu shown below opens up where the user can configure the work center operations.

To illustrate how the alternative work center operation works an example can be used by creating two work centers lane a and lane b, The work center name is provided and the capacity of the work center is set to one.

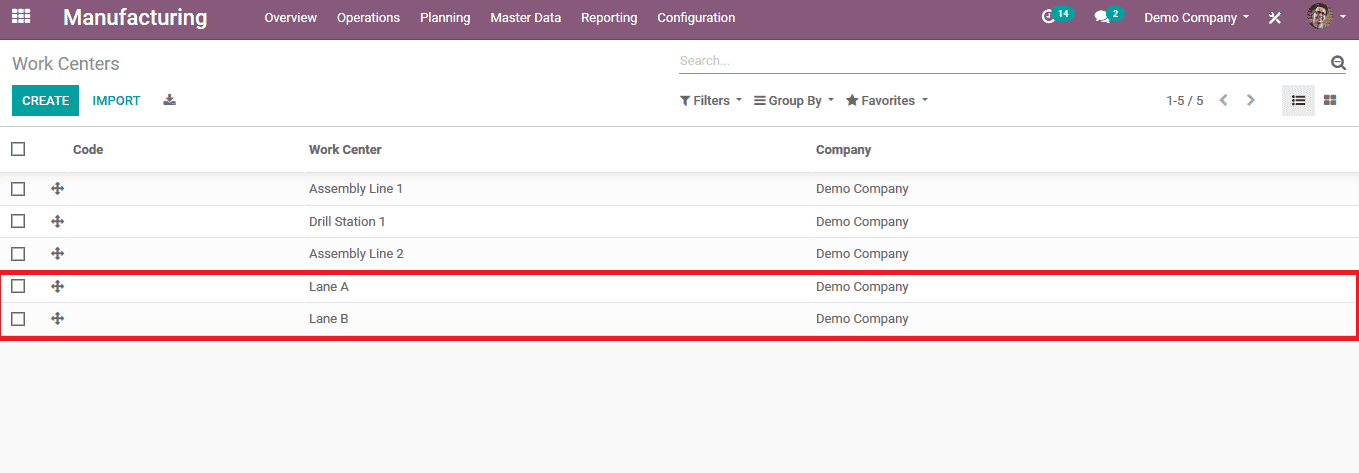

On the work center dashboard, the user can view the work centers created lane a and lane b.

Assign an alternative work center

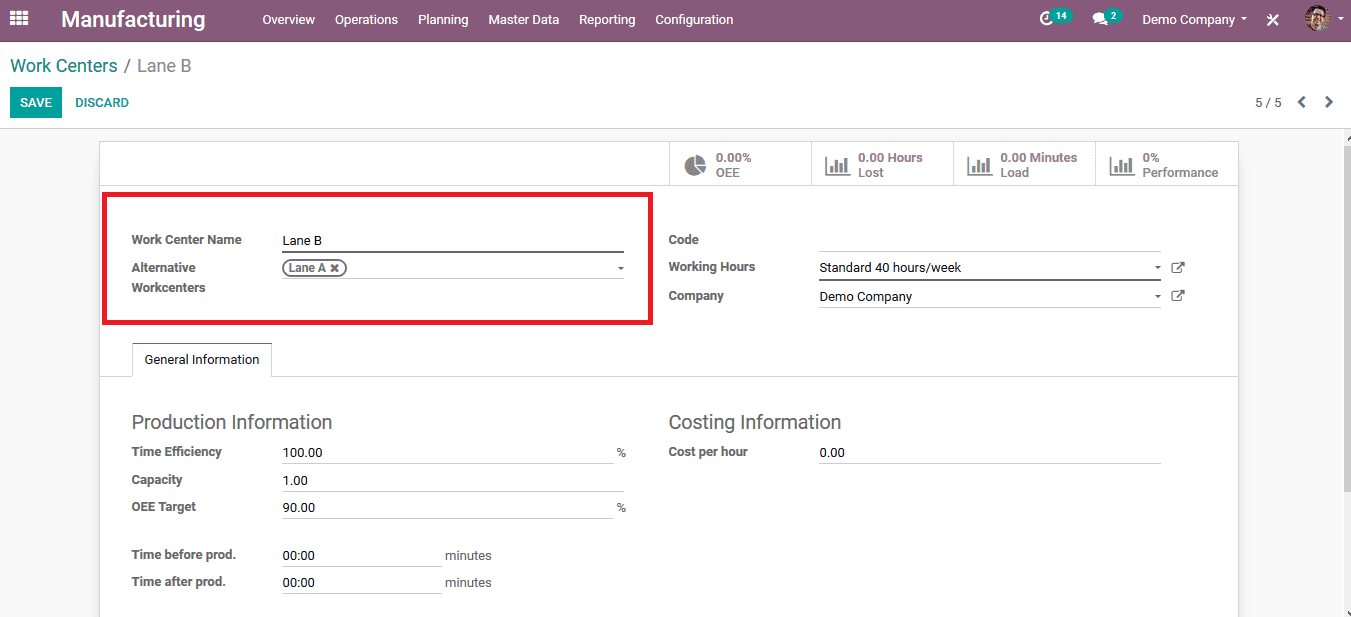

Upon creating the two work centers the user can now assign the alternative work centers. For the work center lane b alternative work center lane a is assigned and vice versa is done for lane a. It can be done by selecting a work center and selecting to edit the details.

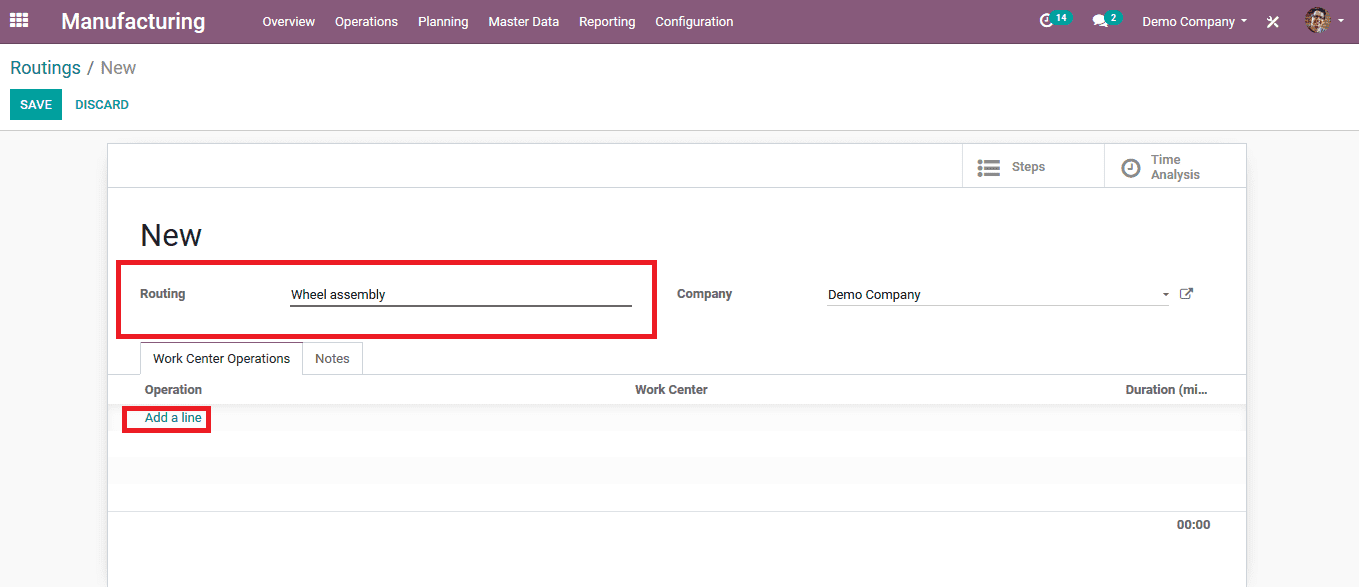

To assign a work center to a product initially it should be assigned to routing to specify the operation being conducted. Let's create the routing operations to be a wheel assembly and an operation can be created in the routing by adding a line in the operation menu.

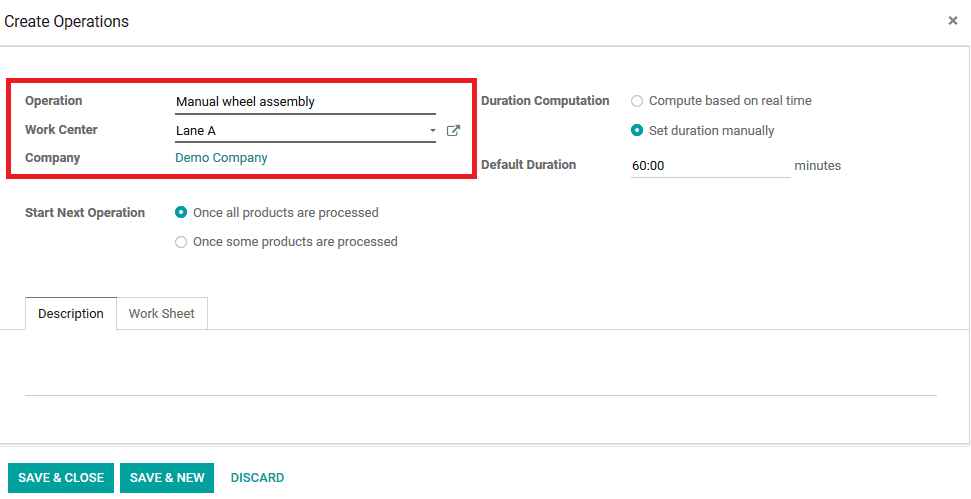

In the operation menu, the operation can be set as the manual wheel assembly and the work center can be assigned as lane a to depict the example. The next operation's beginning schedule can be assigned as once all the products are being processed or once some products are processed. The duration of computation can be set based on the real-time or set the duration manually.

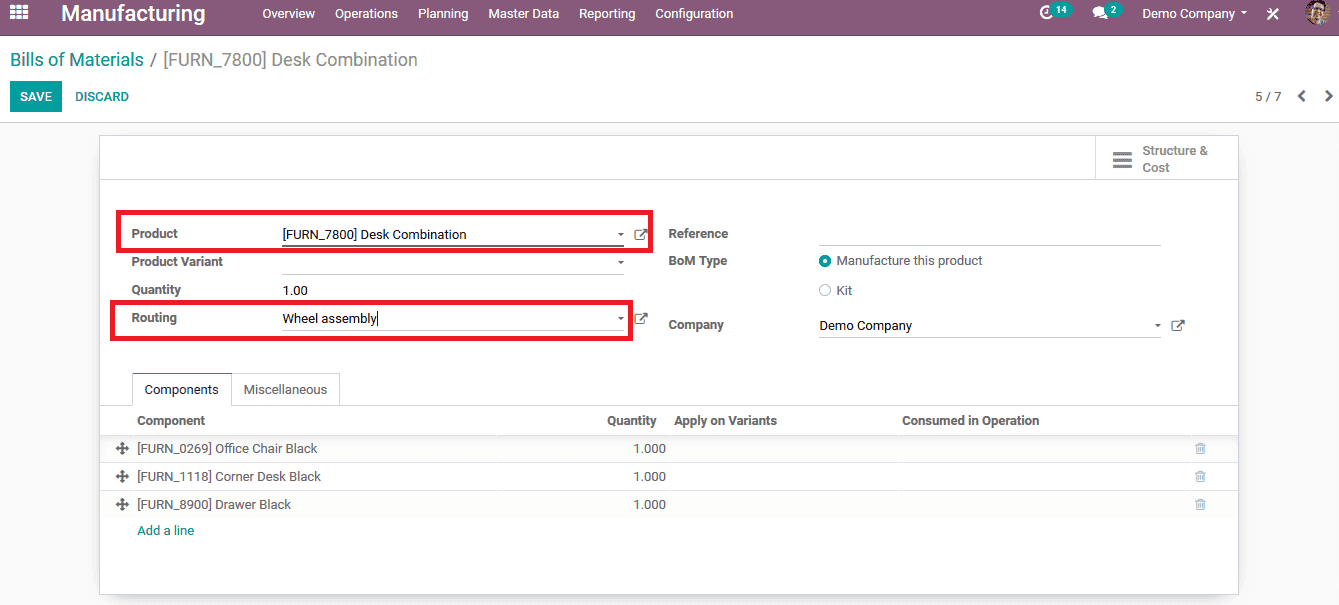

On the routings being set and saved, it can be assigned to the product which should be manufactured. The user can assign the routings in the bill of materials menu of the product. To do so choose the product from the bill of materials menu and assign the routing and the products can be assigned and changed.

How alternative work centers settings operate in a manufacturing order?

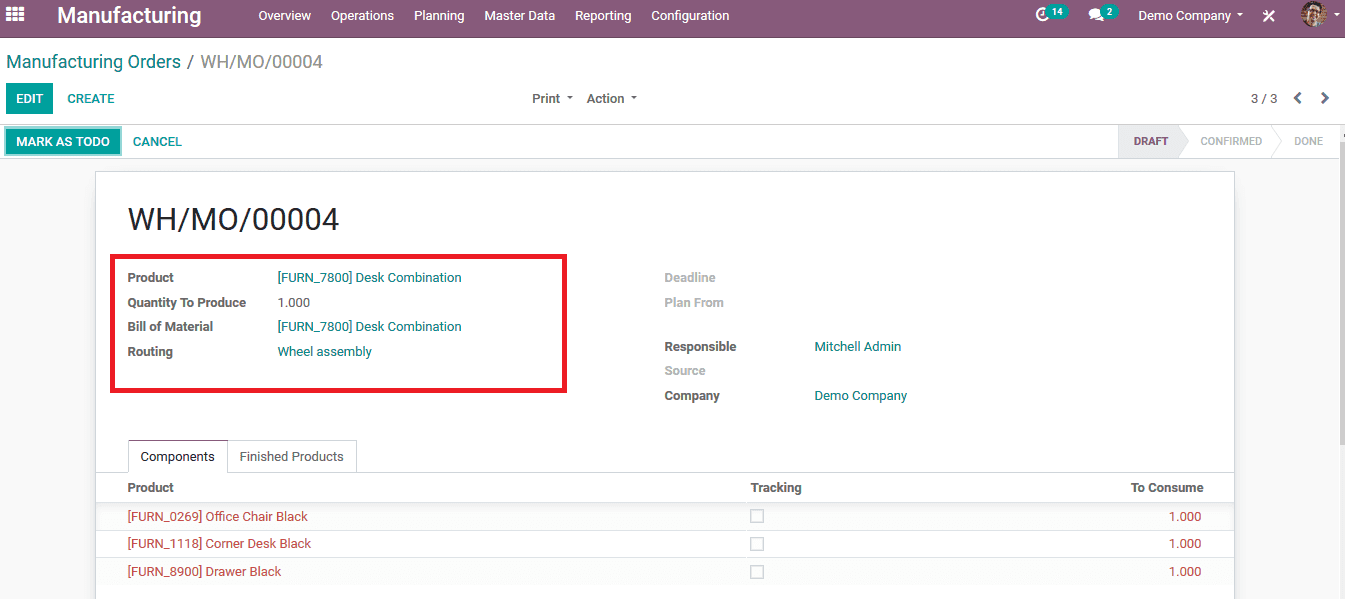

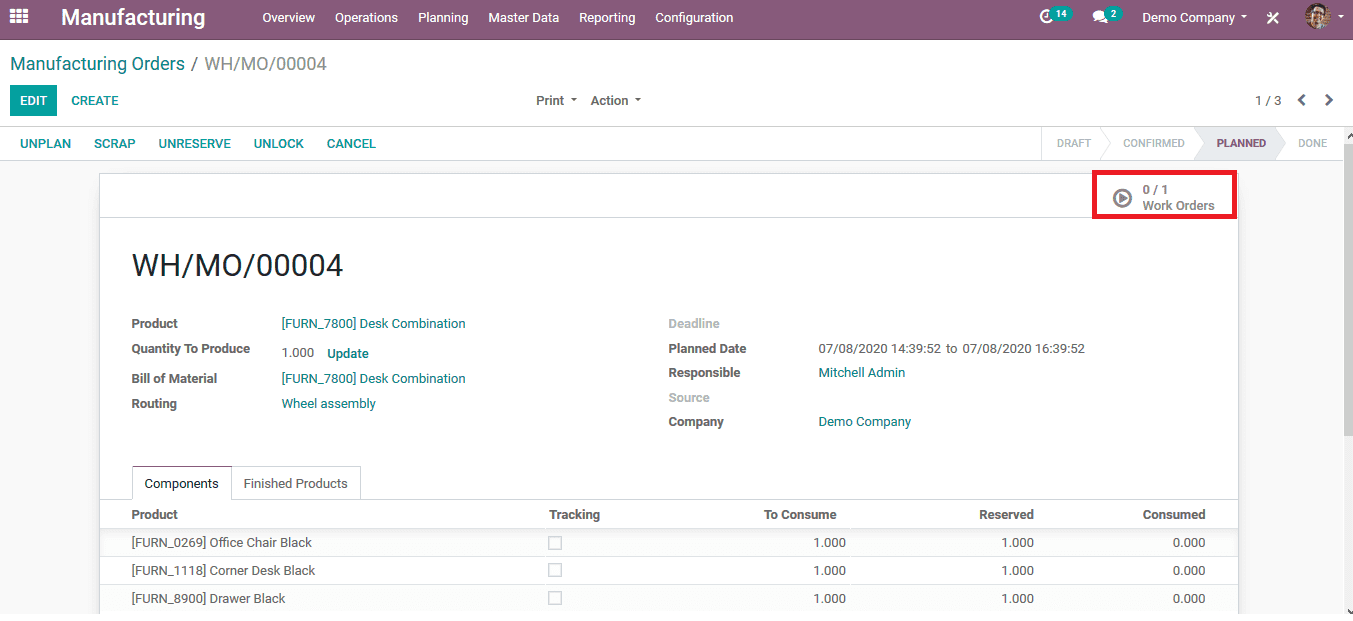

As the bill of materials is assigned and the routings are established the user can now manufacture the product, by creating a manufacturing order. Manufacturing orders can be created in the manufacturing orders menu of the module and by selecting to create a new one option. After providing the details in the descriptions needed the user can opt for the option to mark as todo and the manufacturing is confirmed.

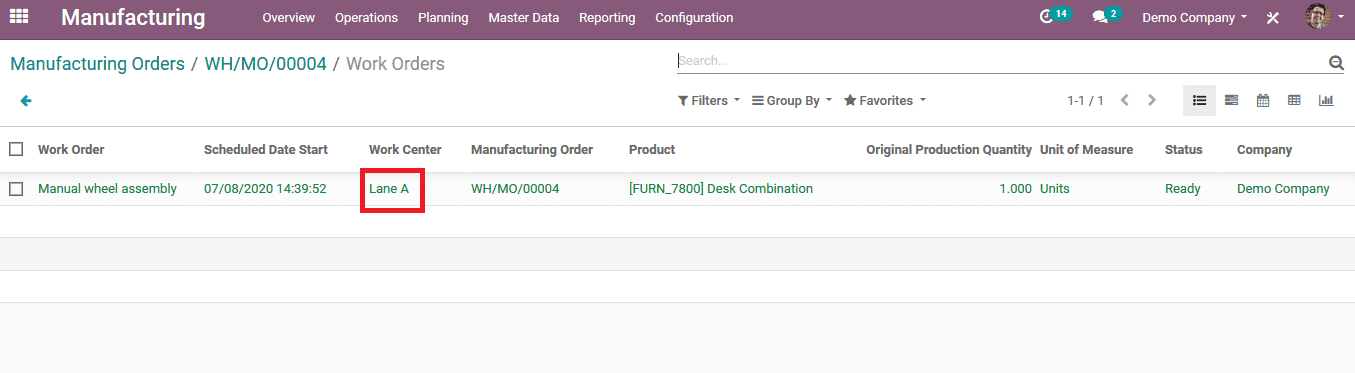

Upon manufacturing order confirmation the user can view the work centers on which the manufacturing is done by selecting the work center menu options available.

As the user can view that the work center operation of the manual wheel assembly is done on lane a and the manufacturing is in progress.

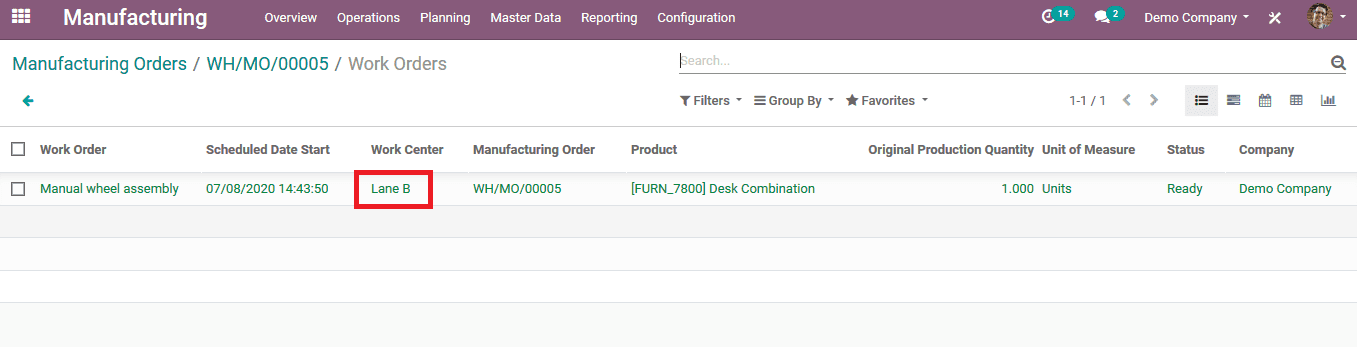

Now when the user or an employee tries to create a new manufacturing order in the platform in the same manner by creating a manufacturing order then by allocating the same product which has been manufactured previously. The user can view that the work center for the new order will be automatically allocated to a different line i.e. lane b since the lane a is performing the earlier order.

The lane b is chosen for the manufacturing process since the alternative work center for the lane a is been assigned as lane b while creating a manufacturing work center. Since the capacity of the lane a is limited to one which can be modified according to the physical capacities of the plant. The next manufacturing order is automatically assigned to the alternative manufacturing lane.

Check out the configuration of Work Center in Odoo 13