The lead time is the period of time between when an order is placed to when the products are delivered. This lead time helps the organization become more productive by cutting down on operational delays. Odoo offers three different lead times. Lead times for manufacturing, delivery, and customers.

The time needed to deliver the requested goods to the customer is known as the customer lead time. Delivery lead time, sometimes referred to as Vendor lead time, is the amount of time a certain vendor has to deliver a product to a business after receiving an order. The amount of time needed by an organization to finish the production of a product is known as the manufacturing lead time.

Let's examine a hypothetical situation that demonstrates how these 3 lead times interact with one another during a single operation.

There is a product called Cotton that can be stored, but it is now out of supply. Upon a customer's request, the product will be manufactured and sent to the consumer. Cotton Fibre is a substance that is used in the production of cotton. The component will only be bought for production purposes; it won't be kept in stock. If a sale order is issued, in such circumstances for the cotton product, delivery only occurs once product manufacturing is complete. The user initially purchases the production component to begin manufacturing.

Let's set the products up for the procedure.

Configure Products

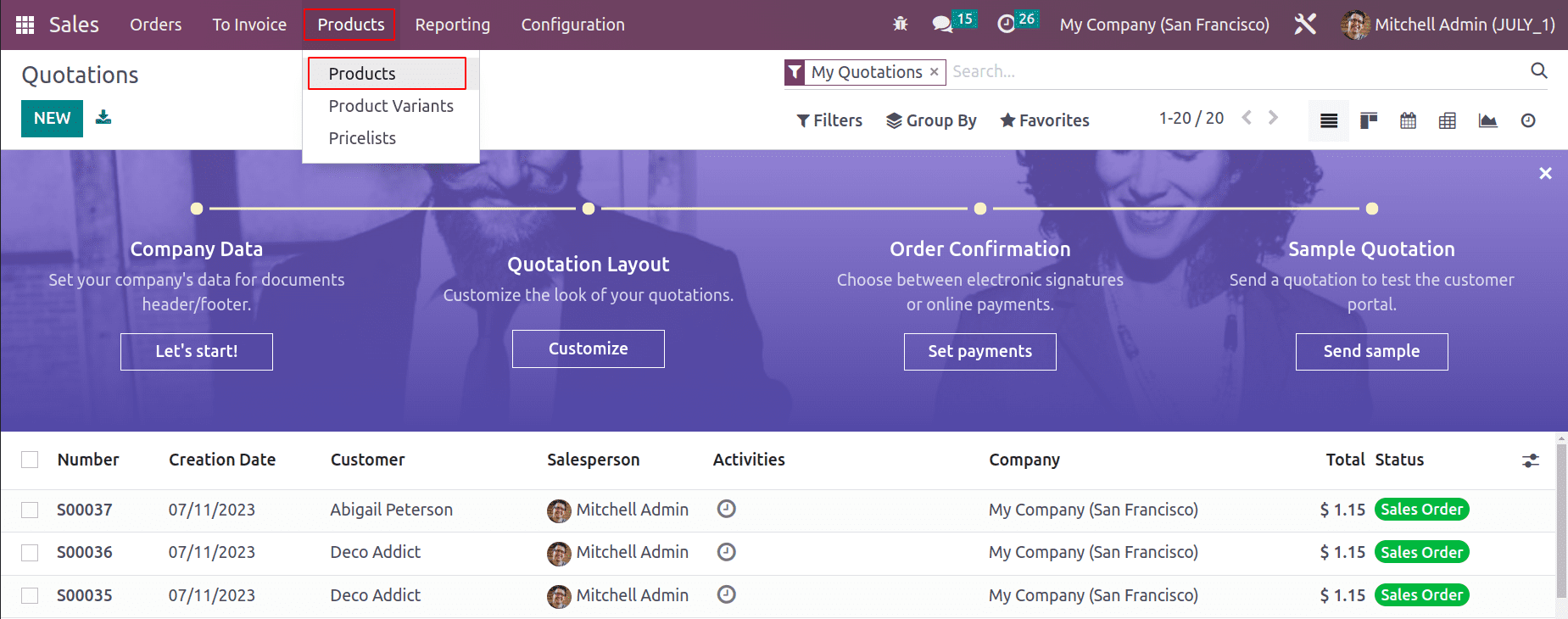

Visit the product tab and select the New button to start creating a new product. Either the Manufacturing or the Sales module can be used to configure items.

Cotton is the first item on this list. Build a cotton-named product. Users can set the Manufacturing Lead Time and Customer Lead Time under the Inventory tab. Manufacturing and Replenish on Order (MTO) routes should be allowed. Here the Manufacturing Lead Time is set as 5 Days and the Customer Lead Time as 15 days.

This means it takes 15 days to deliver the product to the customer and takes 5 days to manufacture the product. So this manufacturing we are done within 15 days of customer lead time.

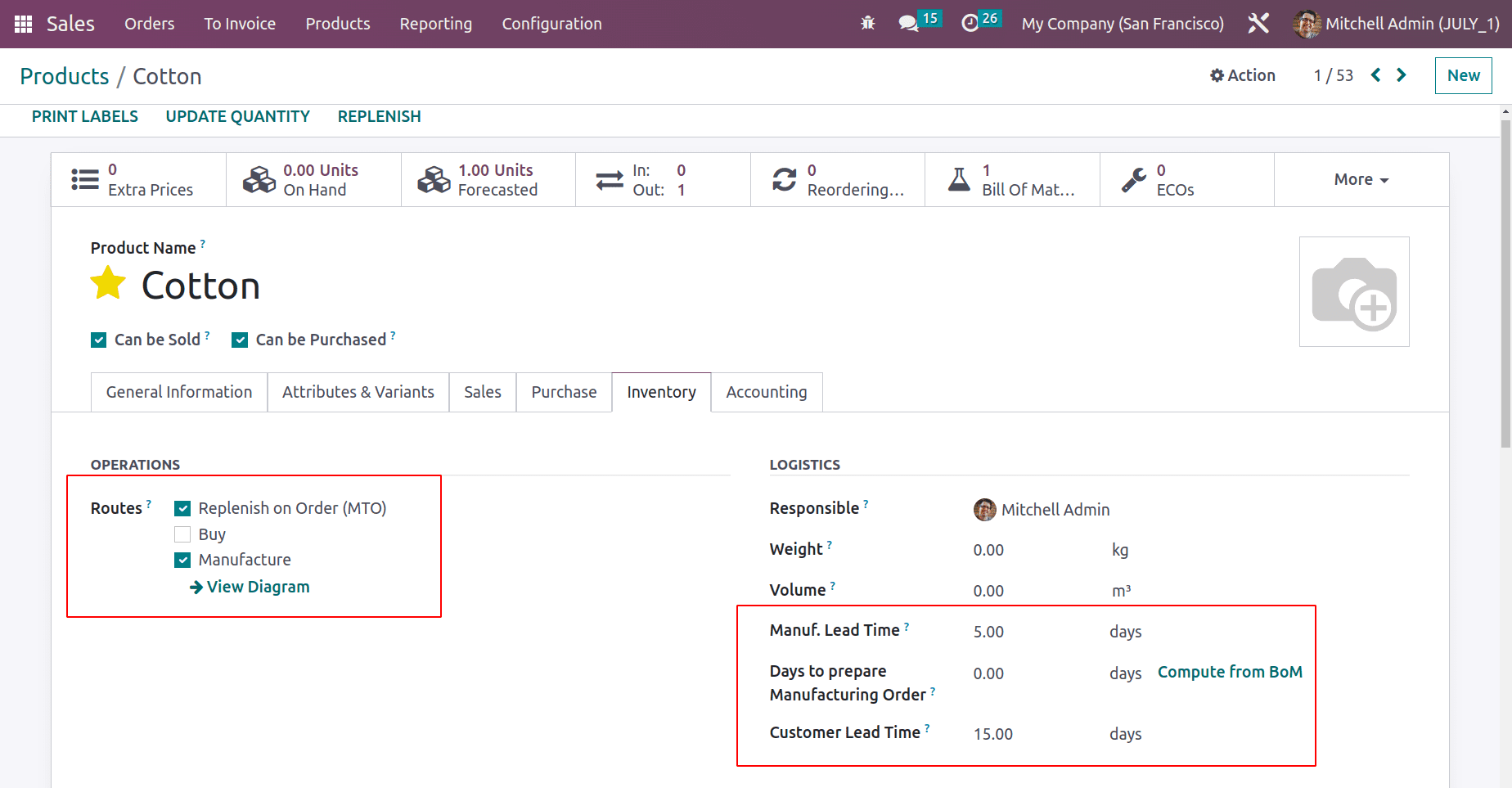

The second product is Cotton Fiber, which can be stored and utilized as a raw material in manufacturing. This component can only be purchased when it is being manufactured and is not presently in stock. Enable Replenish on order(MTO) and Buy, the routes from the Inventory tab, in this case, the product purchase, are active, and replenishment is based on the order. That’s why route ‘Replenish on order (MTO)’ is enabled.

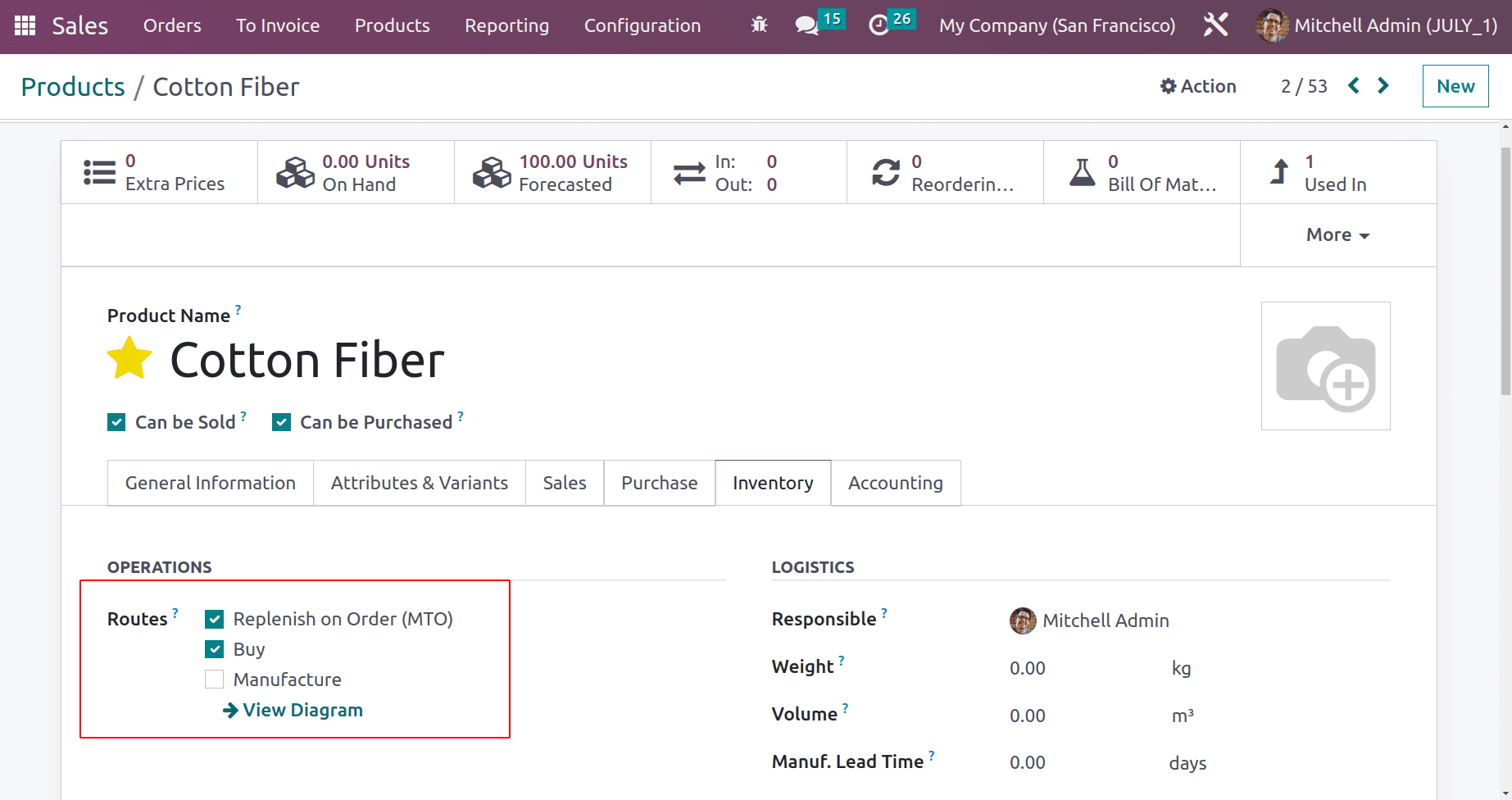

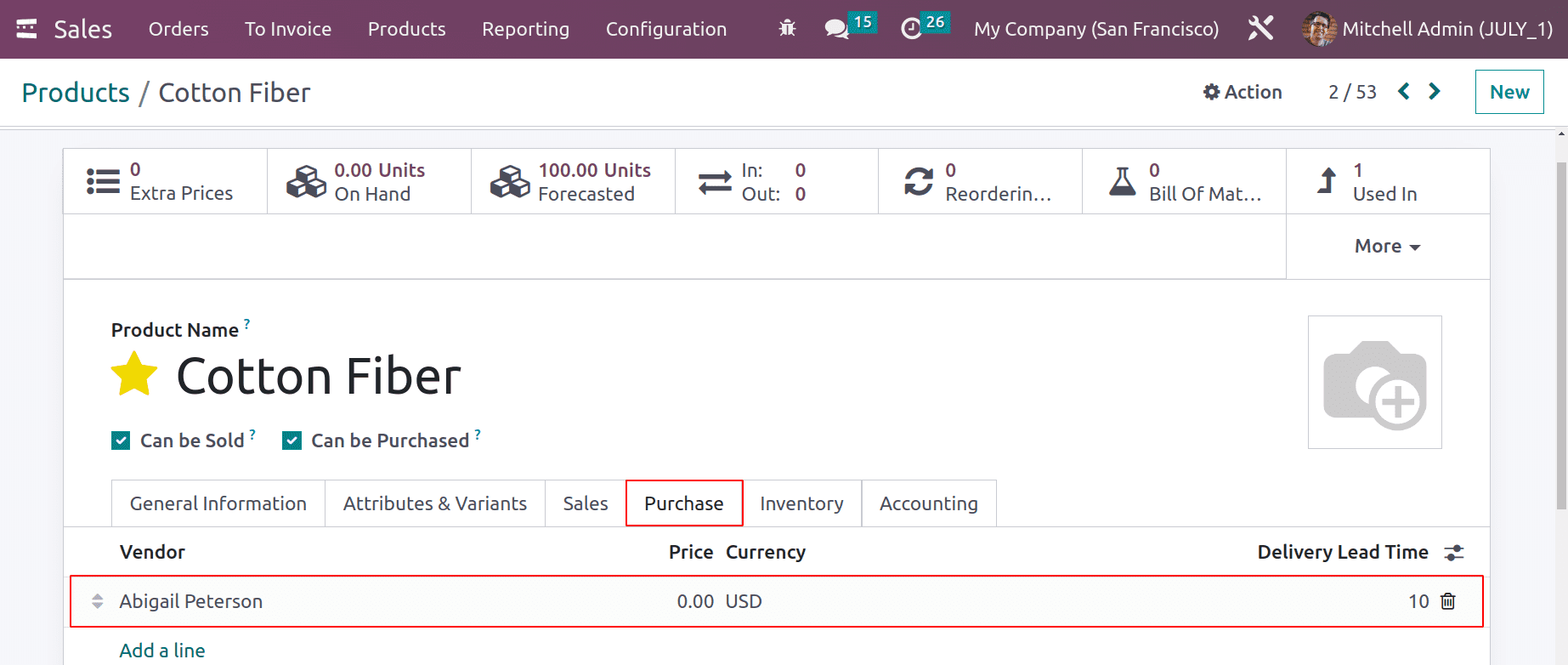

Also, it must be stated from which vendor the product is purchased. Mention the vendor's name and the lead time for delivery inside the product's Purchase tab. The vendor in this case is Abigail Peterson, and it takes the company 10 days to get the goods from the vendor.

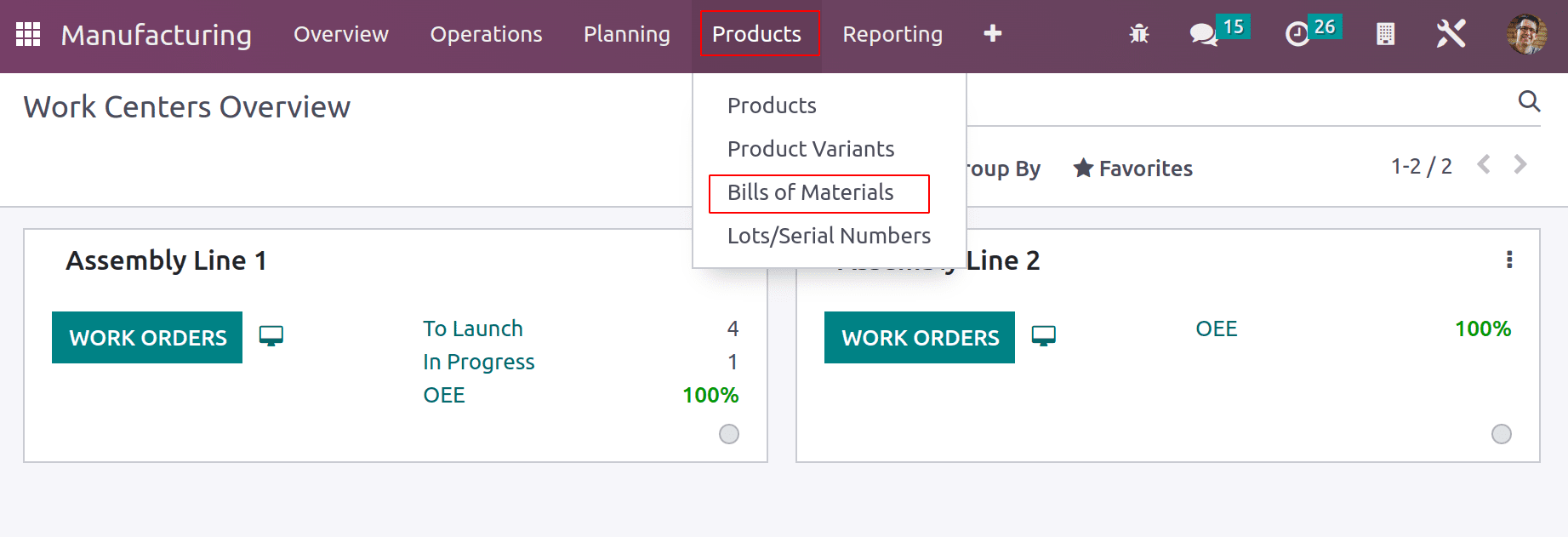

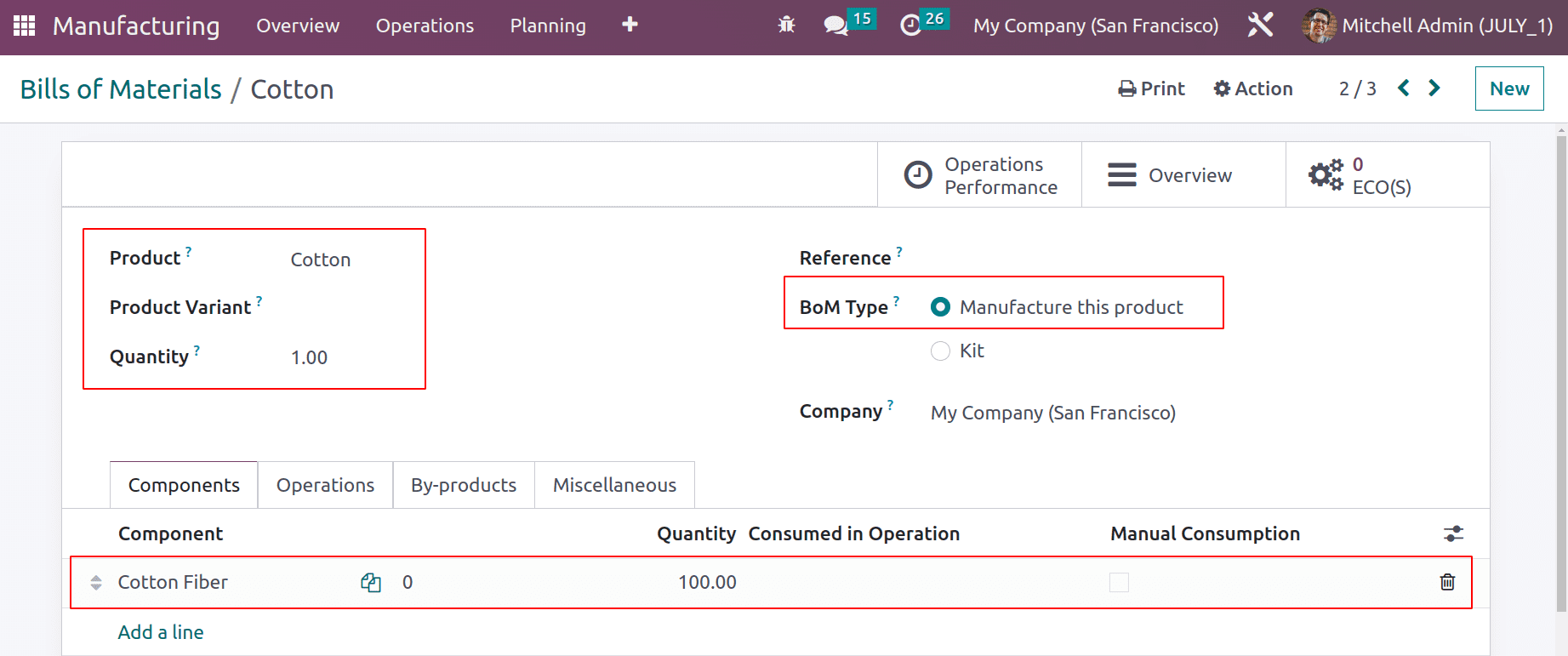

Configure Bill of Material

When the sale is confirmed, Cotton will start manufacturing the goods. A bill of materials is created before the production of a product. So go to the manufacturing module and select Bill of Materials under the Product header. Start creating new.

Make a bill of materials with cotton as the product and Manufacture this Product as the BoM Type. Here, Cotton Fibre, a previously created product, is used as a component. The production operation should be added. Save this after including all the details.

Let's now begin the procedure. As previously stated, if a customer orders the product, the user creates a production process, and to begin manufacturing, a purchase order is generated for the component.

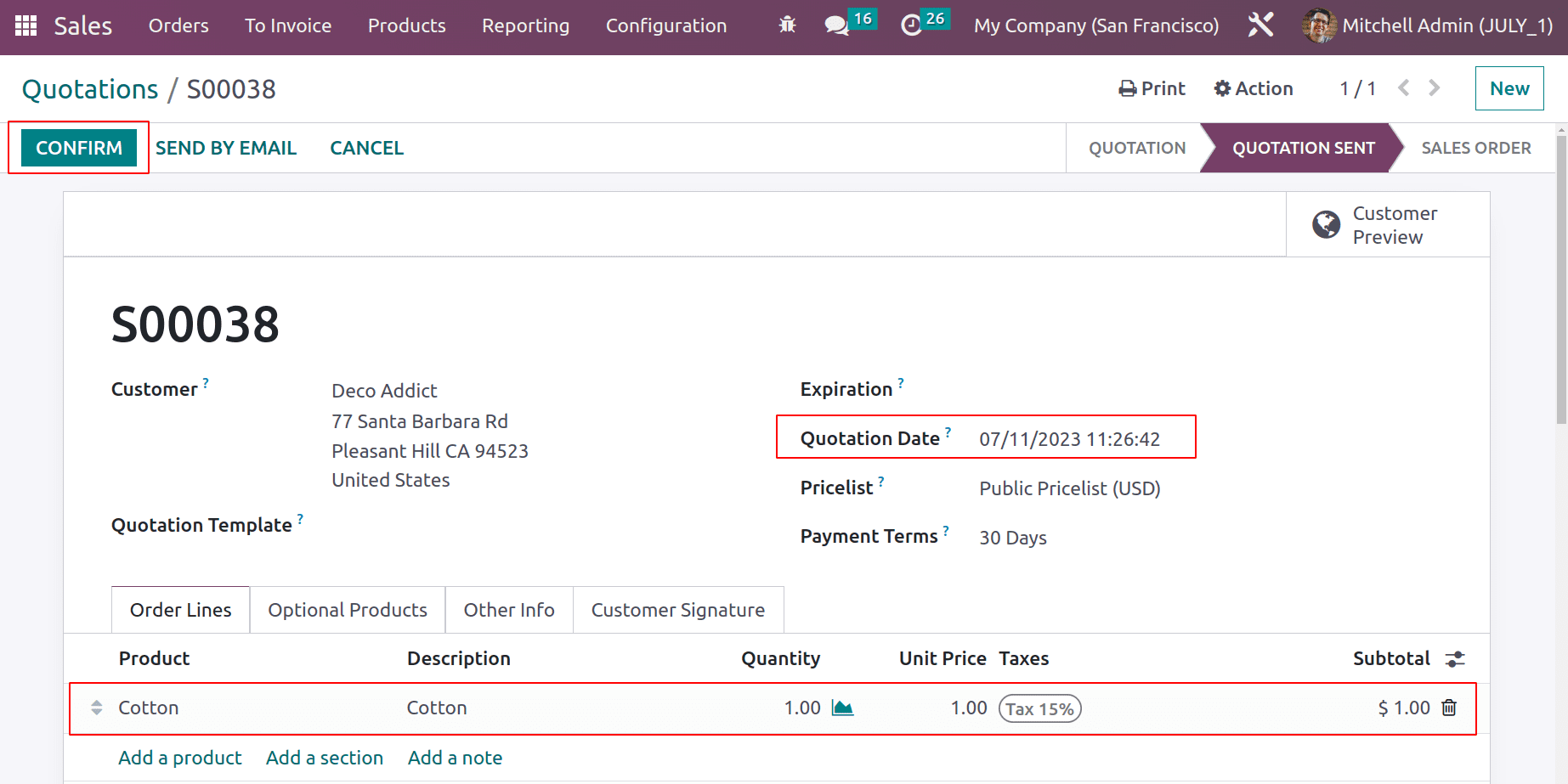

From the sales module, generate a sales quotation. Include the customer in the quotation. Add the product to the order line. Here is the quote that was written on July 11.

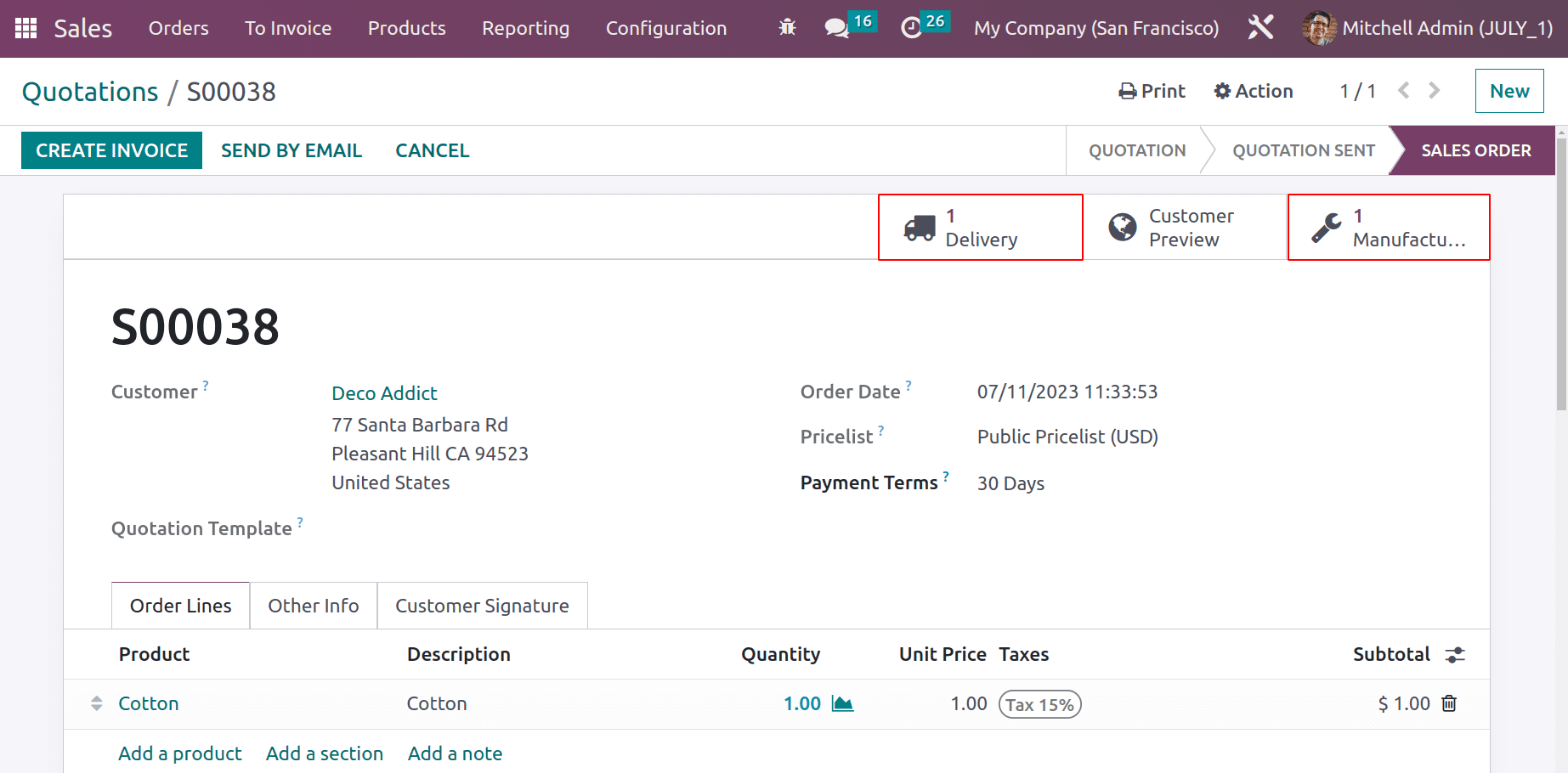

A customer lead time was established inside the product at 15 days. It indicates that the product won't arrive until 15 days have passed since the quotation was created. Verify the quotation. There are two smart tabs displayed thereafter confirmation. One relates to deliveries, and the other to manufacturing orders.

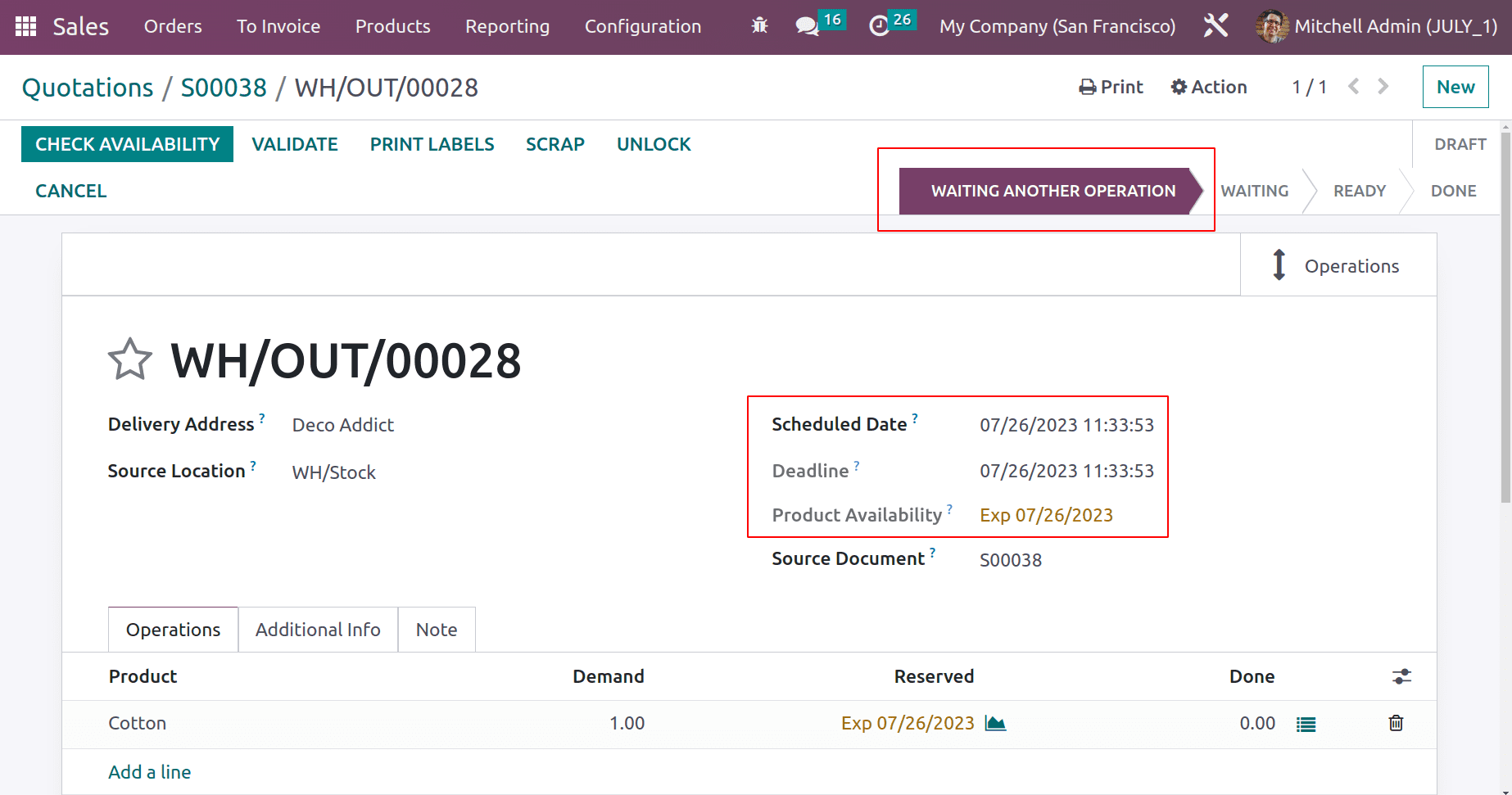

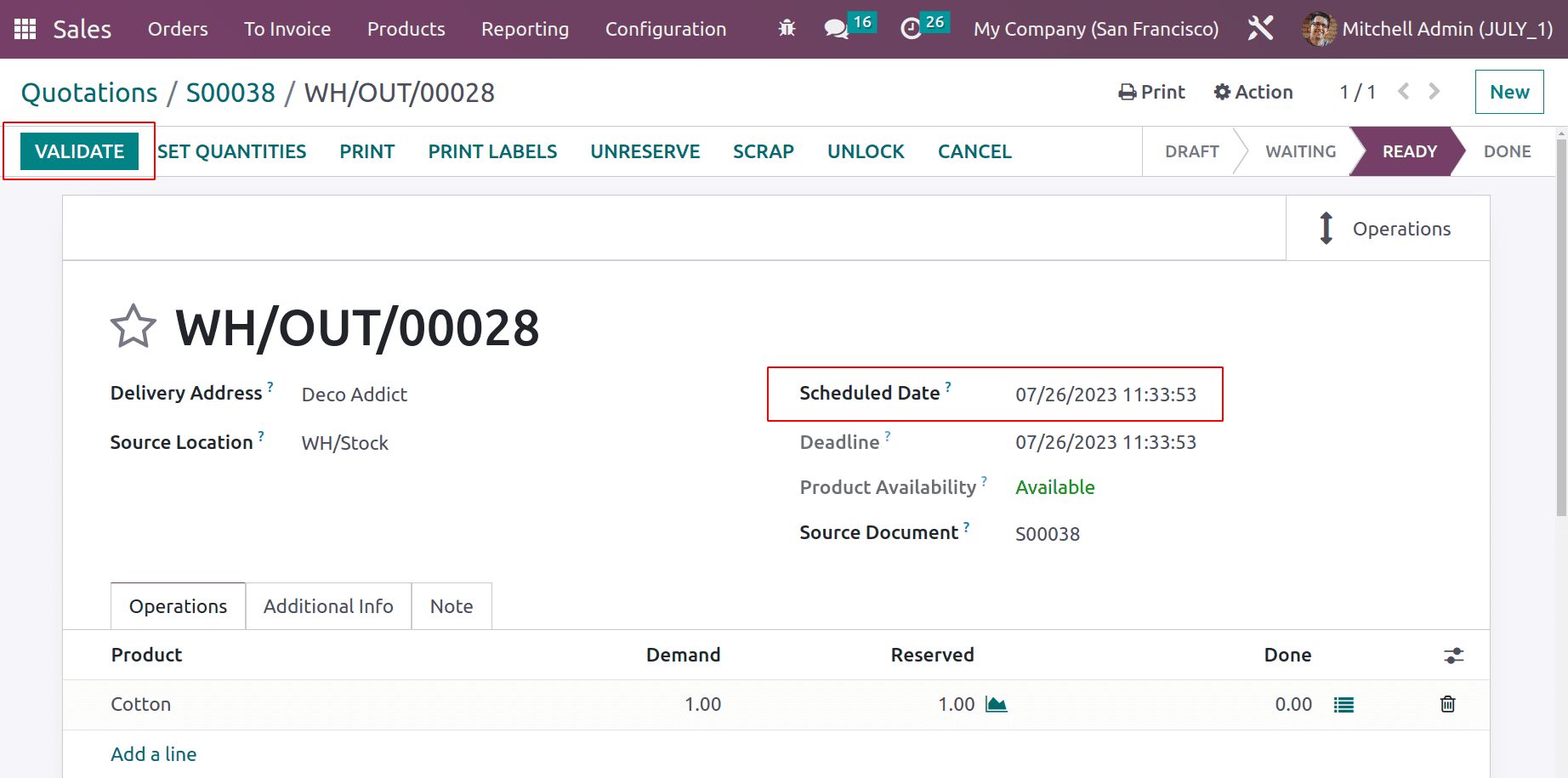

Let's first check the delivery status. Therefore choose the Delivery tab to do it. The delivery date in this instance is July 26th, or 15 days after the order date. However, the delivery is currently awaiting the completion of another operation. Upon completion of the manufacturing procedure, the delivery will be ready.

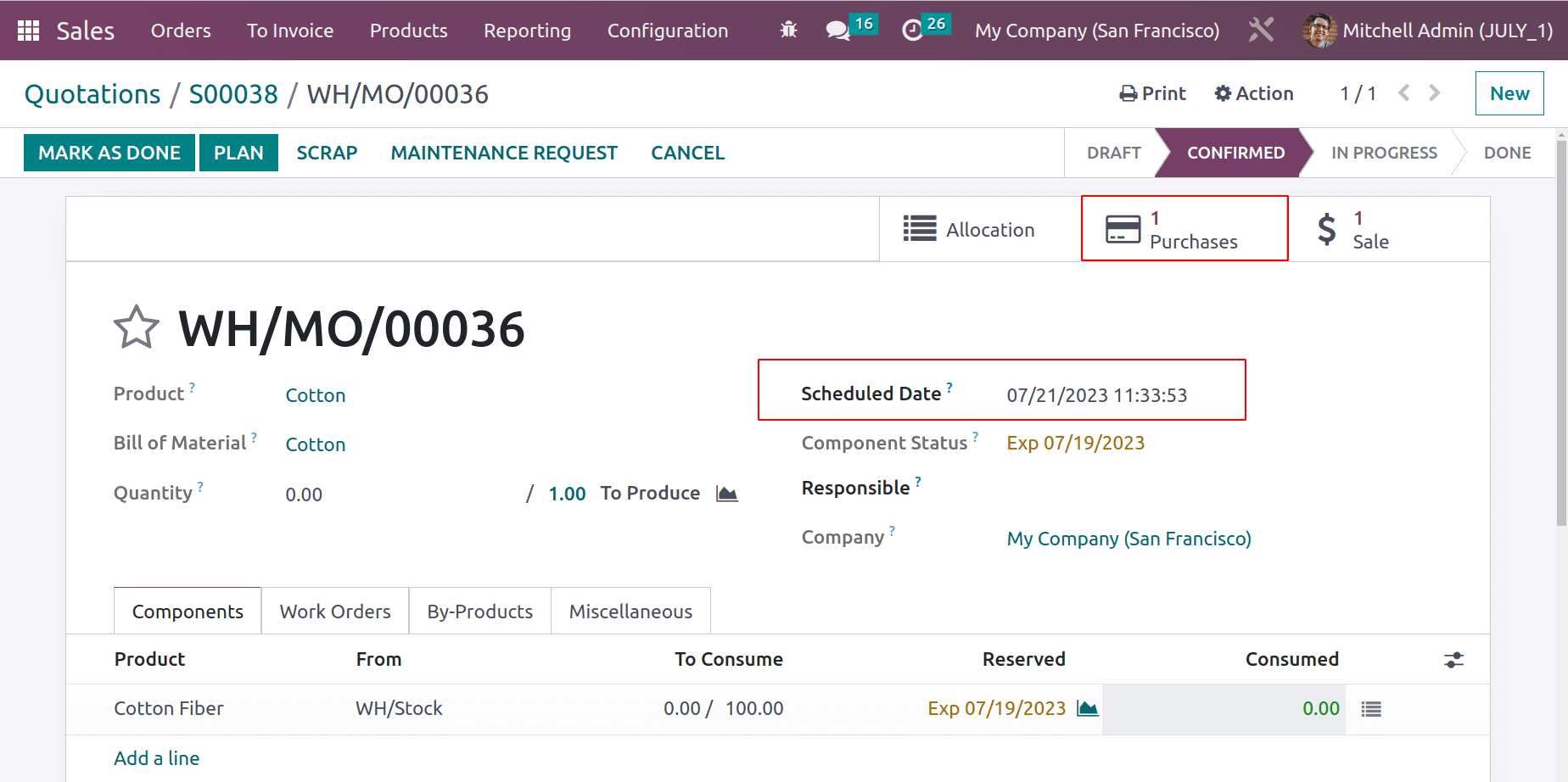

So go back to the sales order and open the second smart tab manufacturing. The manufacturing is scheduled for July 21st. It is because the goods delivery is set to 26th July. Delivery happens just after completing the manufacture. Therefore, the item must be available for sale on July 26. However, in this case, the manufacturing lead time is set at 5 days, meaning the production process will take that long to finish. Therefore on July 21st, they must begin production and production completes in 5 days, which means July 26th. Thus the product can deliver on July 26th.

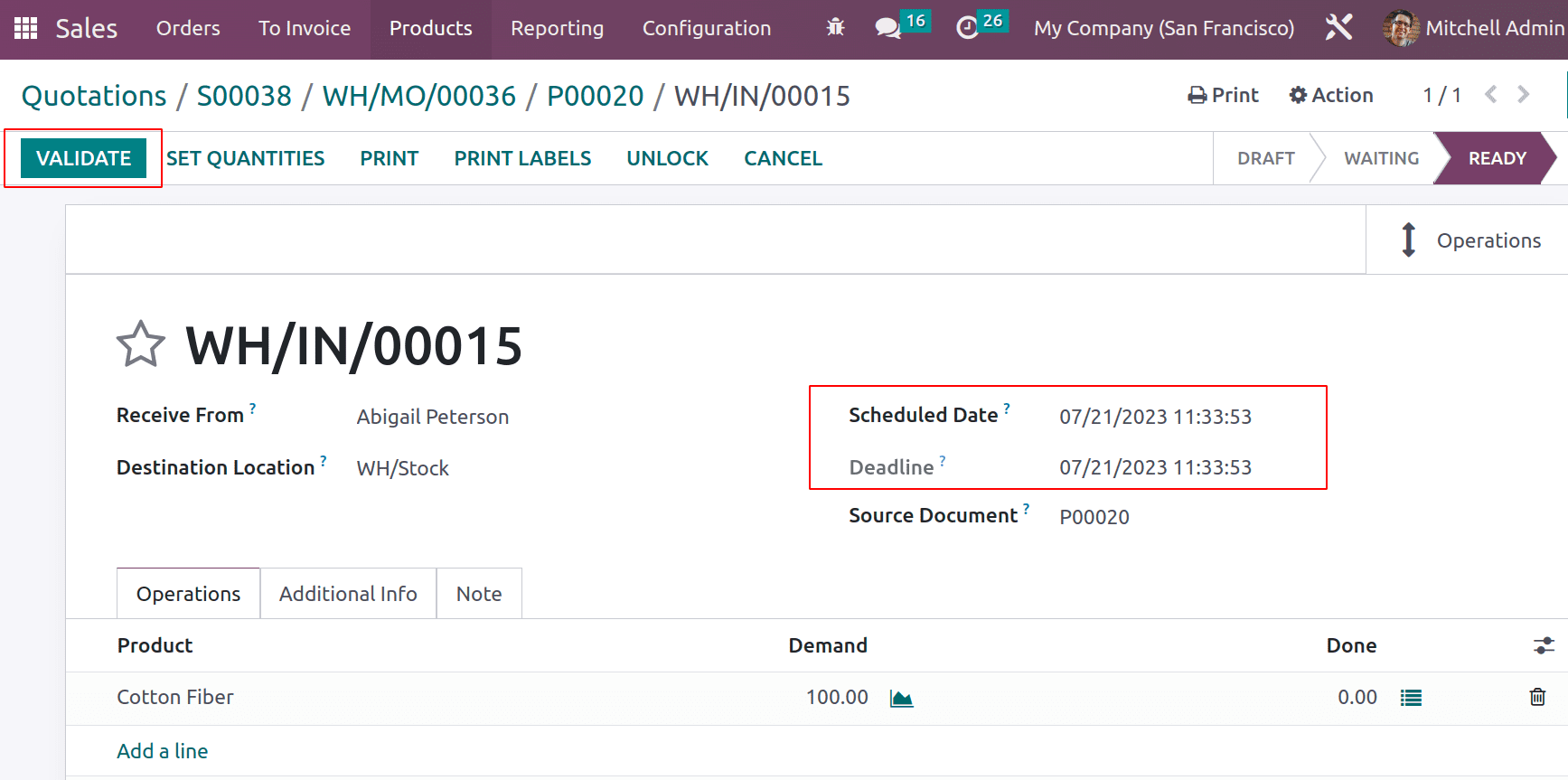

Let's check the status of the receipt by opening the purchase order. Open the smart tab to the production order and make your purchase. This is the purchase order that was created for the Cotton Fibre component. The product is anticipated to arrive on July 21.

The product Cotton Fibre has a predetermined lead time for delivery of 10 days. The first day of production is July 21. Therefore, the component has to be accessible on that day. Consequently, the order must be placed ten days prior to the arrival date. Because of this, the order was made on July 11.

Validate the receipt to finish the purchase order.

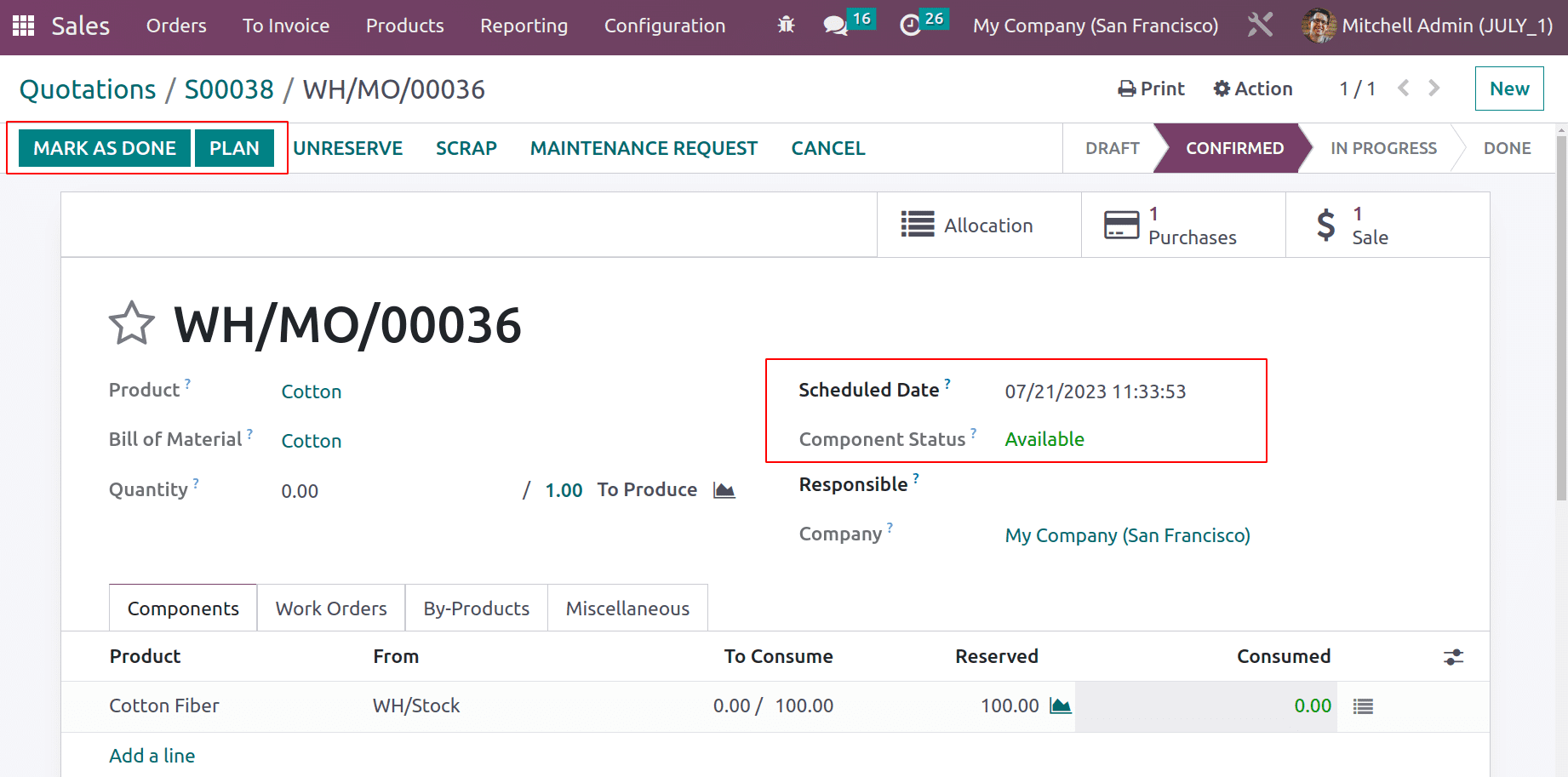

The component is currently available here. The user can finish the manufacturing order by clicking the Mark as Done button after receiving the product Cotton Fibre.

Lastly, complete the Delivery of the product to the customer by clicking the Validate button.

Let's revisit the process and the scheduled date while considering lead time.

In this case, the product Cotton has a 15-day customer lead time and a 5-day manufacturing lead time. Here, the product won't be available till its manufacturing is finished.

If the buyer ordered something, he would receive it after 15 days from the order date. Because the customer lead time was added to the order on July 11th, the delivery date was changed to July 26th. Cotton has a five-day lead time in manufacturing, if the user wishes to deliver a product on the 26th, manufacture should begin five days earlier. So, July 21st is set aside for manufacture. On July 21st, manufacturing is planned to begin here. The material that Cotton Fibre must buy. The set delivery lead time is 10 days. The component must be ready by July 21st, 10 days before its expected receipt. That the Purchase order was scheduled for July 11th. In this case, the date is computed backward from the delivery date.

In conclusion, incorporating lead time enhances operation and effectively allows users to execute tasks without experiencing any delays. Using these lead times, a chain of operations can be finished on time, increasing customer satisfaction.

To read more about how to manage lead time in Odoo 16, refer to our blog How to Manage Lead Time in Odoo 16