Manufacturing is a tough process that takes multiple steps. It can sometimes be very complicated and may force the entrepreneurs to depend on other agencies for completing some task. Manufacturing can have different levels. Some industries involve manufacturing the product from the raw material to the end products. At the same time, some other industries may depend on small industries for semi-finished products for completing their manufacturing process. Sub-contracting can sometimes be complicated as this process requires proper monitoring of the resources and raw materials. The supply of raw materials to the outside agency based on the requirement for the semi-finished product has to be managed with efficiency.

A software solution can help your business to complete this task painlessly. You can outsource the work to small units with an automatic software-assisted system. An ERP solution can come to your rescue to avoid all complicated subcontracting procedures and complete the task with a click.

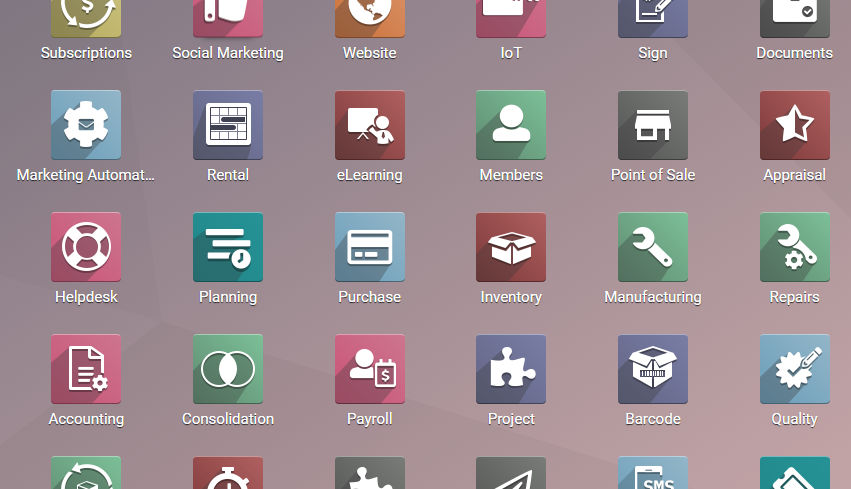

Odoo 14 is a software solution that can help to subcontract an easy task. In this blog, we can discuss how Odoo 14 manufacturing can extend support for managing different subcontracting operations.

Key benefits of subcontracting in Odoo 14

> This feature of Odoo manufacturing helps the user to efficiently track the subcontractor’s inventory of raw materials

> Take care of the inventory of finished products and the order requirement to alert the subcontractor about the need for more semi-finished products

> A tool to assist the users to track all manufacturing and related activities taking place at the subcontractor’s unit

> Ensures the quality of the semi-finished products supplied by the subcontractor.

> Complete assistance for managing subcontractor’s bills

Odoo helps to manage the subcontracting flow with ease

Odoo is a tool that can be used easily by skilled and unskilled persons. A user-friendly application, Odoo supports the management of all subcontracting-related activities without difficulty.

Easy to Configure

Odoo can be configured without consuming much time. We can also say that it is a simple process. To configure subcontracting we have to go to Configuration in the Manufacturing module and select Settings. There we can find a Subcontracting tab. This has to be enabled to manage to subcontract.

When we create a Bill of Materials (BoM) we have to choose the type as Subcontracting.

Efficient creation of Bill of Material for subcontracted products

Bill of Material is the document that allows an investor to keep track of all the raw materials used for the manufacturing process and the material quantity used for the production of a unit of the product.

Let us see how to do this. We have to first go to the Manufacturing Module of Odoo and then check the Master Data. There you will find the option Bill of Materials which can be created in a few steps. At this stage, we can list out different raw materials or components required for manufacturing the product. Here, you can list all components including the components which are directly purchased by the subcontractor. This is done for effective cost management purposes.

The user can identify and list different subcontractors here

Manages Basic Subcontracting Flow

Odoo will enable your subcontractor to get updates on the number of products you need. Creating and sending purchase orders to the subcontractor also becomes effortless with this application. If you do not know how to do this you can check it here. It is very simple. Purchase module, an Odoo module has to be installed and used for creating a purchase order. Here we can define the vendor as a subcontractor based on the type of BOM.

Inventory Valuation

We can now take a glance at inventory valuation for this. We can assume that C is the cost of the finished product. How can we calculate this cost? We can complete this process by adding the cost of raw material sourced by your company (A) and the cost for raw material sourced by subcontractor (B) and the subcontractor service charge (S). Even though we send the raw material A from our inventory to a subcontractor we can set it in such a way that it does not impact the inventory valuation. For this, we have to manage the location of the subcontractor as an internal location.

Helps to Replenishment of Subcontractors

This process can be managed to resupply raw materials to the subcontractors. This can be done by activating the Multi-locations tab in the configuration settings in the Inventory module. This will also help to track the products at the subcontractors’ place. We can also send different raw materials from the company to subcontractors or we can send materials from a third-party vendor to the subcontractor.

Replenishment from the warehouse

We can depend on our own warehouse to supply materials to the subcontractor. This can be done by creating delivery orders. In such situations, we can consider the subcontractor as the buyer and replace the delivery address with the address of the subcontractor.

Let us see how this is done. We can choose the below-given options.

Replenish on order flow.

This has to be done by defining a reordering rule based on the subcontracting location. We will also have to manage the minimum and maximum inventory levels. Here, a delivery order would be created whenever the system automatically triggers a reordering rule.

We can also make use of the pull flow. This helps us to automatically trigger replenishment of raw materials at the subcontractor’s location based on the sale order or forecasted. To manage this we have selected the route as Resupply Subcontractor on Order.

Managing Replenishment from another supplier

We may be purchasing materials from different suppliers. In such cases, we have to direct the vendor to deliver the component to the subcontractor directly. This can be done by enabling drop shipping in the purchase module.

Purchase ? Configuration ? Configuration.

Here, we have to give the delivery address as the address of the subcontractor.

Manage Quality

The quality of the product supplied by the subcontractor can be reviewed with the help of a quality control app. This is possible as Odoo Quality is integrated with Odoo manufacturing. This can on receipt of the product by setting a new Control Point.

This will enable you to ensure a quality check whenever a new product is received.

This is how Odoo helps us to manage our deals with subcontractors.