One of the challenging tasks in most companies is the cost computation of finished goods. Several costing methods are available for cost computation of finished goods, such as actual price, standard price, indirect cost, and average price. Many processes included in manufacturing a commodity and finished goods depend entirely on production time, electricity, direct costs, labor, and more factors. Odoo 15 Manufacturing module ensures you access cost computation of finished goods in your company.

This blog enables you to get cost computation of finished goods in Odoo 15 platform.

We can quickly develop manufacturing orders for a product and analyze the production cost using the Odoo 15 Manufacturing module. Users can also set the Bills of Materials and Lots/Serial Numbers for products from the Manufacturing module. Let's view how to manage cost computation of finished goods in Odoo 15.

To Set up Computation Cost for Finished Goods in Odoo 15 Manufacturing

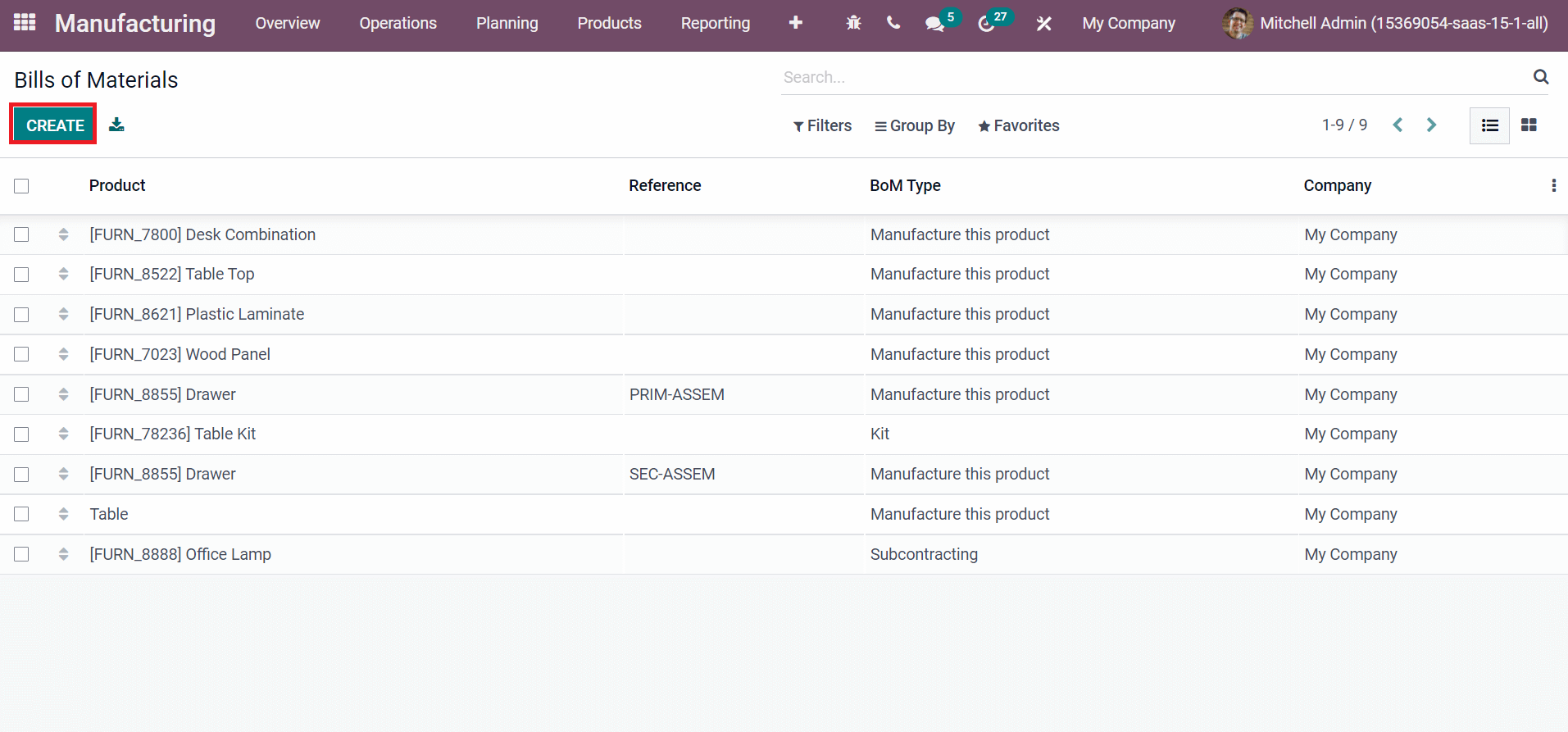

The first step we need to do is manufacture a product. After that, we can generate Bills of Materials for production and evaluate the cost of production. Let's consider the situation of manufacturing a table and how it works. The components needed for a table are a Screw, bolt, tabletop, and table leg. Now, we can formulate the Bills of Materials for the Table. For that, choose the Bills of Materials menu inside the Products tab, and all created lists of BoM in your company are viewable here, as denoted in the screenshot below.

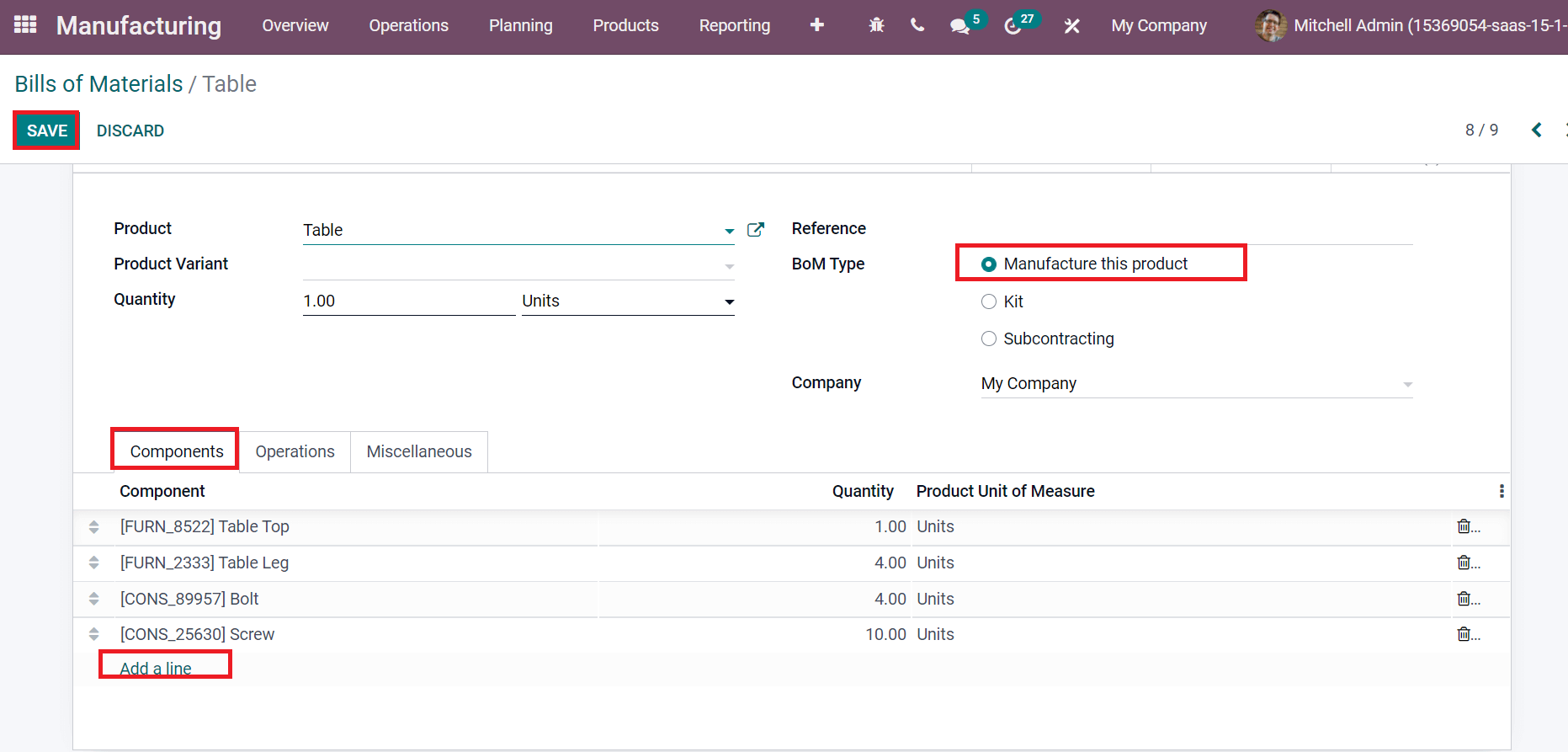

You can see the data of each Bill of Materials, including BoM Type, Product, Company, and Reference. By clicking on the CREATE icon, we can develop new Bills of Materials for your materials. In the new window, select your product as 'Table' and enter the number of tables that need to be manufactured in the Quantity field. Here, we are adding one unit to the table. Set the BoM Type as Manufacturing this Product and choose your company. Inside the Components tab, we can add the products Table Top, Bolt, Table leg, and Screw necessary for manufacturing the table, as depicted in the screenshot below.

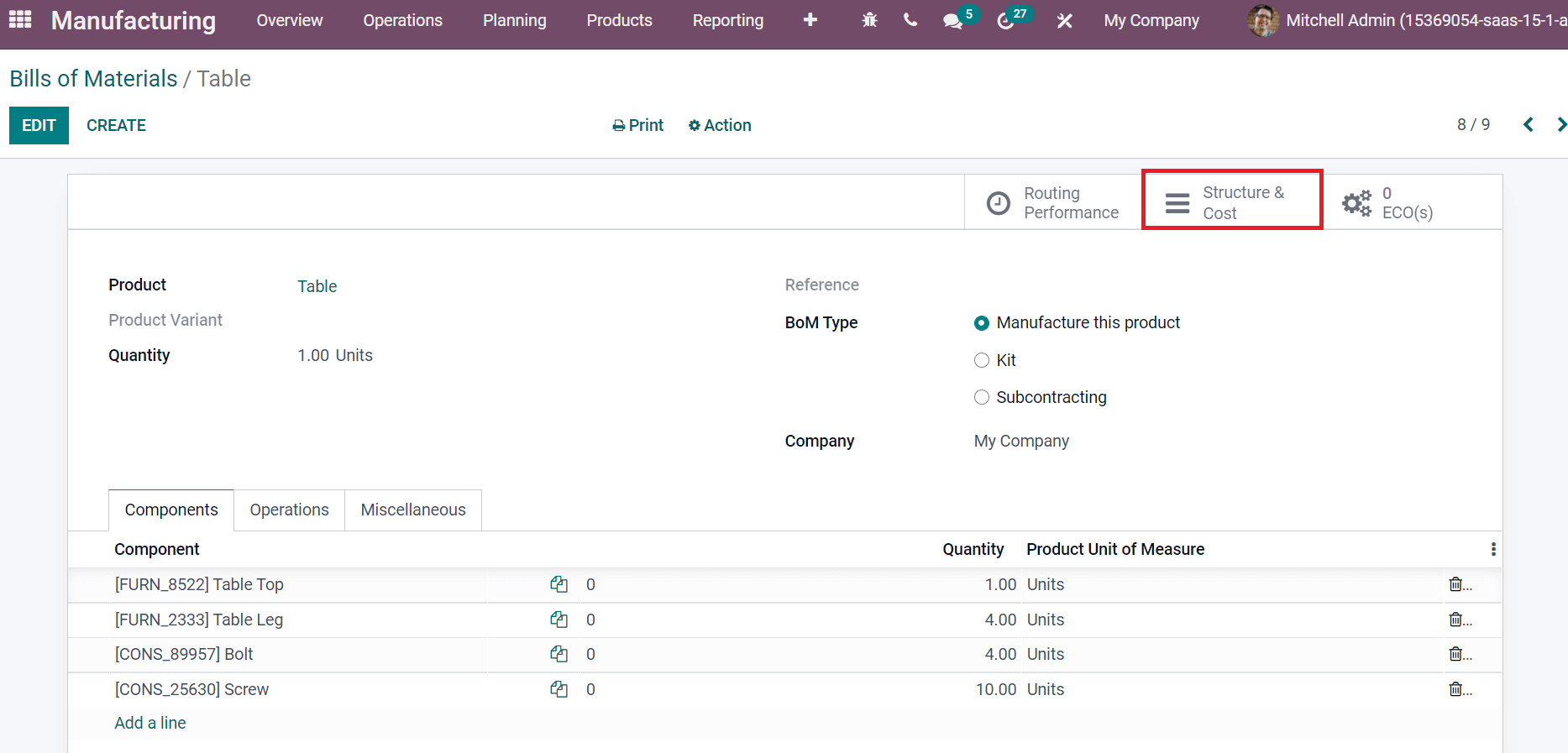

Firstly, we add one unit of Table Top by clicking on the Add a line option from the Components tab. In the same way, you can apply four table leg and bolt units. Finally, we need to enter ten units of Screw for the production of the table and select the SAVE icon. Users can get the cost details for the production of the table by selecting the Structure & Cost smart button, as displayed in the screenshot below.

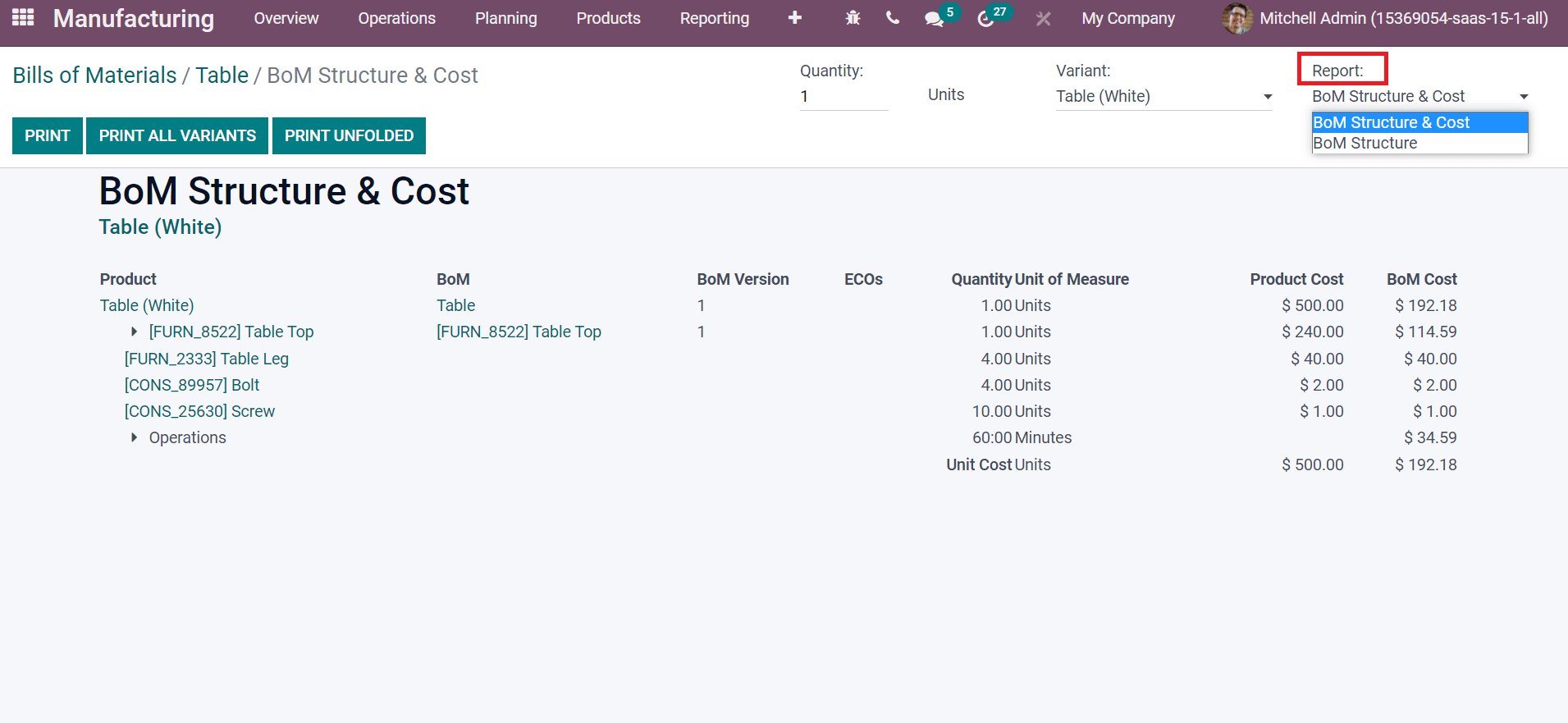

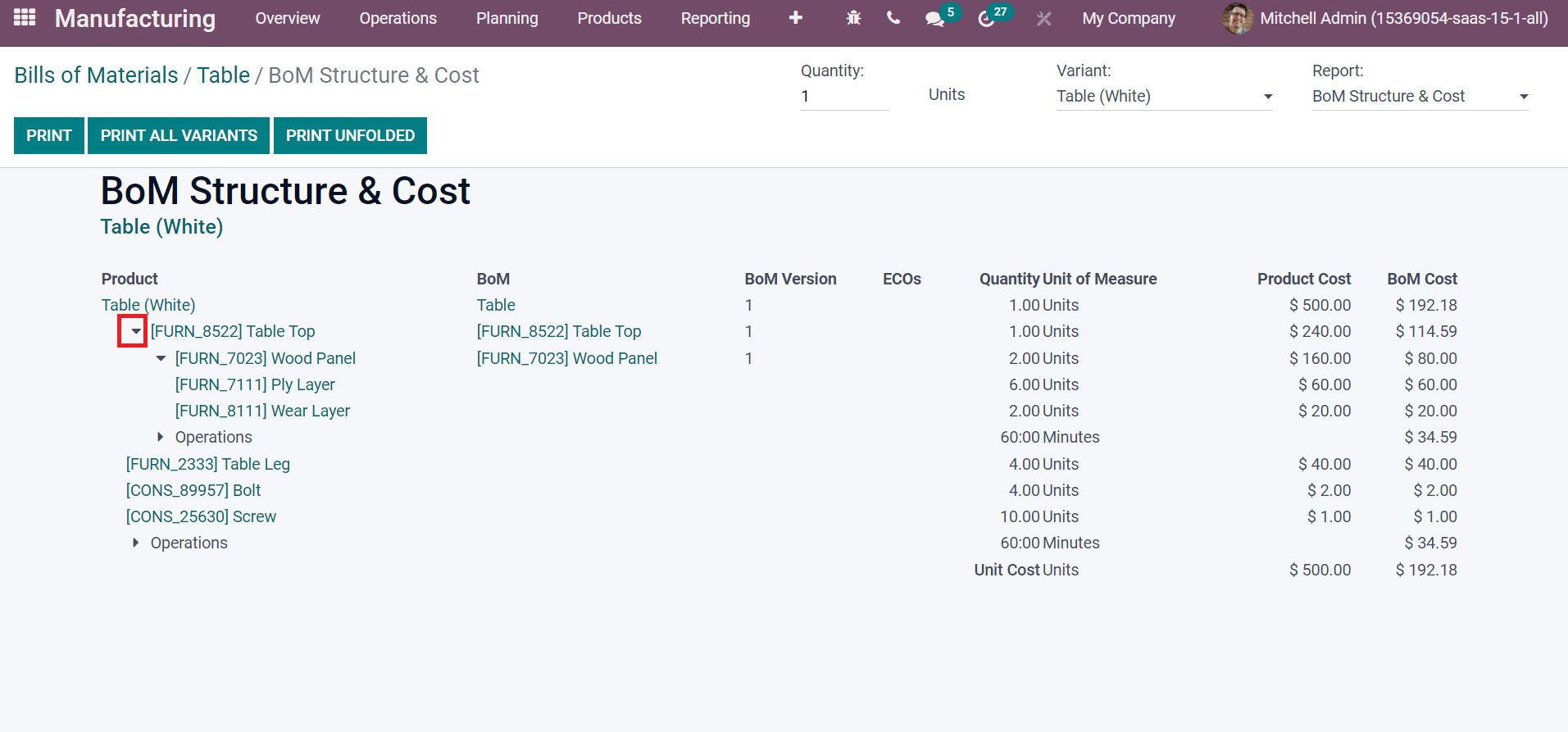

By selecting the Structure & Cost smart button, you can analyze your product's structure and cost. We can evaluate the BoM Structure & Cost and BoM Structure separately from the Report option in the BoM structure & Cost window, as portrayed in the screenshot below.

We can compare BoM and Product Cost from here. Users can unfold the details by clicking on the arrow near Table Top, as marked in the screenshot below.

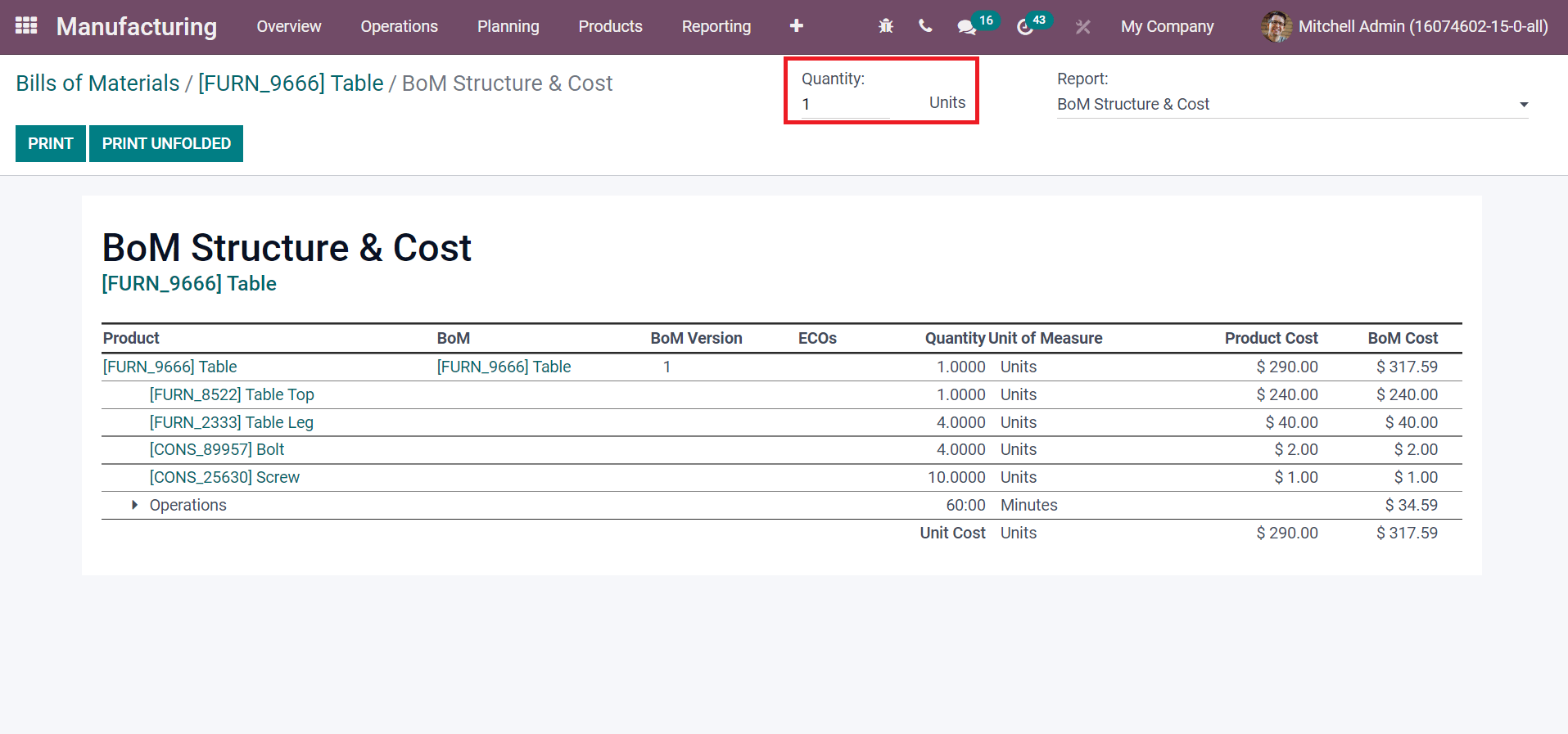

A Table Top is essential for the manufacturing of a table. At the same time, a Table Top is produced using other materials like wood panels. After unfolding the Table Top, we can see that it is manufactured using a Wood Panel. Moreover, the Wood Panel is formulated using the Wear Layer and Ply Layer, as shown in the above screenshot. The Product Cost, BoM, Quantity Unit of Measure, and BoM Cost of each product are visible in the BoM Structure & Cost window. We can analyze the manufacturing for bulk quantities of commodities by changing the Quantity as displayed in the screenshot below.

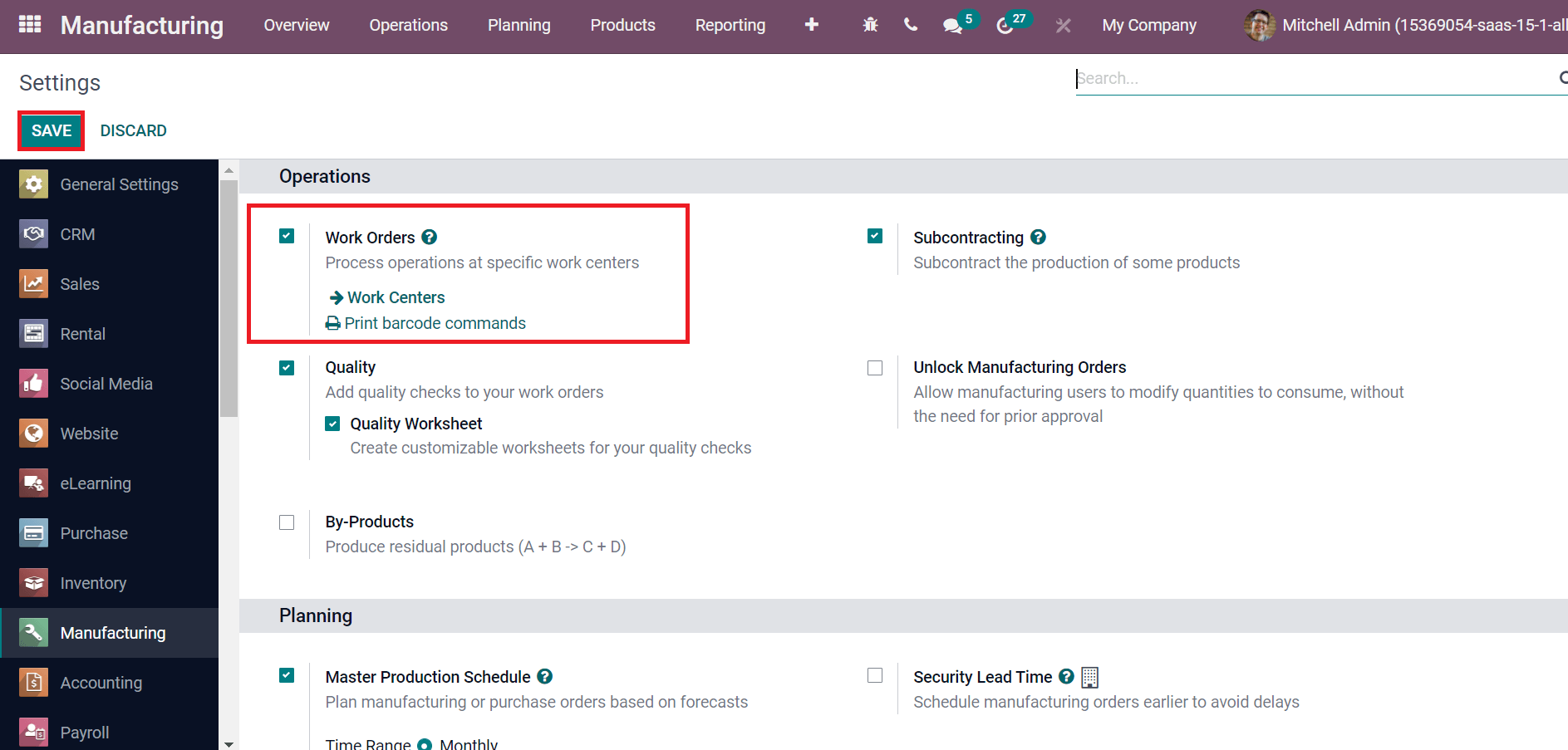

Next, let's create operations for the table using the Odoo 15 Manufacturing module. Various operations are performed for manufacturing materials, including assembling, cutting, etc. It is necessary to activate the work orders field from the Odoo settings. Select the Settings menu in the Configuration feature and enable the Work Orders option below the Operations section, as illustrated in the screenshot below.

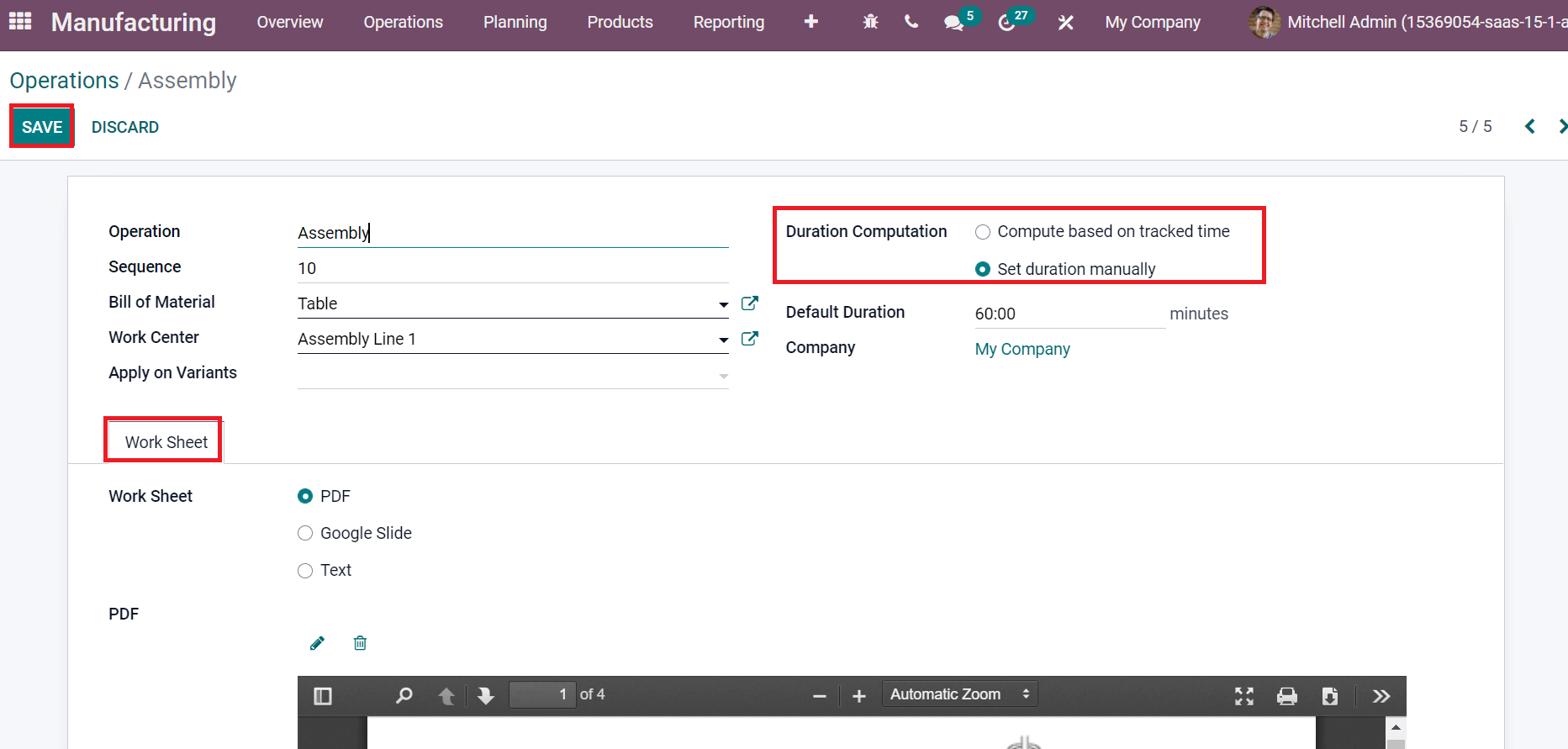

Users can easily develop operations at various work centers by activating the Work Orders field and clicking on the SAVE icon. We can view the Operations tab in the Manufacturing dashboard after enabling the Work Orders option. Later, click on the Operations menu in the Configuration tab and select CREATE icon. In the new window, we can add Operation as 'Assembly' and Bill of Material as 'Table'. Users can set the sequence order displayed in various work centers inside the Sequence field and Work Center as 'Assembly Line 1'. Duration Computation for operations is classified into two types: Compute based on tracked time and Set duration manually, as represented in the screenshot below.

After enabling Set duration manually, a Default Duration field is visible before you. Here, you can add the time in minutes, and we set a Default Duration of 60 minutes. That is, the work center activates the product manufacturing within 60 minutes. The efficiency did not deal with operation time due to manual duration computation. By activating Compute based on tracked time, efficiency is based on the time necessary for product manufacturing. We can also set the Work Sheet as PDF, Text, or Google Slide inside the Work Sheet tab and select the SAVE icon to develop Assembly Operation.

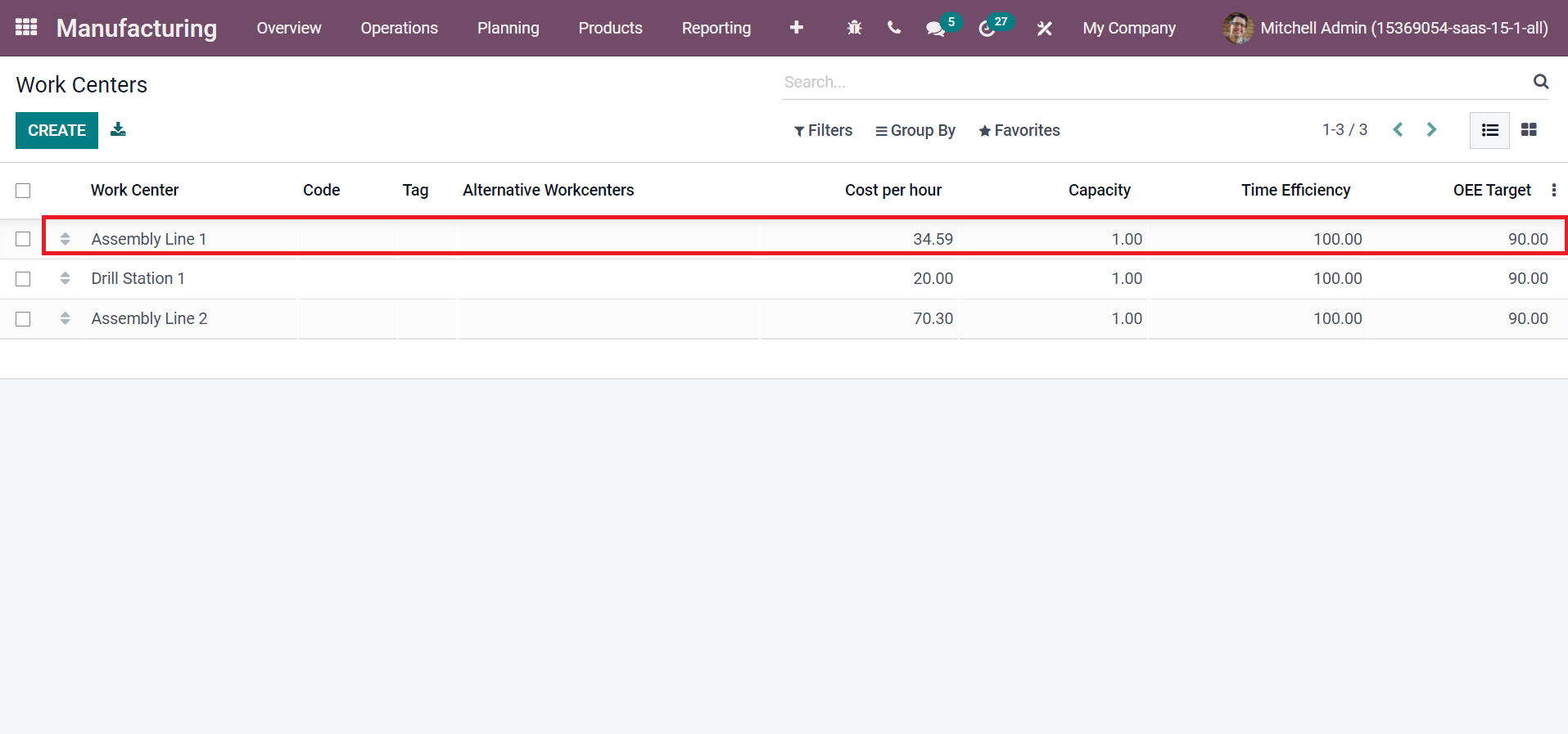

Now, let's move to the work center 'Assembly Line 1'. For this purpose, select the Work Centers menu in the Configuration tab and choose Assembly Line 1, as shown in the screenshot below.

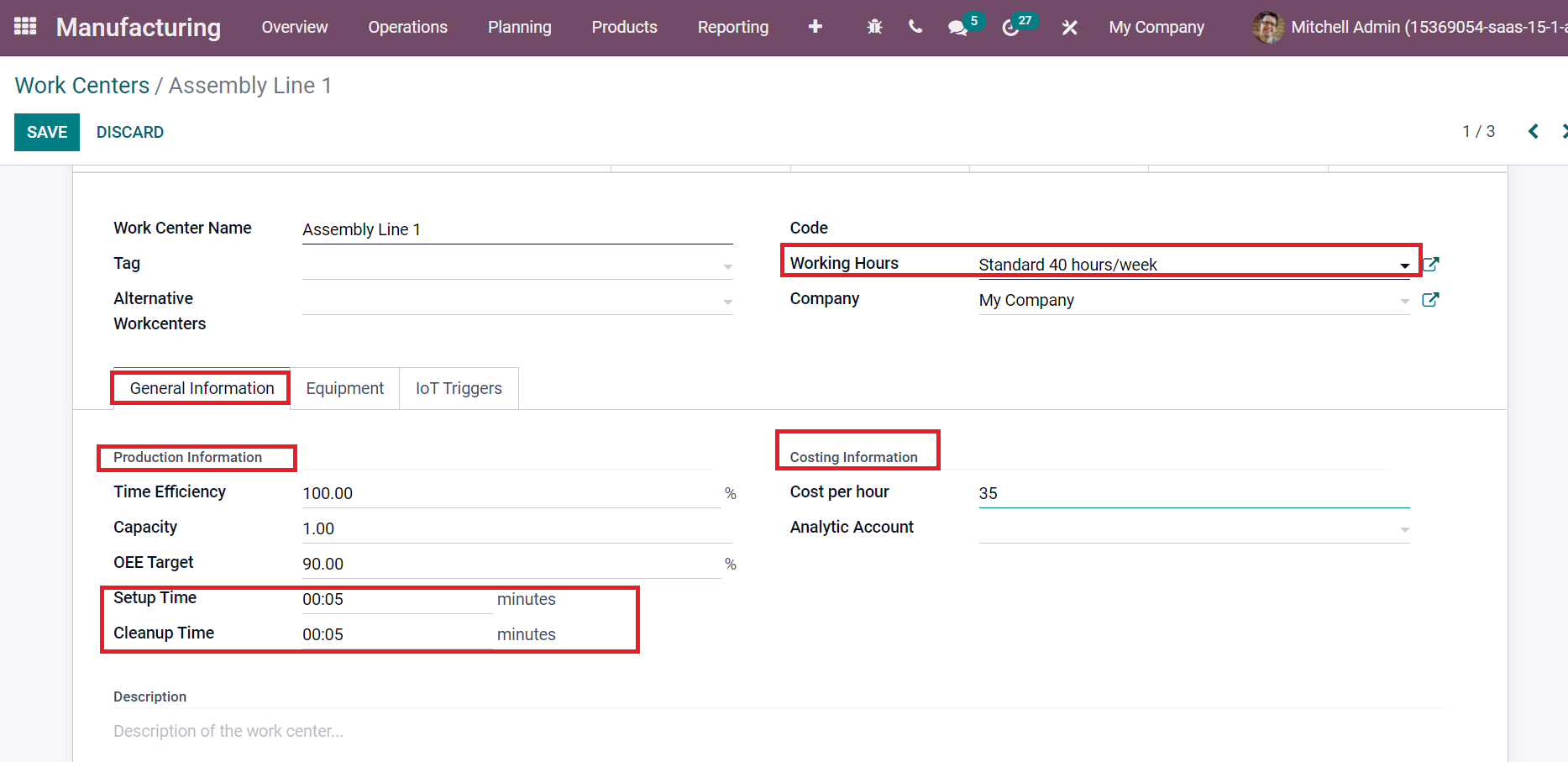

In the new window, you can see Work Center Name and Working Hours for Assembly Line 1, as denoted in the screenshot below.

Inside the General Information tab, we can manage the Production Information and Costing information. We added cost per hour as 35 below the Costing Information section. You can also Setup and Cleanup Time for production inside the Production Information. We set 5 minutes for each Operation and the total minutes for the manufacturing table is 60 minutes that were already created before. Hence, the entire time will be 70. (60+5+5). So, the cost will be (70/60) * 35 = 40. After assigning the work center and Operation, we can add Operation in BoM.

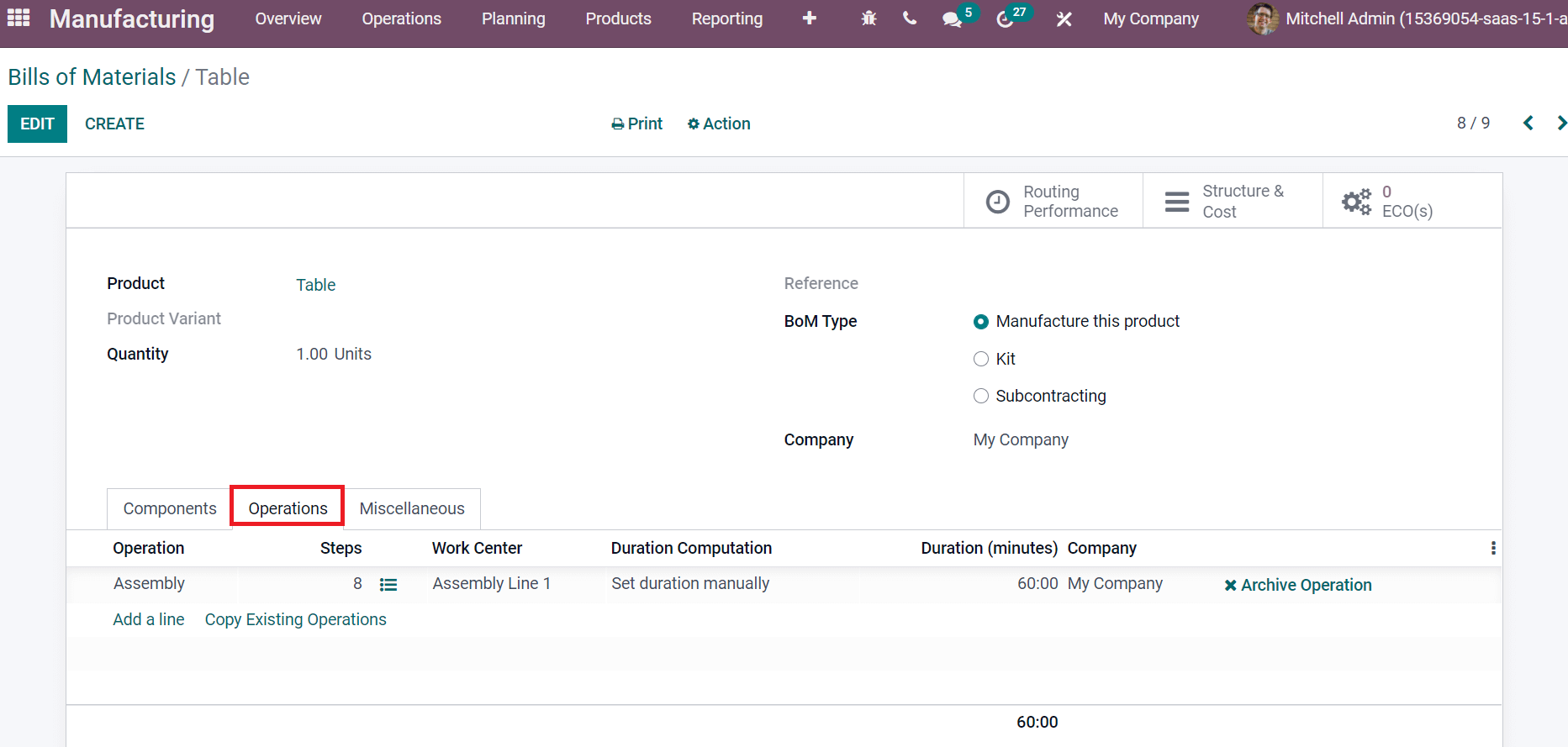

Now, go back to your Bills of Material' Table' in the Odoo 15 Manufacturing module. Inside the Operation tab, you can add the work center by selecting the Add a line option specified in the screenshot below.

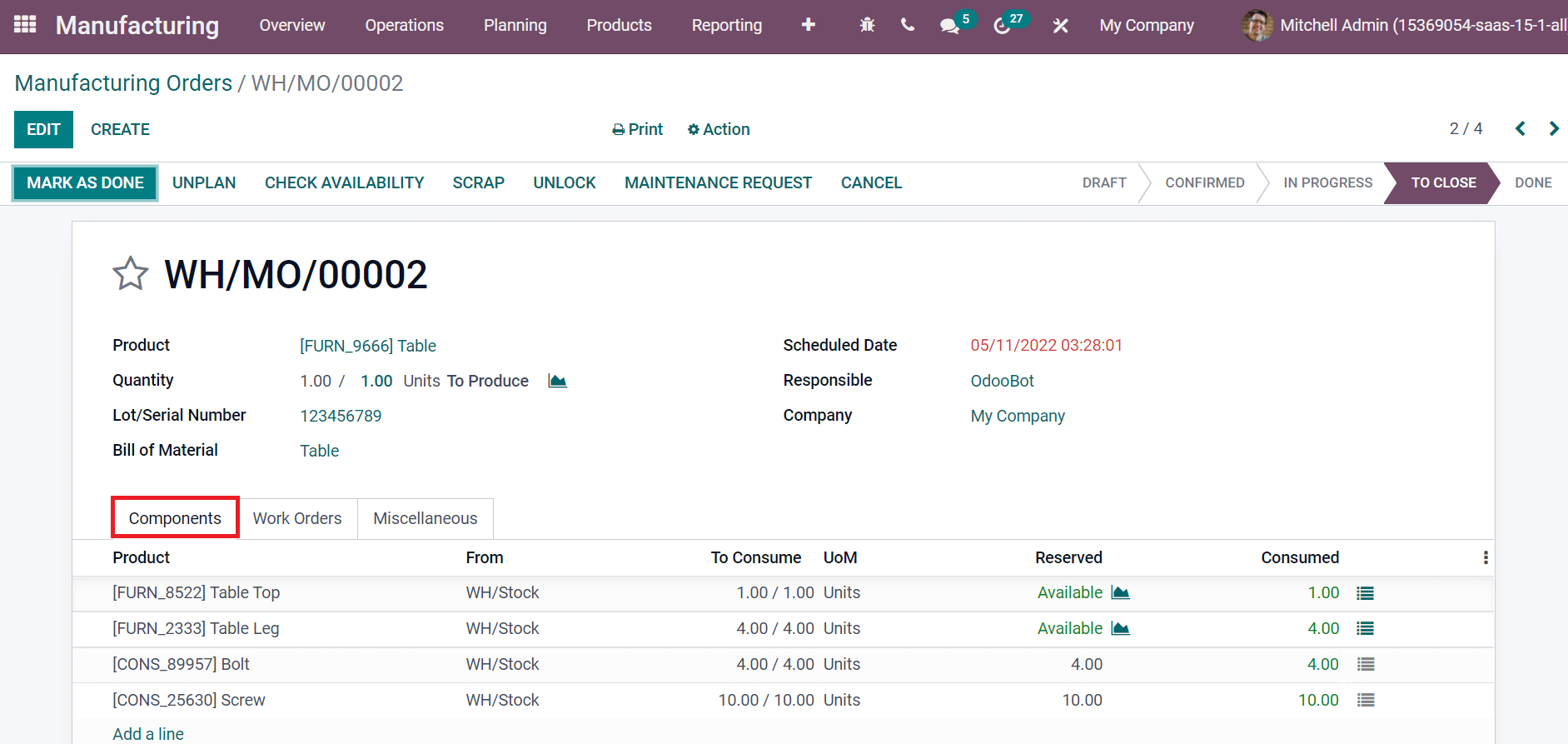

We apply the work center 'Assembly' inside the Operations tab. Next, let's generate a manufacturing order for 'Table'. Select the Manufacturing Orders menu in the Operations tab and select the CREATE icon. On the new page, choose your Product 'Table', Company, and Bill of Material. By selecting the Product Table, all products needed for table manufacturing are automatically applied inside the Components tab and SAVE or CONFIRM, as depicted in the screenshot below.

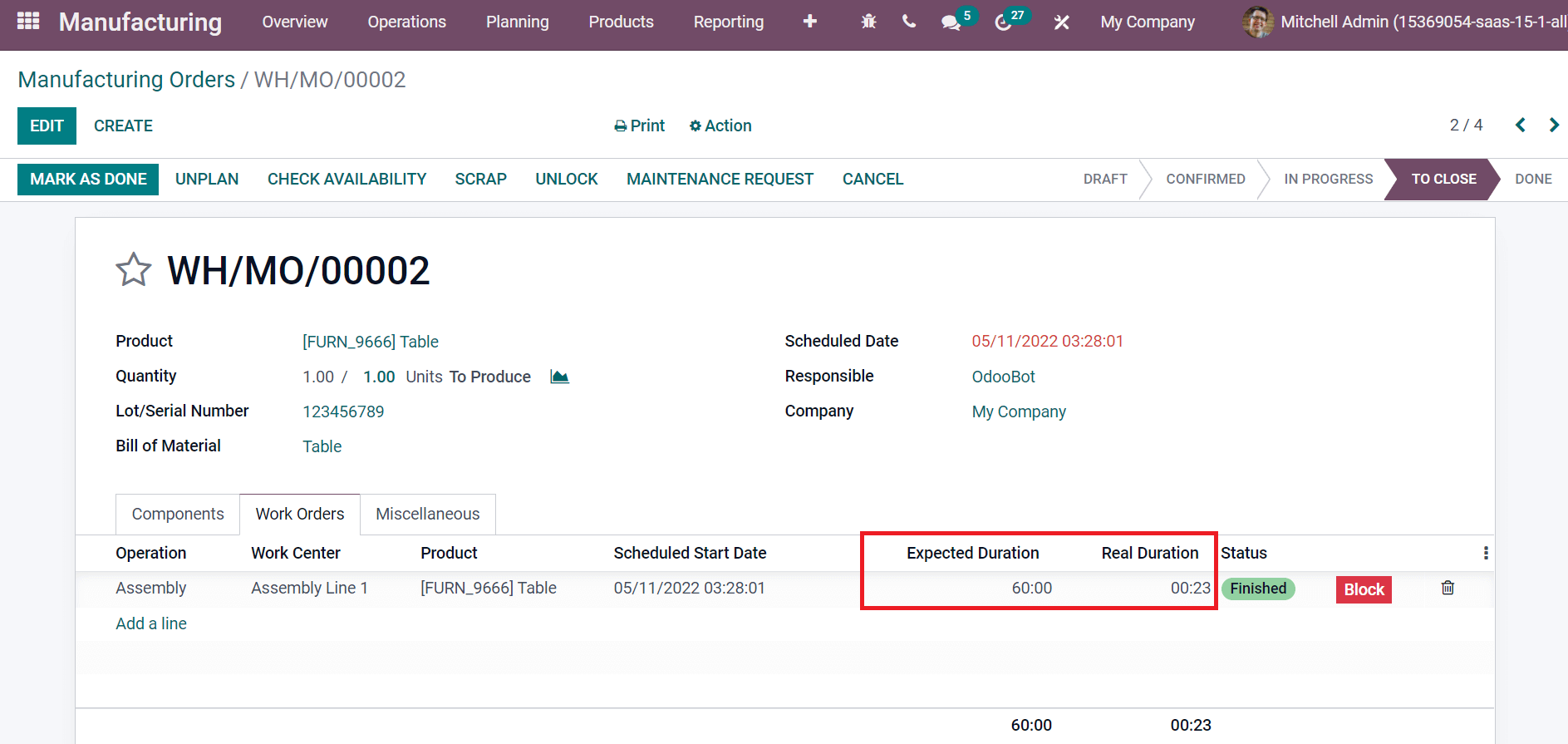

The To Consume field shows the required Quantity needed to produce each product in a table. In addition, the Expected Duration and Real Duration are visible below the Work Orders tab, as displayed in the screenshot below.

The actual time to produce a table is the Real Duration, and how much time is needed for table production is an Expected Duration. To calculate BoM cost for a work center is the product of price per hour and total time taken. That is, (Real Time + Setup and Cleanup Time) * cost per hour. The BOM cost for a product is the product of raw materials cost and total Quantity consumed. That means (Cost per unit product * Quantity Consumed). The sum of the BoM cost of product and work center is the total BoM cost of completed goods. That means (Total BoM cost of product + work center). This method calculates the BoM cost for the product, work center, and total for finished goods.

We can easily manage cost computation for finished goods in an organization with the support of the Odoo 15 Manufacturing module. You can quickly develop Bills of Materials, Work Center, and Operations for your manufacturing order and compute its cost at the end. Organizations quickly improvise business growth by calculating the cost of finished goods with the assistance of an Odoo ERP.

To read more about the importance of Odoo Manufacturing Cost, refer to our industry page Odoo Manufacturing Cost