The Master Production Scheduler (MPS) in Odoo 17 is a tool that optimizes production planning and scheduling processes in manufacturing operations. It facilitates effective resource management, enables meeting customer demands, and reduces costs for businesses. Users can generate production plans based on demand forecasts, sales orders, and inventory levels, considering constraints like production capacity, lead times, and material availability. The MPS allows for end-to-end supply chain insight and real-time data interchange through module integrations with Inventory, Sales, and Purchasing. All things considered, the MPS aids companies in streamlining processes, increasing productivity, and reacting swiftly to consumer requests.

This blog provides an in-depth discussion and overview of the functionality of the Master Production Scheduler feature within the Odoo 17 Manufacturing Module.

Configuring Master Production Scheduler In Odoo

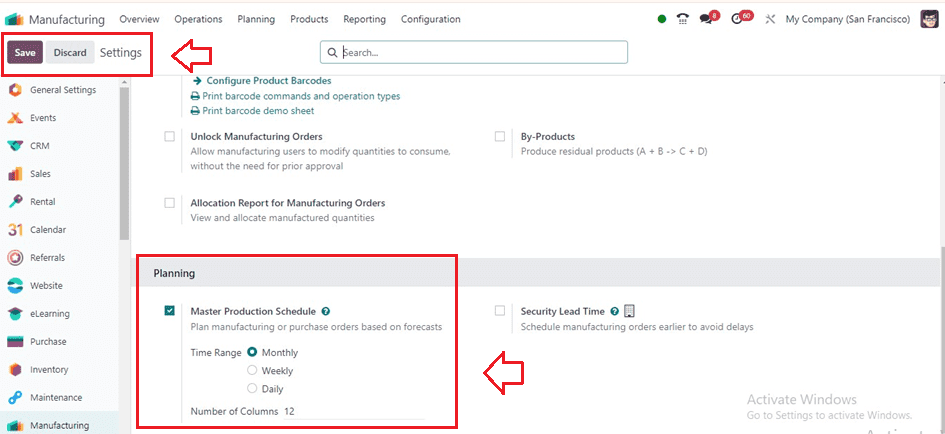

In the "Settings" window of the Odoo 17 Manufacturing Module, under the "Planning" section, you will find the "Master Production Schedule" option. This is where you can enable the Master Production Scheduler capability, as seen in the picture below.

After enabling the option, the time interval for the Master Production Scheduler (MPS) inside the ‘Time Range’ option, whether it be Monthly, Weekly, or Daily, along with the number of periods to be consistently displayed, can be specified within the MPS options.

Planning Master Production Scheduler

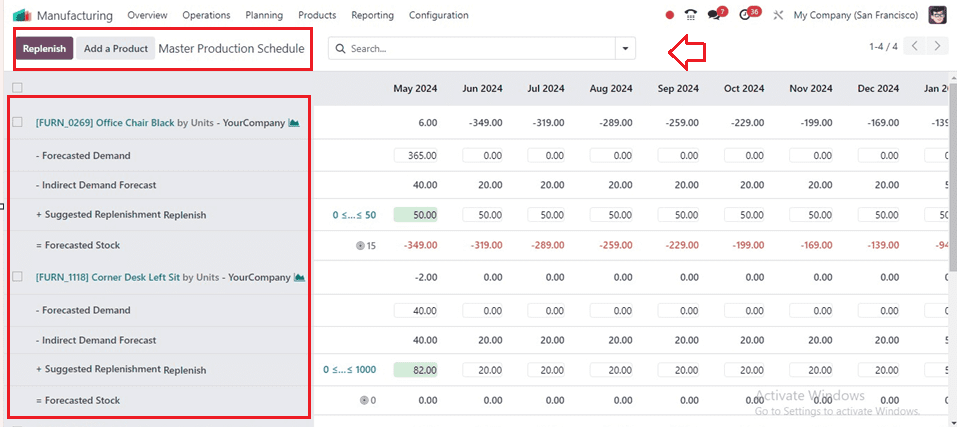

Initiating the planning process for a new Master Production Schedule involves accessing the "Master Production Schedule" option within the "Planning" menu.

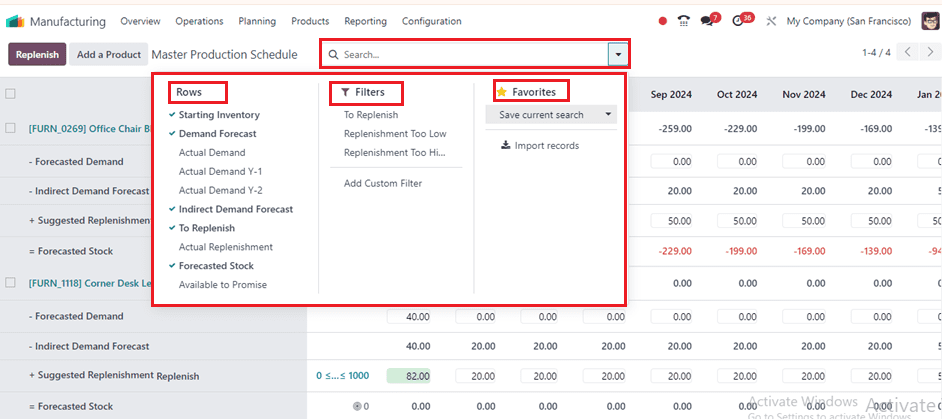

The screenshot below illustrates how users can customize which information to display within the MPS view by choosing the "Rows" option from the advanced search bar. This allows users to specify variables like Starting Inventory, Actual Demand, Indirect Demand Forecast, To Replenish, Actual Replenishment, Forecasted Stock, Available to Promise, and many more.

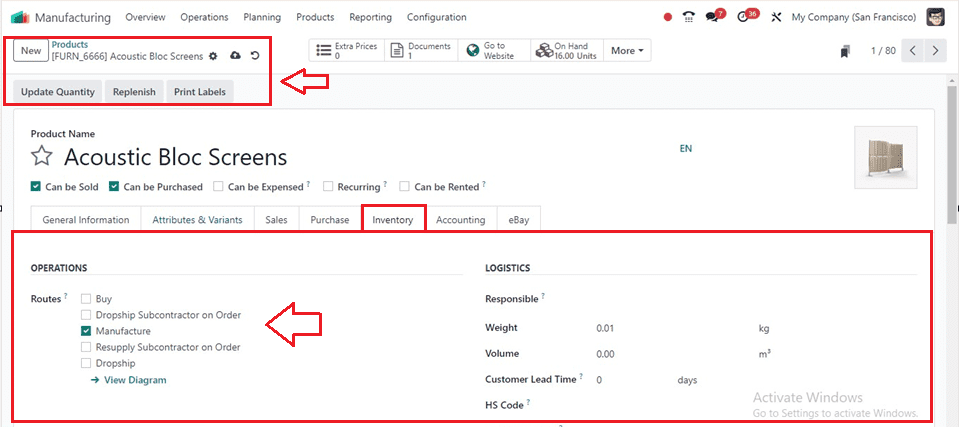

Setting Manufacturing Route

The required product's "Routes" of operation must be set to "Manufacture" inside the MPS for Odoo to be able to produce a manufacturing order upon replenishment. As seen in the picture below, this setting may be changed by navigating to the "Inventory tab" of the particular product configuration form view from the "Products" menu.

Adding a New Product in MPS

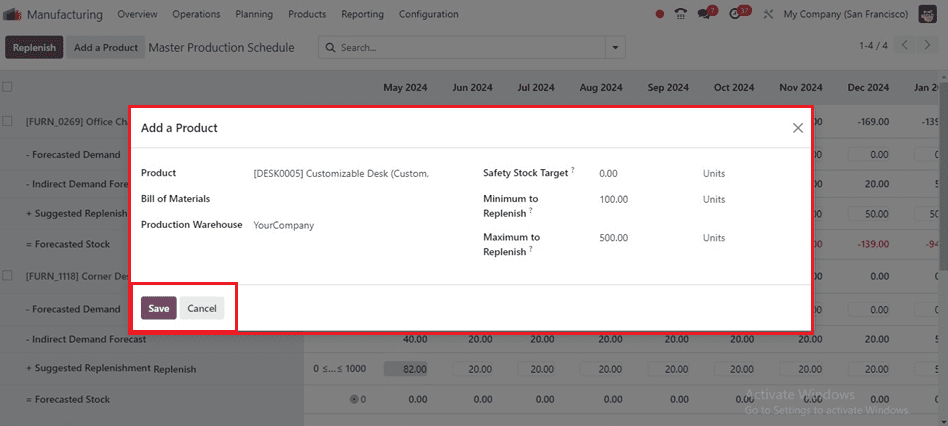

By displaying a form box where users may enter product details such as the product’s Name, Bill of Materials, and Production Warehouse, the "Add a Product" button simplifies the process of adding a new product to the Master Production Schedule.

Parameters such as Safety Stock Target, Minimum to Replenish, and Maximum to Replenish can be defined to manage inventory levels effectively. Upon completion, users can save the changes by clicking the "Save" button, as depicted in the screenshot below.

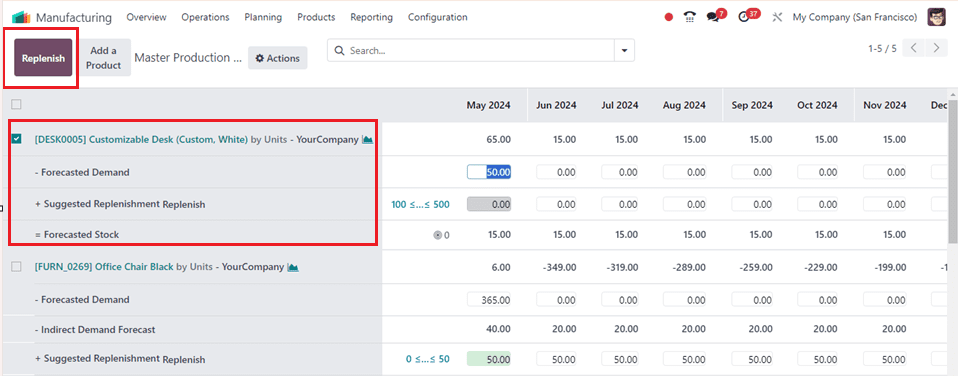

The new product will be added immediately to the MPS dashboard and its information regarding stock levels for the upcoming year, provided every month, can be accessed. Users can manually input projected demand in the "Forecasted Demand" column, view suggested replenishment quantities in the "Suggested Replenishment" section, and observe the projected stock available at the end of each period in the "Forecasted Stock" field as shown below.

Replenishing a Product

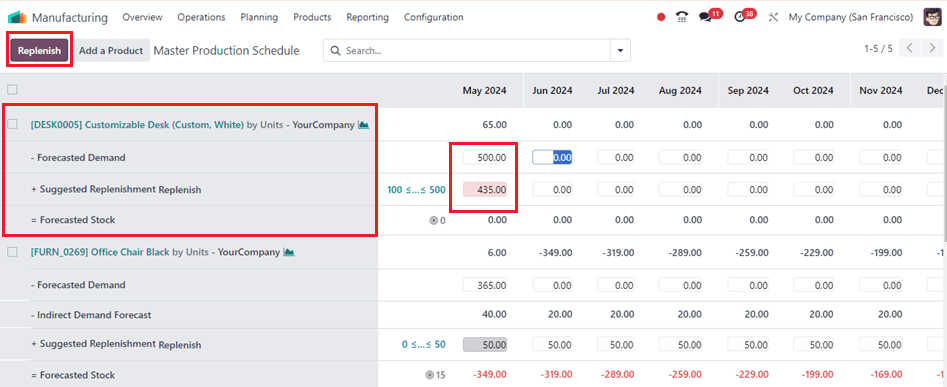

After setting the ‘Forecasted Demand,’ the quantity to replenish for different periods is automatically computed. The replenishments based on lead times (vendor or manufacturing lead time) are displayed in green and can be launched by clicking the ‘Replenish’ button.

Odoo will create a production or buy order depending on the product's operational route when you pick the "Replenish" option. These orders will be visible within the Manufacturing Orders portal, with MPS indicated as the source.

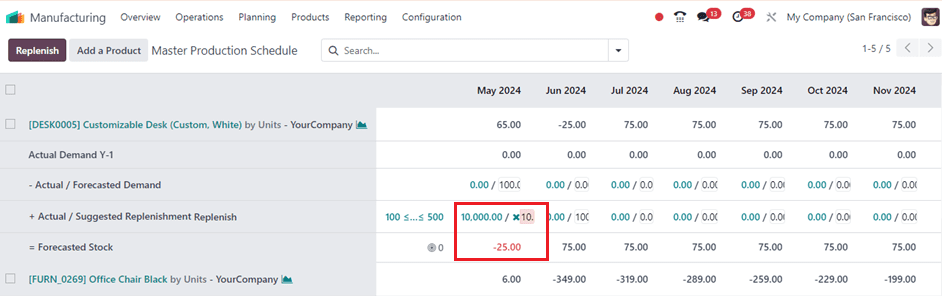

If the Suggested Replenishment amount is manually changed, the cell's left side will display a little cross. To return to the value that Odoo has automatically computed, just click the cross.

The cells within the Suggested Replenishment line exhibit varying colors to indicate different scenarios:

*Green: Indicates the quantity of products recommended for replenishment to attain the expected safety stock based on demand forecasts and indirect demand forecasts.

*Grey: Denotes that a replenishment order has been generated, and its quantity aligns with current data.

*Red: This signifies that a replenishment order has been generated, but its quantity exceeds the current data.

*Orange: Indicates that a replenishment order has been generated, but its quantity is insufficient based on current data. Additionally, red cells may appear within the Forecasted Stock line, indicating an anticipated negative stock level during the specified period.

In conclusion, the Master Production Scheduler in Odoo 17 is a powerful tool for businesses to streamline production processes and enhance efficiency. Its intuitive interface and robust features enable users to manage schedules, optimize resource utilization, and meet customer demands, enabling greater control over manufacturing operations and success in competitive markets. To read more refer to Master Production Schedule in Odoo Manufacturing