In a manufacturing organization, there will we different stages throughout a product production procedure. Each stage will contain various processes so that it needed diverse types of equipment to process them. So setting different physical spaces for a particular stage is very important. Here comes the importance of the work center in Odoo Manufacturing. A work center is said to be a physical space in a manufacturing organization, where various kinds of manufacturing procedures are done.

By taking advantage of Odoo, the end-users are allowed to configure the Work Center details that helping the manufacturing process very easily. The performance of the work center is mainly assessed through their production capacity, efficiency factor, etc. the blog discusses the features and configuration of the work center.

Let us see the configuration of the work center

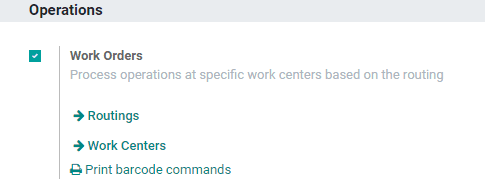

To enable the work center to go to,

Manufacturing -Configuration - Settings - Operations - Work Orders

You have activated the option of work orders. For marking the changes Click the Save Button. You can see the changes occurred as like in the dashboard shown below.

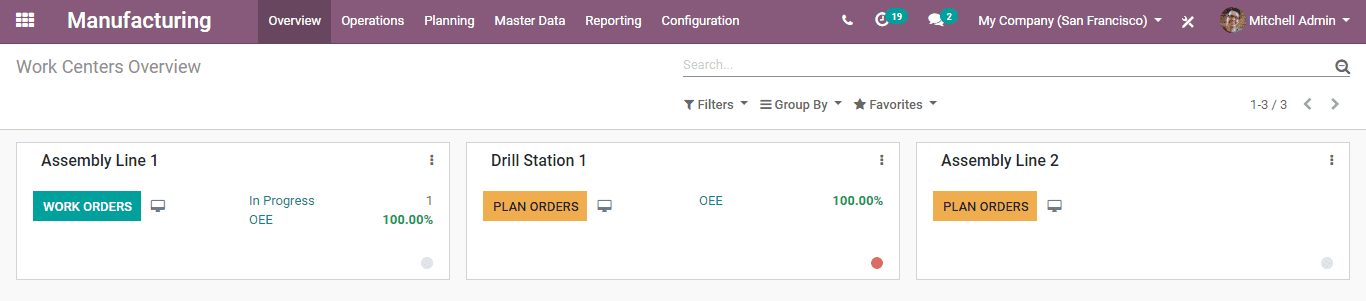

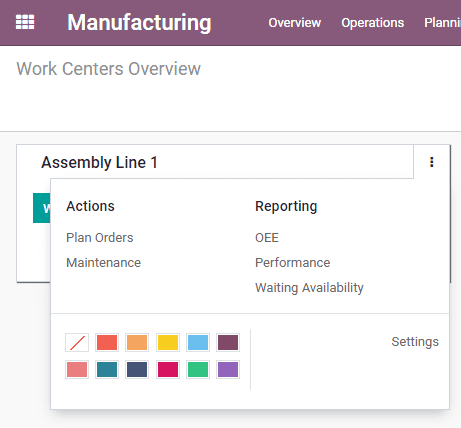

There is also an option to handle the work centers straightly from the dashboard itself. From there itself the end-user can perform actions and take the reports.

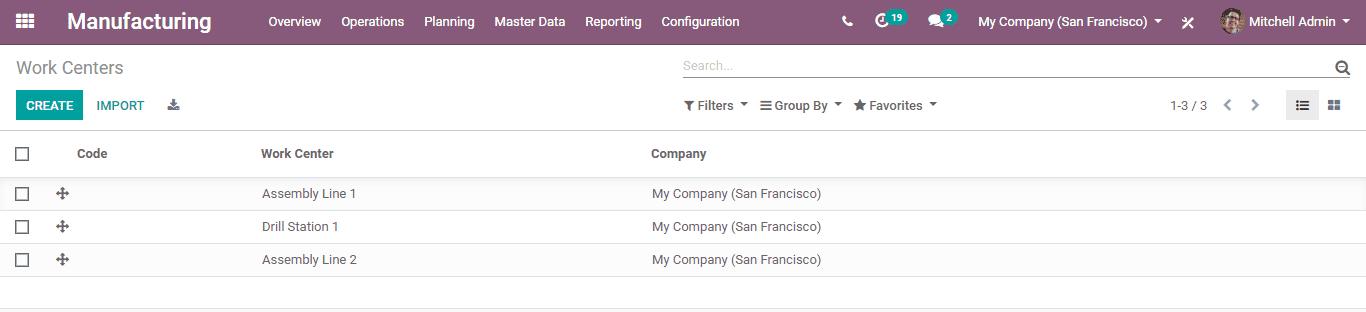

You can add to the work center straightly by clicking the Work Center button in the configuration menu or by

Manufacturing - Master Data - Work Centers

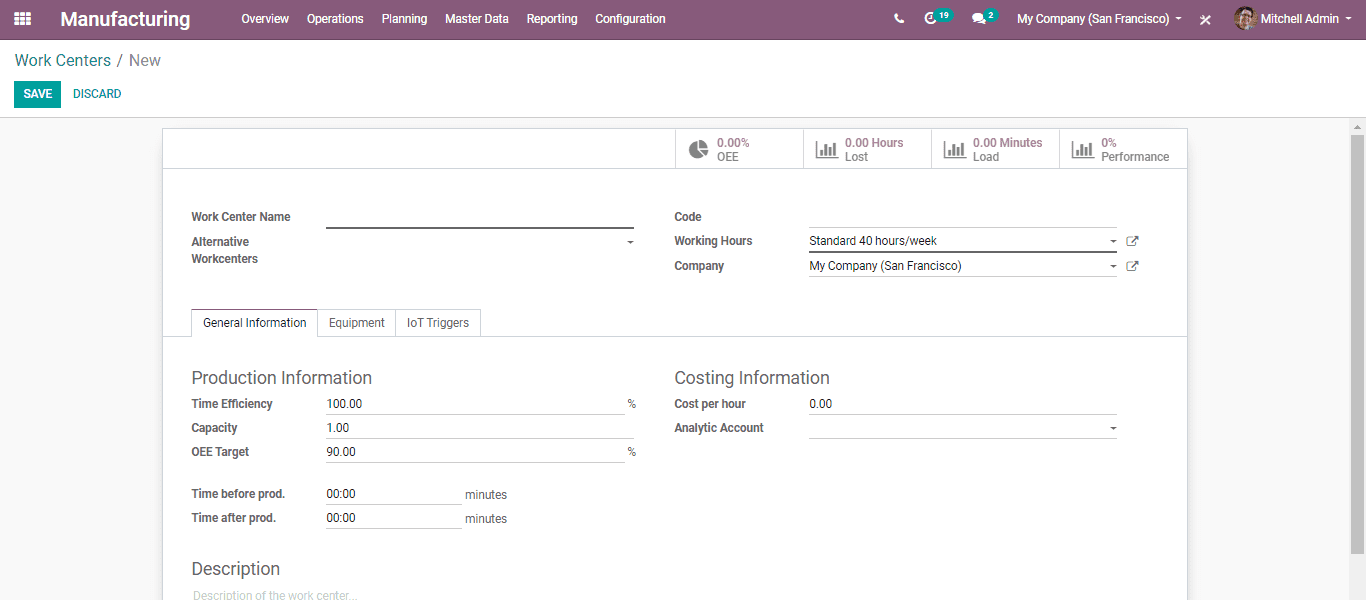

For creating a new Work Center click the Create Button.

A new creation form contains details like:

a) Name of the work center

b) Alternative Work Centers

c) Code for the particular work center

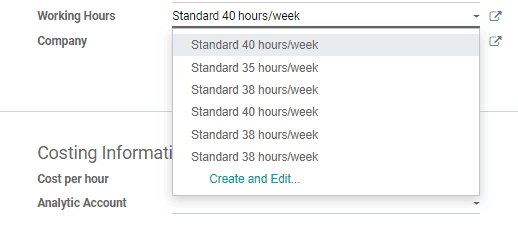

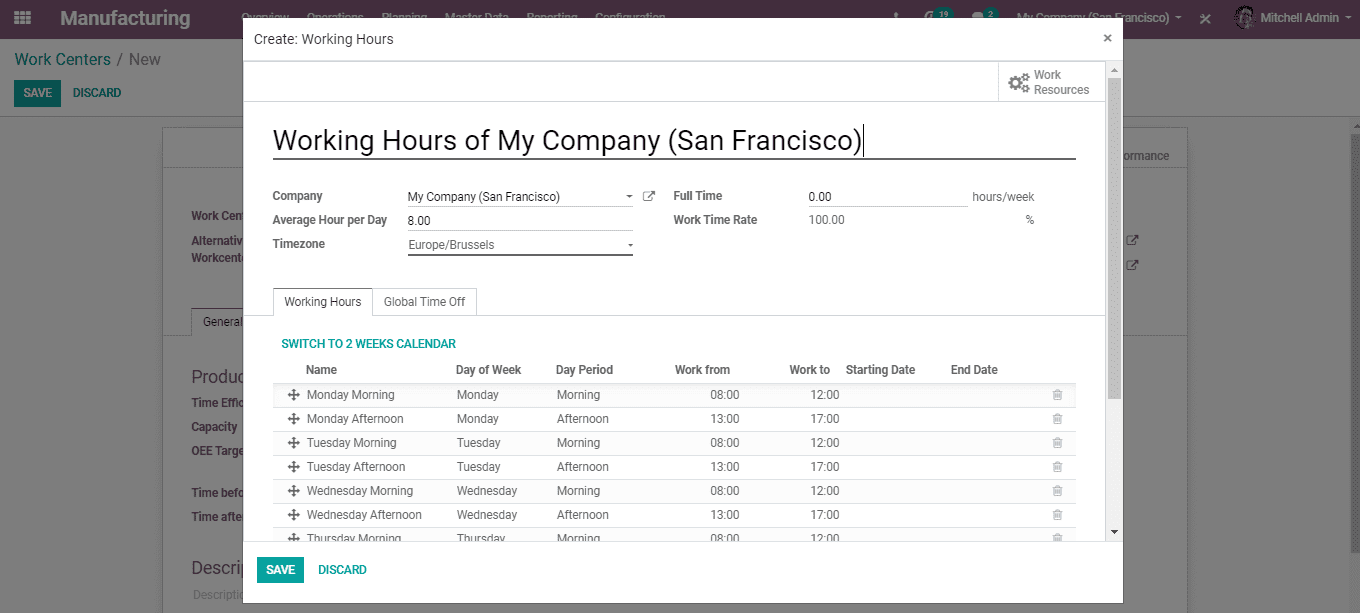

d) Schedule of the resource that is the work hours

In the General Information tab:

a) Time Efficiency

b) Capacity

c) OEE Target

d) Time before prod

e) Time after prod

f) Analytic accounting

g) Description

By clicking any of the buttons shown in the image above you can start using the work center and observe what is happening in the work centers and its efficiency.

Work Center Features

Meanwhile Work Center is a part of a production facility, where each and every task is associated with a concerned process is performing. It can act as a master data that appear for Production lines, Assemble Working Process, and Production lines, etc. it is a central navigation component that is made for the end-users. Ultimately it helps the users to know more about the manufacturing processes.