The manufacturing module of Odoo is of great help to the manufacturing firms as it helps the production unit to conduct their work in a streamlined fashion. Odoo performs intuitively via setting routes and plans on the manufacturing order, significantly improving the productivity of the work centers.

To know more on work centers, read our previous blog Work center in odoo 12.

We know that manufacturing is not a single step process. Each manufacturing process has to go through different stages so as to assure the qualitative end product. Each product during its production stage is bound to through different work centers, performing a part of the manufacturing process. And finally, at the end of the route, the product gets its final shape.

Briefly saying each production has its own route. Every company will encompass its own manufacturing route for a specific product to get it manufactured. And one can configure these manufacturing routes without much stretch utilizing Odoo, thereby carry out the operations in its simplest way.

The routing can be called as the route that directs a product towards different work centers.

Work Center

Work Center is the physical location in a manufacturing company that is destined to perform a different manufacturing process. One can configure work centers in Odoo and can perform route based production activities. The performance of the work center indicates its efficiency, production capacity and more.

Create work center

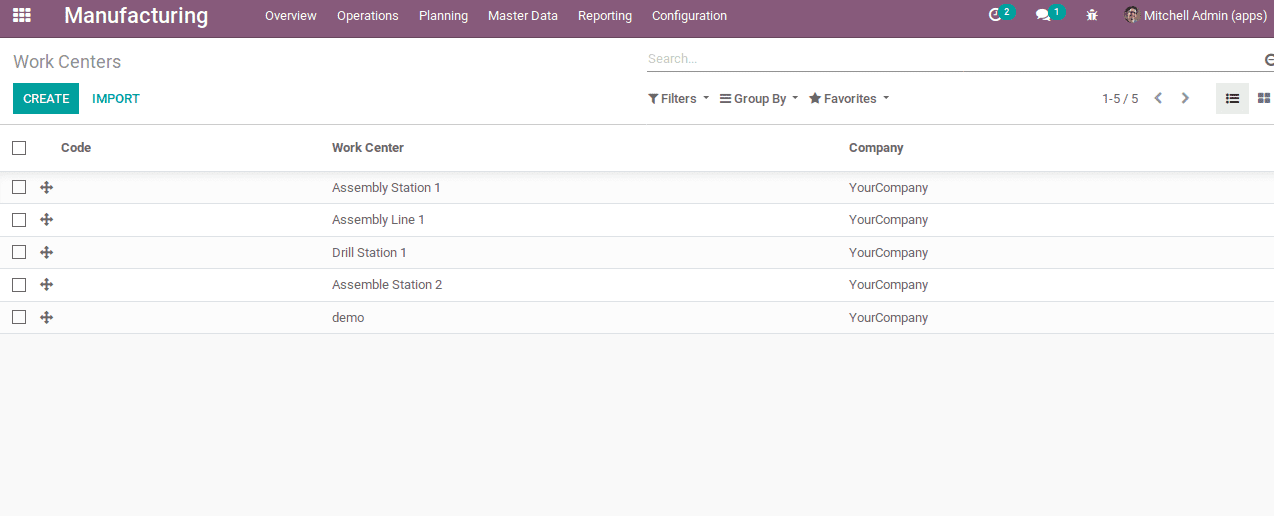

Manufacturing -> Master Data -> Work center

You can click on the CREATE button to create a new work center. A wizard thereby appears on the page as shown below.

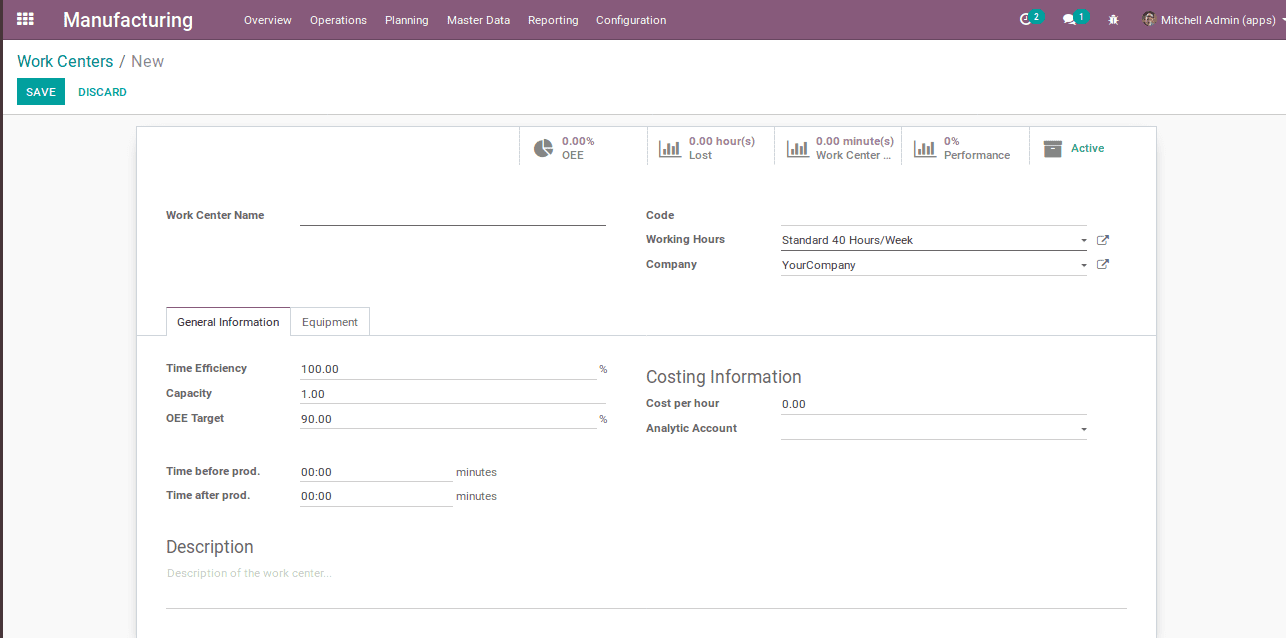

In the wizard, there are the options for configuring a work center such as defining the name of the work center, also the working hours of the work center in a week.

Also, there come two tabs titled general information and equipment. General information contains time efficiency in percentage i.e. the time consumed for production.

Secondly, Capacity. It denotes the capacity of the work center i.e. the total number of quantity that it can produce at a time. The time before production and time after production denotes the time taken for setting the work center prior to production and later cleaning and rearranging the work center post their production. And Costing information decide the cost of hours for the work center.

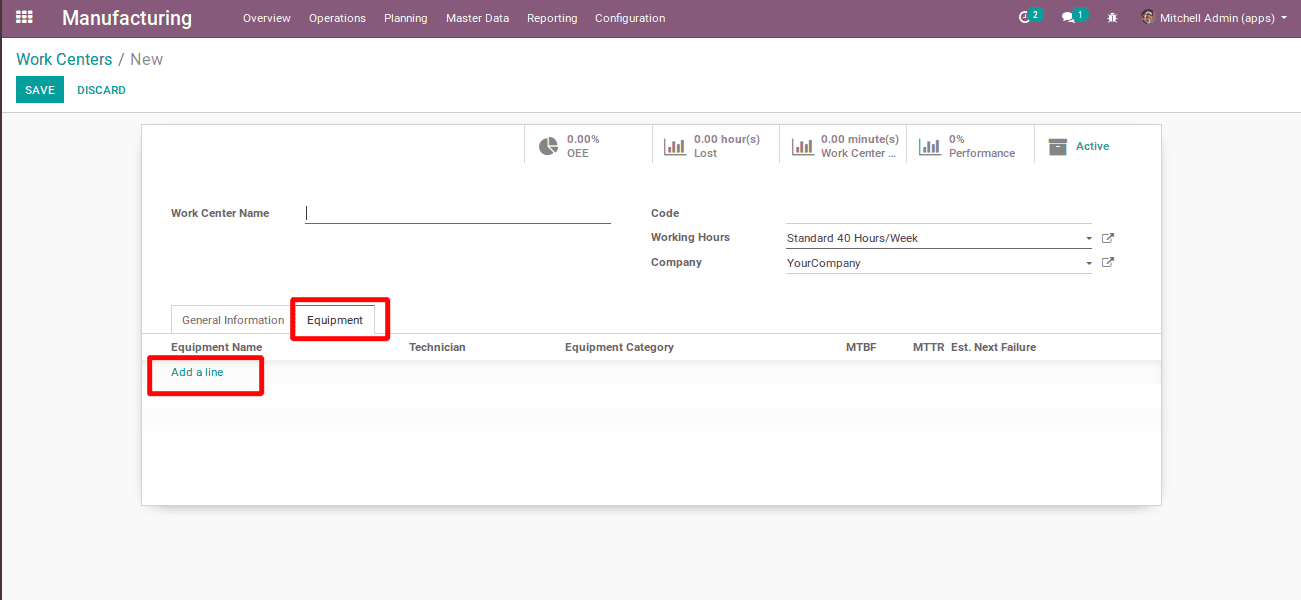

The Equipment window contains the details of the equipment used in the Work Center (shown below).

There is a button to add a line to add equipment. Upon clicking the button, a pop-up window will appear on the page as shown below.

Create Routing

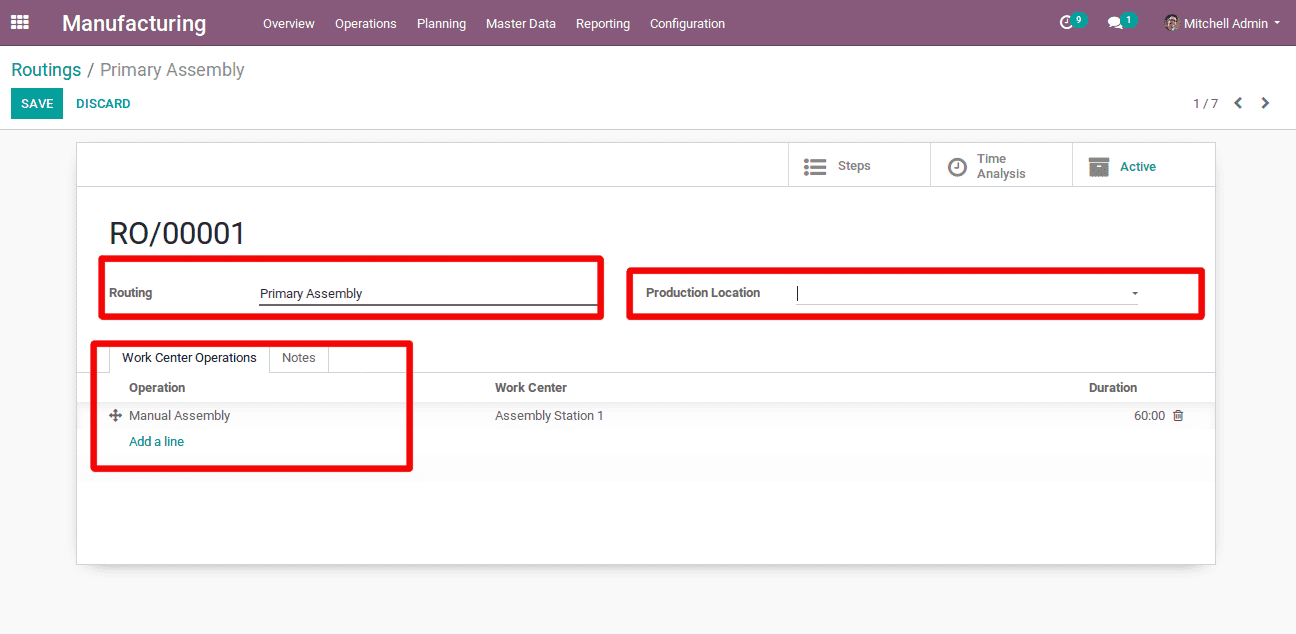

Manufacturing -> Master data -> Routing

In this page, one can see all the routing and a button for creating the new routing.

There is a window for creating new routing. One can fill the name of the routing, production location and add work operation there. Also, there defines an option for add operation. Click add a line, the action brings in a pop-up window like below:

In this wizard there contains the name of the operation, work center, and duration computation. The duration computation comes along with two options: compute based on real-time and set duration manually and also an option for setting default duration. Once you mark all your changes, click the SAVE button to save the operation and later save the route.

Later you can select the created route at the time of BOM creation.

This is how routing is done in the manufacturing module of Odoo ERP. To read more about the importance of Odoo Manufacturing Routing, refer to our industry page Odoo Manufacturing Routing