Manufacturing is a process of converting raw materials or components into finished goods or products. For a company that handles a large number of manufacturing products, they need to track every manufacturing order efficiently and effectively. The Manufacturing Module in Odoo is self- reliant, independent, and robust in handling the complexity of Production, Managing Bills of Materials, Planning the Manufacturing Orders, and Tracking Work Orders, etc. The manufacturing module is one of the basic applications in Odoo. You have to install the ‘Manufacturing’ app from Odoo Apps to avail of this module on your ERP. Since the Manufacturing module is highly integrated with Inventory Management, you can keep your inventory automatically updated with each manufacturing process.

The working methodology is very simple in Odoo manufacturing. One can create a Manufacturing Order of a product and pass it through your different stages in the production line and complete production. One may customize manufacturing procedures matching the company’s process using the work center and routing concepts. Also, the end-user can easily manage ‘scraps’ during any stage of manufacturing procedure and ‘unbuild’ a manufactured product if needed. An organization may assign different level users to overlook the entire manufacturing procedure for the effective management of business processes.

Create a Manufacturing Order(Simple Method)

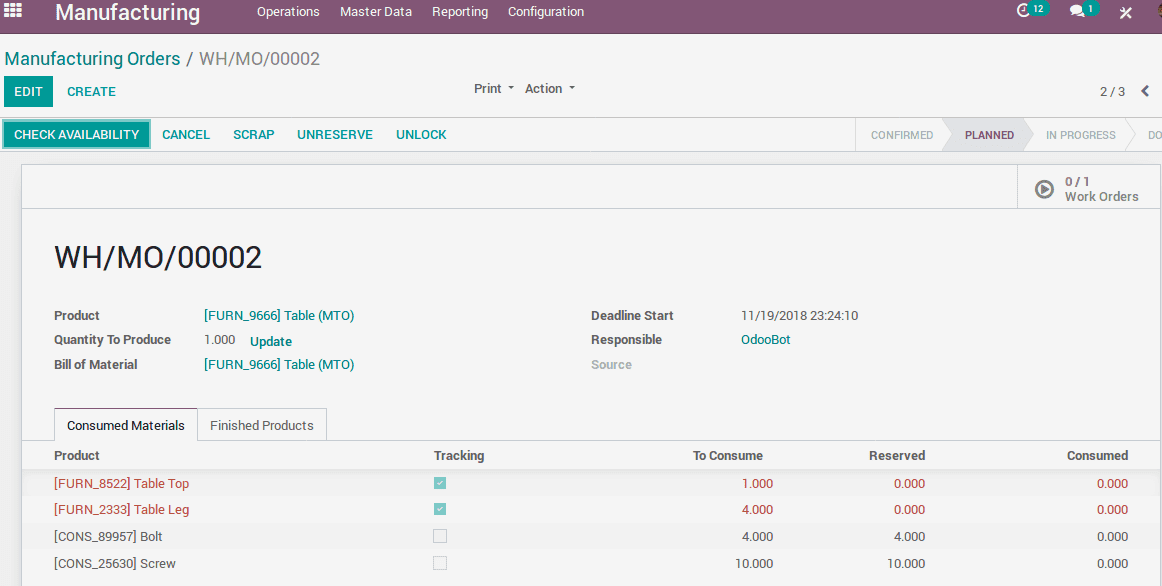

Manufacturing > Operations > Manufacturing Orders > Create

1) Choose a product from the list (or you may create a new one)

2) Choose the Bill of Material.

3) The finished product tab will show the number of finished products.

4) Consumed Material tab will display the material consumed for the production.

5) Click “Check availability” to see the availability of raw materials in inventory.

Manage Production

Once you have created and confirmed a Manufacturing order, you can start production. Odoo will list all the Manufacturing orders under Manufacturing > Operations > Manufacturing Orders.

You can view the status of all ongoing manufacturing orders from here.

Select a Manufacturing Order from the list.

Since Odoo offers negative inventory support, one can start production even without ensuring the raw material availability.

Click “Produce” to start production.

Once you start production, the status bar will change as follows

“Mark as Done” to complete the production process.

Create a Manufacturing Order (Advanced Method)

Comparing to a simple method, the advanced method provides each company to configure a more detailed manufacturing process such as setting up THE Work Centers, Routing, Work Order management, etc.

To enable this feature:

Manufacturing ->Configuration -> Settings

Enable ‘ Work Orders’.This will enable a new menu in the dashboard to manage Work Center, Routing, and Work Order.

Manufacturing > Operations > Manufacturing Order > Create

Fill the fields the same as before.

Select a ‘Routing’ mechanism, this will be automatically filled once you choose the BoM.

The Status bar will give the end-user a new option plan, click it to create the work order according to your routing plan.

In the new window, you will have an option to check the availability of raw material. (Odoo support negative inventory)

Click <Save>

Unlike in simple methods, now you just created a Work Order the production process has not started yet.

Manage Production

To Start Production you have two option either

Open a manufacturing order and Click the “Work Order” button in the form. Or you can access all your work orders from

Manufacturing > Operations > Work Order

In the first case, you will see all the work orders listed there with their status.

Select the Tasks from Work Order one by one and complete it.

Complete all the processes in the Work Order to complete Production.

Once you complete all the process in Work Order, then you can add the product into the inventory

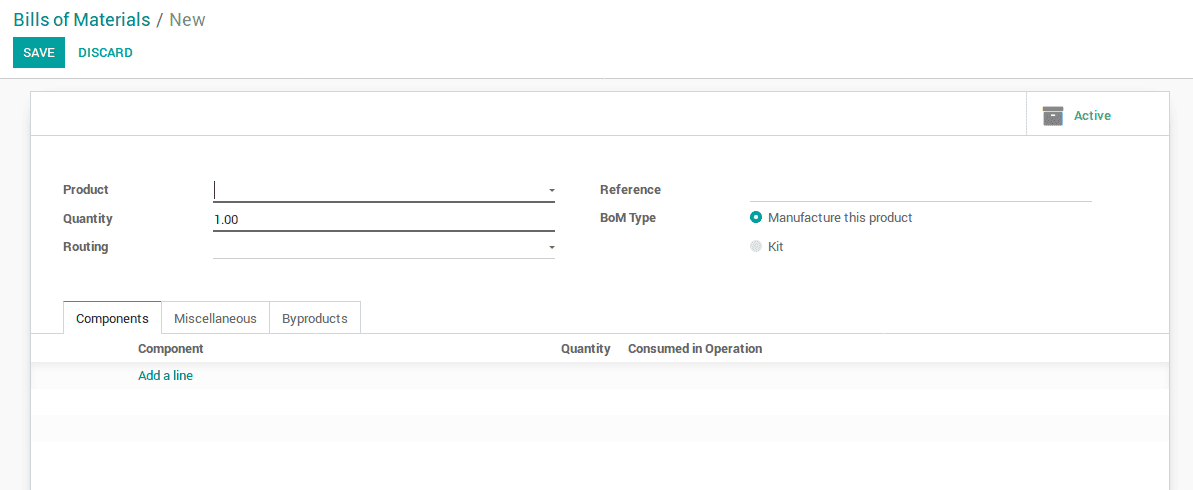

Bill of Materials

BoM is the basic building block of any manufacturing process. It is the list of raw materials needed to produce a product. So while creating a manufacturing order for a particular product, one needs to select corresponding BoM from the list. BoM will help the user to create the inventory updated during the manufacturing process. So before creating BoM, one first needs to add the raw material to the product list in inventory.

Manufacturing > Master Data > Bill of Materials > Create

Select a product from the list.

Go to Settings > Manufacturing Order > Product variant option to enable select product variant option. (In case you produce a product variant)

The reference field is used to distinguish different BoM for the same product.

Click Add an Item field and add the raw materials for your product. “Routing”, the field is used to specify the WorkCentre routing of the manufacturing process.

Under the Miscellaneous tab in BoM, Sequence defines the order in which your BoMs will be selected for production orders, with lower numbers having higher priority.

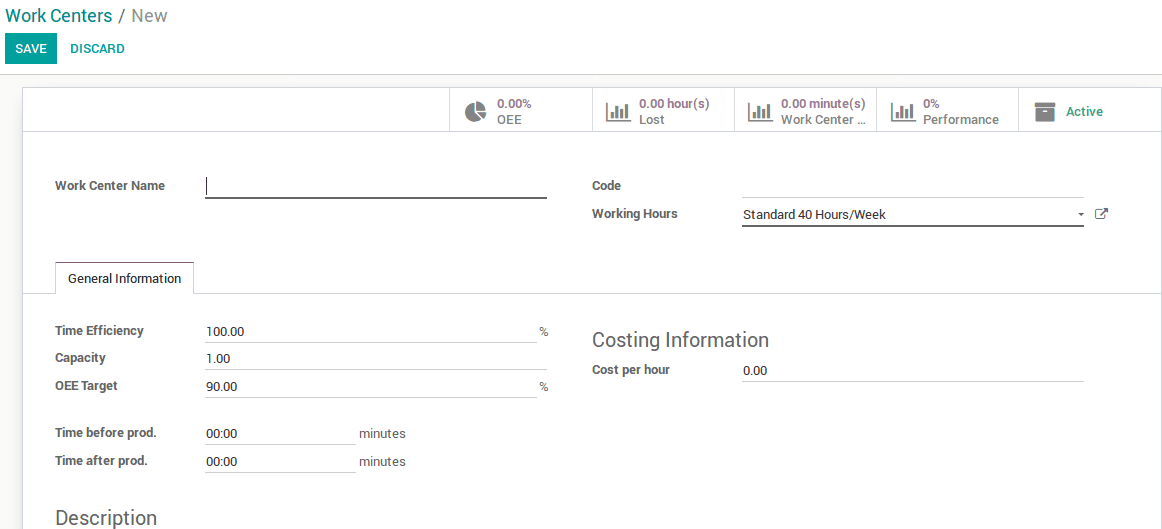

Work center

As the name indicates, it is the Physical place in your firm where different manufacturing processes are done. You can create your work center details with all its performance indices.

Later you can use this data to analyze the efficiency and other details of each work center.

Create a Work Center

Manufacturing > Master Data > Work Centers >Create

Click <save> and mark <Active> to make it available for use.

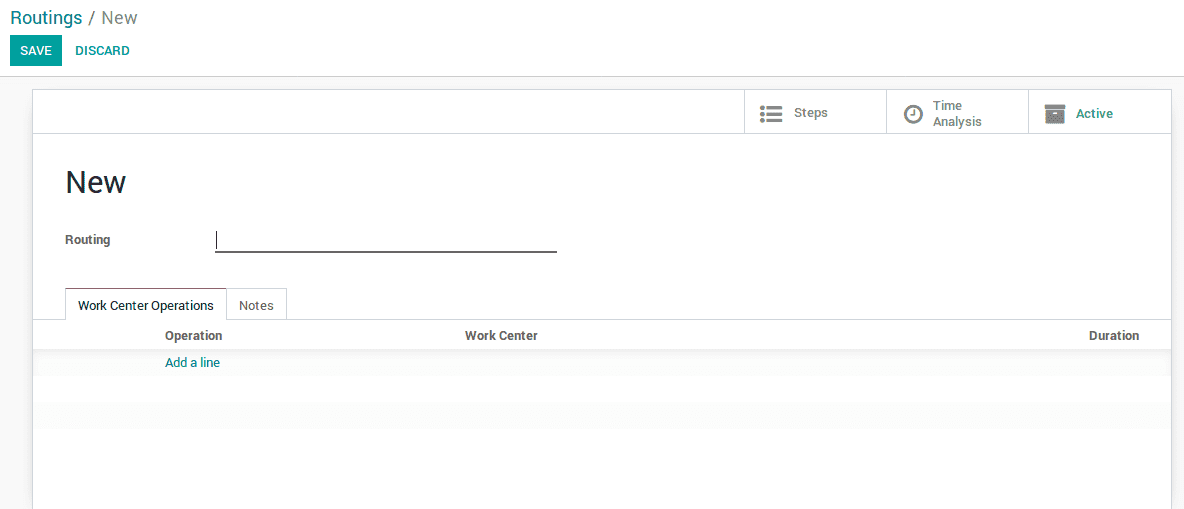

Routing

Each product has its own routes. The manufacturing process is not a single step process it may contain many work centers and each work centers have its own processes and process time.

From this menu, we can set the order or route of each manufacturing. It purely depends on the manufacturing company process. Some company has the same type of manufacturing process. There we create single routing. Some company has a different manufacturing process for different products. There we create each multiple routing.

Manufacturing > Master Data > Routings > Create Give Route a Name

Click Add an Item to add the work centers included in this route

Click <save> and <Mark Active>

Work Order

Once you have created and confirmed the Manufacturing Order with a specific route. All the processes in the route are listed as work orders. So in order to complete a production, we must complete all the associated processes in the work order. We can access Work Order related to a Manufacturing Order, either from Manufacture Order form or directly from Manufacturing > Operations > Work Orders.

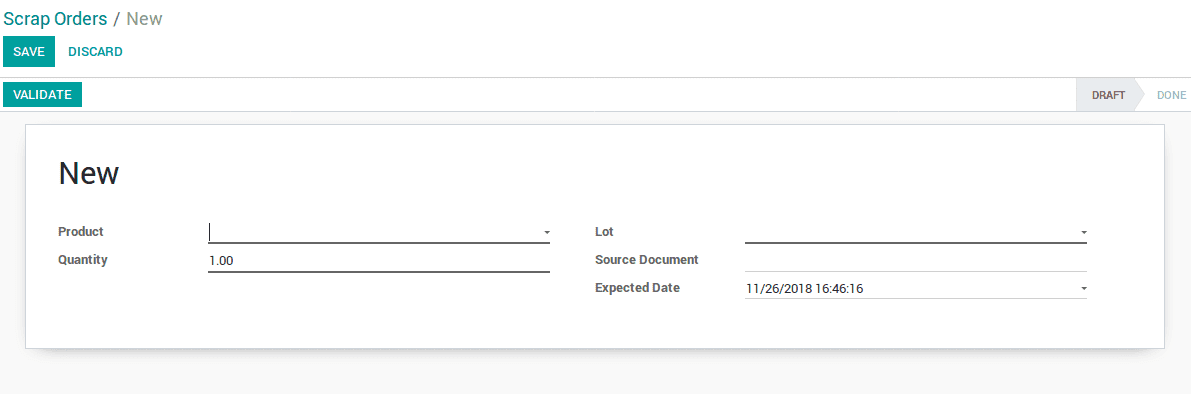

Scrap

One of the most useful features of Odoo is that you can create Scrap at any stage of the production line. You can always see a Scrap button almost all the stages of the production line. Click this button to create instant scrap entry in inventory. You can create fresh scrap entry from

Manufacturing > Operations > Scrap > Create

Or you can make a quick entry by clicking on the Scrap button available on almost all forms of production.

Fill the fields and click “validate”. It will be automatically inserted into the inventory.

Unbuild Orders

Another useful feature in Manufacturing is Unbuild. We can rebuild the products into its bill of materials. This is actually a reverse process of production.

Manufacturing > Operations > Unbuild Orders > Create

Select the product which needs to Unbuild, select the bill of materials and quantity.

If you need to specify a particular Manufacturing Order we can mention it here.

Click <Done> and <Save>

Productivity Losses

Manufacturing > Configuration > Productivity Losses > Create

Reporting

Odoo Reporting tools can produce concise yet very effective reports. You can view different types of report on Manufacturing Orders, Work orders, Work center Performance etc. under Reports tab.