The warehouse operations of a company should be operated with precise operating rules to avoid conflict and cowshed of company operations. Furthermore to say the routing of the products in the warehouse of a company should be drafted in an efficient and reliable way. Odoo has an efficient warehouse management system that provides the user with advanced features to manage the inventory and its operations. The Odoo platform operating integrated with all the company operations including, sales, purchase, HR management, and many more aspects of Odoo will be a reliable tool to manage the operations of the inventory.

Odoo 14 the fastest Odoo released in the last Odoo experience meet is packed and loaded with advanced operational features that would allow the users to undergo their business efficiently and effectively. Warehouse routing is one of the advanced features which comes in handy for the user. The routing operations combined with the rules of product movement will allow the user to have a reliable path of product moves. Further to say these routings can be described and customized by the user based on their requirements and terminologies of business operations or product movies in a company.

This blog will provide insight into the Warehouse management and routing operations of Odoo 14.

How does it work?

The warehouse is the physical location where the products of the company are being stirred. The inventory operations are triggered and managed from here. Further to say the Odoo platform allows the user to create and manage multiple warehouses at the same time.

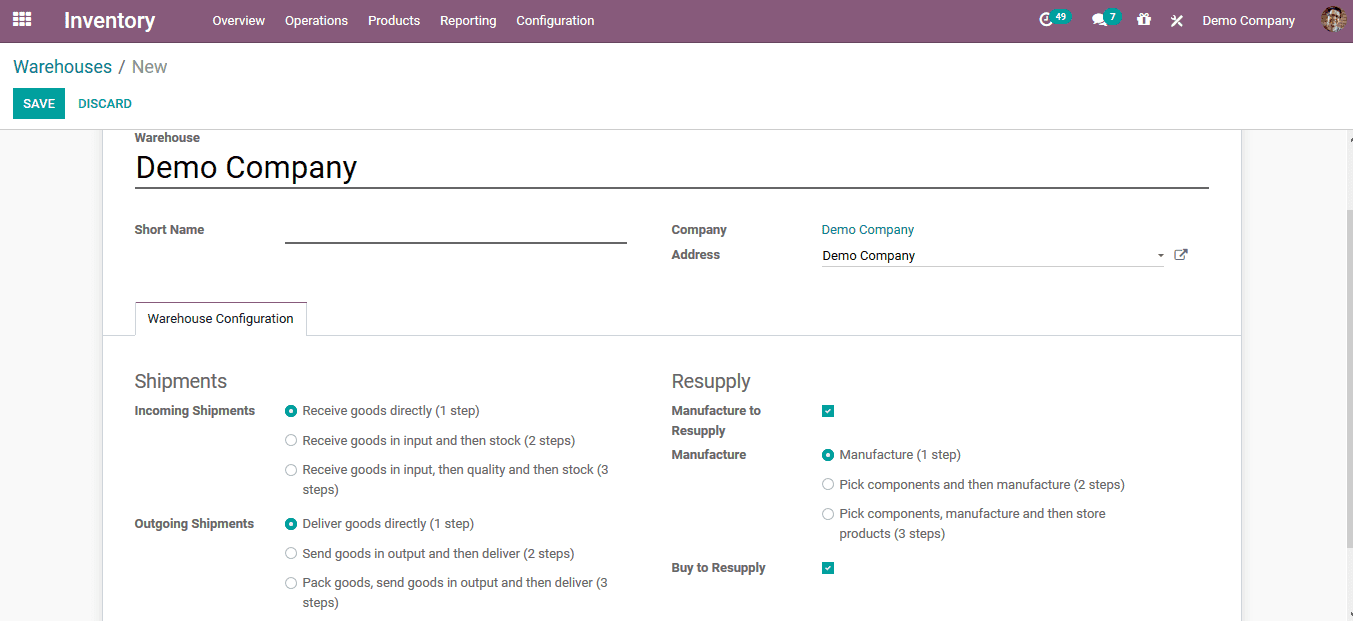

The warehouse menu accessible from the configuration tab of the inventory module allows the users to view all the company warehouses and create a new one. Here, all the warehouses of the company are listed and the user can edit the details of the ones required and the user can also create a new one.

In the warehouse creations window, the user can provide a name, assign a short name, and allocate the address of the operation. Additionally, the shipment option for both the incoming and outgoing ones can be configured. In addition, the resupply options along with the manufacturing aspects of the warehouse can also be configured.

Locations

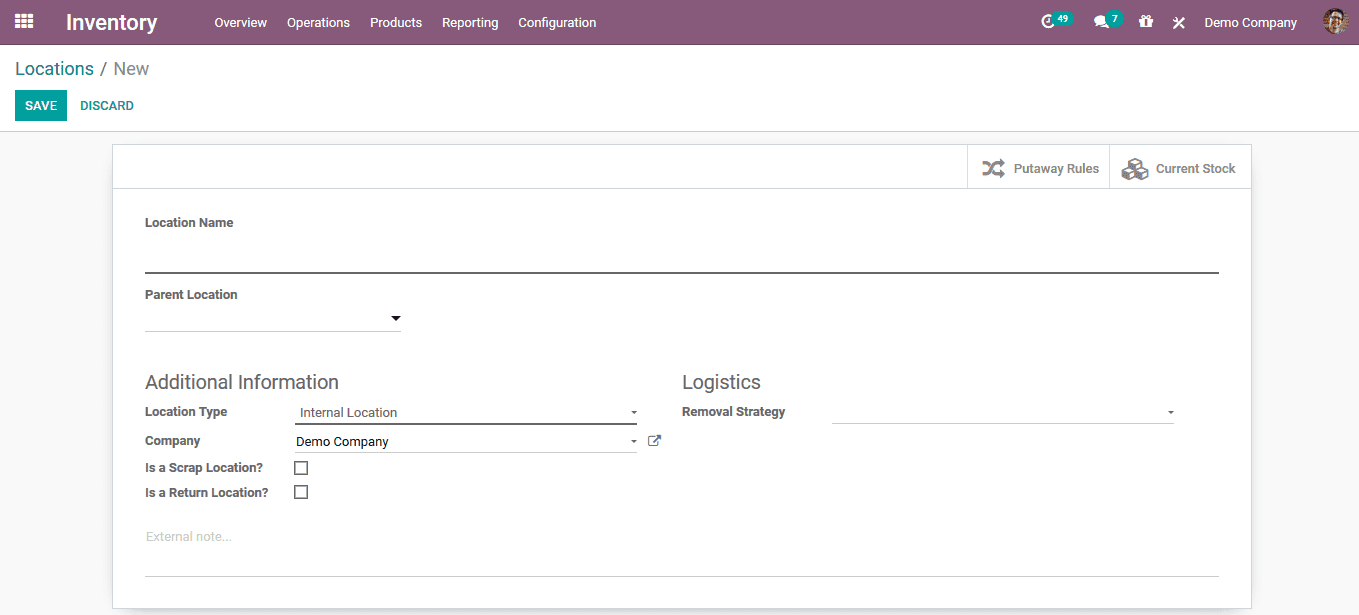

The locations are the exact places of the products being placed in a warehouse operation in Odoo. These locations can be physical and virtual ones. The platform also allows the users to configure the partner, vendor as well as customer locations in Odoo.

Locations menu can be accessed from the configuration tab of the inventory module which showcases all the locations described in the platform. Here, the user can also avail of the option to create new locations as per their requirement. In the locations creation window, the user can pass an anime and the parent locations. Additionally, the location type, company, and removal strategy can be chosen from the list. Moreover, the user can assign the respective locations as a scrap of return locations.

Routes

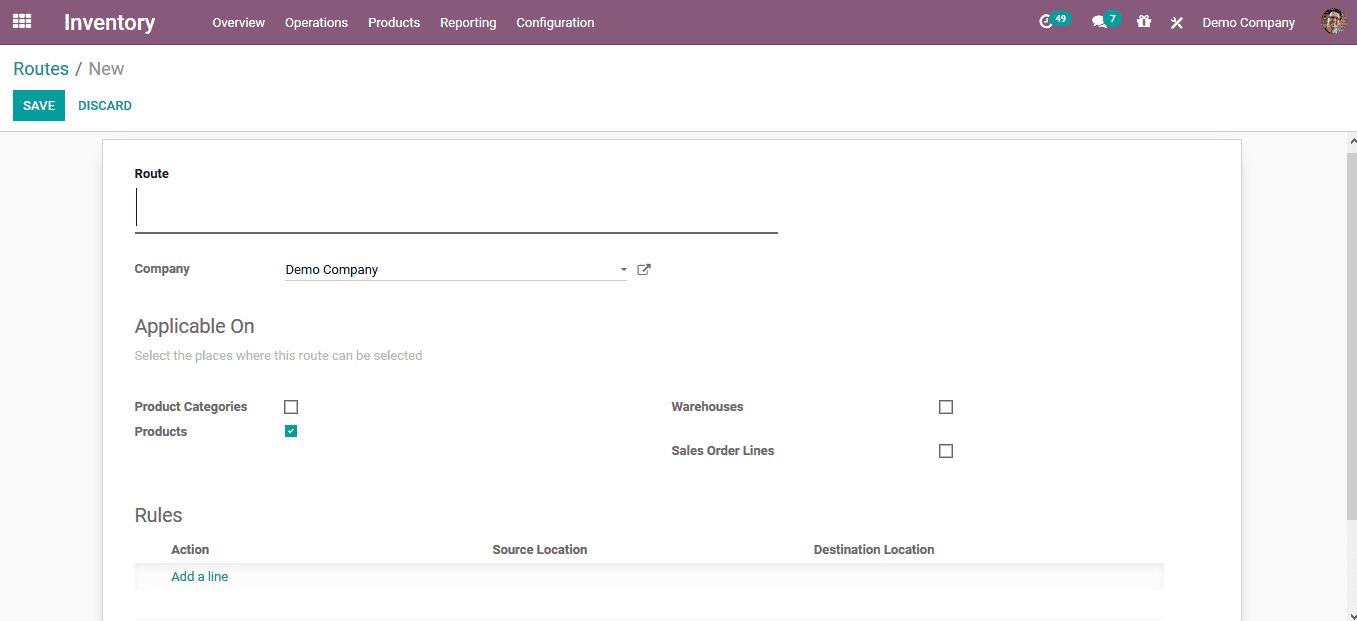

Routes of the product move in the inventory can be described in the Odoo platform. These routes of operations can be defined to be reliable and efficient to the inventory and warehouse operations.

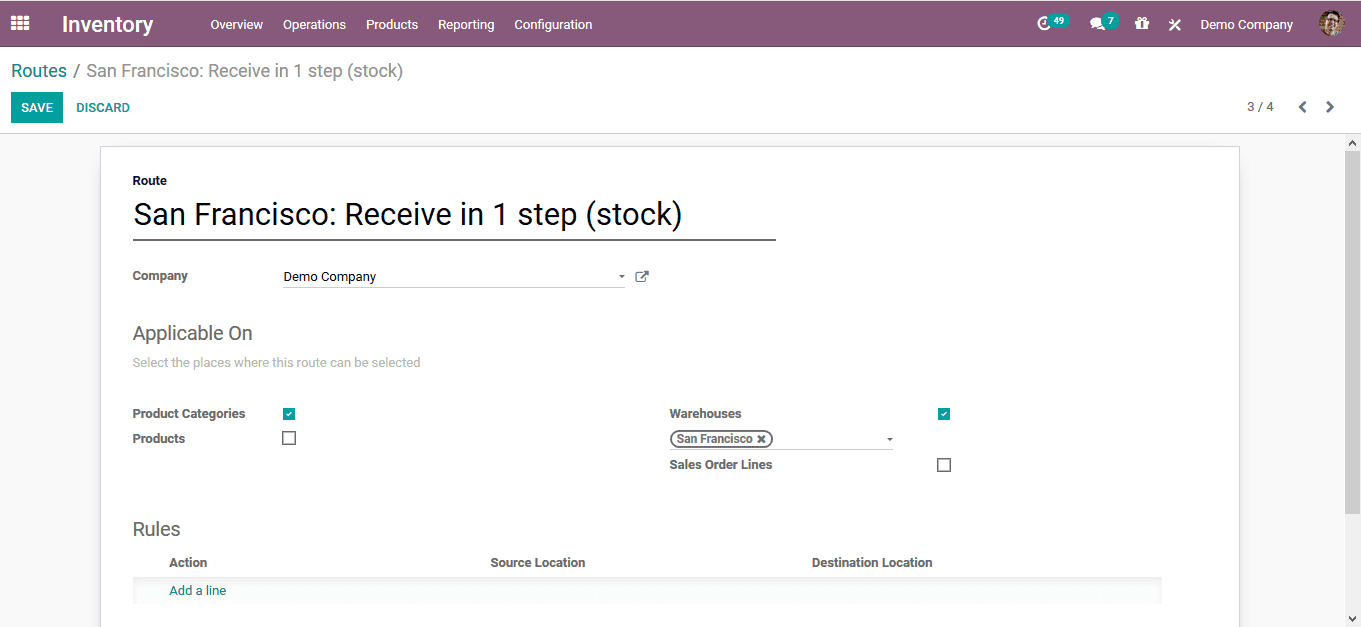

The routes menu can be viewed from the configuration tab where all the routes of operation of the company are defined. The user can create new routes where they have to define a name, allocate the company, assign the applicability, and add the rules which can be defined by selecting the add a line option available. The route can be made applicable for the product, product category, warehouse, or a sales order line.

Procurement rules

The procurement rules of operations are triggered when the customer comes to buy the product. The procurement rules defined will establish the route operations for product removal in Odoo.

There are three types of procurement rules which can be defined in Odoo

- Product movement from one location to another within the warehouse or a separate warehouse

- Triggering of manufacturing orders based on the order and requirement

- Triggering the purchase or busing rule which will initiate a purchase order.

In case of application to the warehouse, the user will have to describe the warehouse for the respective route to be applicable.

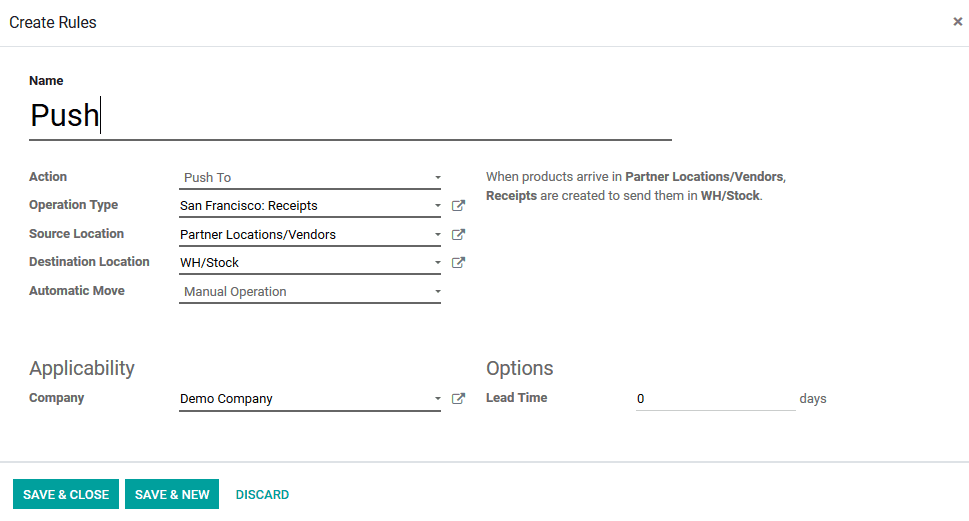

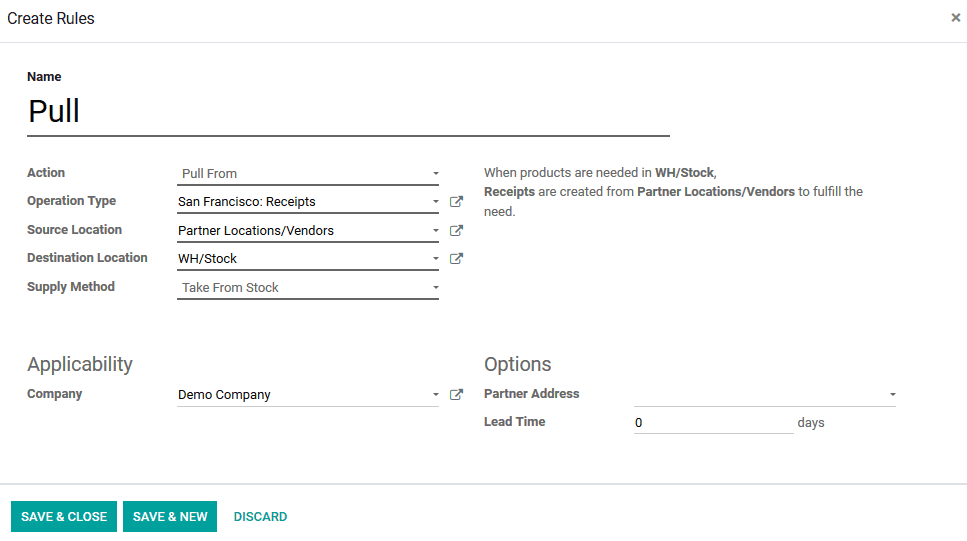

On creating the rules the user can either define it as a pull rule or push rule.

In case of the push rules, the user can allocate the location from which it is pushed to a destination.

In the case of the pull rule, the products are being pulled from the respective location to the destination.

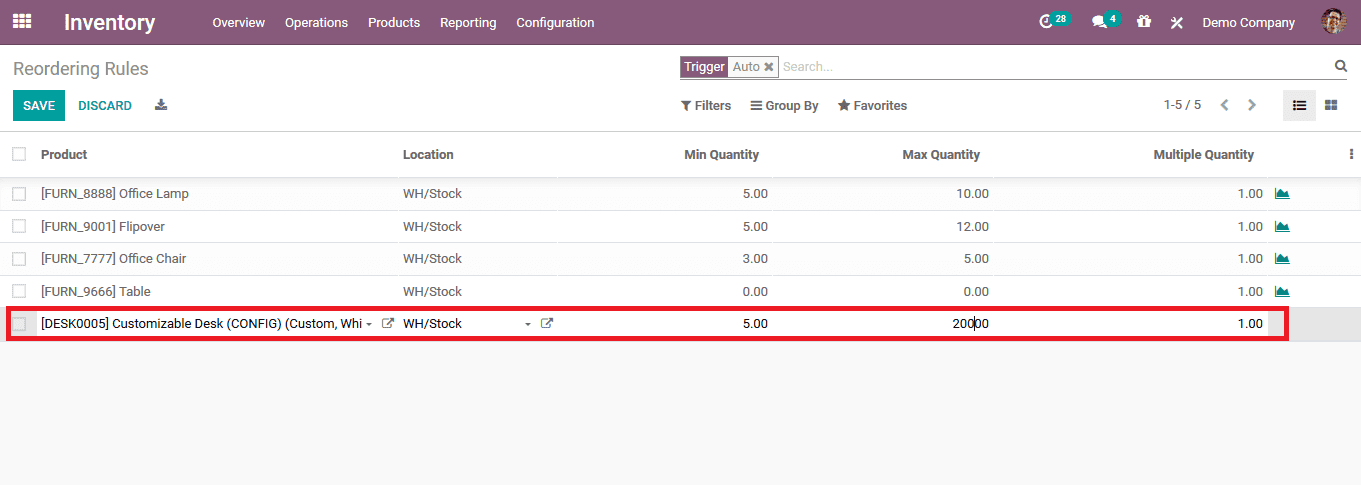

Reordering rules

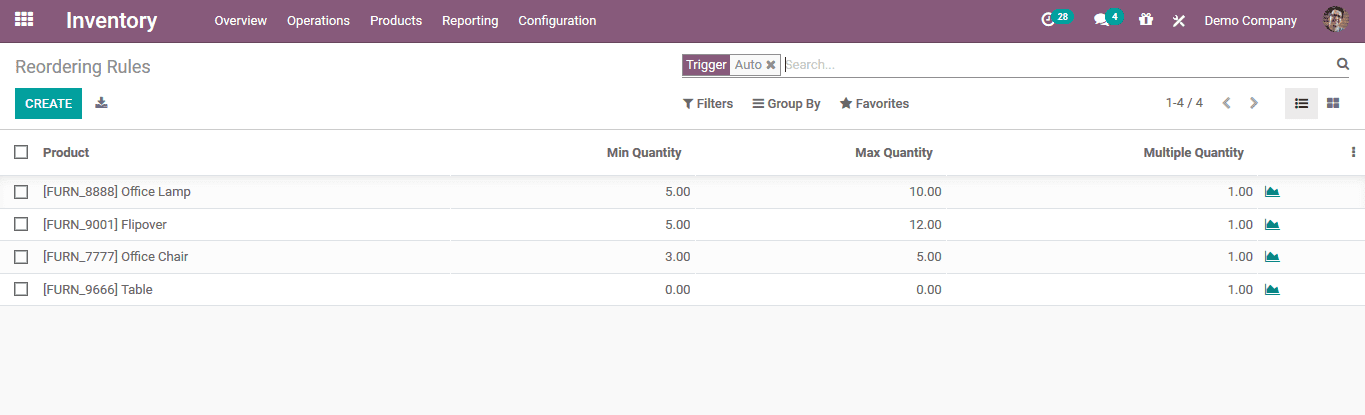

The feature of automation which can be set on the product reordering in Odoo. These rules can be defined for each product based on company operations. All the reordering rules are defined in the reordering rules menu accessible form the configuration tab.

The reordering rule can be defined for a specific product with the minimum and the maximum quantities defined.

Watch Video: Odoo 14 Reordering Rule

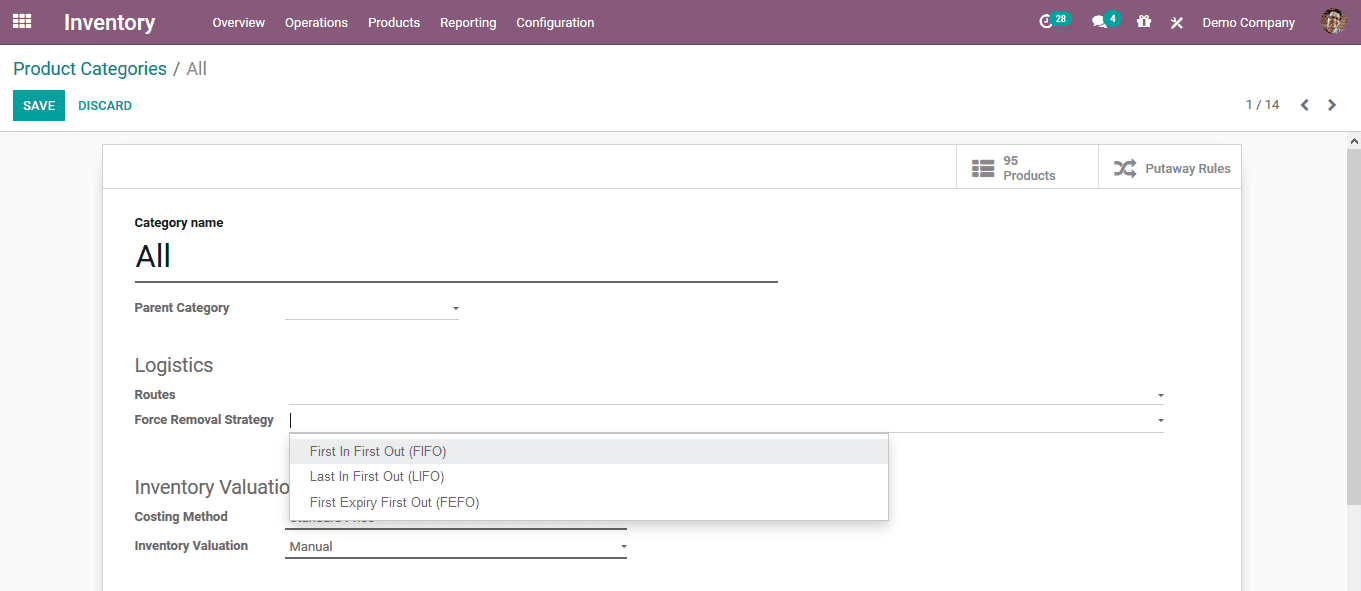

Removal strategies

The Odoo a platform allows the user to define removal strategies of the product removal upon sales. These strategies could automate the product removal and will bring in the autonomy of operations of the Odoo inventory. The removal strategies can be defined as FIFO, LIFO, and FEFO which will define the removal strategies product categories.

FIFO: First in first out which is the removal strategy similar to the operation of a queue where the initially incoming product is sold out at first.

LIFO: Last in first out which as per terminology of operations can be coined as opposite of FIFO. Here the last incoming product is sold out.

FEFO: The first expiry first out is based on the description of the expiry dates and the rules defined while creating a product in Odoo. The product which will be recently expired will be sold out at the initial instance rather than the order of their arrival to the inventory.

Expiry dates

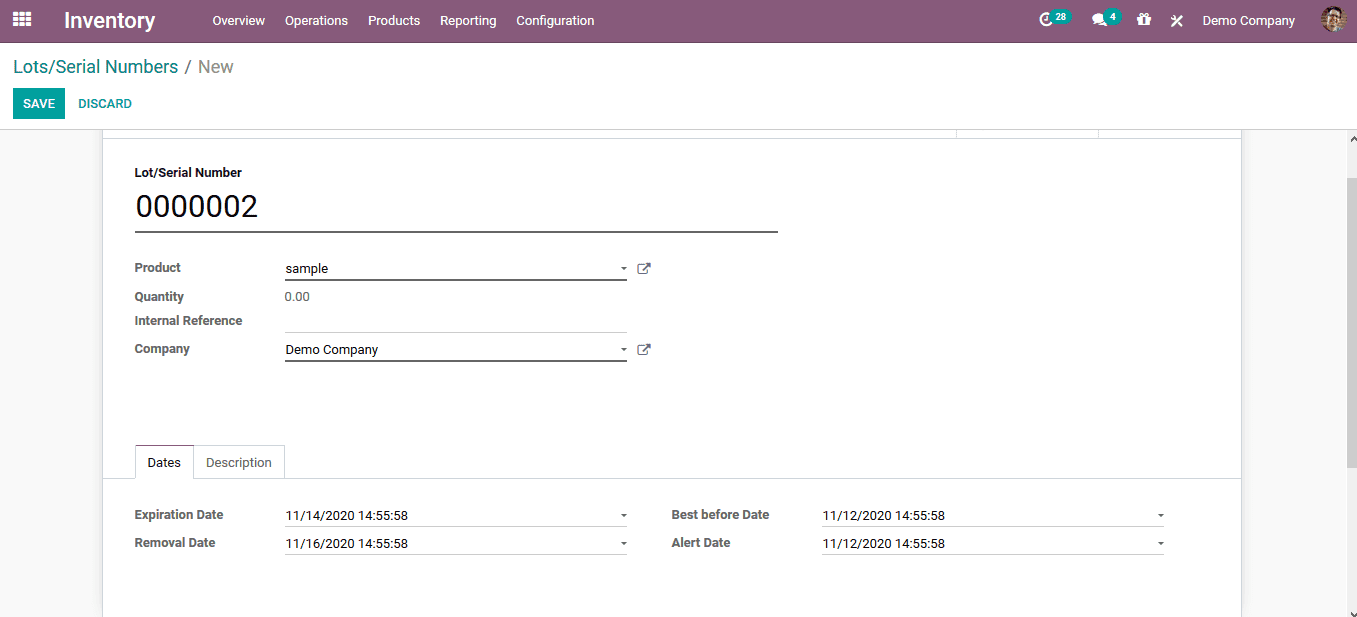

The expiry dates of the product can be set for the sales of the perishable items in the Odoo platform. Furthermore, to set the expiry date on the product the user should enable the options in the inventory settings menu.

On enabling it the user will be able to define the expiry date of the product for the respective lot and serial number. While defining the serial number for the product the user can assign the expiration date in the dates menu.

Here the removal date and the best before date along with the alerts dates on the product can be defined.