To build is to construct. Then, what is unbuild? Unbuild is the reverse process of building. That means to unbuild a product means to separate its components. In a manufacturing industry, we may have to unbuild two different types of products. The first one is the product manufactured by our own company. The second type is the product purchased by the company.

Can we do the unbuilding process without any documentation? No. Like every other task in an industry unbuilding also has to be documented and managed through a proper channel. We have to use a software tool to coordinate this process as well. Unbuilding, the reason for unbuilding, and other details have to be entered in the document to ensure transparency in the industry.

Odoo Manufacturing

Odoo Manufacturing is a tool that has all features and functionalities to manage a manufacturing industry the most efficient way. Odoo manufacturing offers support for product manufacturing by preparing manufacturing orders and other documents.

Key highlights of Odoo manufacturing are

- Manufacturing order management

- Work order management

- Scrap order management

- Unbuild order management

- Product management

- Bill of material management

- Lot/Serial number management

- Product variant management

- Master Production Schedule

- Report analysis

Odoo Unbuild Orders

Odoo Unbuild orders support you in two ways

1. To unbuild a product manufactured your own company

2. To unbuild a product manufactured by some other company and purchased by your company,

In this blog, we can have a detailed discussion about how we can manage these two types of unbuild orders.

When will we want to unbuild a product? It can be due to different reasons. The first one could be the damage to the product. Though the product may not be saleable you may not have to scrap the whole product as only one or two components used for production may be damaged. Then we can separate these components and move them to our raw material stock.

For example, a wooden table. You might have completed the production of the wooden tables. But at the quality check your team detects some issues with the table legs. Then you don’t have to scrap the whole product. Instead, you can unbuild the product and reuse the tabletop. Only the table legs will have to be scrapped. This saves money and material.

In some other cases, a manufacturer may be purchasing a product from another vendor for using some parts of it or for recycling them.

Unbuild Orders

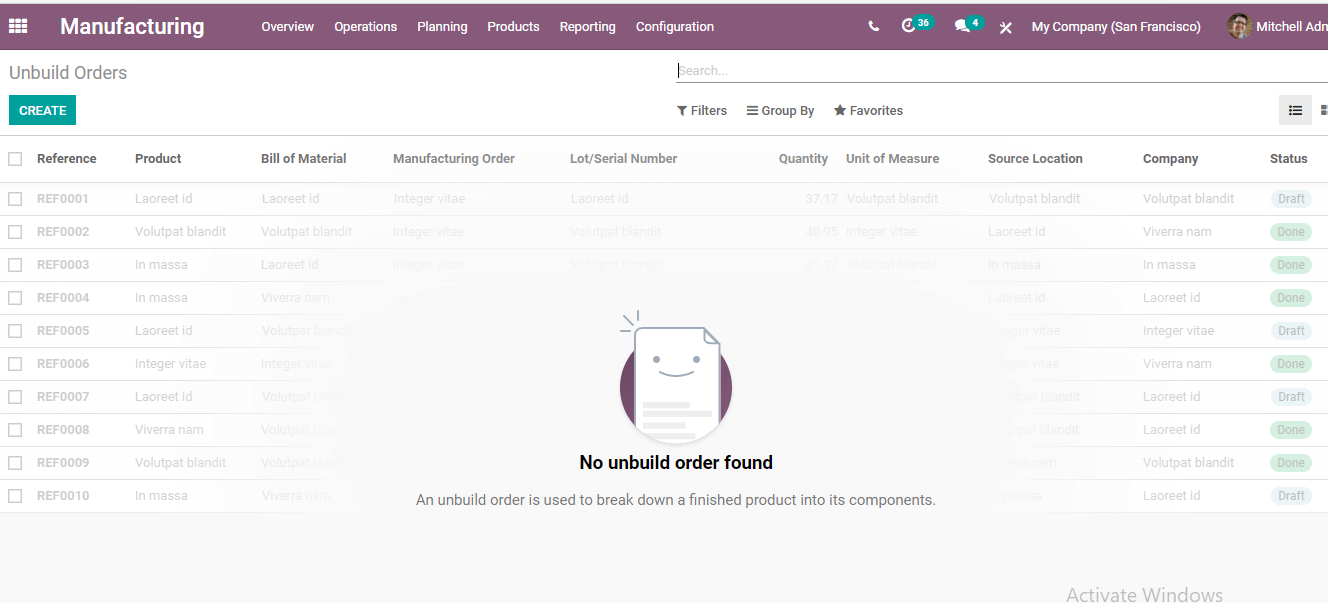

In the Manufacturing module, we can view menus like Overview, Planning, Operations, Reporting, Products, and Configuration.

Here, we can take Unbuild Orders option from the Operations menu.

So far we have not prepared any Unbuild Orders. So we have the Create button to carry out the process.

Let us use it.

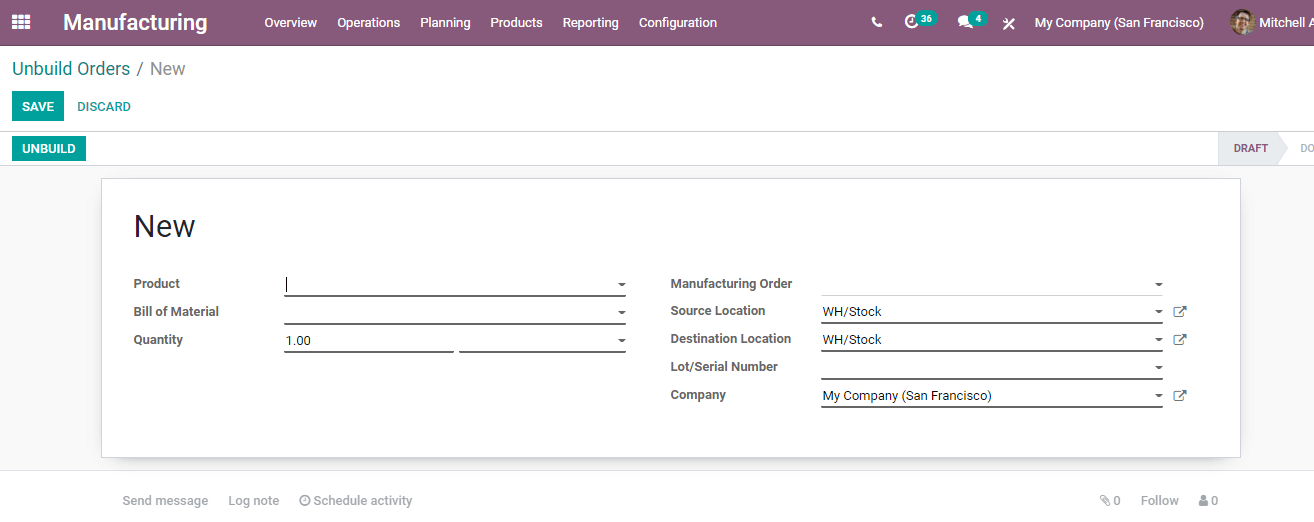

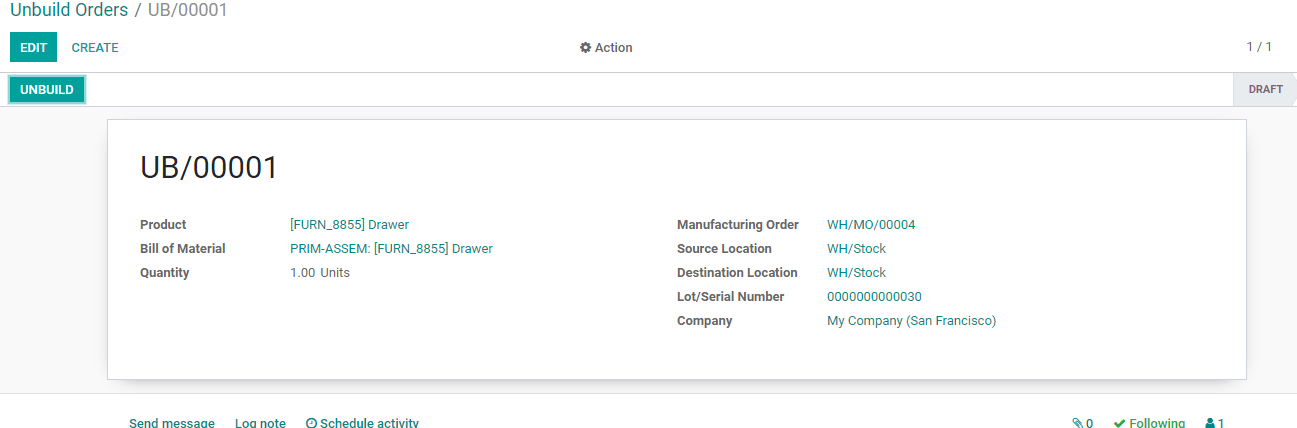

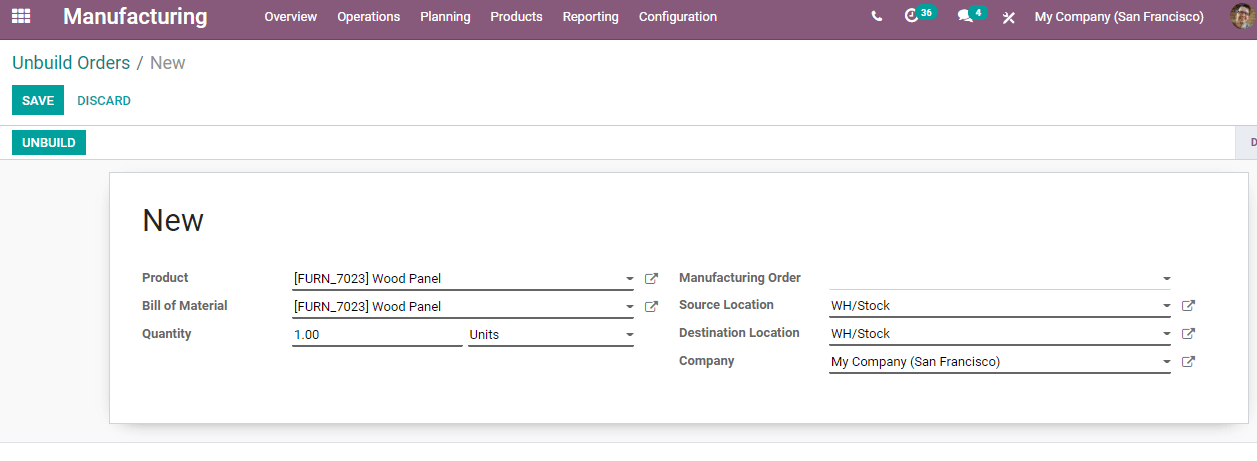

Here, we have got the unbuild form.

Unbuild order for the manufactured product

First we can check how to prepare to unbuild order for a manufactured product or for the product manufactured at your own company.

We can find a few fields here.

Product: Add the product name which you want to unbuild

Bill of Material: Fill in the BoM of the product that has to be dismantled. This will help to easily track the components and the quantity of the components

Quantity: The number of units to unbuild

Manufacturing Order: If you are unbuilding a product that was manufactured at your own unit, you can attach the manufacturing order details here.

Source Location: The location where the product that you want to unbuild is stored.

Destination Location: The storage space to which you want to shift the separated components.

Lot/Serial Number: This will help the system to choose the product which has been damaged or which you want to dismantle.

Company: The name of the company

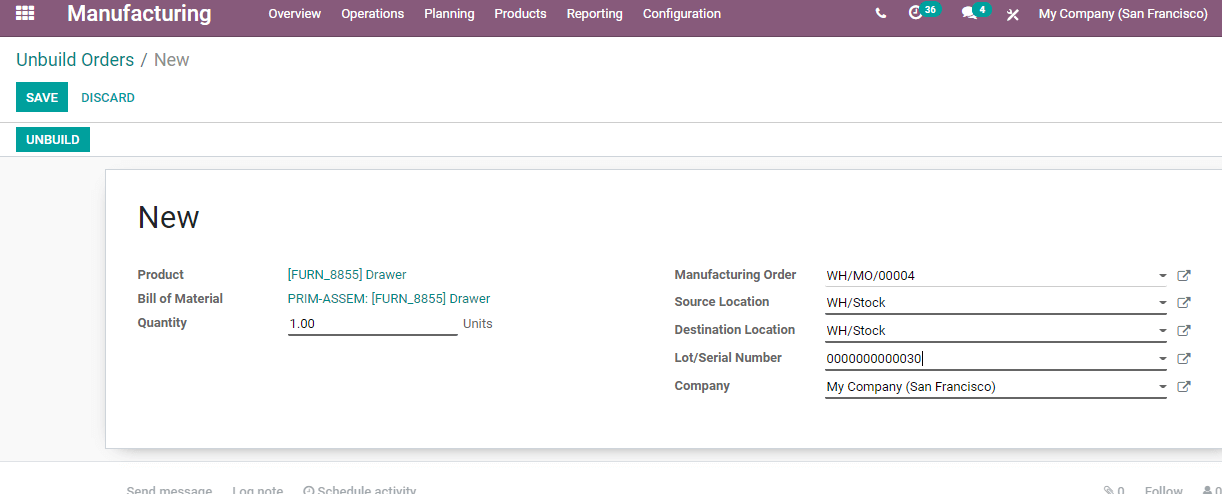

Here, I have chosen a Drawer and then the BoM got automatically updated. I decided to unbuild only one quantity. The manufacturing order can be chosen with the help of the drop-down menu.

Then the source location gets automatically updated.

The destination location can be fixed by us.

I have also given the lot/serial number and the company name.

Now we can Save or Discard the order.

I will save it and then go for Unbuild.

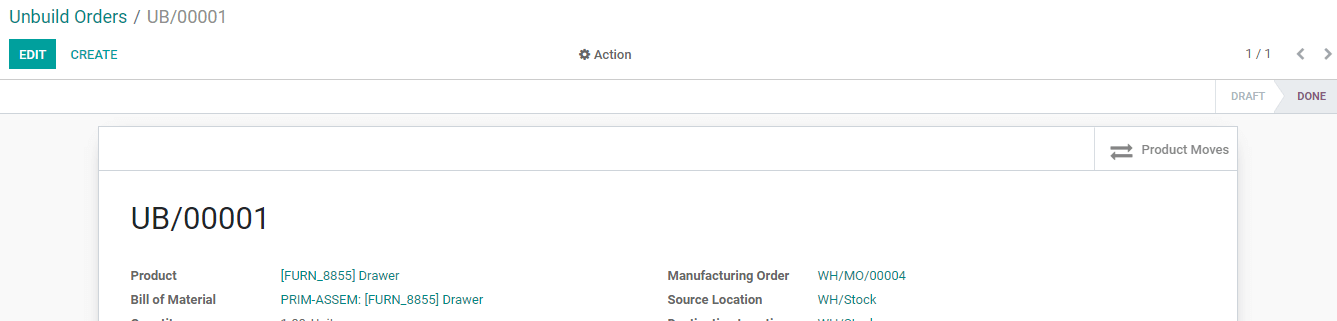

The status will then change to Done.

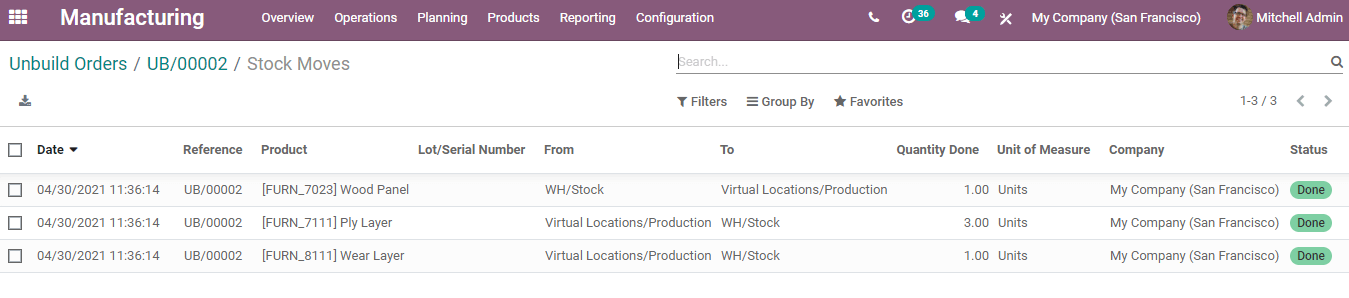

On the same page, we can find Product Moves

This will help us to trace the movement of the product.

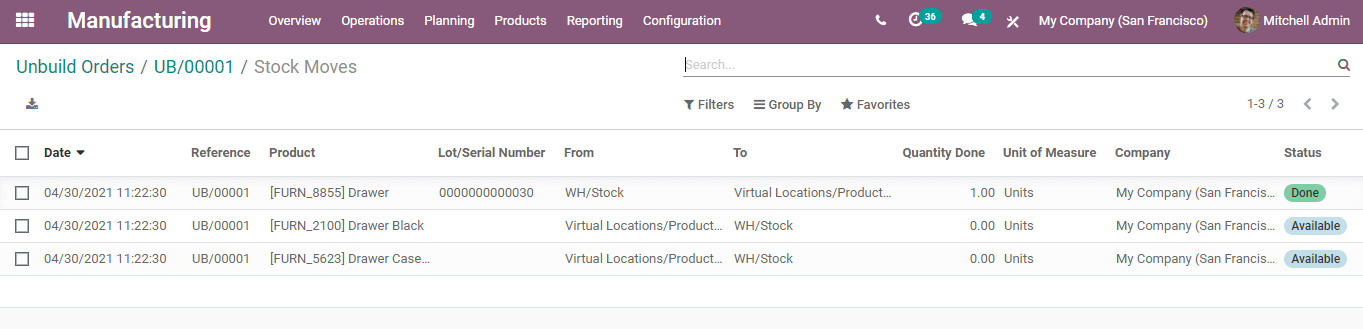

Here, we can see that the product Drawer has been moved from WH/Stock to virtual locations/Production.

We can also see that the components have been moved back from Production to Stock. If we had specified the shelf number in the Bill of Material or MO we could get it here also.

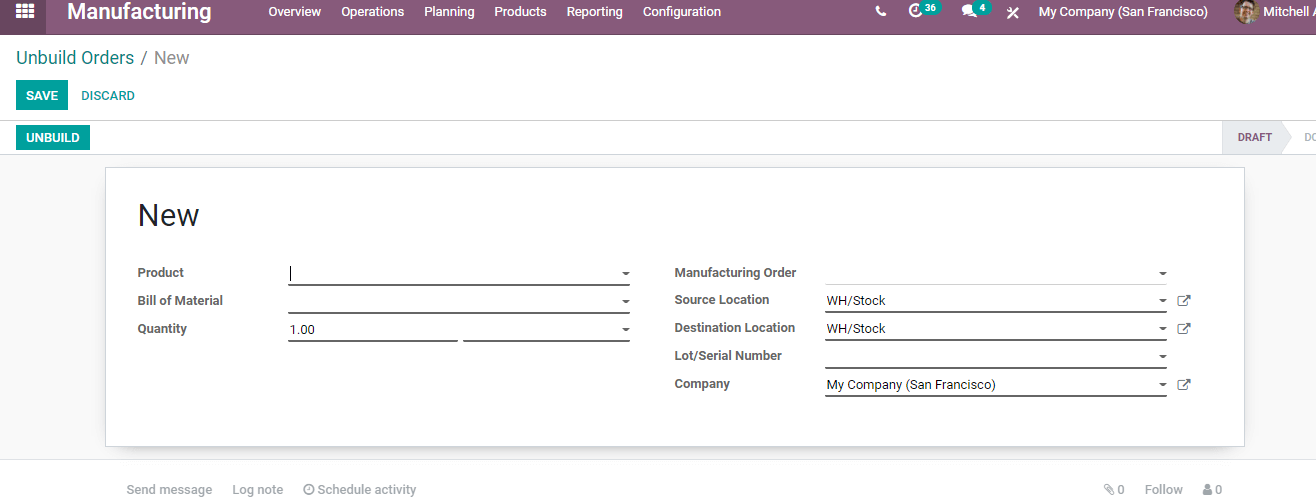

Unbuild order for a Purchased product

Now, it’s time to prepare unbuild orders for the purchased products.

This can also be done using the same form

As we did earlier, we have to fill in the fields Product, Bill of Material, Quantity, Source Location, Destination Location, Lot/Serial number, and company details here.

We have chosen the Wood panel as the purchased product. The Bill of Material got updated automatically as earlier and we can set the quantity.

Then, we do not have to include the manufacturing order details here as the product was not manufactured but purchased.

We can add source location and destination location here along with company details

Then SAVE and UNBUILD

Now we can check product move

Here, we can find that the product has been moved from stock to production location.

Then the components have been moved back from the production location again. It has been moved to the stock.

Hope you have understood the method to use unbuild orders in Odoo 14 Manufacturing.

We have already discussed in detail the different features and functionalities of Odoo 14 Manufacturing. You can get a glance at the general as well as functional blogs about Odoo 14 Manufacturing.

We have discussed Scrap order management, manufacturing order management, work center management, bill of material management lot and serial number management, and all other features of the manufacturing module.

For more details, you can visit

www.cybrosys.com. You can also mail at

odoo@cybrosys.com or dial

+918606827707