The Inventory module is organized into a single unit in its operations and linked to every functional module of the Odoo platform, both with the major modules and with the supporting and auxiliary modules, in order to provide comprehensive and efficient administration of the warehouse management operations. The business will be able to manage its online sales, retail, and wholesale operations from the sale platform of the Odoo ERP thanks to the centralized infrastructure. With the aid of the special tools and menu options mentioned, the Odoo Inventory module will offer total operation control for the business. One of the explicit aspects of the Odoo platform, which makes it the finest among the top business management software, is the ability to customize and adapt the operations based on the organization.

Odoo Inventory management uses specific operating tools that are well-designed to satisfy the comprehensive and realistic operational requirements to tackle all facets of the warehouse in a business. A warehouse is a location where goods are kept. It serves as the company's warehouse. A company may have a number of warehouses. The products can be replenished by moving them between warehouses. For distributing items and raw materials among warehouses, Odoo offers the "Resupply" option. This is possible when products are unavailable in any of the warehouses. The Odoo Inventory module makes this process rather simple.

Let us look at how to configure and manage the resupply feature in Odoo 16

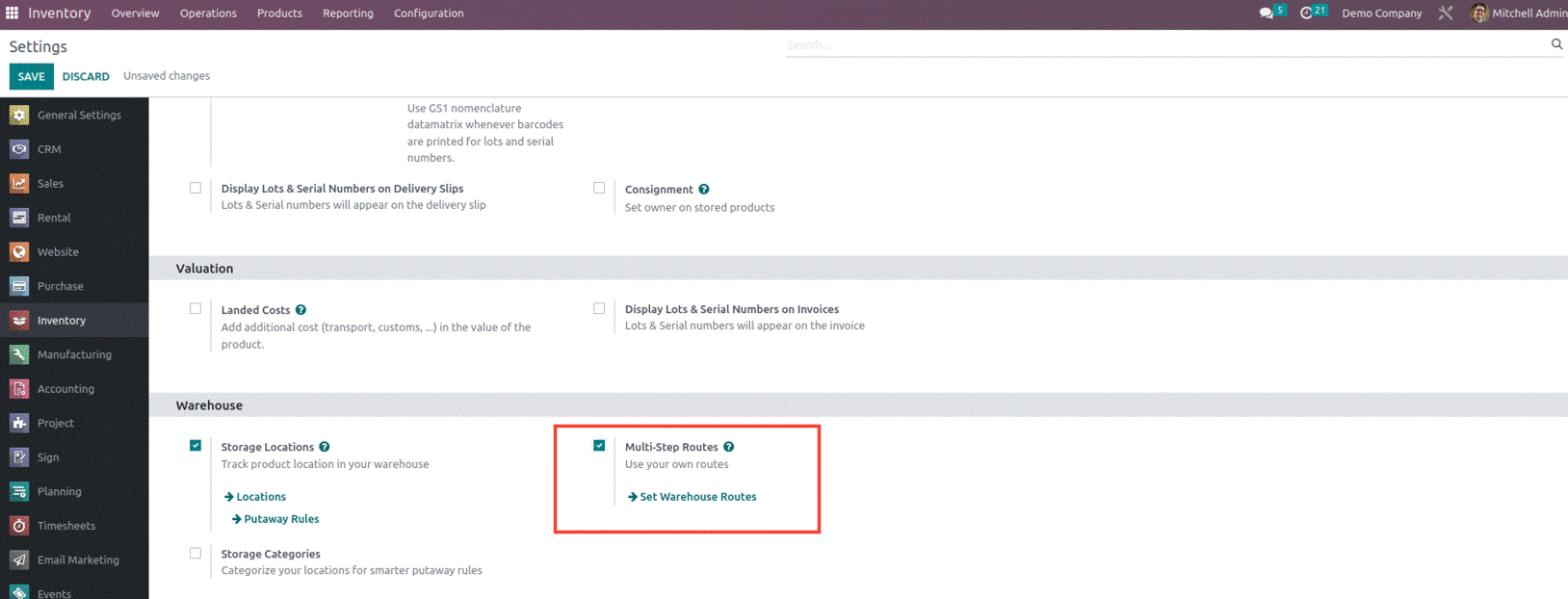

To configure the Resupply feature, we must first enable the Multi-step Routes options from the settings of the Inventory module, along with which we can also set up multiple Warehouses, as shown below.

A frequent user case for multiple warehouses is to have one primary distribution center that resupplies to its various stores and in this instance, every store is treated as a local warehouse. A product is ordered to the main warehouse when a store needs to restock. The user can quickly specify which warehouse can restock another warehouse using Odoo.

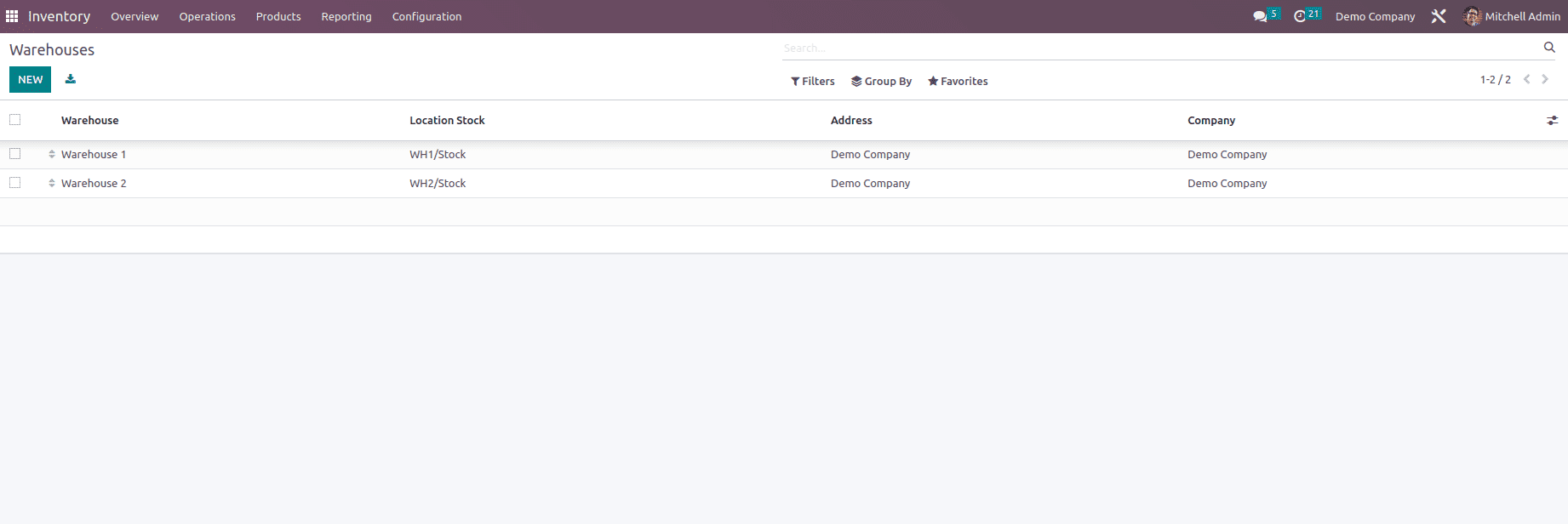

Suppose we have two warehouses, Warehouse 1 and Warehouse 2, where warehouse 1 is the primary warehouse and the second one is the secondary warehouse, as shown below.

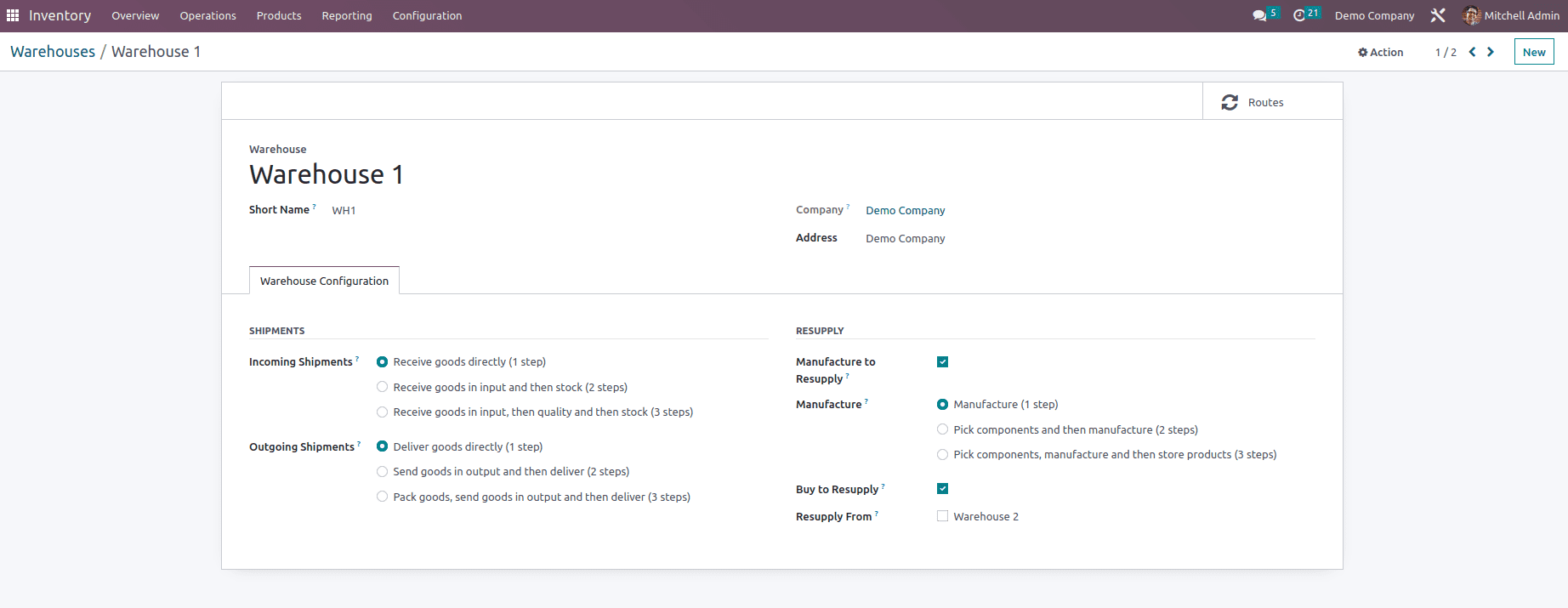

The screenshot of the Warehouse 1 is shown below.

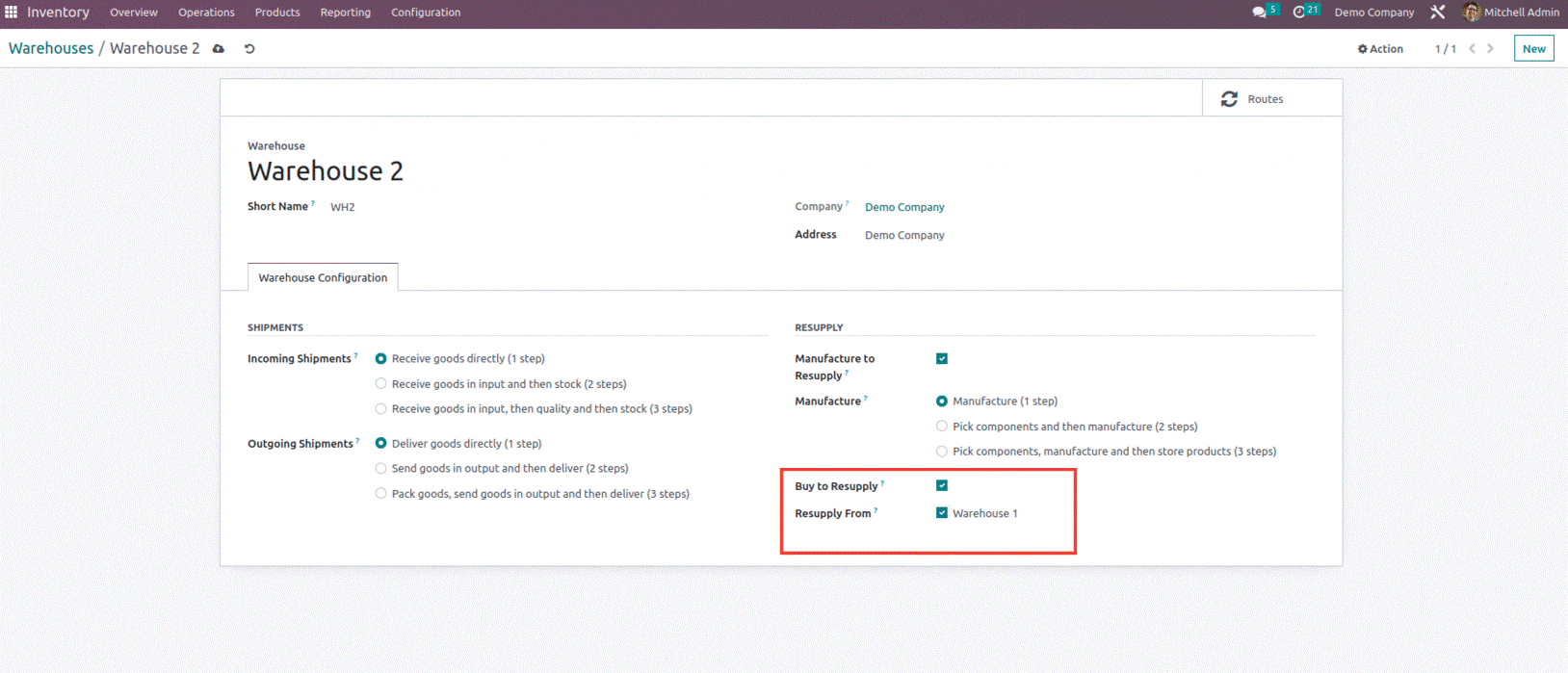

Suppose the second warehouse is low on inventory, the first warehouse will replenish it, and for this to happen, we need to enable the Resupply feature from the warehouse form.

The Resupply section of the Warehouse Configuration tab contains a number of settings. For the purpose of producing goods at your warehouse, turn on the Manufacture to Resupply option. When you select the Manufacture to Resupply option, a new field called Manufacture appears before you. The three types of manufacture Pick components, manufacture (1 step), create and then store items (3 steps), and manufacture (1 step). (2 steps). As seen in the screenshot below, you can select the necessary production procedure.

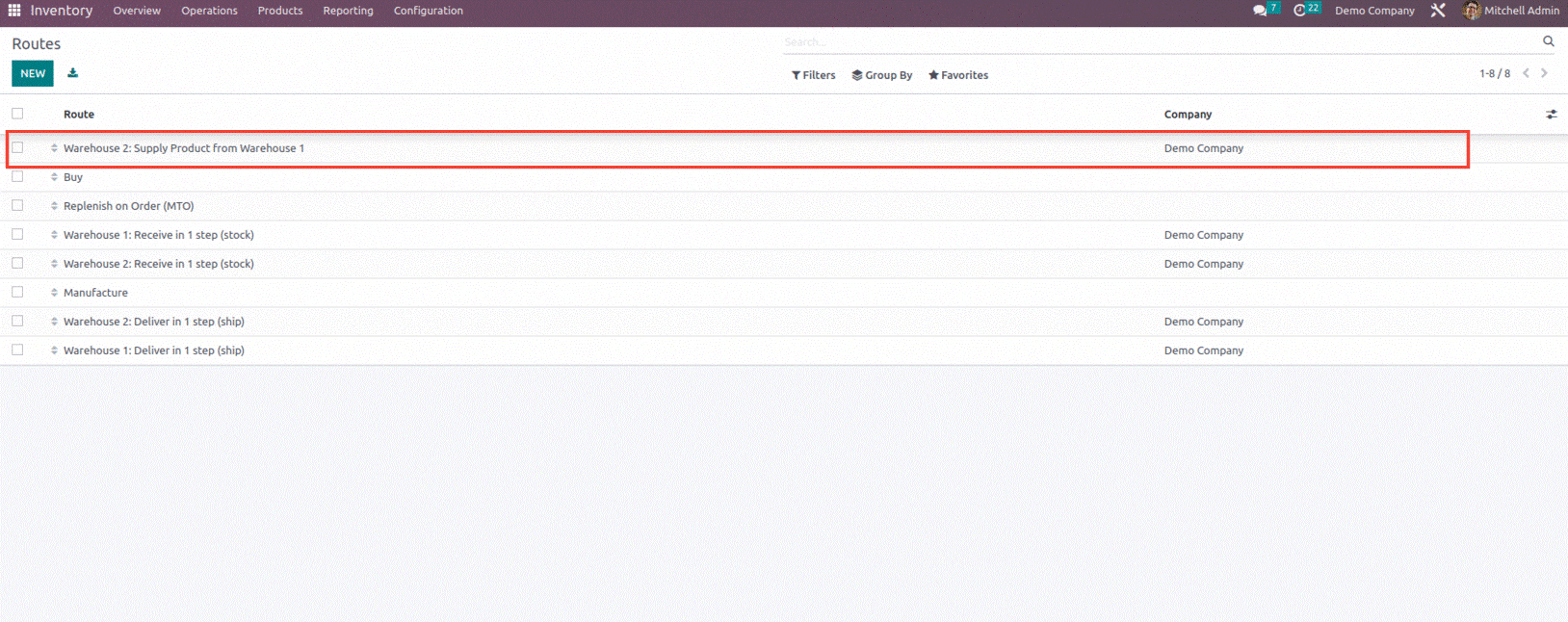

So when we enable this feature, we can see that an additional route will be created inside the route form in accordance with the resupply option being set as shown below.

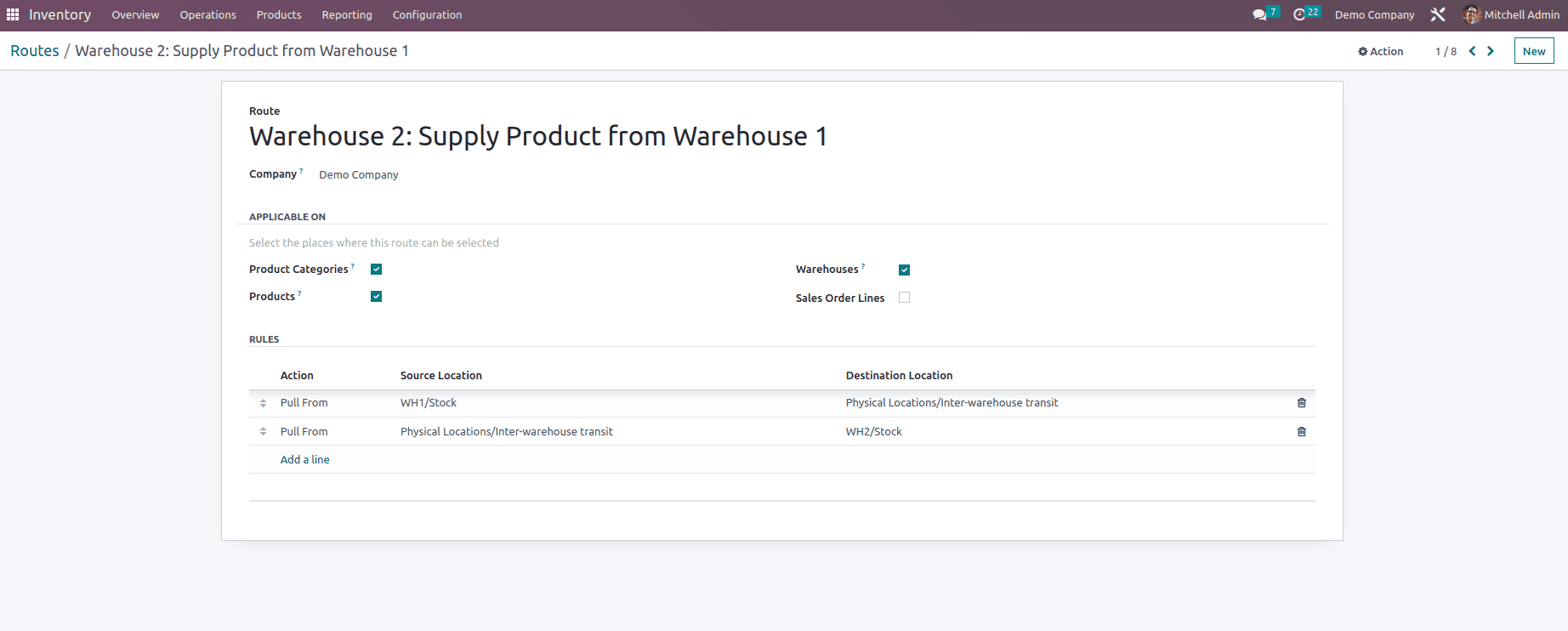

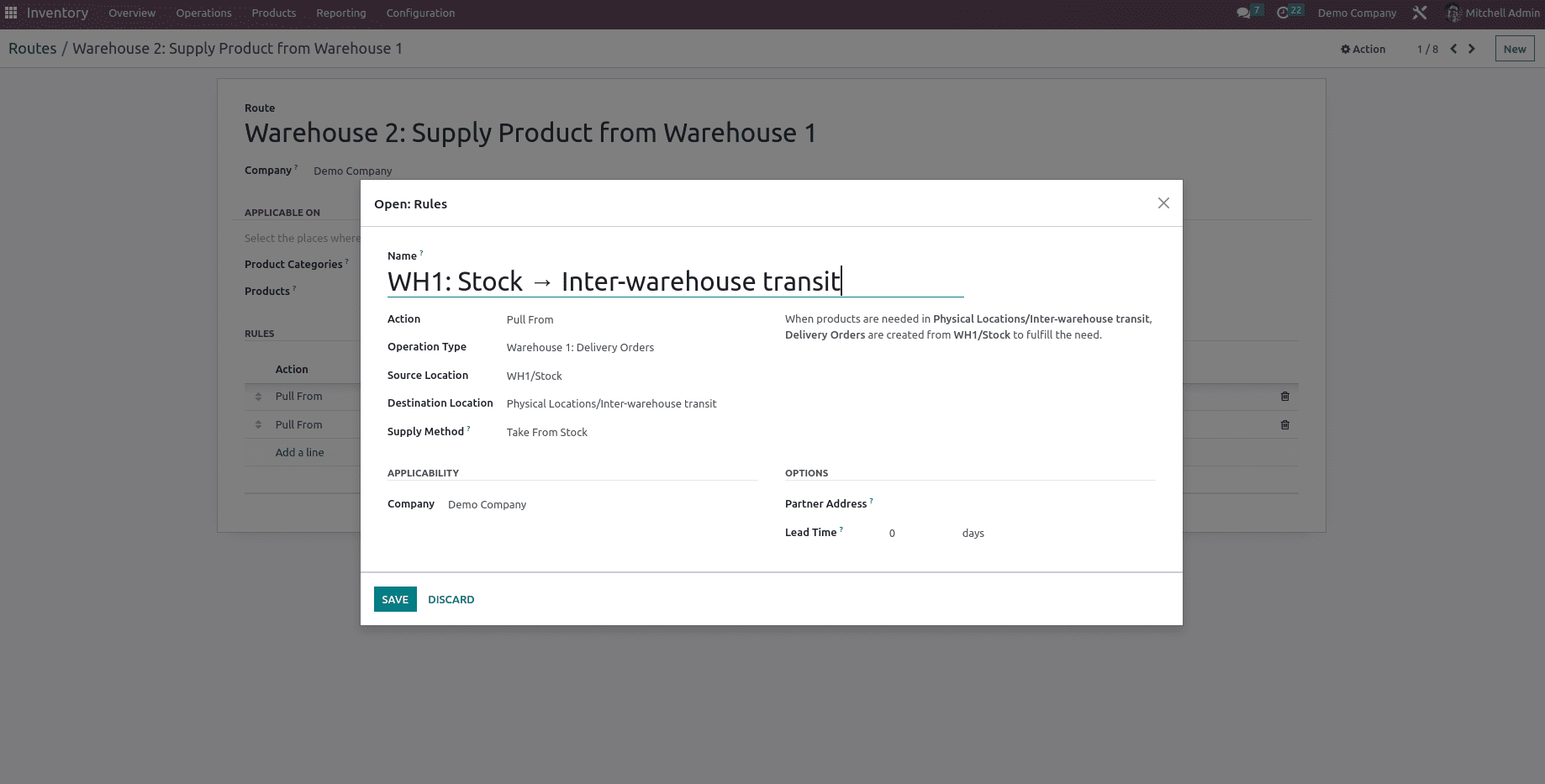

And when we open this route, we can see that the main route is named as Warehouse 2: Supply Product from Warehouse 1, and below it, two rules are added; one is WH1: Stock -> Inter warehouse transit, here When products are needed in Physical Locations/Inter-warehouse transit, Delivery Orders are created from WH1/Stock to fulfill the need.

Within the main route, there are sub-rules included, as shown below,

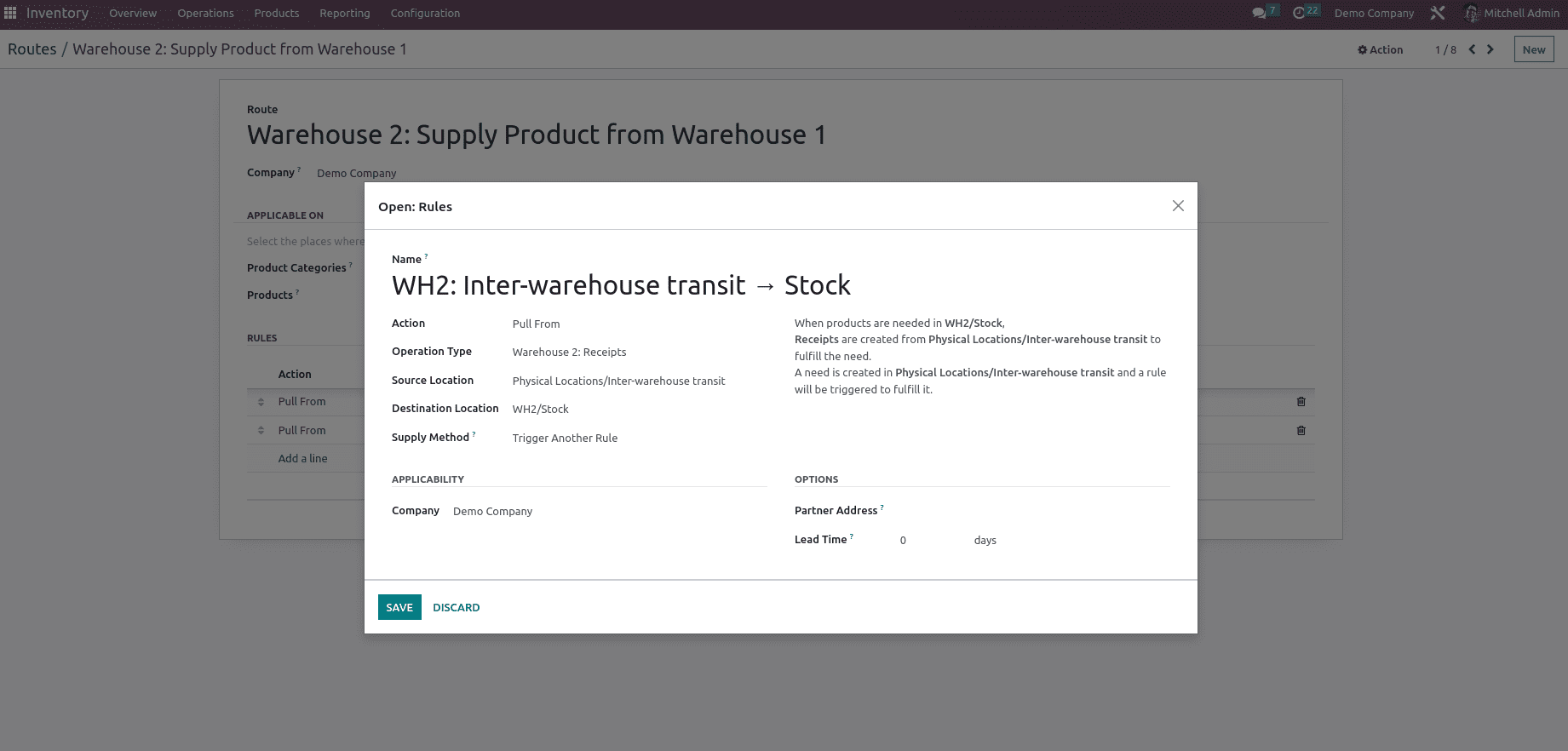

In the second rule applied, when products are needed in WH2/Stock, Receipts are created from Physical Locations/Inter-warehouse transit to fulfill the need. A need is created in Physical Locations/Inter-warehouse transit, and a rule will be triggered to fulfill it.

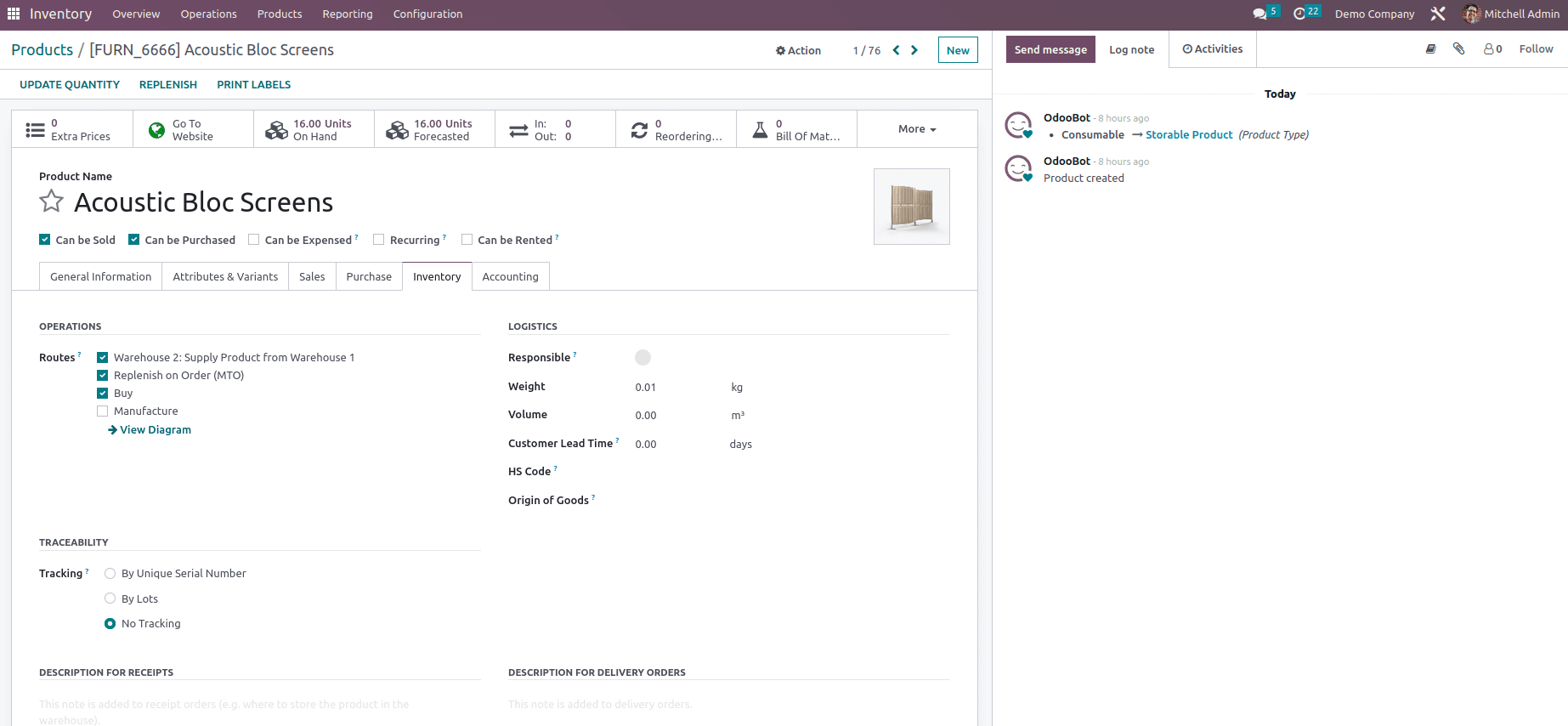

Once the rule and routes are created, we need to update the product route which we are planning to sell, as shown below.

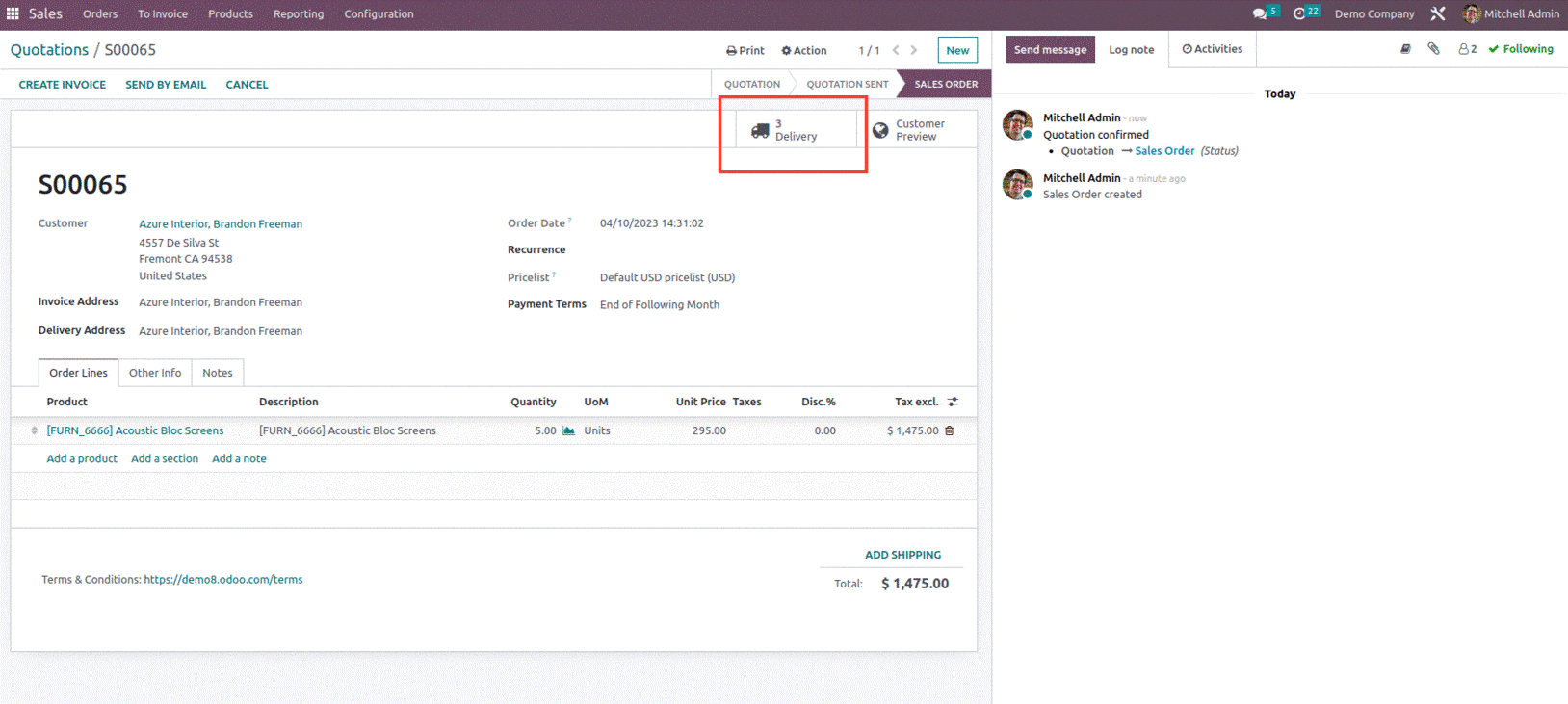

Now let us create a sale order with a warehouse specified as warehouse 2, which doesn't have sufficient product on hand, and confirm the order. This will generate a smart button with three transfers and deliver the product from warehouse 2, which doesn't have sufficient product on hand.

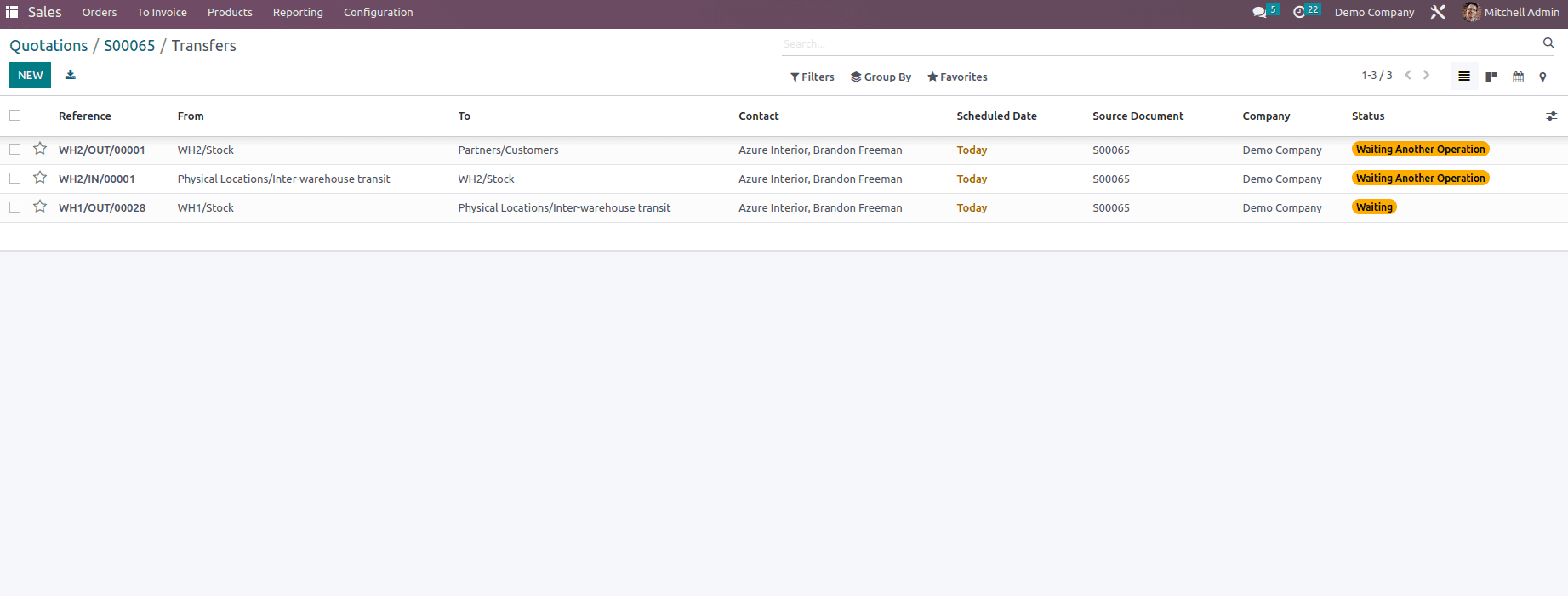

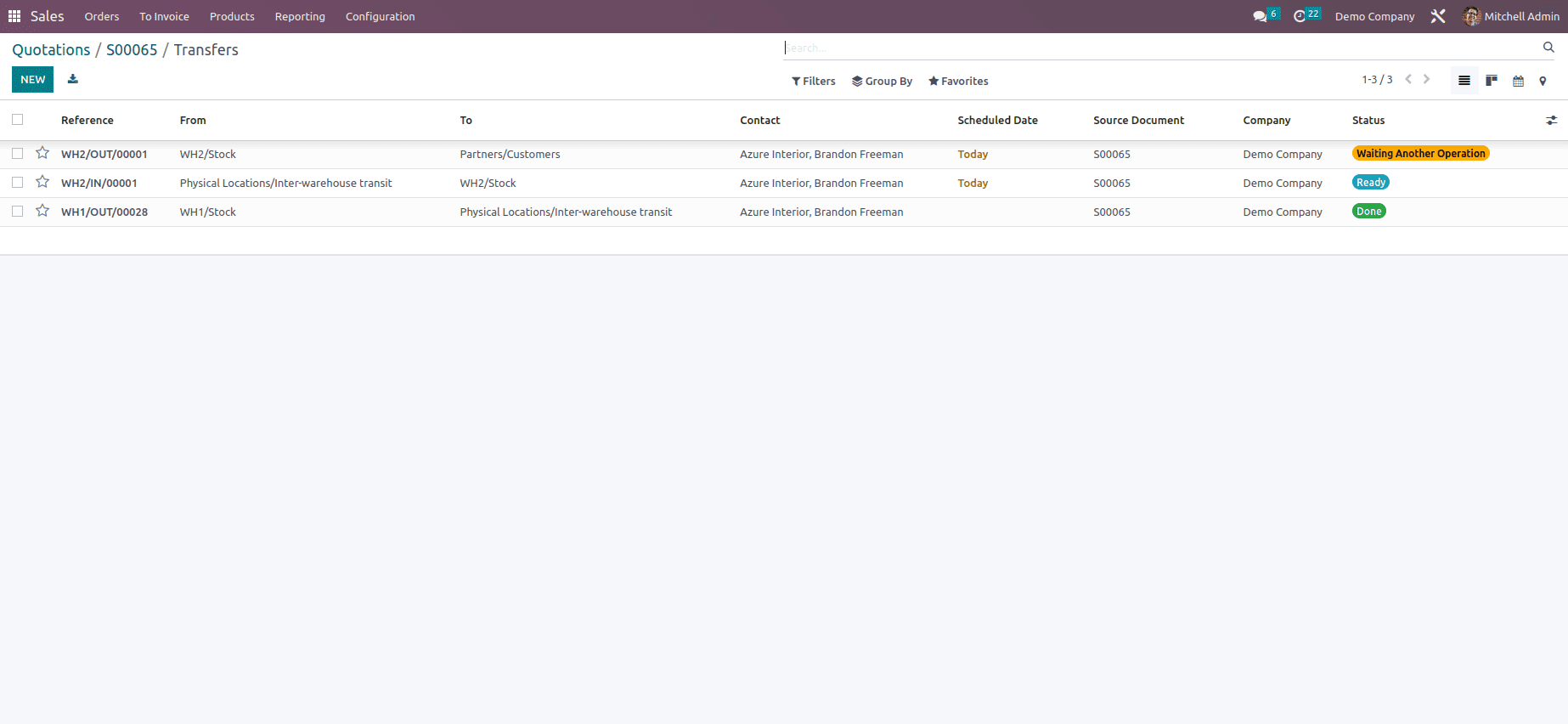

The three transfers are WH1/Stock to Physical Location/Inter-warehouse transit and once its validated only it will move to the next transfer, i.e., from Physical Location/Inter-warehouse transit to WH2/Stock and finally from WH2/Stock to Partners/Customers.

Once the transfers are done, the product will successfully move to the customer from Warehouse 1 when products are out of stock in Warehouse 2.

This is how resupply is done between the warehouses when products are unavailable in any of the warehouses created.