Various operations are necessary for manufacturing fabric items in the textile industry, and it is a type of manufacturing industry. Coloring, sewing, weaving, stitching, and more processes occur inside the textile industry. Proper coordination is essential for managing all these activities within different work centers and warehouses. The product Bills of materials give the quantity of the component needed to manufacture a complete commodity. Individuals can quickly coordinate several processes with the support of ERP software and link multiple Bills of Materials to each material. Users can optimize manufacturing steps by saving time using the Bills of Materials feature in Odoo 15 Manufacturing module.

This blog assists you in identifying advanced peculiarities of Odoo 15 Bills of Materials for the Textile Industries.

The constituents list required for product manufacturing is a Bill of Materials. Odoo 15 Manufacturing module ensures you apply a BoM type for a specific product and evaluate routing performance quickly. Let’s analyze the vast features of Odoo 15 Bills of Materials for the Textile industry.

Importance of Bills of Materials for the Textile Industry

The introductory price of a finished product depends on two factors such as labor cost and components. It is easy to determine the accurate price of components for a manufacturing process using Bills of Materials. Moreover, users can quickly configure the expected time for finishing a manufacturing process within Odoo 15. We can improve the work performance of an industry by maintaining bills of materials for products. Odoo bills of material allow you to configure products, variants, and other operations. Now, let’s see salient features of bills of materials for industry.

Easy to manage Components of a product

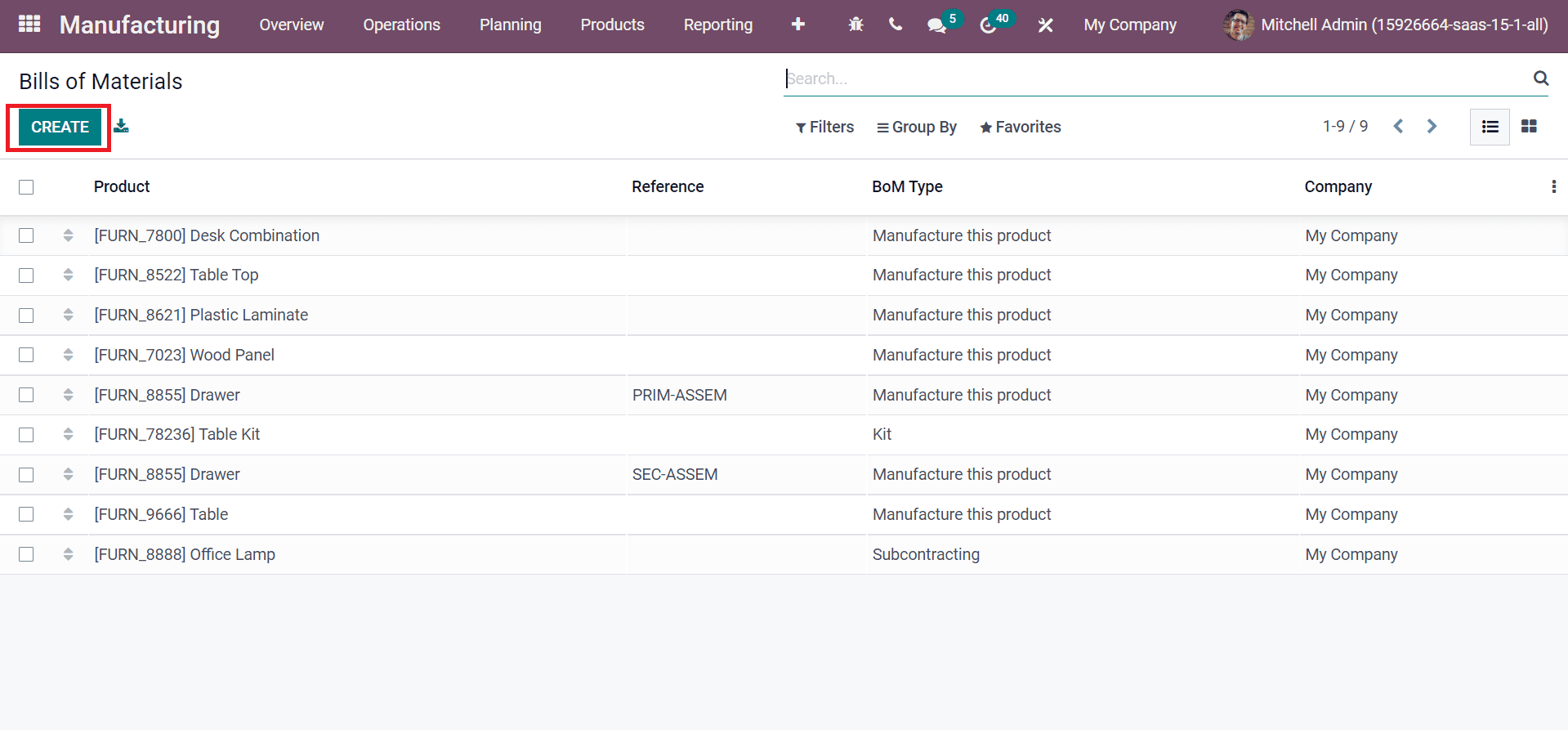

Bills of materials are an effective way to manage your product components in the textile industry. For that, select the Bills of Materials menu in the Products tab of the Odoo 15 Manufacturing module. We can develop a bill of material for a product ‘Table’ in the textile industry. Click on CREATE icon in the Bills of Materials window, as represented in the screenshot below.

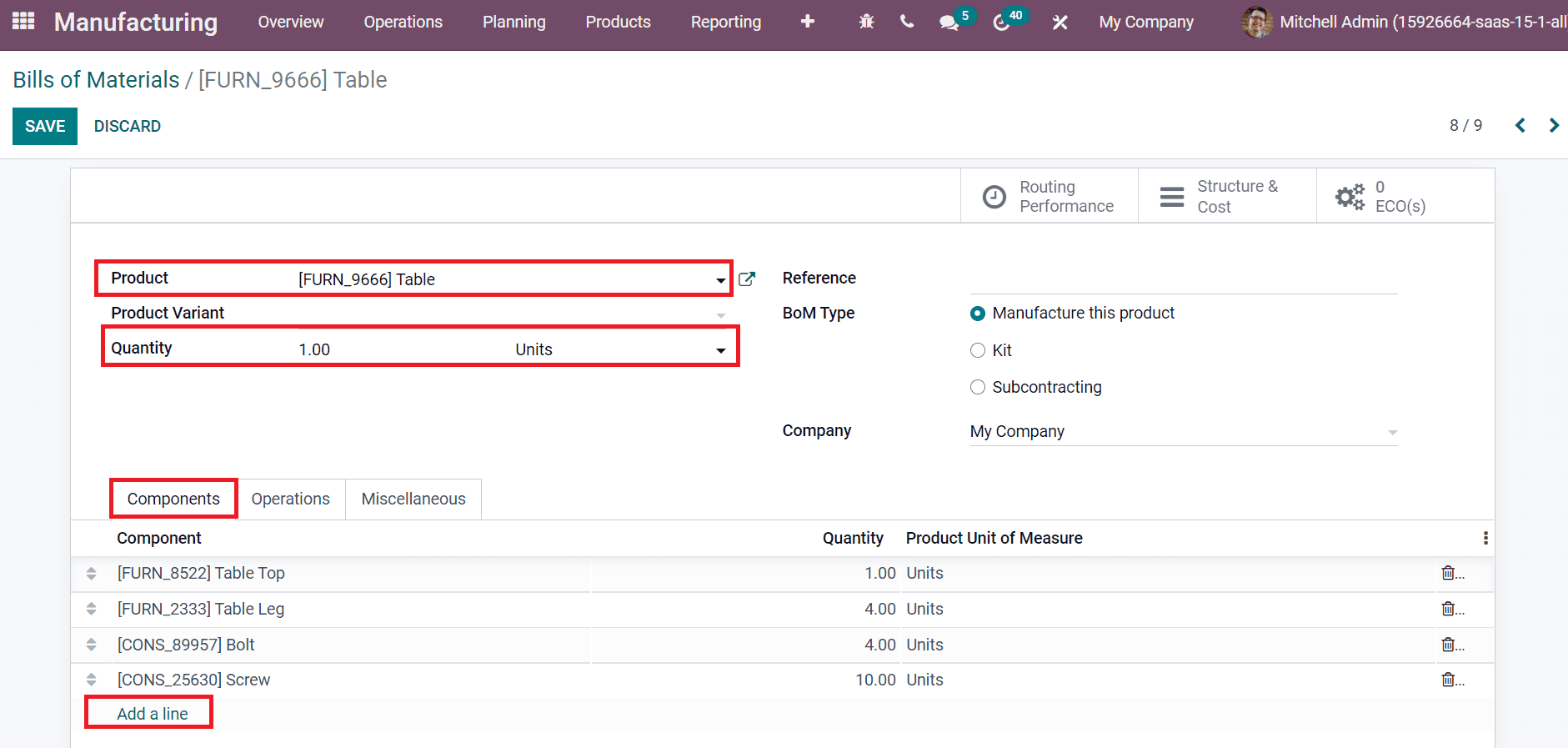

Choose your Product as ‘Table’ and Quantity in the new window. You can add different materials needed for table manufacturing inside the Components tab. Click on Add a line option to apply components for your product as denoted in the screenshot below.

Here, we added the components such as Table Top, Table leg, Screw, and Bolt for the table manufacturing process. In this way, you can apply any components for your product manufacture inside a textile industry. Investors can select components for a commodity using Bills of Materials by seeing the product. The components feature inside the Bills of Materials window ensures the application of sub-products for a manufacturing process. After adding the components list, you can quickly save the changes and develop bills of materials for a table.

Choose a BoM Type for your Product

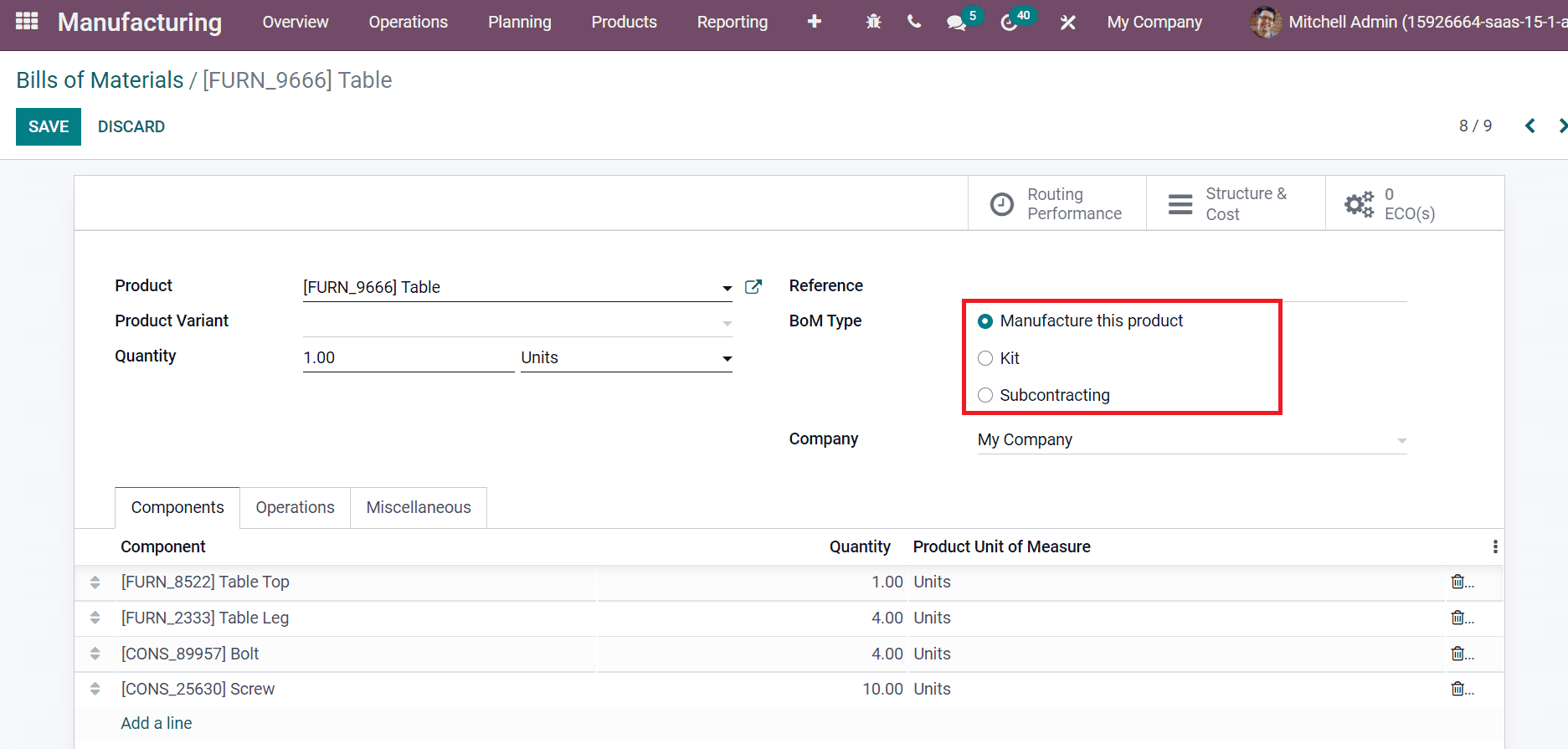

Odoo 15 Manufacturing module assists in choosing a specific BoM Type for your products in the textile industry. Inside the Bills of Materials window, BoM Type is classified into three types: Kit, Manufacture this Product, and Subcontracting, as specified in the screenshot below.

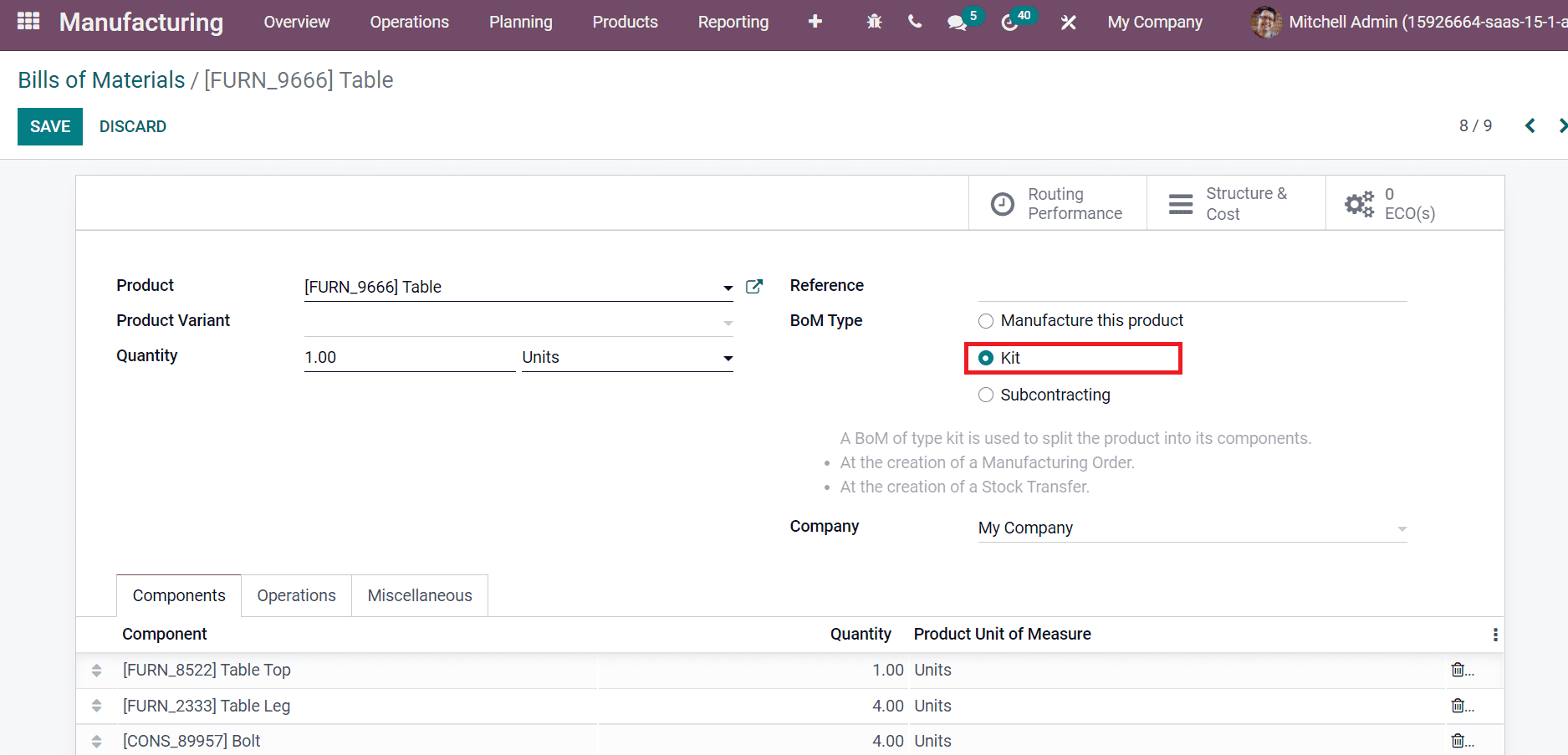

Users can manufacture a product using several components by selecting the Manufacture this product option in the BoM Type field, as displayed in the above screenshot. We can also split products into various components using BoM Type Kit, as portrayed in the screenshot below.

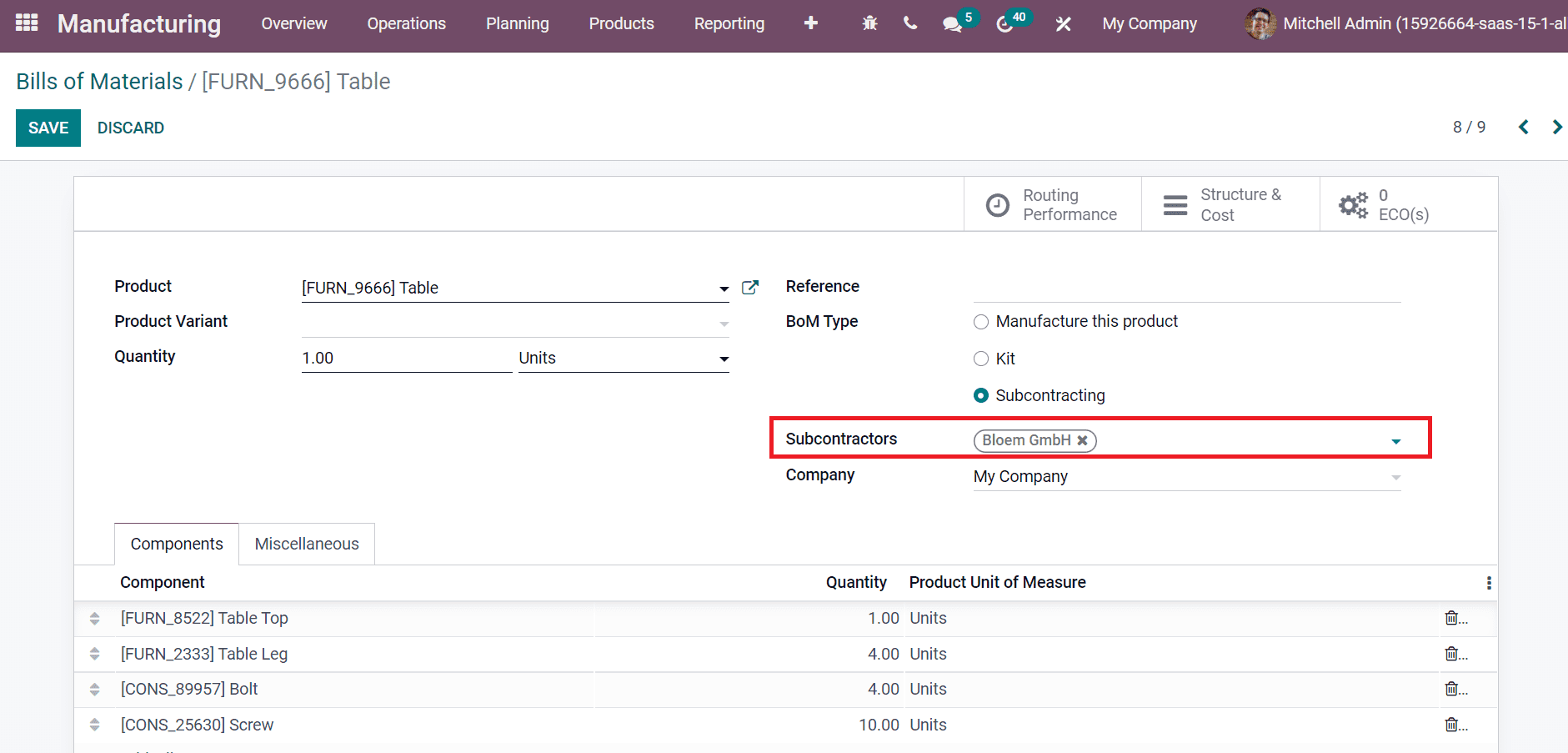

It is easy to create a manufacturing order and stock transfer by choosing Kit as BoM Type. By choosing Subcontracting from BoM Type, we can add various subcontractors for bills of materials in a product. You can select a partner from the Subcontractor field, as illustrated in the screenshot below.

We can choose the required BoM Type for product manufacturing in a textile industry using Odoo 15 Manufacturing module.

Analyze the Structure and Cost of a product

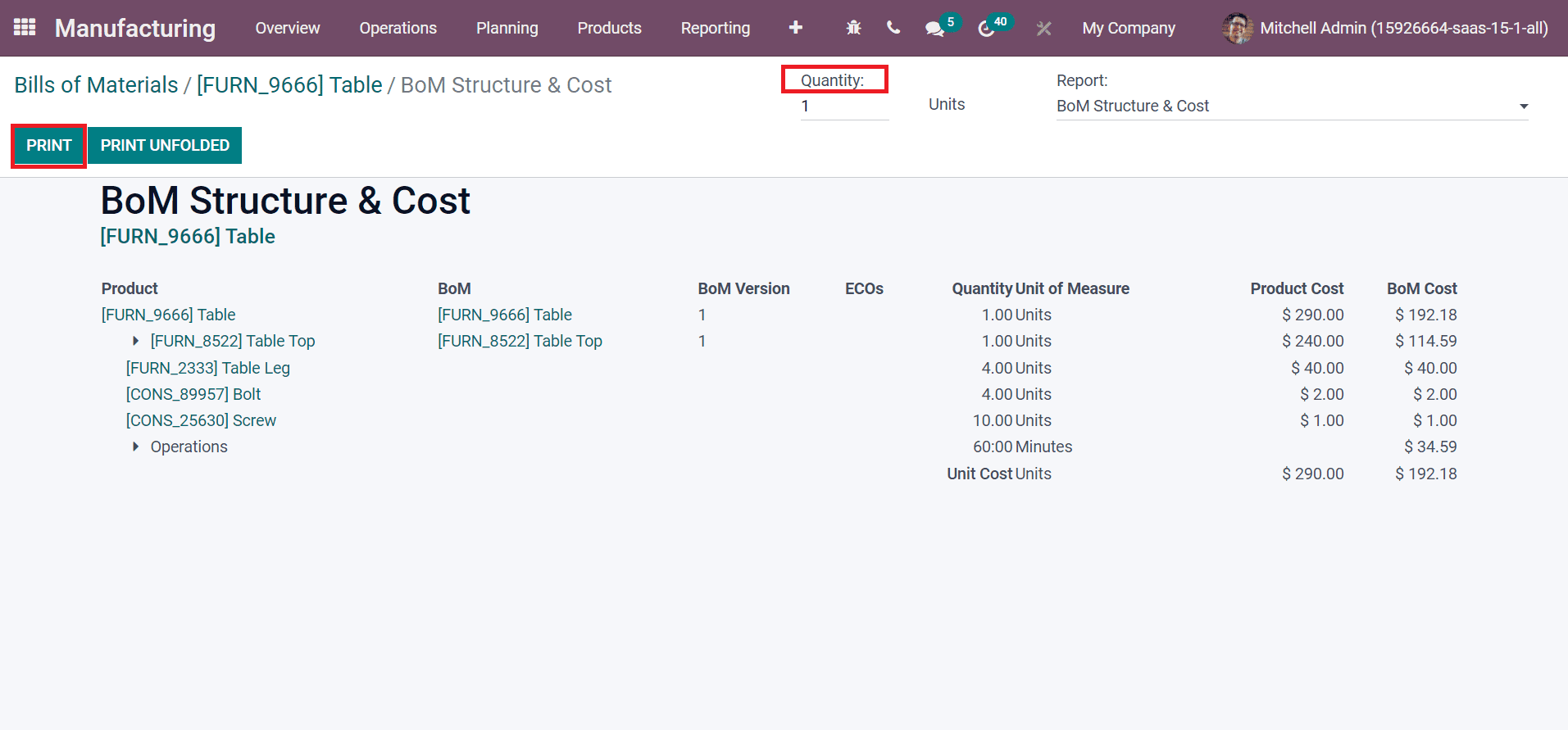

Users can evaluate product costs within the Bills of Materials window. By clicking on Structure & Cost smart button in the Bills of Materials window, you can quickly analyze the product structure. In the BoM Structure and Cost window, you can see product reports based on Quantity, as portrayed in the screenshot below.

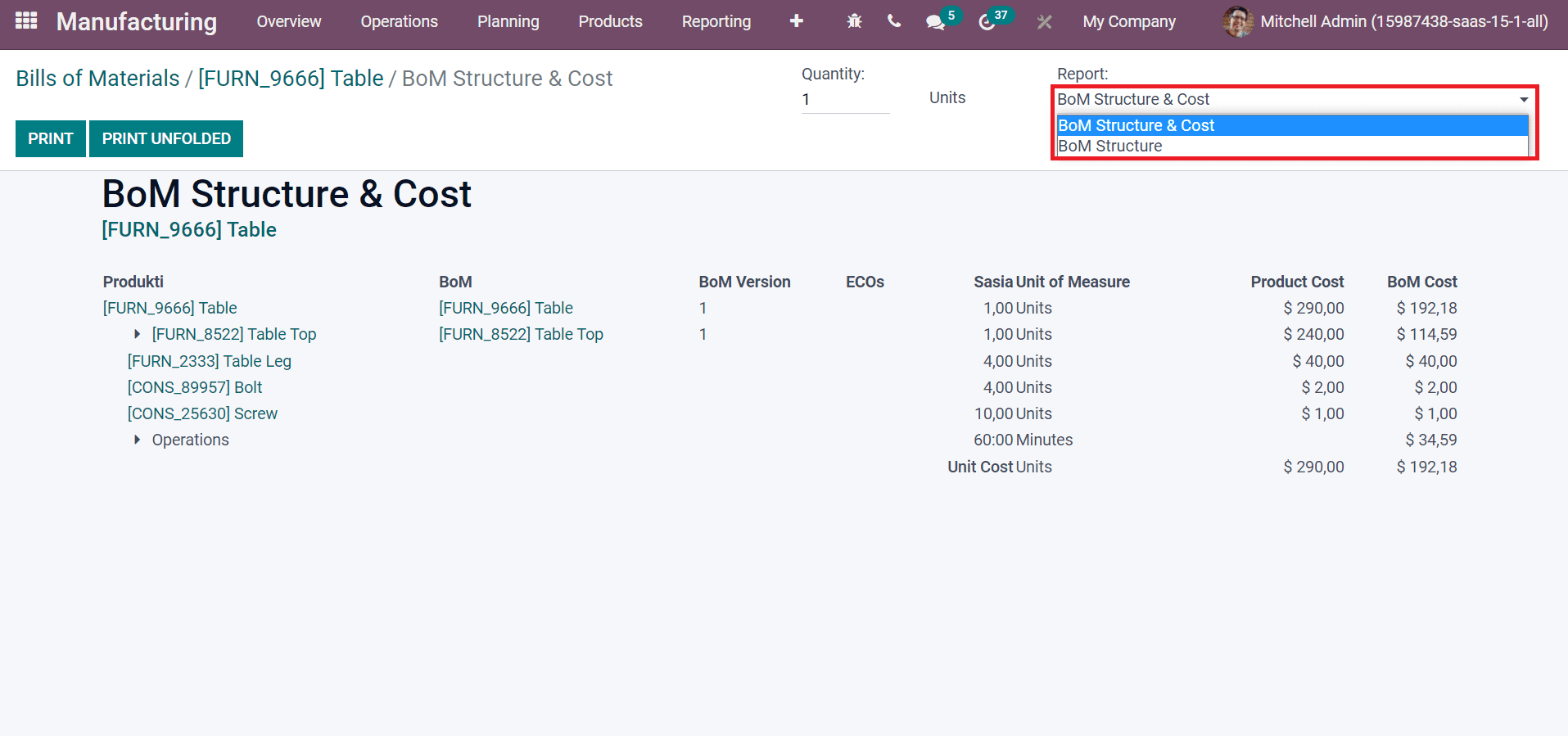

Select the PRINT icon to download your BoM structure & Cost report of products in the textile industry, as displayed in the above screenshot. Users can evaluate product details such as BoM Cost, Quantity Unit of Measure, BoM, and other information inside the BoM Structure & Cost report. As specified in the screenshot below, you can analyze the Report based on BoM Structure & Cost & Cost or BoM Structure.

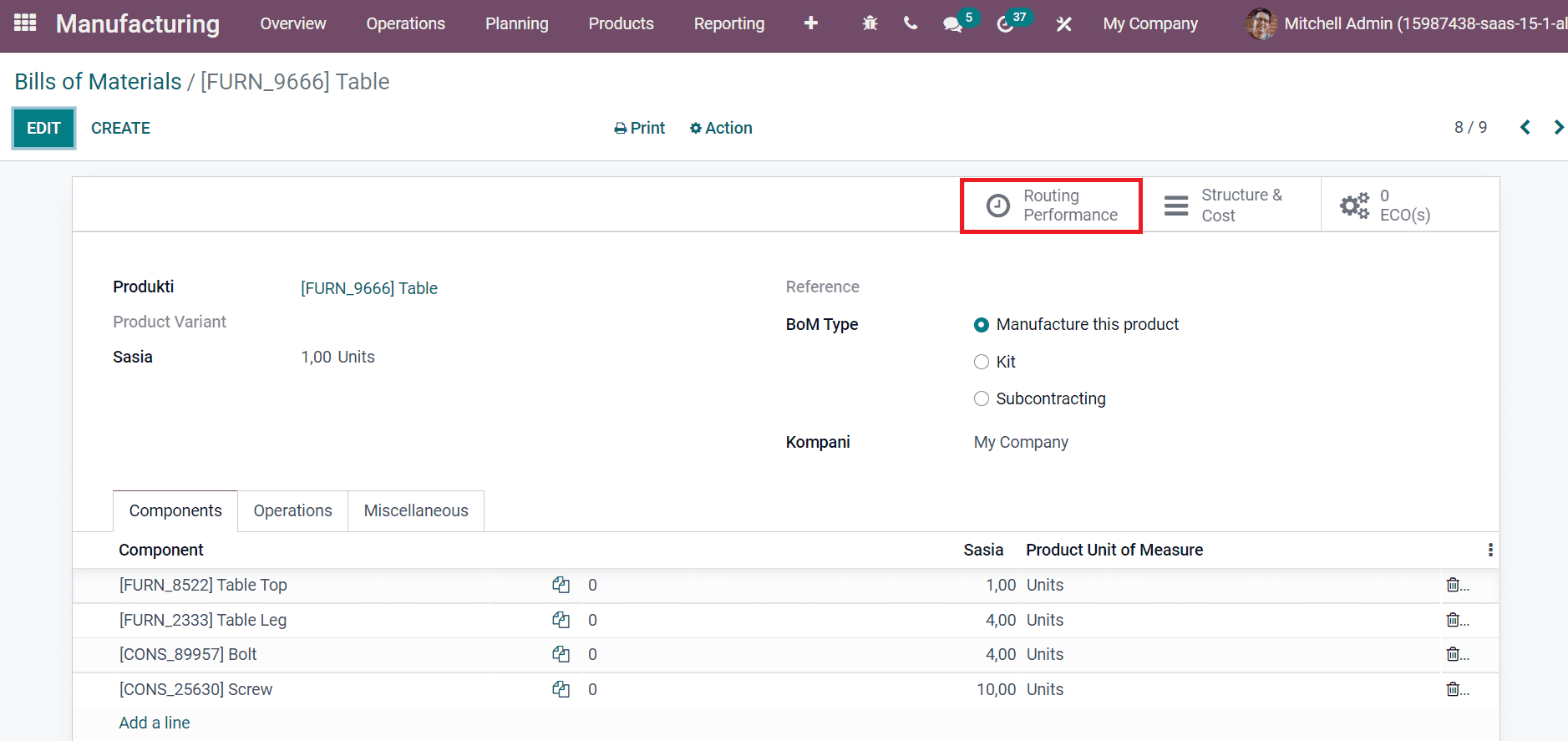

Quickly Evaluate Routing Performance of a Product

One of the necessary parts of BoM is routing performance, and it shows the role of various work centers in completing product manufacturing. Select the Routing Performance smart icon after generating a Bill of Material for a table, as portrayed in the screenshot below.

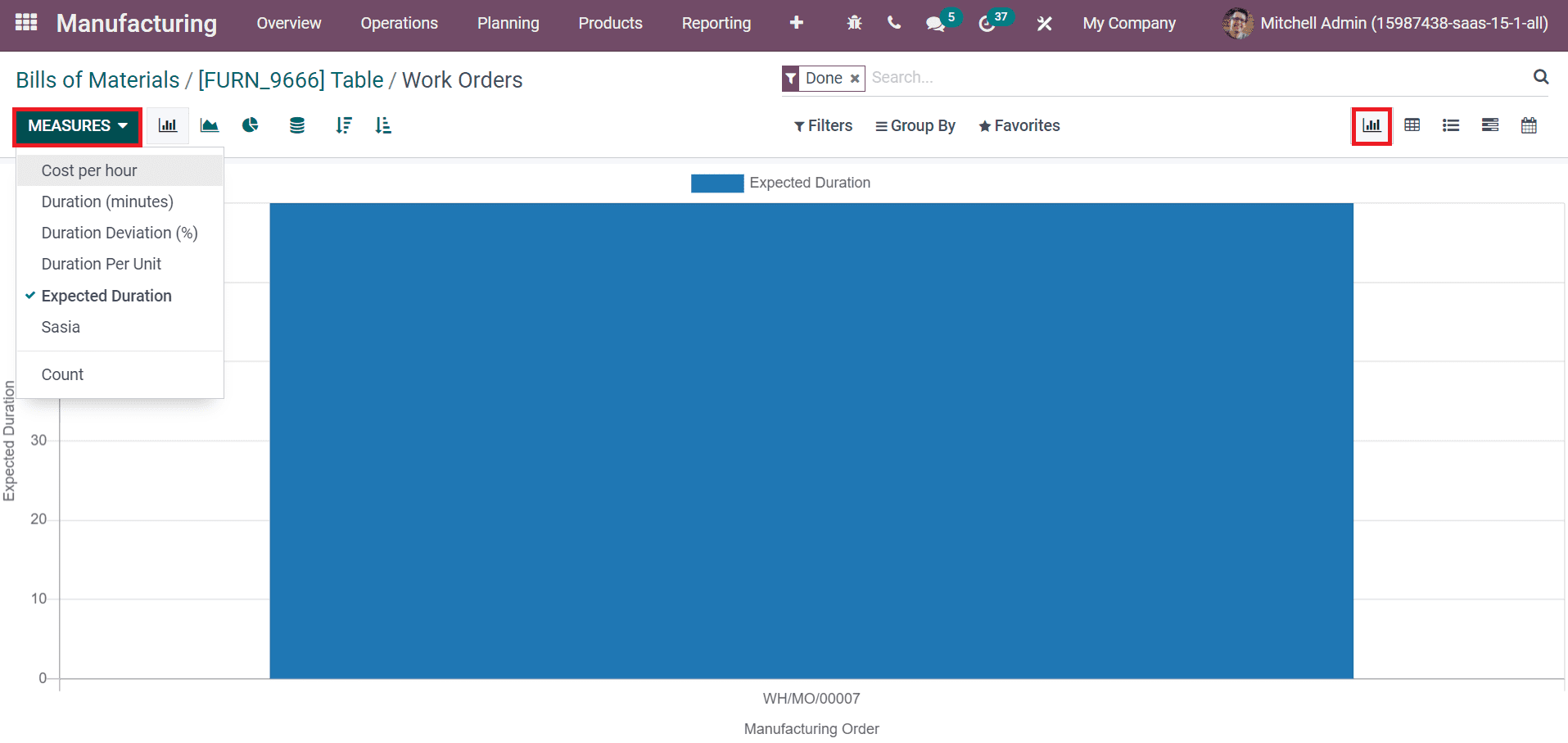

Graph view of the Work Orders window shows Manufacturing order details on the X-axis and Expected duration on the Y-axis. We can add different measures to the graph by selecting the MEASURES icon, denoted in the screenshot below.

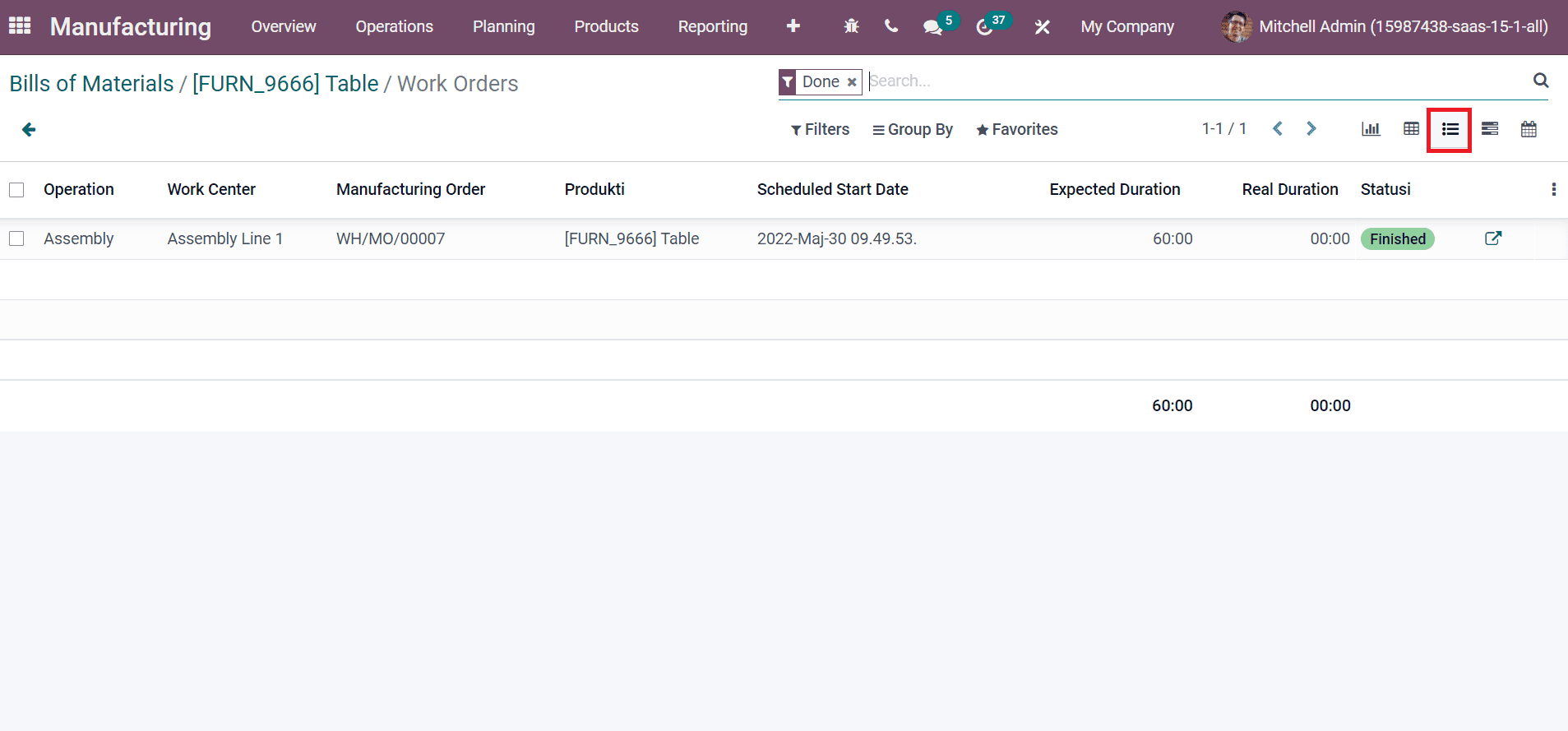

In the List view, you can view the total expected duration to complete a manufacturing process for a product. Various details about your product work order, such as Work Center, Expected Duration, Manufacturing Order, Operation, Status, and more, are visible inside the Work Orders window, as displayed in the screenshot below.

Manage Miscellaneous options in BoM

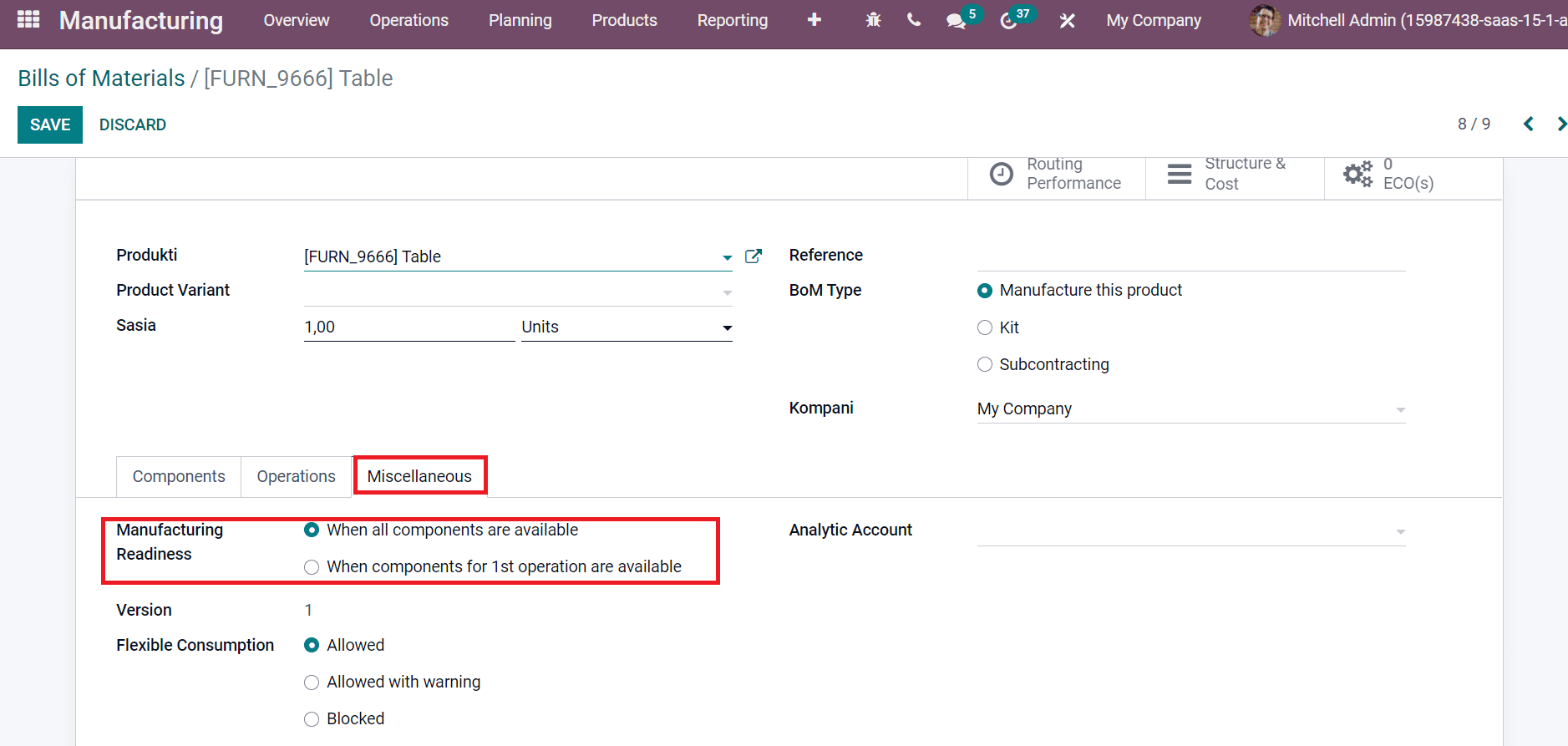

Users can manage analytic accounts and consumption for products inside the Miscellaneous tab in the Bills of Materials window. Manufacturing readiness defines after considering a manufacturing order. Manufacturing Readiness classifies into two types: When all components are available and When components for 1st operation are available, as illustrated in the screenshot below.

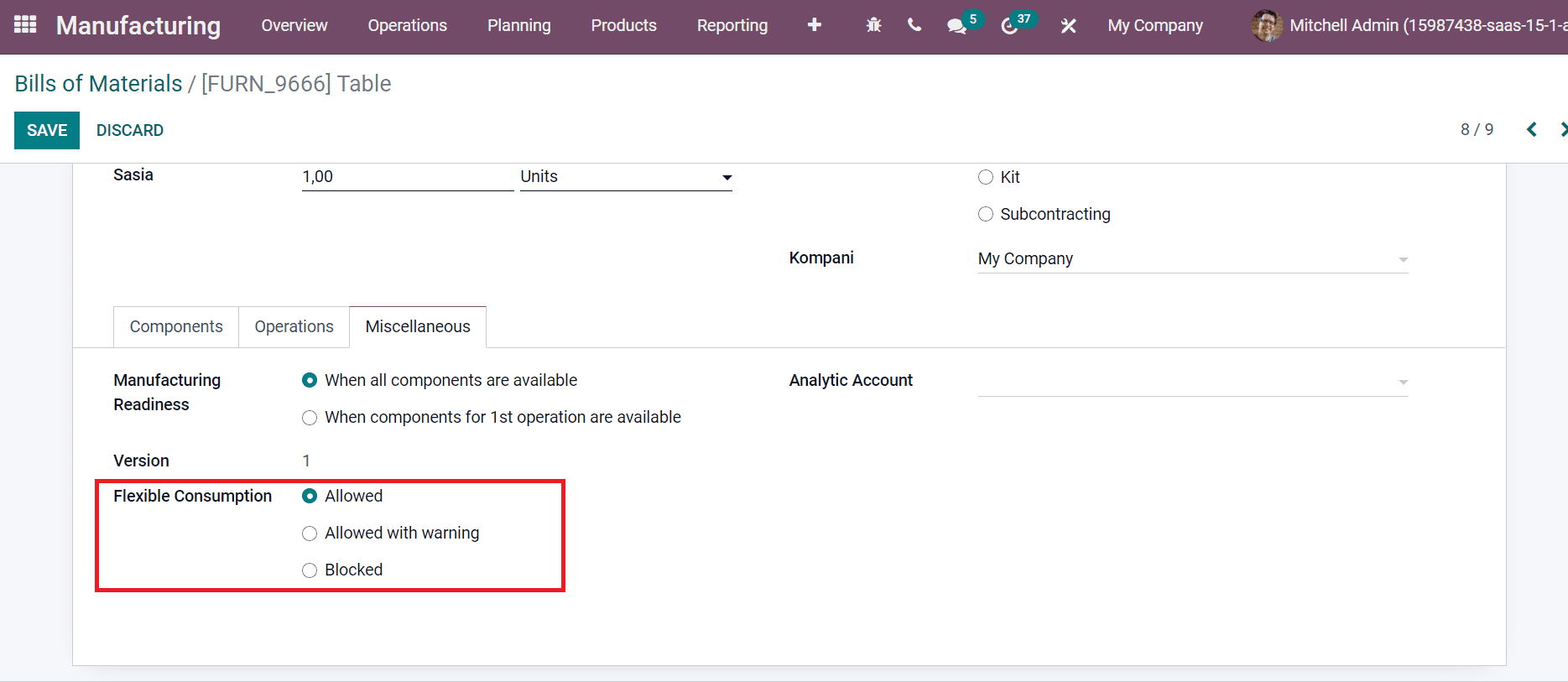

Using the Flexible Consumption field, you can consume more or fewer components than the defined quantity in BoM. Flexible consumption classifies into three categories: Allowed, Allowed with warning, and Blocked, as specified in the screenshot below.

The components are acceptable for all manufacturing users by selecting an Allowed option. A manager can close a manufacturing order by choosing the Blocked option in the Flexible Consumption field.

Bill of Material feature in the Odoo 15 database assists you in managing product components, BoM types, and evaluating the routing performance. Apart from these, it is easy to analyze the structure and cost of a specific product. Users can manage the Bills of Materials for a particular product with the support of Odoo 15. Refer to the following blog to know about Odoo 15 Manufacturing's significance in the Textile industry.