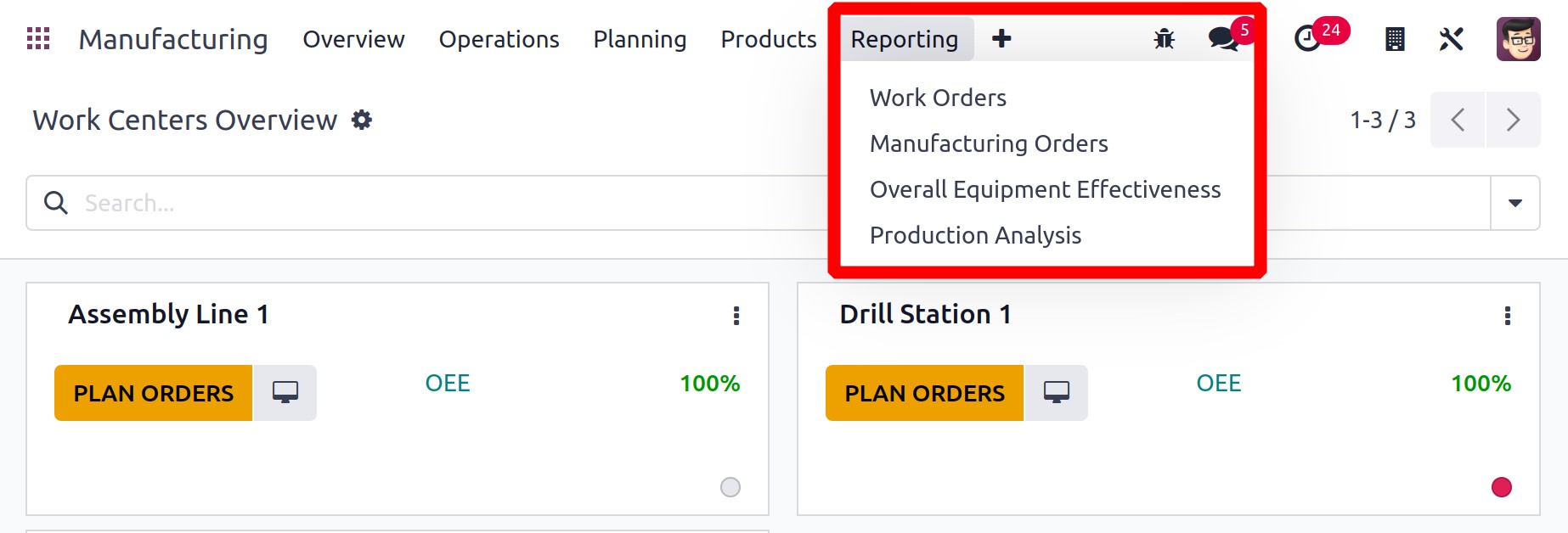

Reporting

Users can acquire a precise analysis of the actions carried out in a module thanks to the reporting platform in Odoo17. This function, which is available in the Manufacturing module, helps you to gain a sense of the manufacturing operations carried out during a certain time period. You can find reports on work orders, manufacturing orders, overall equipment effectiveness, and production analysis under the Reporting option. Let's carefully review each of these reports.

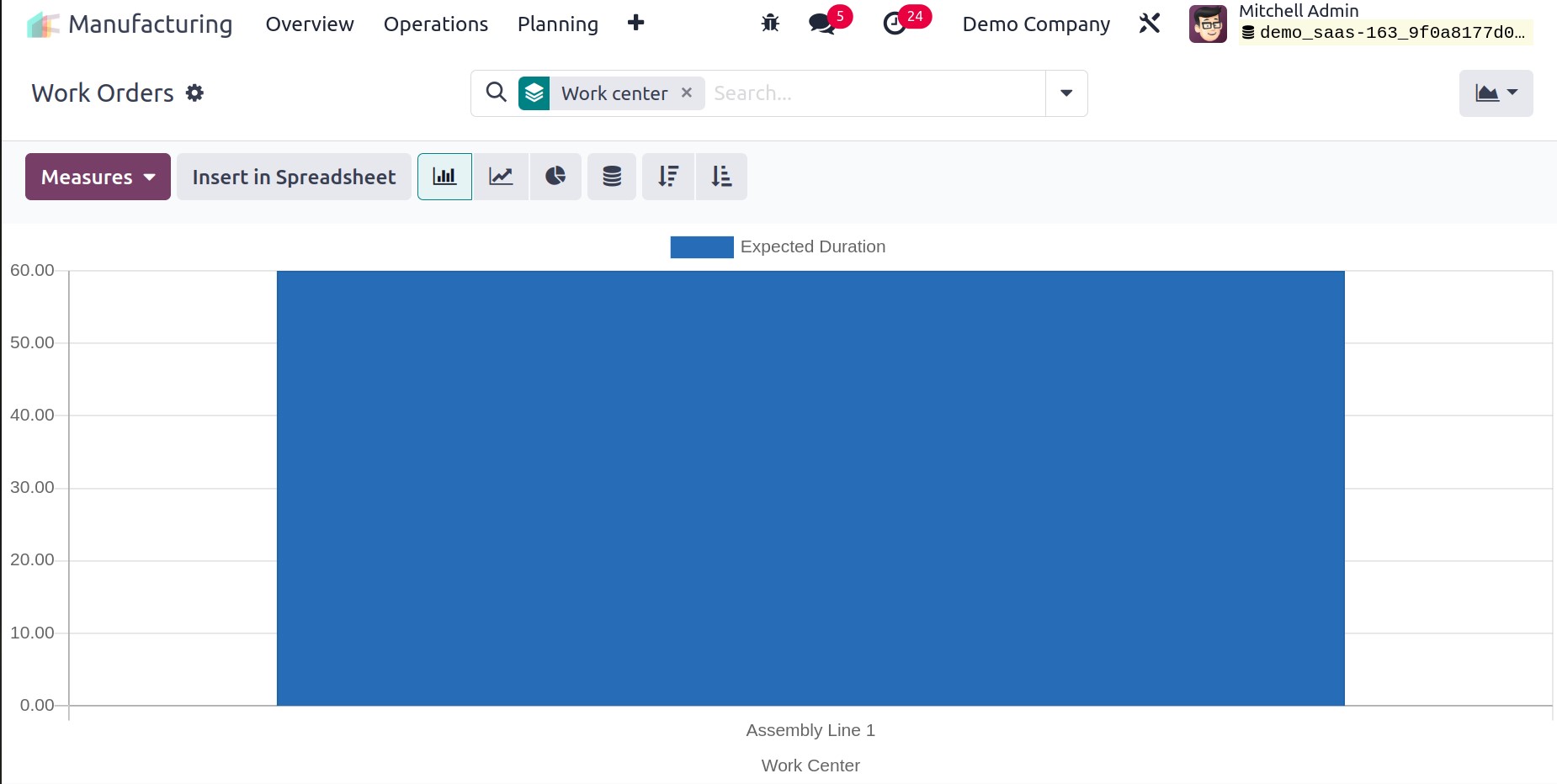

Work Orders

The Work Orders reporting option allows for analysis of the work orders created in the module. This platform provides Gantt, List, Graphical, and Pivot views. The report's graphical representation is displayed below.

You can switch between line, pie, and bar charts when viewing the graph. Additionally, it can be organized in ascending and descending order. You may create reports for work orders in Odoo17 based on stages like Ready, Waiting, Pending, In Progress, Done, Late, and Start Date by using the default filters. Get reports on the work orders based on the Work Centre and Product by using the Group By option. You can create tailor-made reports of the work orders using the customize option offered by the Filters and Group By option.

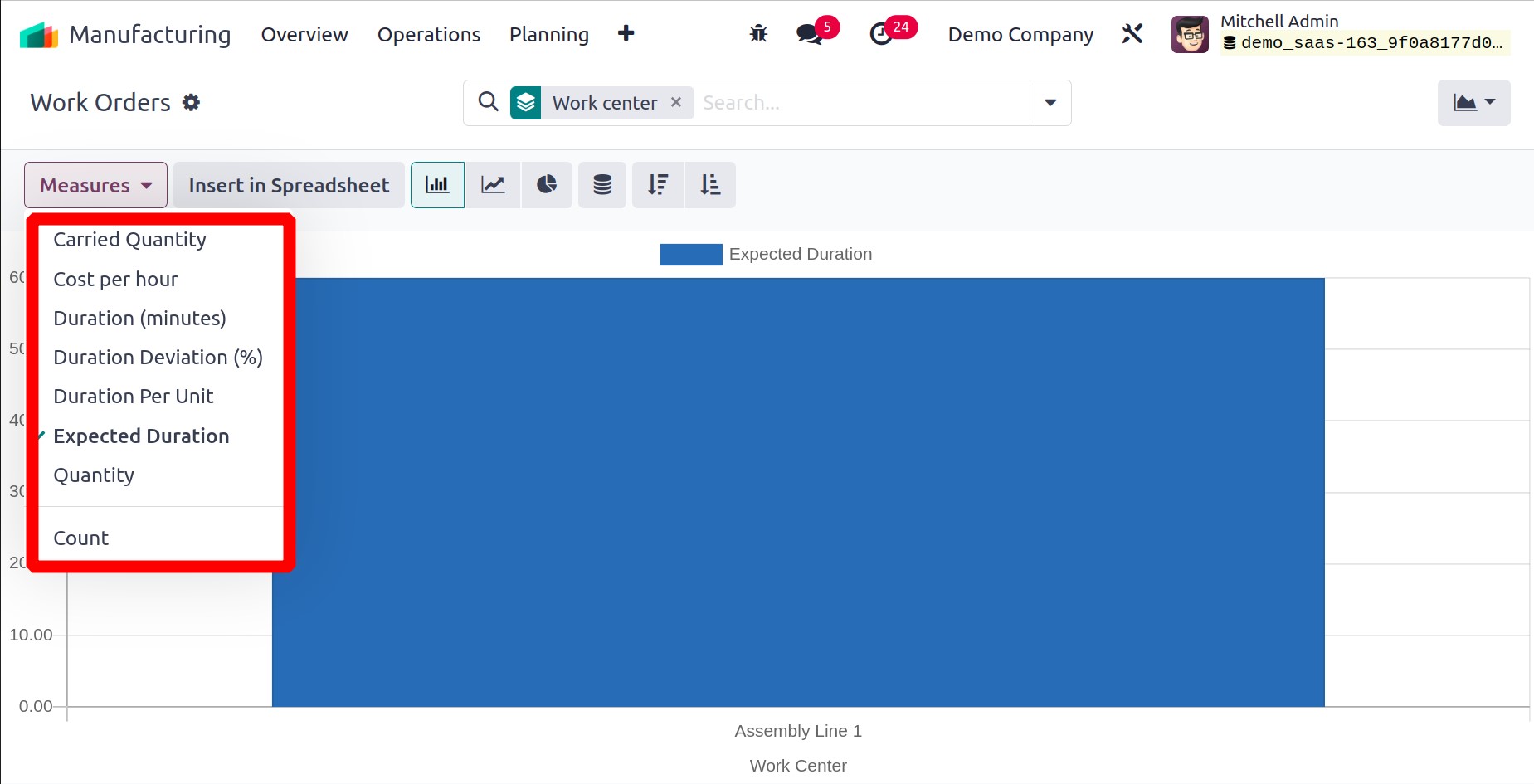

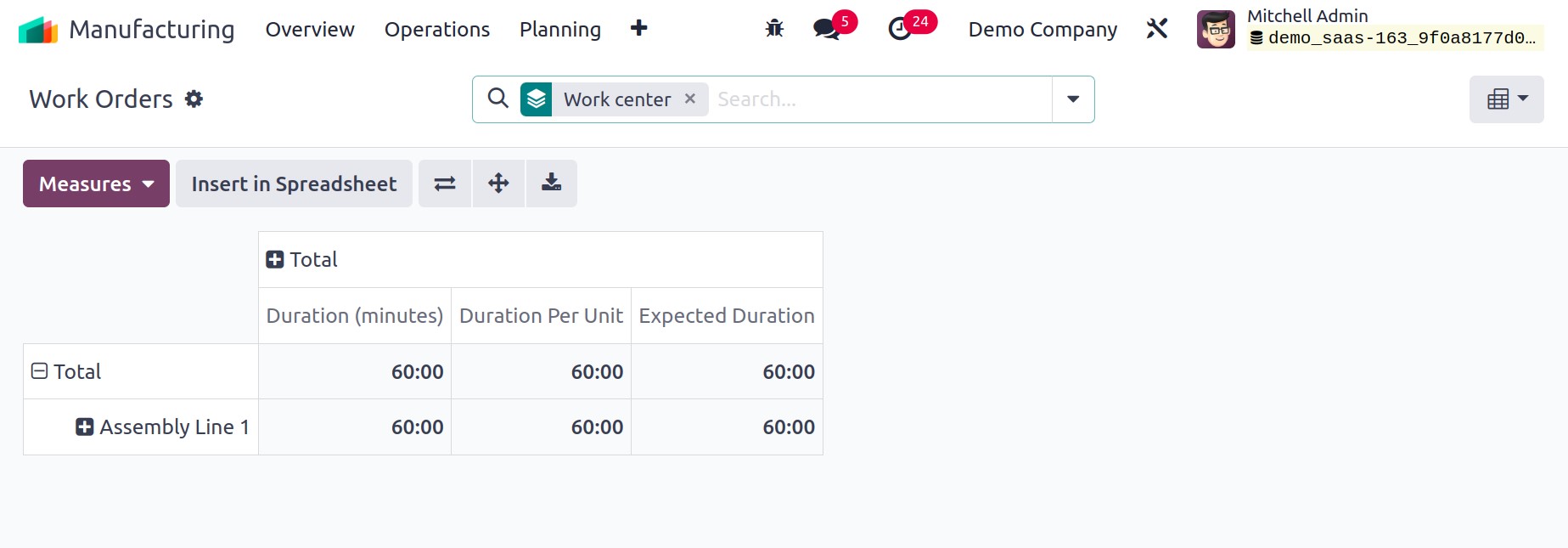

By activating Measures like Carried Quantity, Cost per Hour, Duration, Duration Deviation, Duration per Unit, Expected Duration, Quantity, and Worksheet Page, you can widen the scope of the Pivot Table's display.

To add this report to a spreadsheet for additional analysis, use the Insert in Spreadsheet button.

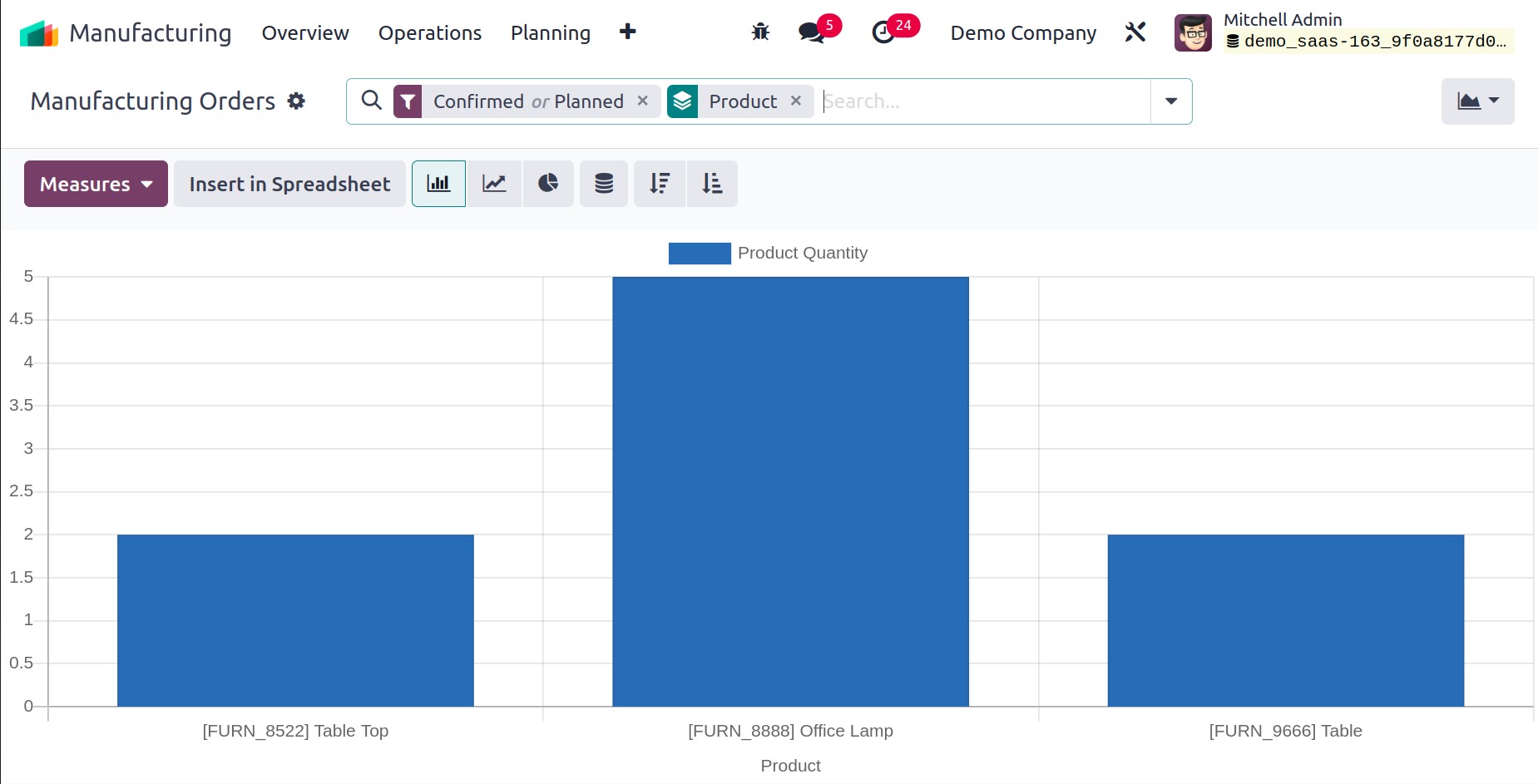

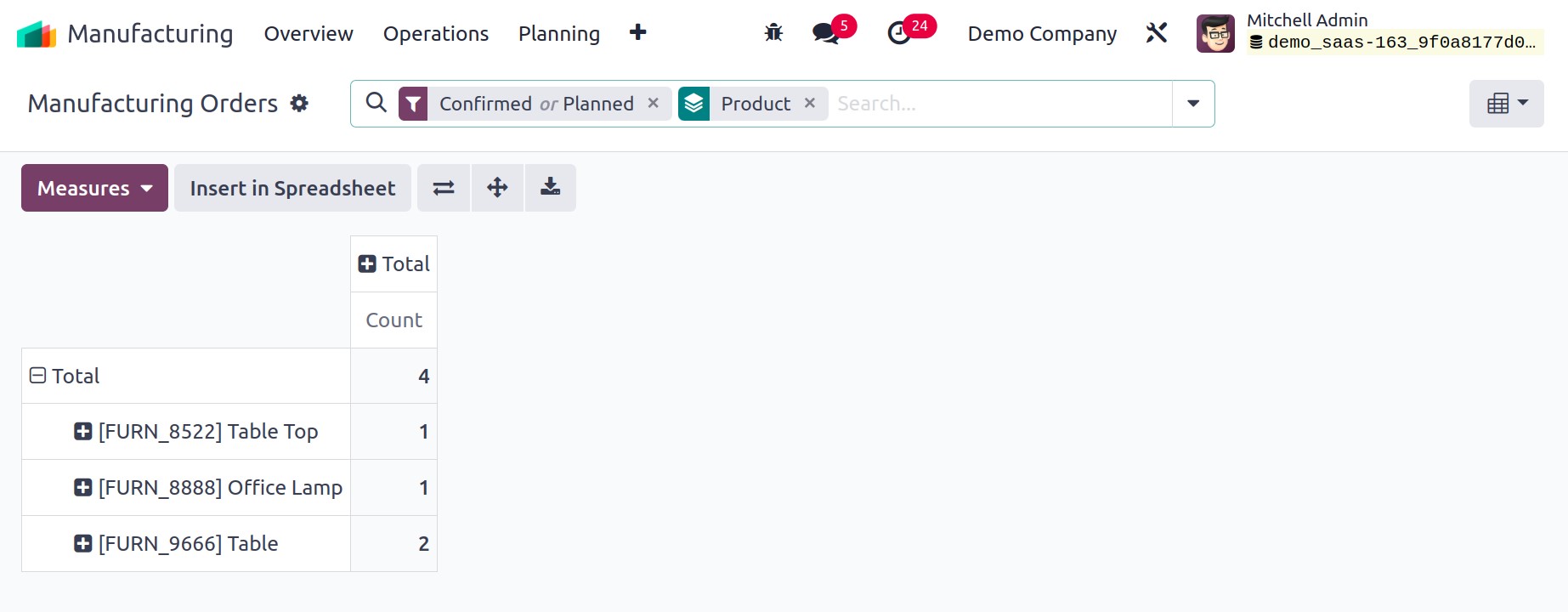

Manufacturing Orders

You can view the report of the manufacturing orders handled by your company here. The manufacturing order's Product, Status, Material Availability, Procurement Group, and Scheduled Date can all be used to generate reports.

To Do, Starred, Unbuilt, Draft, Confirmed, Planned, In Progress, To Close, Done, Canceled, Waiting, Ready, Planning Issues, Scheduled Date, and Warnings are the standard filters provided in this reporting platform.

The manufacturing orders' pivot view is depicted in the screenshot up top. The report can be improved by including more measures like Back Order Sequence, Extra Unit Cost, Producing Quantity, Producing Quantity, Total Quantity, and Count.

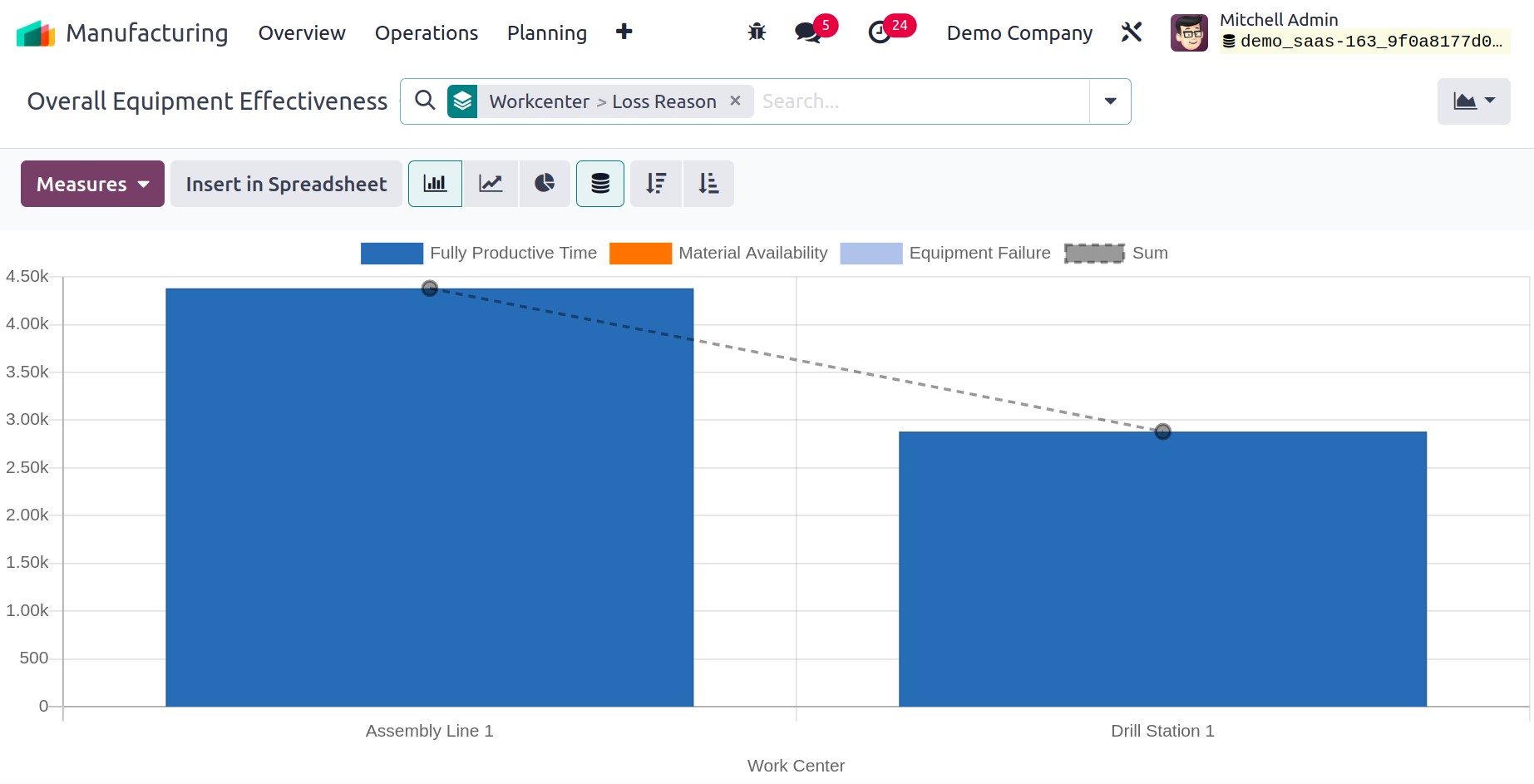

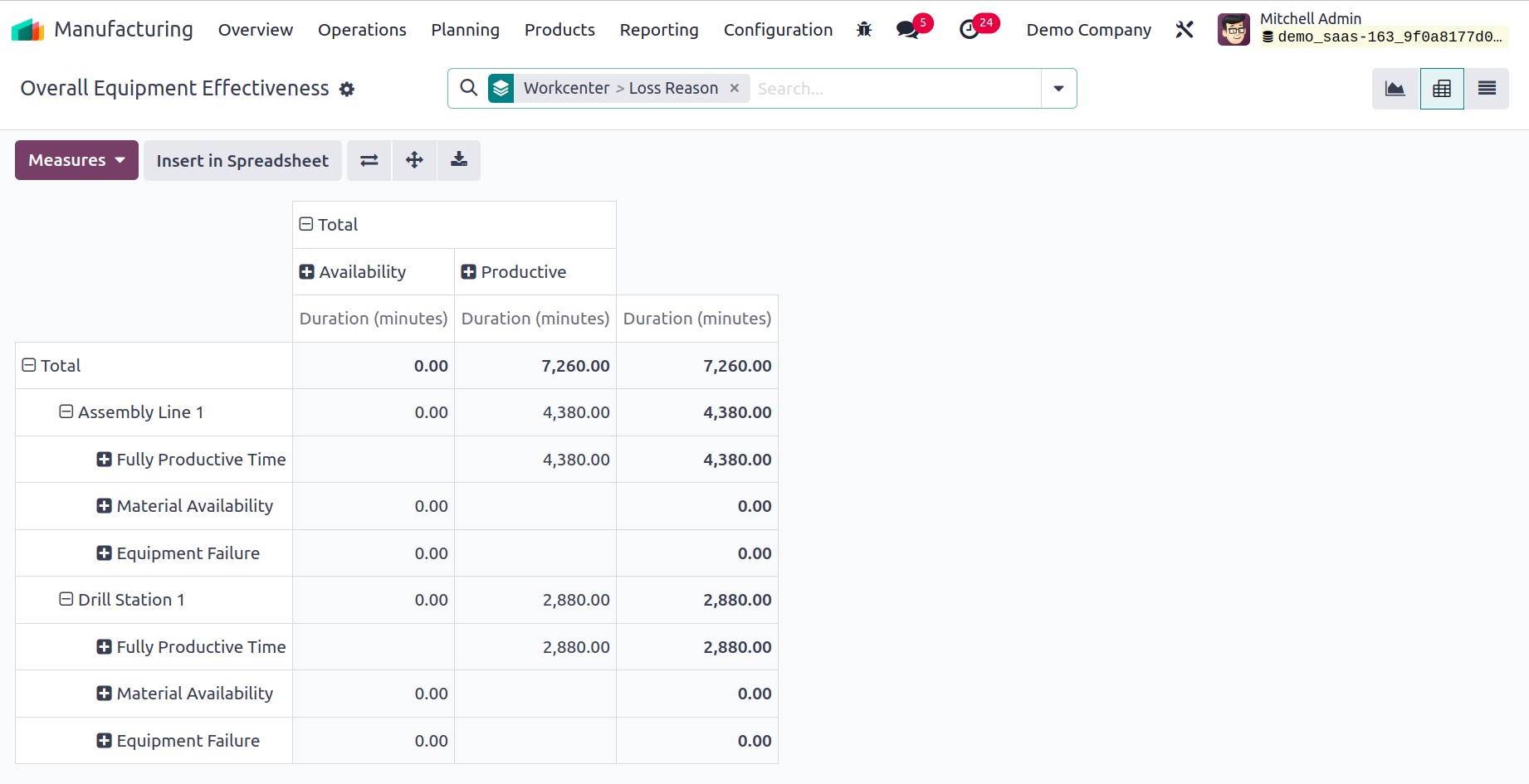

Overall Equipment Effectiveness

The overall equipment effectiveness reporting platform can be used to analyze the overall equipment effectiveness of the company's work centers. Users, work centers, and loss reasons can all be used to generate reports.

To enhance the report, utilize the filters Availability Losses, Performance Losses, Quality Losses, Fully Productive, and Date.

The report's metrics can be configured to Duration, Employee Cost, and Count.

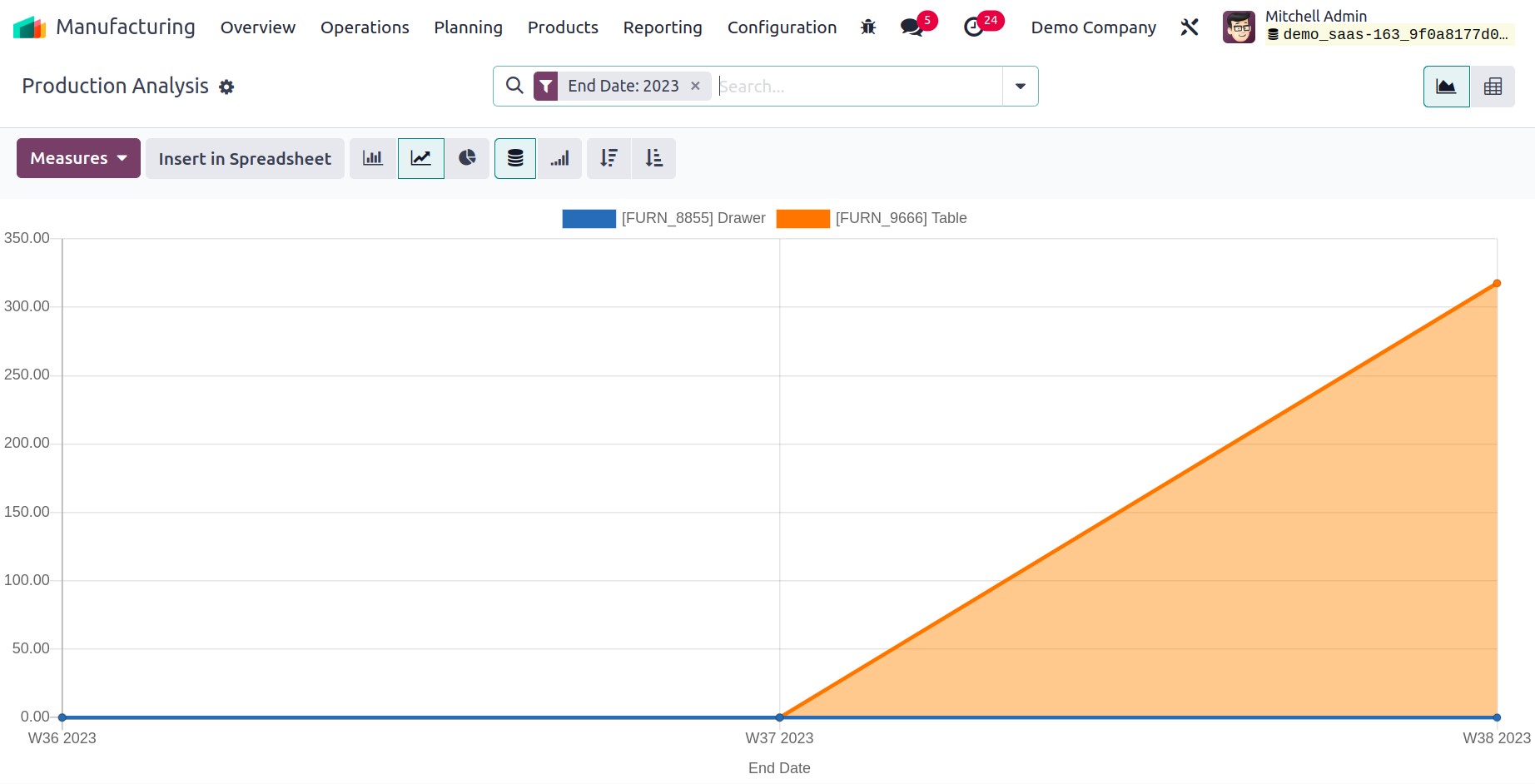

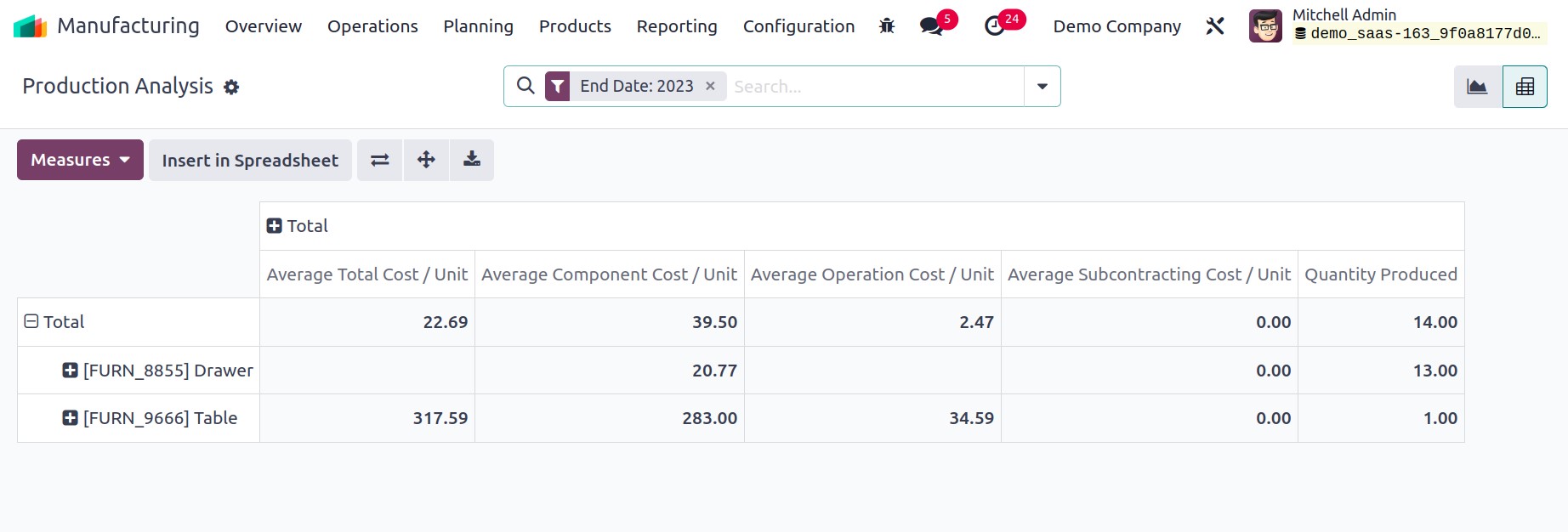

Production Analysis

The Production Analysis option under the Reporting menu can be used to undertake production analysis on a daily, weekly, monthly, or annual basis. Based on the product and finish date, this platform will produce reports of the production analysis.

To acquire the reports of the production at the end date of each product, specify the End Date of the Production as a filter.

Measures for this report include Quantity Produced, Total Component Cost, Total Cost, Total Cost of Operations, Total Operation Cost, Total Subcontracting Cost, and Count. You can also include Average Component Cost/Unit, Average Operation Cost/Unit, Average Subcontracting Cost/Unit, Average Total Cost/Unit, By-Products Total Cost, Duration of Operations/Unit, and By-Products Total Cost.