Operations

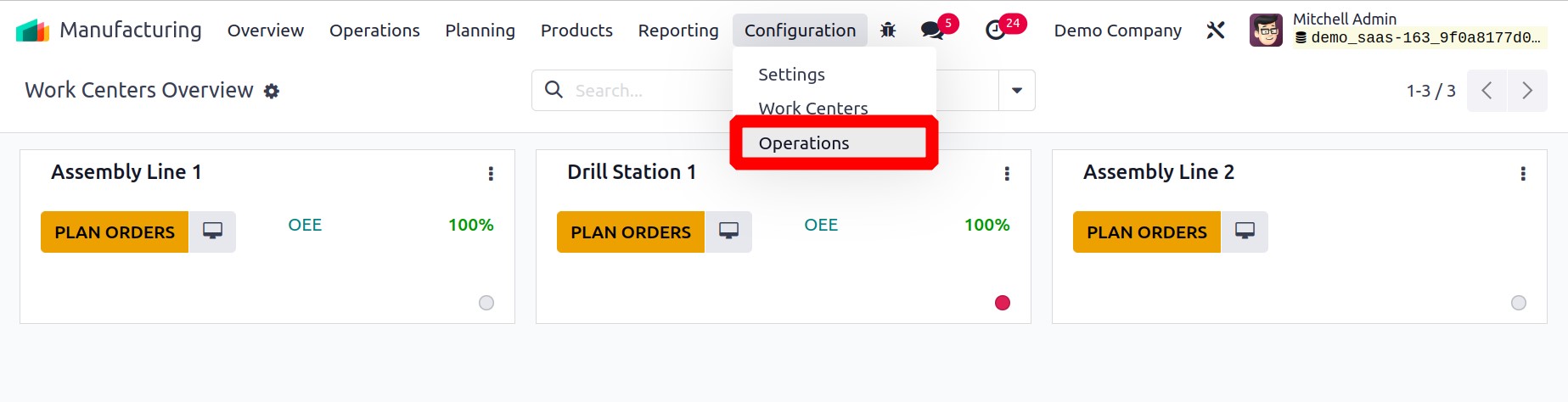

In order to accomplish the work orders within the allotted period, a work center consists of several operations to oversee. It involves several different procedures, including component assembly, packing, testing, and more. While creating a manufacturing order, you can allocate different operations to a work center. You can configure such operations for each work center using the Operations menu found under the Configuration of the module.

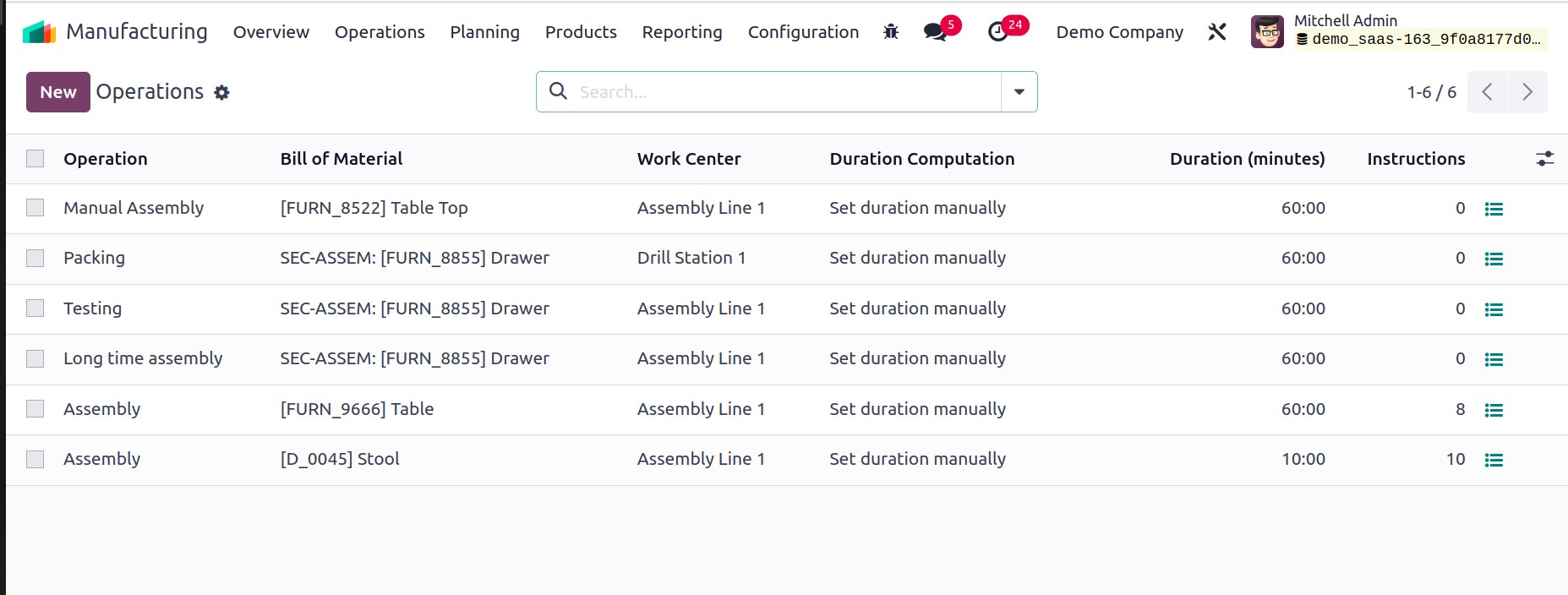

This platform will display a list of operations that have previously been set up together with information on the operation, the bill of materials, the work center, the duration computation, the duration, and the instructions. A button that provides you with a detailed look of the instructions is located close to the Instructions box. You can make a new Operation for a work center by selecting the New button.

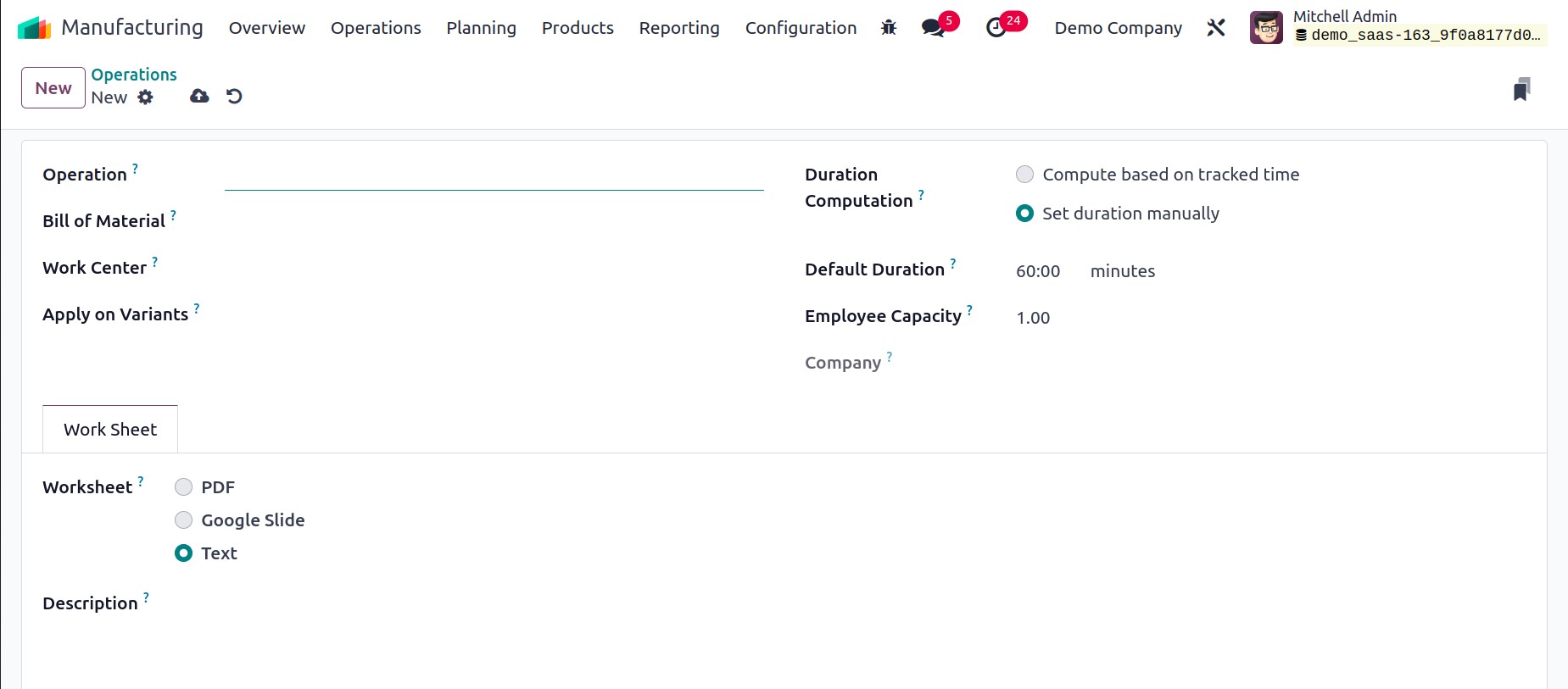

The name of the Operation might be mentioned in this area. You can provide them in the relevant fields if this procedure is being configured for a certain Bill of Material and Work Centre. Mention them in the Apply on Variants section if you wish to apply this operation to the product variants listed in the BoM.

There are two techniques for calculating duration. Using the option to "Compute based on the tracked time," you can determine the operation's overall duration based on the time that has been recorded. Alternatively, you may set the duration manually by choosing that option. Here, you may find the operation's default duration. The Employee Capacity section allows you to enter the minimum required staff size for the process to be completed successfully. Once the Company has been mentioned, you can create a spreadsheet for the operation. A worksheet can be added to an operation as a PDF, Google Slide, or text. The Operation is ready for usage once the worksheets have been included.