Warehouse Management

One of the primary tasks in a company's inventory operations is warehouse management. A company's warehouses need to be adequately maintained and supervised to ensure efficient stock operations and transfers. Odoo17, a fantastic inventory management helper, may provide you with platforms specifically designed to efficiently manage company warehouses. Using the capabilities provided by Odoo17, you may manage several warehouses at once. Depending on the kind of business it operates, a corporation will own a different number of warehouses. No matter how big or how many warehouses a business has, Odoo17 will always make sure to streamline the process.

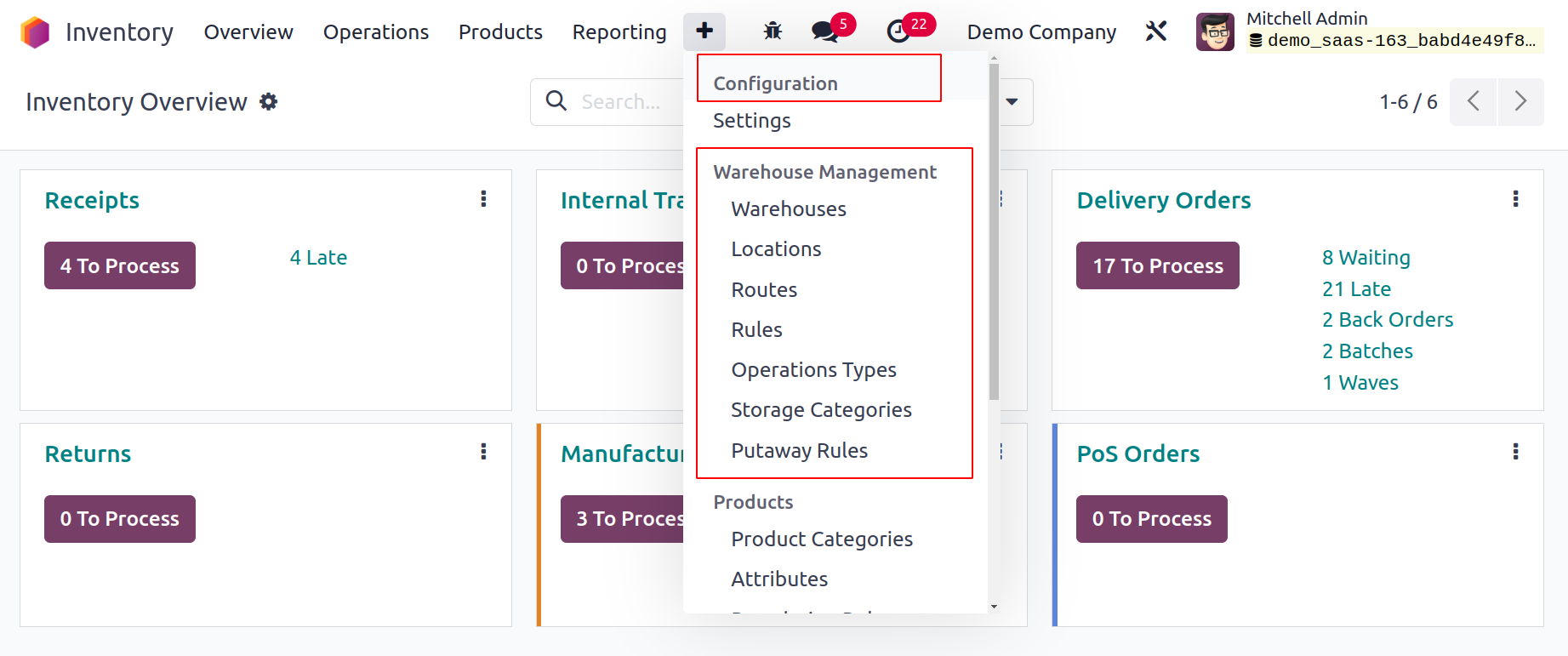

Advanced features including Warehouse, Locations, Routes, Rules, Operation Types, Storage Categories, Storage Category Capacity, and Putaway Rules are available in the Warehouse Management tab of the Odoo17 Inventory module's Configuration menu.

Warehouse

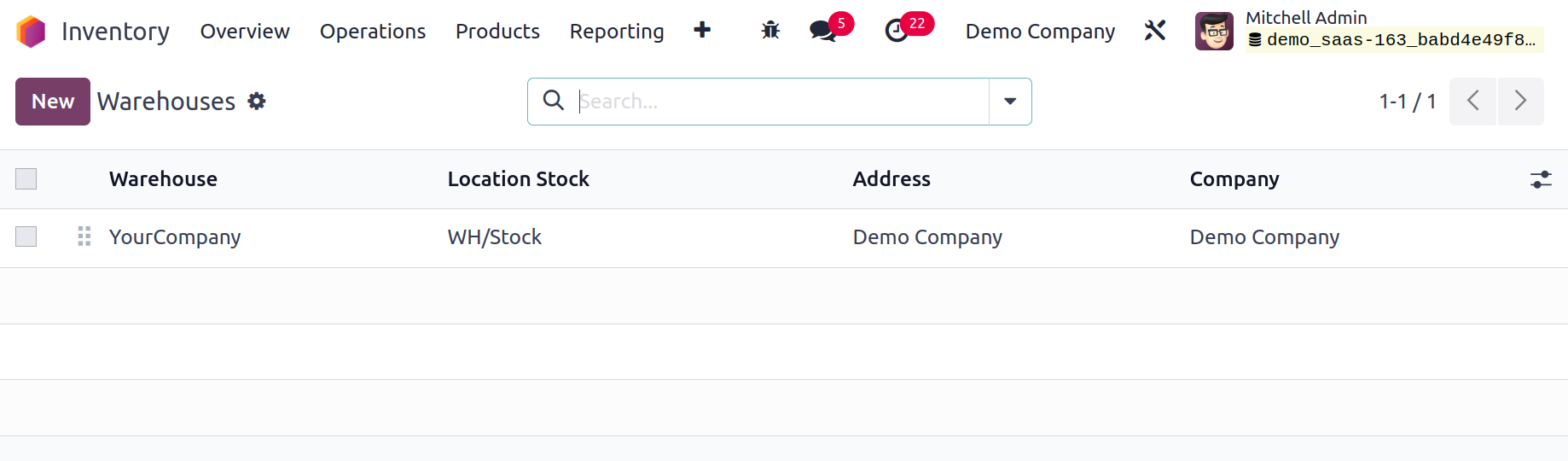

You can do various warehouse management tasks with the help of these solutions. Let's start by looking at the warehouse settings in the Odoo 17 Inventory module. You can do this by choosing the Warehouses option under Configuration.

The warehouse platform's list view is depicted in the screenshot above. From this view, you can obtain information about the Warehouse, Location Stock, Address, and Company. Let's configure the information for a new warehouse to the Odoo Inventory module using the New button.

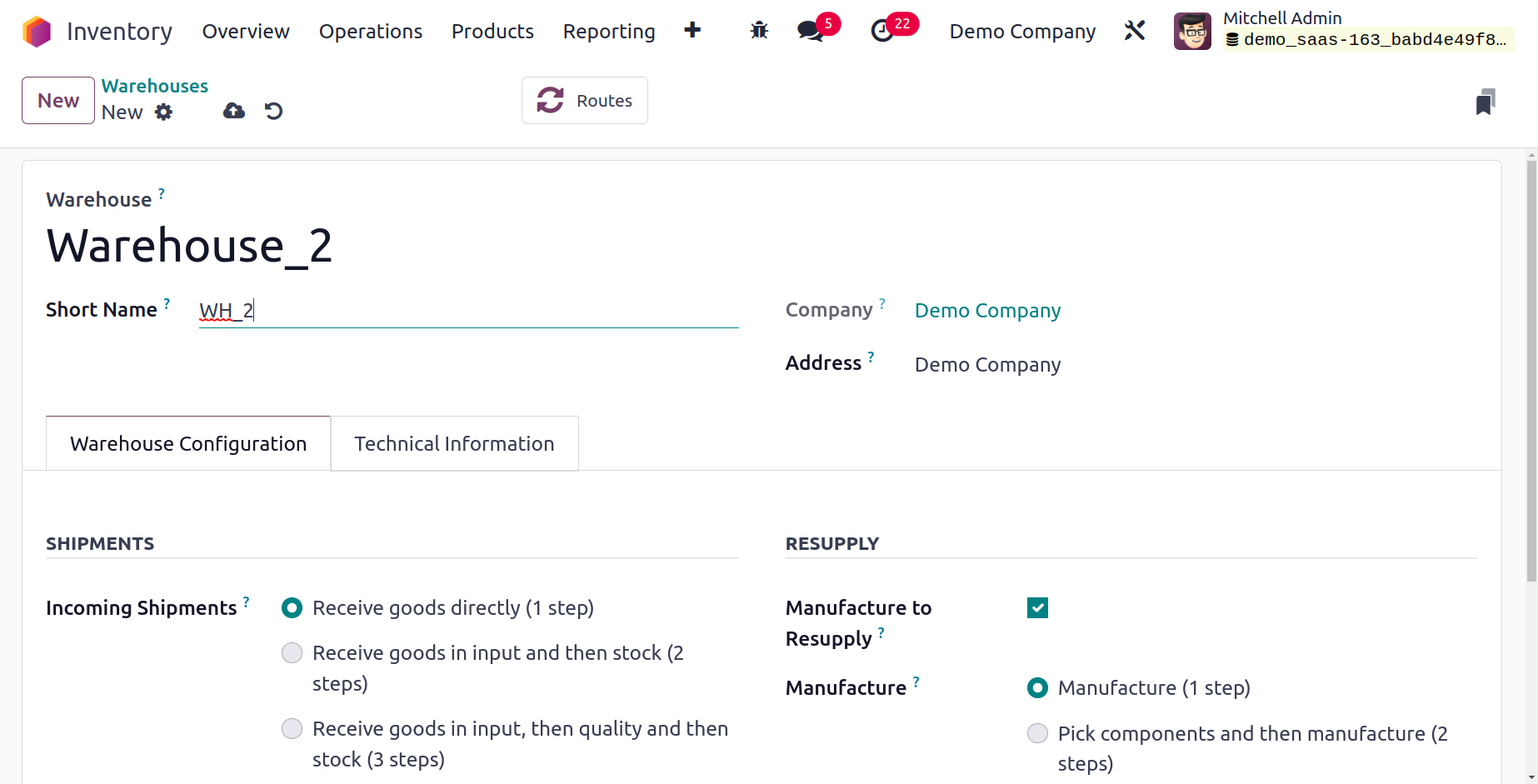

You can enter the Warehouse, Short Name of the Warehouse, Company, Address, and Intrastat Region in the corresponding fields of this window. You must provide information about your shipments and resupply in the Warehouse Configuration tab.

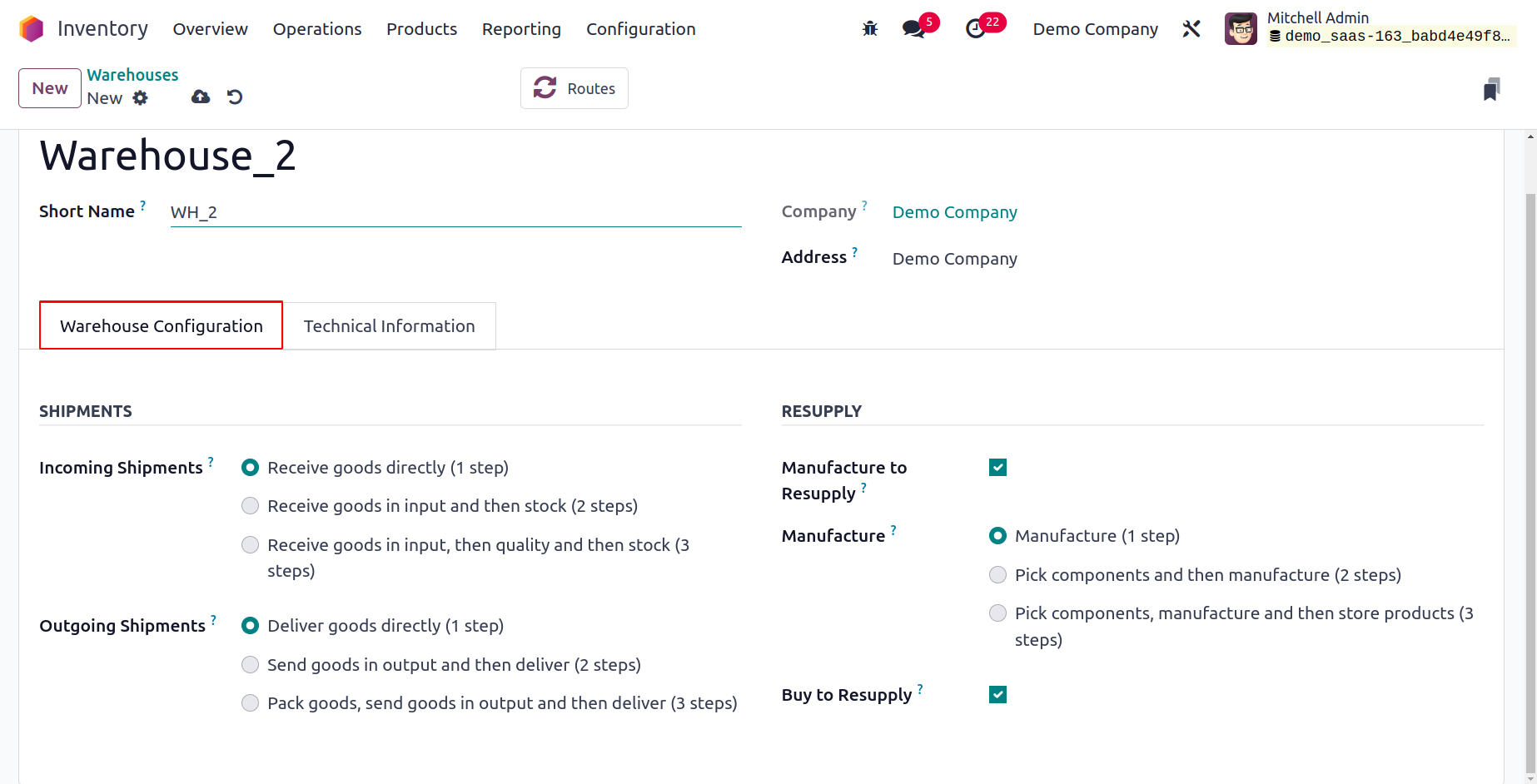

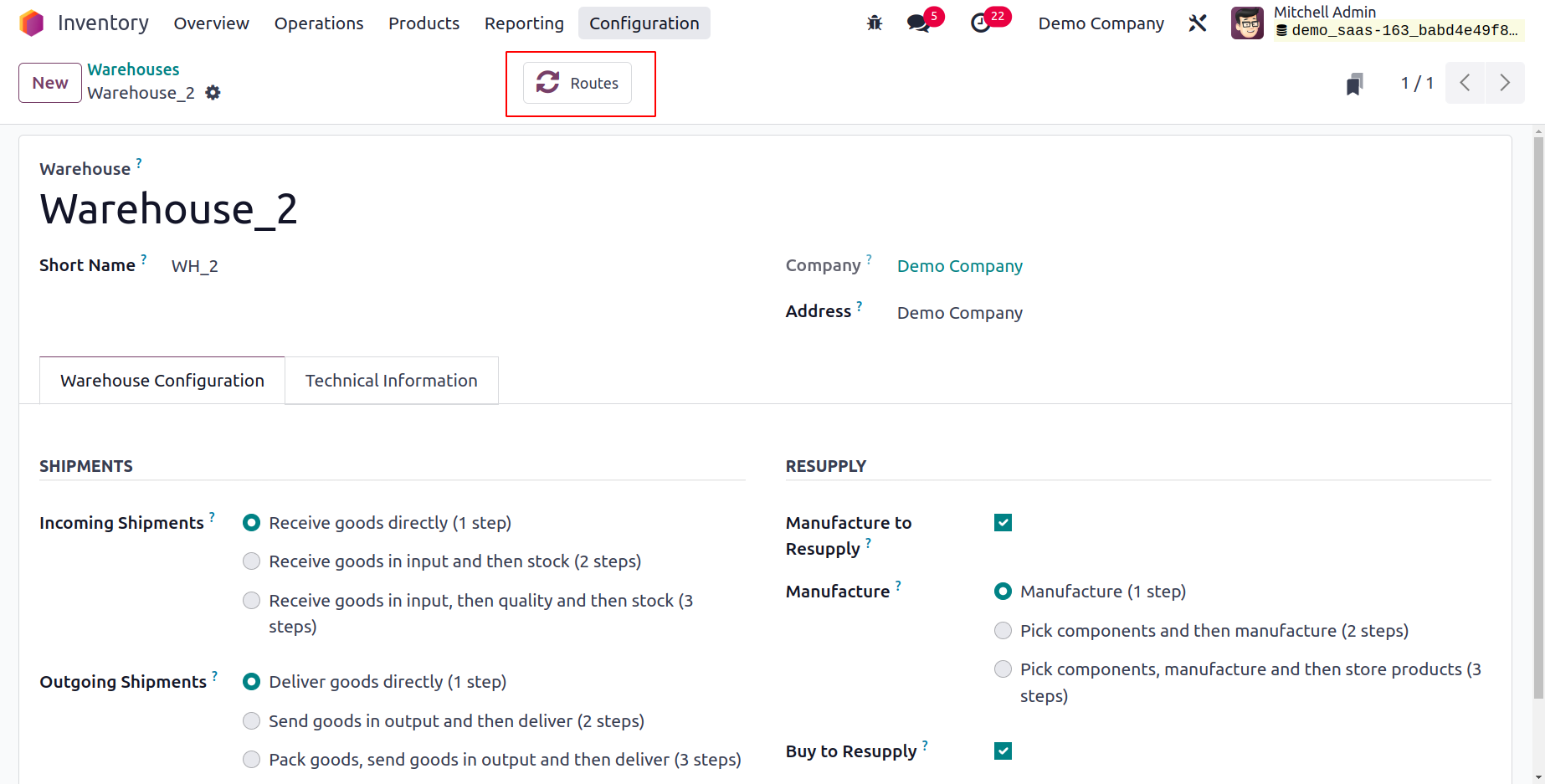

You can choose how to handle the product's incoming shipment under the Incoming Shipment section. You can receive products straight to the warehouse by choosing the Receive goods directly option. The incoming shipment contains two steps when using the Receive products in input and then stock technique. The products will be obtained initially and then relocated to the stock in this two-step process. Use the Receive goods in input, then quality, and then stock method of incoming shipment to apply quality checks after receiving the items before stocking. Similar alternatives will be accessible for Outgoing Shipments as well, and you can choose the best one for this warehouse's shipping needs. You can activate advanced features under the Resupply tab.

You can dropship subcontractors with components by turning on the Dropship Subcontractors functionality. The components can be resupplied to subcontractors using the Resupply Subcontractors. This will make it easier for the manufacturer to provide the necessary materials to the subcontractors. You can utilize these features to restock components from one warehouse to another. When raw materials are needed, it is simple to replenish them in warehouses. By turning on the Manufacture restock option when a product is out of stock, you can create it in the warehouse for restock. Three ways to describe manufacturing processes are provided. You can move the components directly to the production area and begin the manufacturing process by choosing the Manufacture option. The Pick components and manufacturing technique has two steps that you must adhere to. Prior to moving to the production area for manufacture, you must first unload the stock's components at the input point. The option Pick components, make, and then store items allow you to choose the components, create the products, and then store them in the warehouse. You can buy raw materials to replenish and keep them in this warehouse by turning on the Buy to replenish feature in Odoo 17. The information about the newly configured warehouse will be saved when you click the Save button.

The window's top-right smart button, Routes, provides access to the routes management window for this warehouse's activities.

We will go into depth about how to set up several locations for stock management in the following section.

Locations

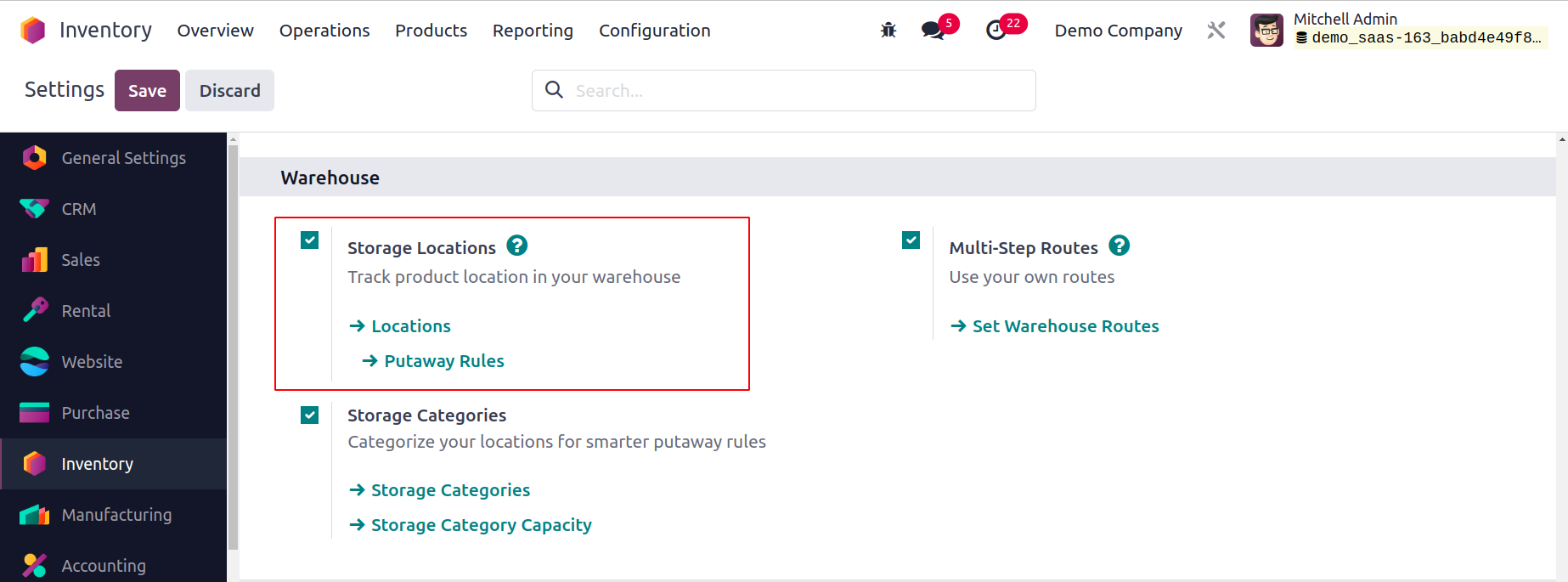

You can specify the areas in your warehouses where the products are stocked by using the platform to configure and manage various locations available in the Odoo17 Inventory module. You can manage many stock locations inside a single warehouse. You may enable the Storage Location function, which will help you track product location in your warehouse, from the Settings menu of the Inventory module.

Now, as seen below, the Inventory module's Configuration menu has an option for configuring Locations.

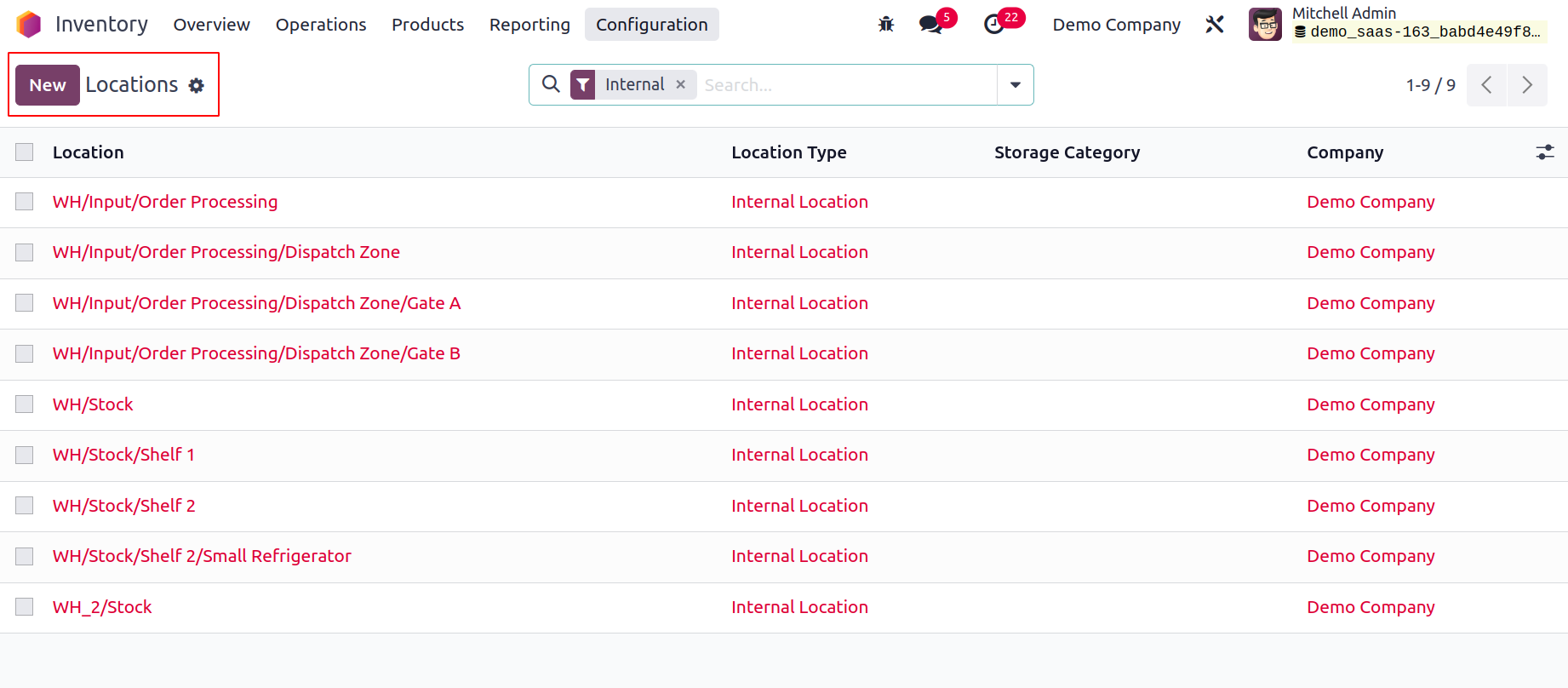

Details about the Locations, Location Type, Storage Category, and Company are provided in this platform's list view. While talking about how to set up a new location in Odoo 17, we will go through each of these options in more detail. You can do this by selecting the New button.

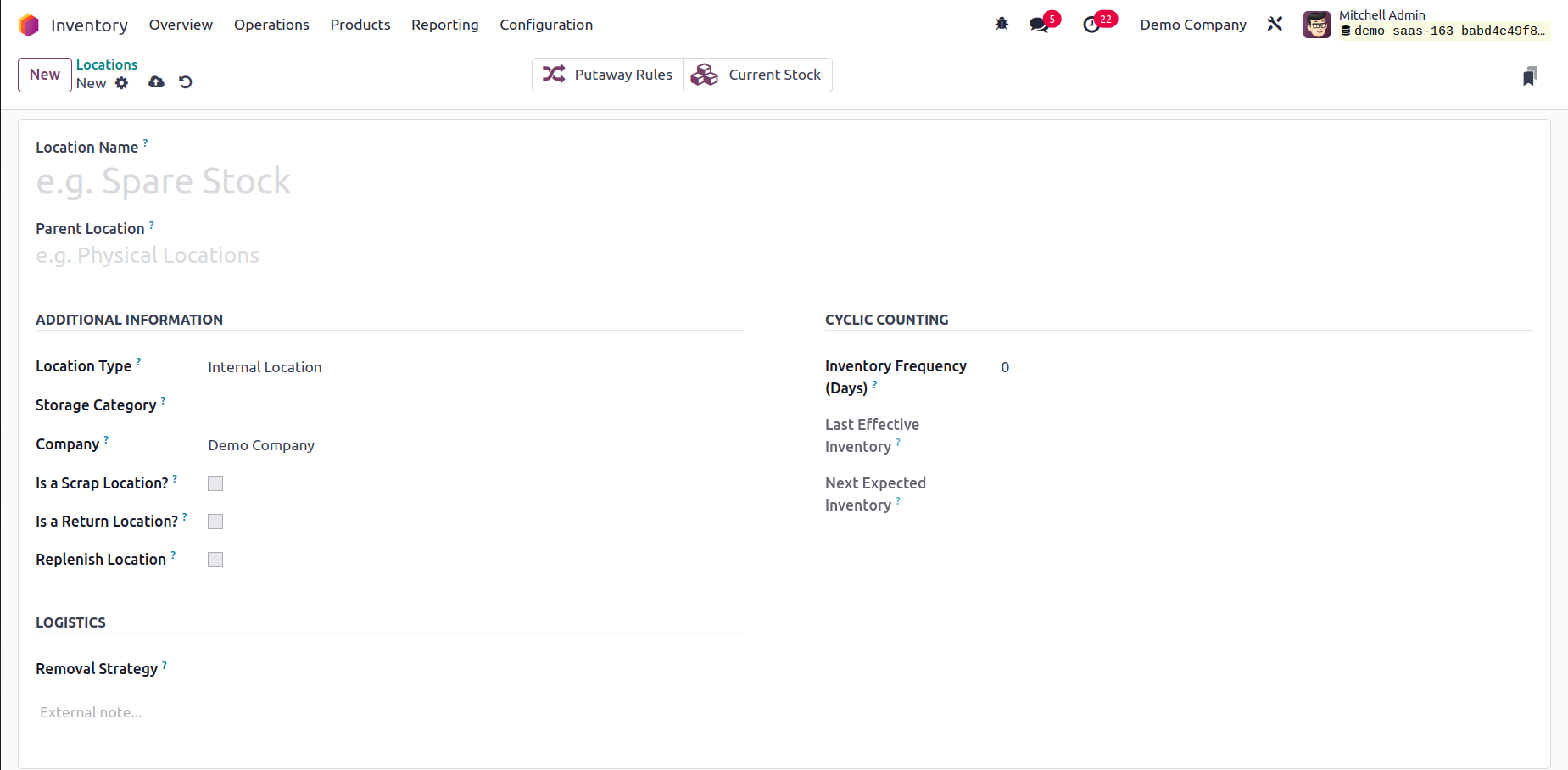

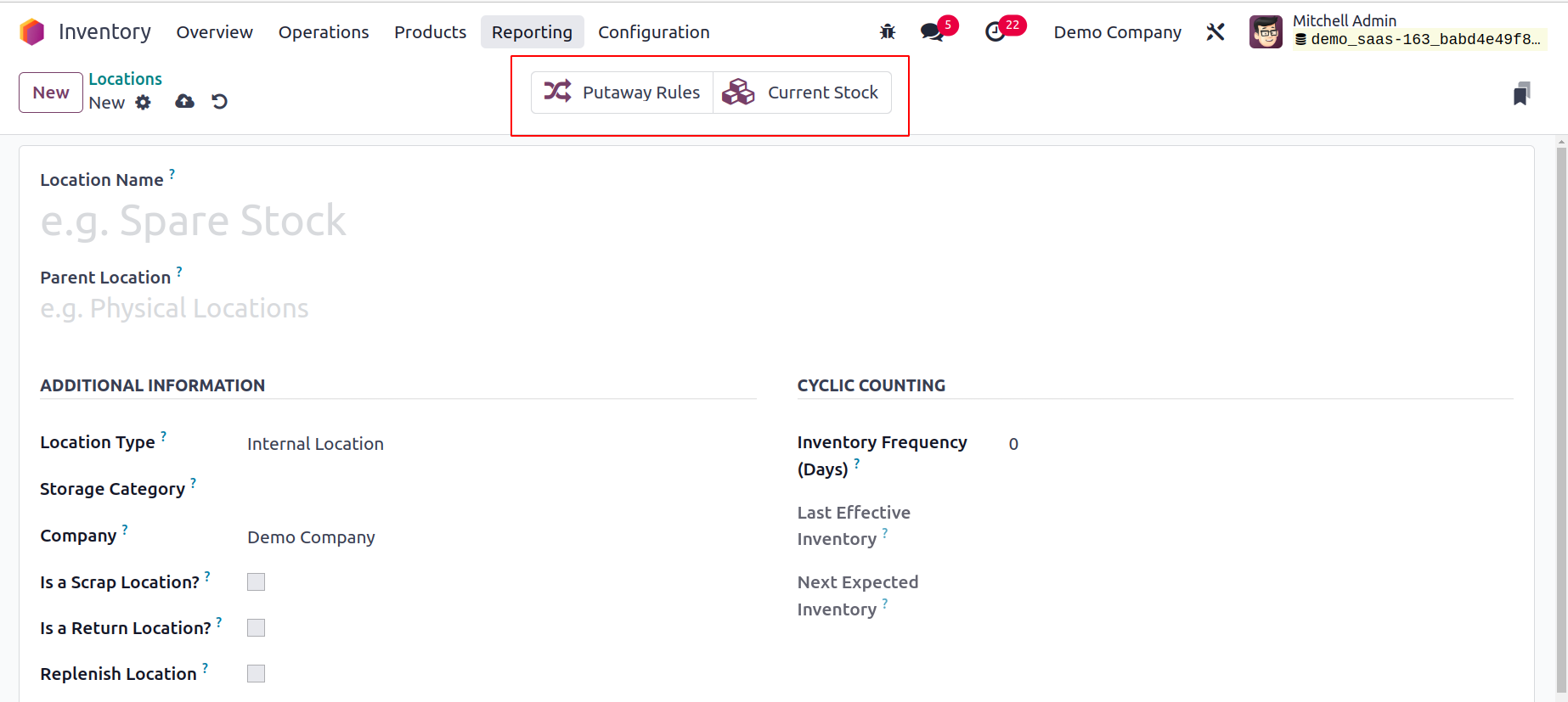

The window for creating a new location is displayed above. You can enter the location name in the field provided here. The Parent Location option allows you to specify the parent location that contains this location. From the drop-down menu, you can choose the parent location. You can define the tabs for Additional information, Logistics, and Cyclic Counting. The inventory count for the products kept at this location will be automatically

set at the specified frequency if it differs from zero. You can choose Location Type for the new one from the available options.

The location types that are available are,

Vendor Location: A vendor location is a virtual location that depicts the place where the goods that are sold by your merchants are made.

View: View is another type of virtual location that is used to organize your warehouse in a hierarchical fashion. They are unable to physically store goods.

Internal Location: Your warehouse's actual, physical locations are known as internal Locations.

Customer Location: A virtual location that depicts the places where the goods you send to your consumers will end up.

Inventory Loss: This virtual area also functions as a counterpart for inventory activities needed to adjust stock levels.

Production: Activities related to production are carried out in this virtual counterpart place. This location's components can be consumed to create finished goods.

Transit Location: In intercompany or inter-warehouse activities, the Transit Location should be used as a counterpart location.

You can indicate the storage grouping that is being used in this location by filling out the Storage Category section. If multiple companies share this location, you can leave the Company box blank. By turning on the Is a Scrap Location? option, you can approve the placement of scrap and damaged products here. By turning on the Is a Return place? option, this place can be utilized as a return location to hold returned goods. For this business, a new specialized subcontracting location may be created by activating the Is a Subcontracting Location. The Barcode field allows you to enter the barcode that is used at this site. To have all amounts replenished at this place, use the Replenish Location function.

Add a line to the Cyclic Counting tab that says "Inventory Frequency" in days. The inventory count date for the items kept at this location will be automatically set at the specified frequency when the difference is greater than zero. The date of the most recent inventory at this location will be displayed in the Last Effective Inventory column. The Next Expected Inventory field will display the date of the following scheduled inventory based on a cyclic timetable.

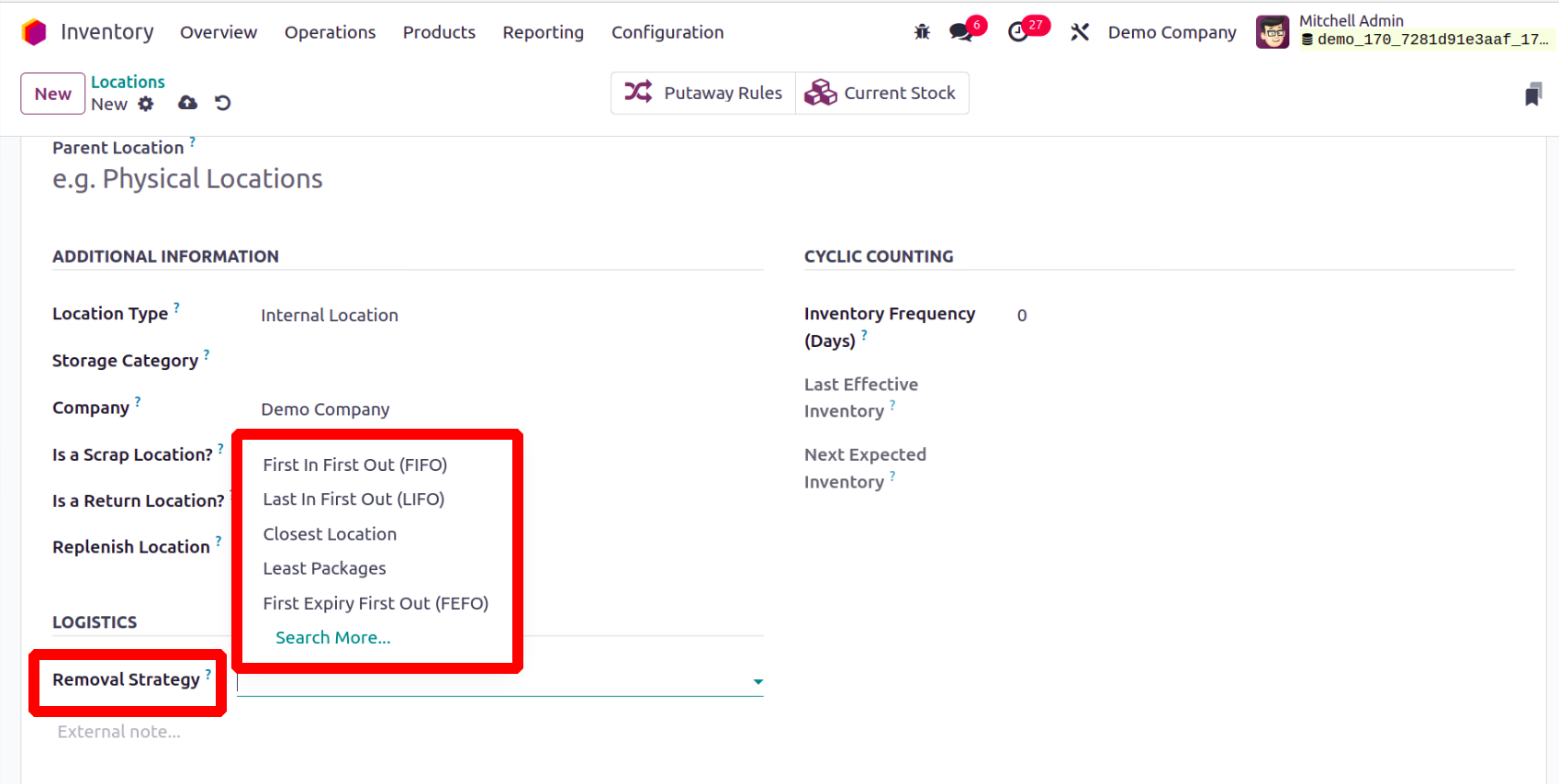

It outlines the standard procedure for recommending the precise location, the lot, etc., to take the products from for this location. If no parent locations are given here, a fallback is performed to the product category level, where this technique can be enforced. The available Removal Strategies are,

FIFO: The items or lots that were initially stocked will be removed first.

LIFO: Products or lots that were last stocked will be removed first.

Closest Location: The items or lots that are closest to the desired location will be transported out first.

FEFO: Products/lots with the earliest possible removal date will be removed first.

Least Packaging: Products can be added to packages. So the small package will be removed from the stock first.

Additionally, in the location window, there are special smart buttons for things like stocks and putaway rules. The Putaway Rules button will open a window with instructions for moving products from one place to another, and the Current Stocks button will provide information on this location's most recent stock updates.