Warehouse Management

One of the most important tasks that has to be carefully managed and organized is warehouse management in terms of a company's inventory control. Warehouse management is important for the smooth operation of product transportation and stock management. Odoo 17, a top-notch inventory management software, provides a sophisticated platform for easily managing the activities associated with your company's warehouses. This platform will oversee and manage several warehouses at once.

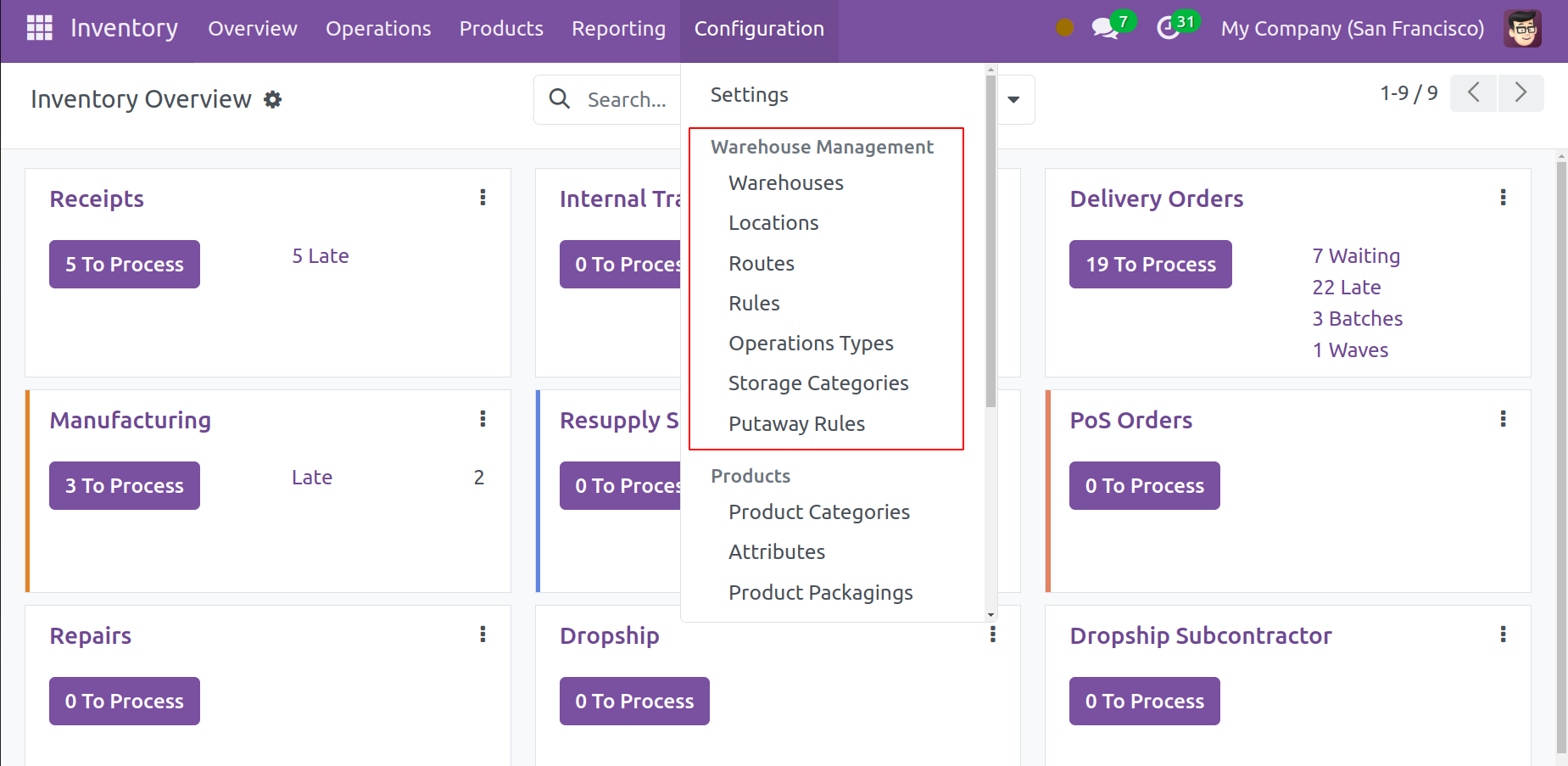

Warehouses, Locations, Routes, Rules, Operation Types, Storage Categories, and Putaway Rules can all be managed through the Warehouse Management tab of the Inventory module's Configuration menu.

With the help of these alternatives, you may carry out a number of tasks that will simplify warehouse administration. You can make a list of the warehouses that your business owns by choosing the Warehouses option from the Configuration menu.

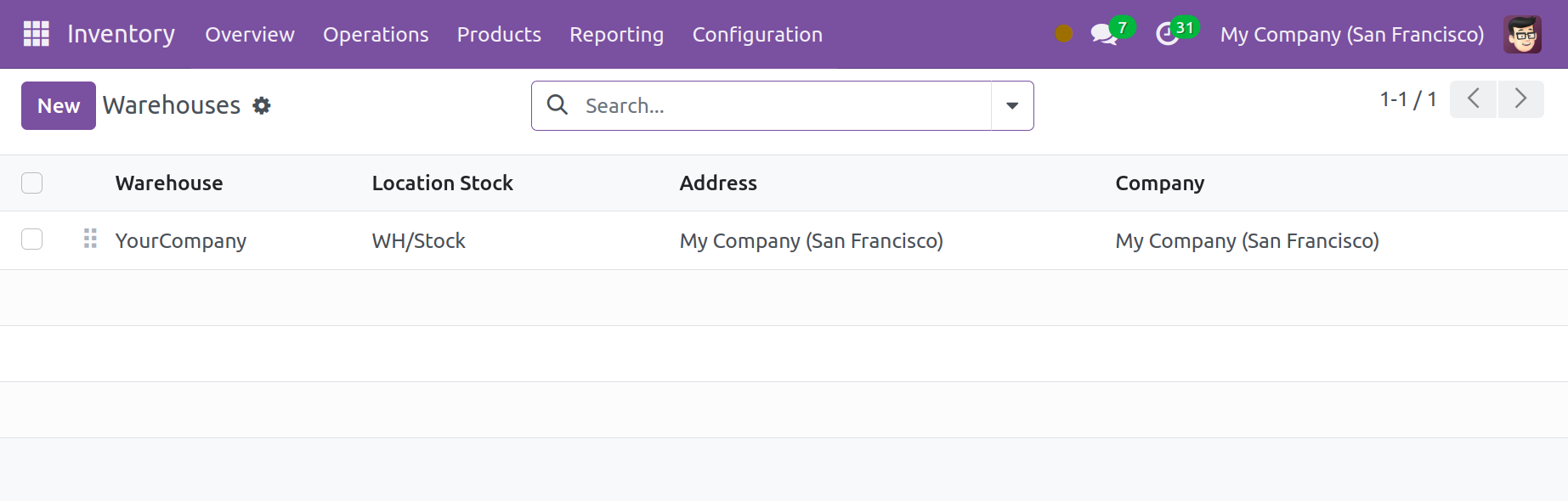

The warehouses are displayed in a list view similar to the one in the above image when you click on the Warehouse option. The names of the warehouse, location, stock, address, and company are displayed in the list. For your business, utilize the New button to establish a new warehouse.

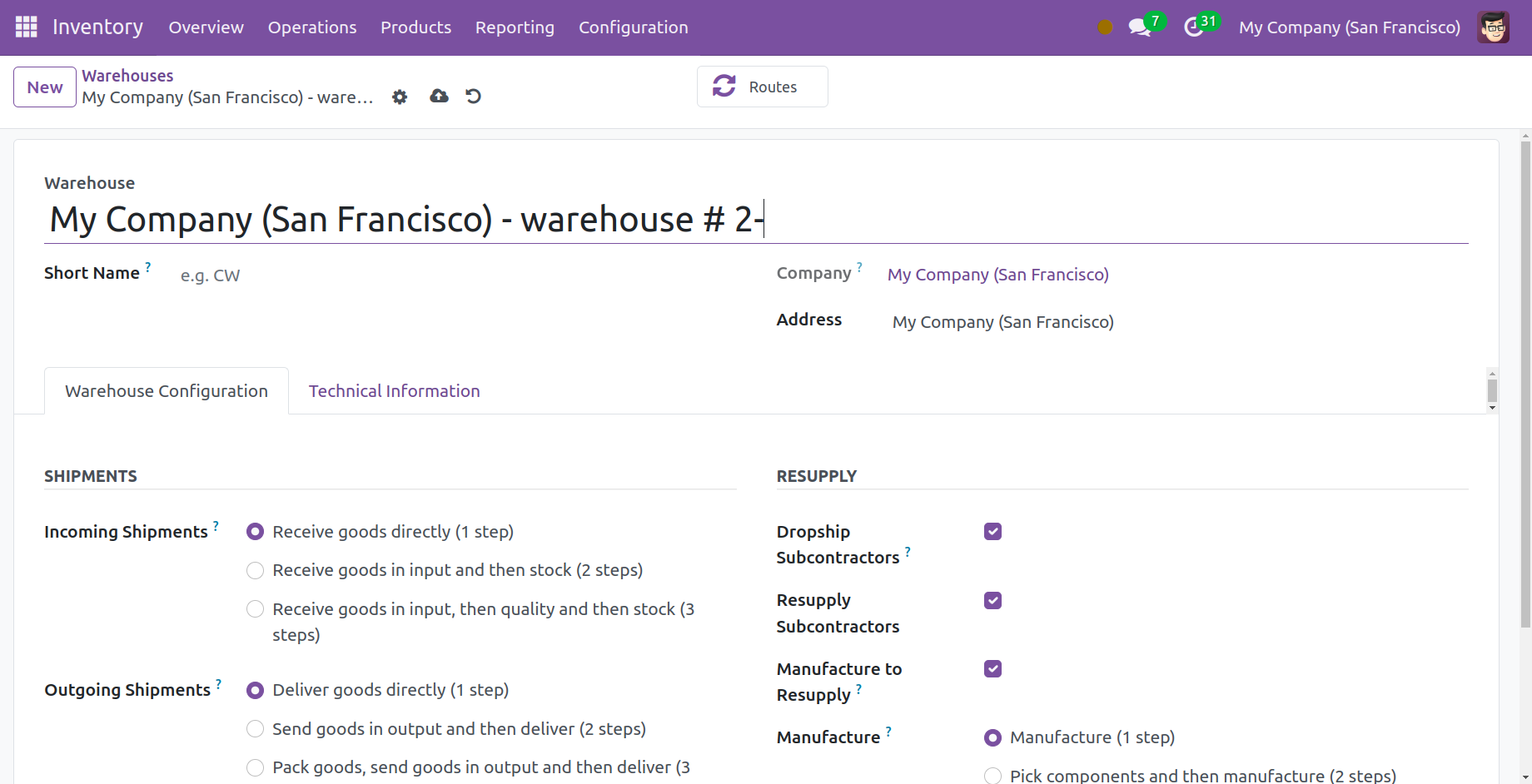

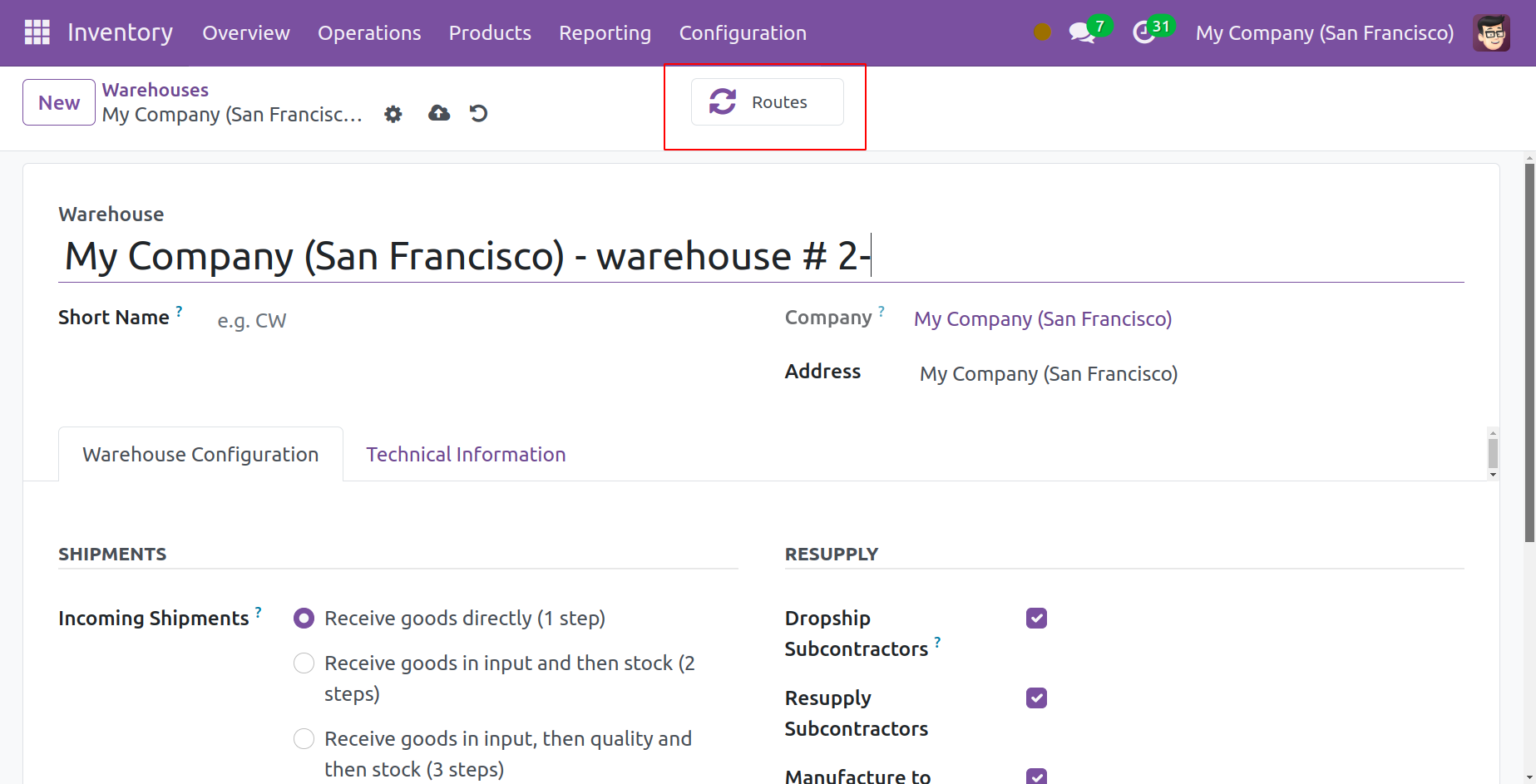

The warehouse's name, short name, company, and location can all be entered in the corresponding fields in the warehouse form view. You can specify the Shipment and Resupply details on the Warehouse Configuration tab.

To specify the incoming path to take while shipping the product to this specific warehouse, use the Incoming Shipments field. Selecting the one-step option will allow you to get things straight to the warehouse. The product will be received first and then transferred to the appropriate stock under the two-step option. Receiving the items, inspecting them for quality, and placing them in the appropriate stocks are the three phases. The default outgoing route for an outgoing shipment will be specified in the Outgoing Shipments. The first option involves just one step: the products are delivered straight from the warehouse. The second choice entails delivering the items after they are sent in output. The third alternative requires you to package the products, send them out, and then deliver them.

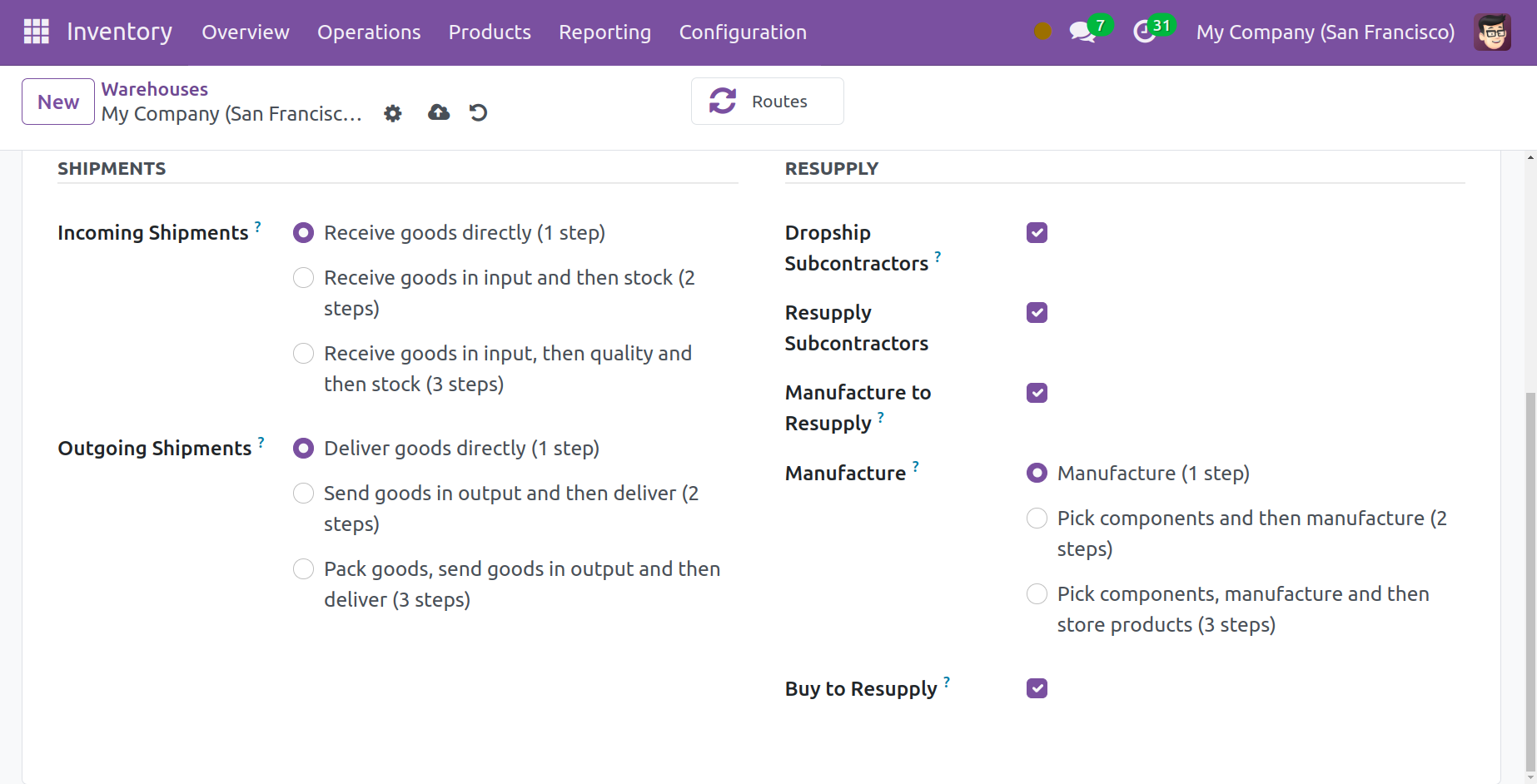

You can activate the Dropship Subcontractor function from the Resupply menu to dropship components to subcontractors. You can use the replenish Subcontractor capability to replenish the subcontractors with components in the event that necessary. Warehouses make it simple to replenish raw materials when demand calls for them. When a product runs out of stock, you can activate the Manufacture Resupply option to manufacture it in the warehouse for resupply. You have three options to specify the steps in the manufacturing process in the Manufacture field. You can directly make the product with the first choice. The second alternative requires you to move to the production location for manufacture after unloading the components from the stock to the input location. Using the third method, you can keep the products in the warehouse after selecting the parts and having them manufactured. By turning on the Buy to Resupply feature, raw materials can be purchased to be restocked and stored in the warehouse.

To obtain information on the routes used by this warehouse for operations, utilize the Routes smart button that is present on the pane.