Quality Control Points

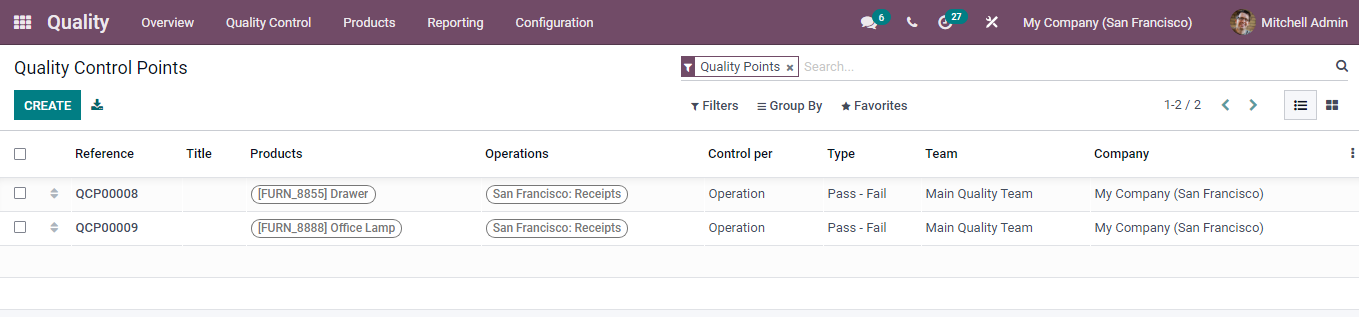

Quality Control Points help in defining the stages in which the product needs to be checked. Measures to check the quality of the products can also be determined from here. To configure these factors, select the Quality Control Points option from the Quality Control option. Existing Quality Control Points are listed along with the details of their Operations. The list can be grouped on the basis of Test Type, Team and Responsible. More details regarding the product’s quality control points can be viewed by selecting them from the list.

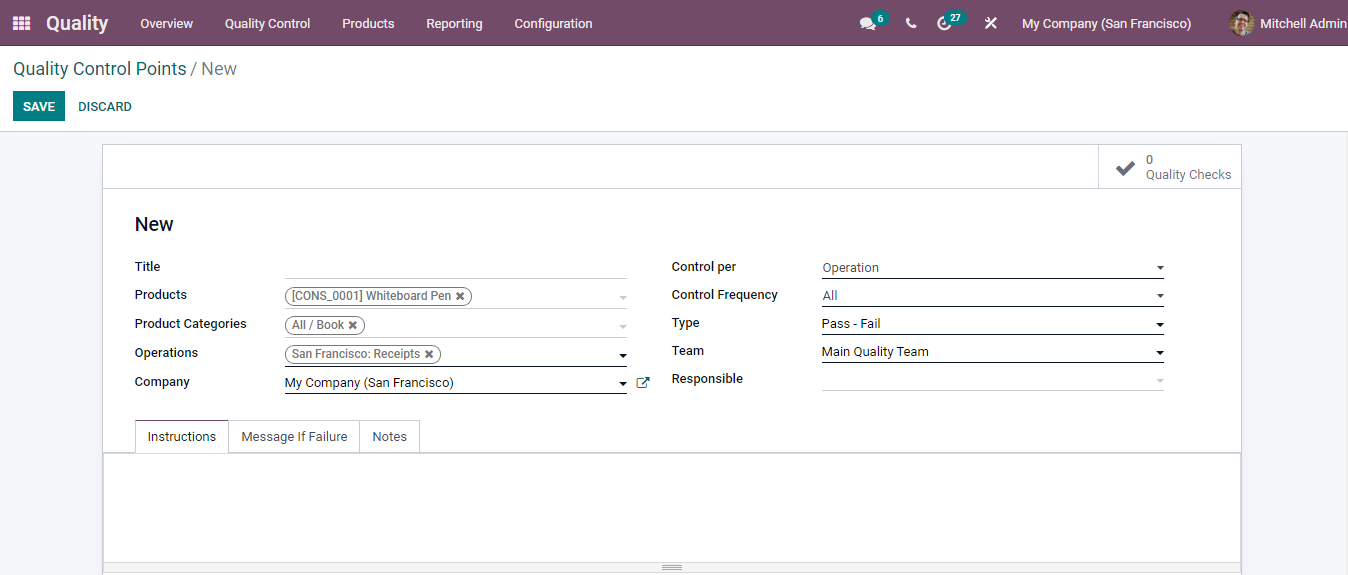

To create new Quality Control Points, select the CREATE option. At the displayed page enter the details such as:

Title: Enter the name you intend to give to the creating quality control point.

Product: Select the product from the drop down menu on which the quality points must be applied.

Product Category: The quality points will be added to all the products which fall under the selected product category.

Operations: Select the stage from the drop down menu at which the quality should be checked.

Control Per: Here you can define if the quality check is done at the Operation Level or at more granular Lot or Serial Number level.

Control Frequency: You can select the intervals for quality checking as All, Randomly or Periodically. When selected Randomly, mention the percentage of the operations that must be completed for quality checking. And in case of Periodically mention the frequency of days at which quality has to be checked.

Type: Define the type of quality control point in this field. The type can be Pass-Fail, Instructions, Take a Picture, Measure or Worksheet. You can make use of these types while doing quality checks. For example when you have selected the Pass-Fail type, you will have the option of Pass and Fail while Quality Checking process. With this you can indicate whether the product has failed or passed the quality check.

Team: Select the team which will be in charge of the quality control.

Responsible: The employee responsible for the quality control can be selected from the drop down menu.

Instructions: Any additional instructions that must be looked at during the quality control can be mentioned in the text box.

Message if Failure: Any messages to be provided at the time of failure can be added in this provided field.

Notes: At the Notes field describe why you need to perform the quality check.