Bill of materials

Bill of Material is the document that keeps a record of the components or raw materials

used for the manufacturing of a product. Odoo 14 Bill of Material ensures the proper

documentation of all components used for the manufacturing of a product. It also

includes the quantity details of the component for the production of the product.

What is more the routing of the manufacturing process and individual steps take

while manufacturing gets recorded in the Bill of Material (BoM).

Odoo offers support to the user to link multiple BoMs with each product. This ensures

the documentation of the multiple variants of the product.

In Odoo 14, Routing is done at Manufacturing at BOM itself. Create multi-level Bills

of Materials: Set a Bill of Materials with in another BoM

Optional routing: Generate new routings for work orders. This will

sequence your production depending on the routing used. Create new routings for

work orders. This will sequence your creation relying upon the routing utilized.

Version changes: It enables the inclusion of configurable alternatives

while creating orders.

Phantom of Bill of Materials: Allows the sale of products in kits

or to build replacement parts by Creating phantom BoM.

Setting up a BoM: The user can skip assignation of routing to the

Bill of Material if the user decides to manage the manufacturing operations using

manufacturing orders. In such cases, the manufacturing process will be completed

in a single step and routing will not be required.

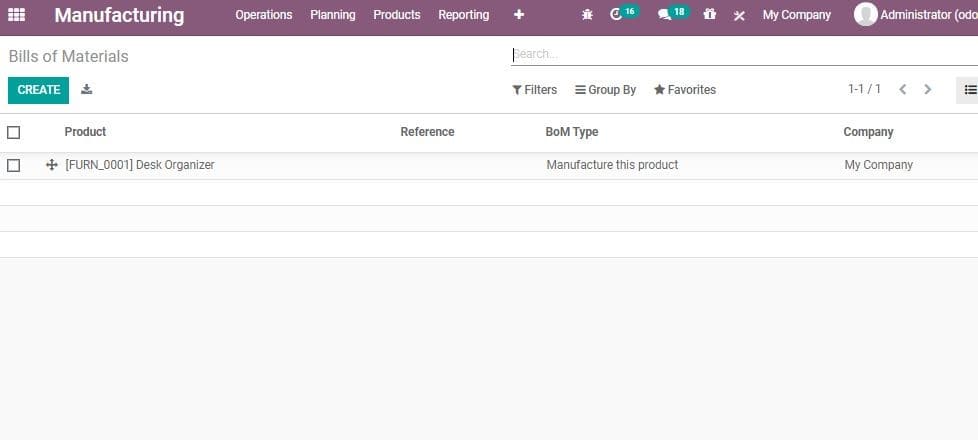

A user can create a new BoM by clicking CREATE button. But, for that, the user will

have to create a product under the Product Menu.

After that go to the Bills of Materials under Product menu to CREATE BoM.

Now you can click CREATE button to create new Bill of Materials.

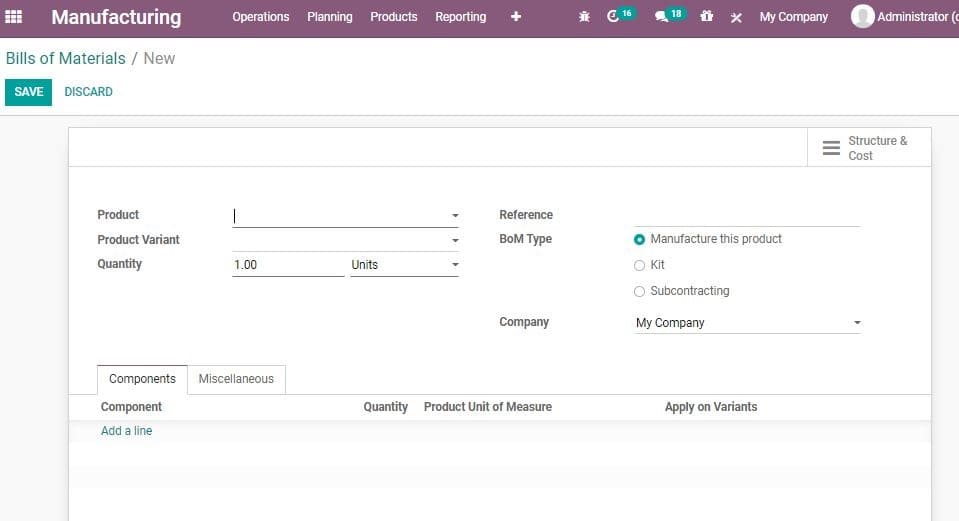

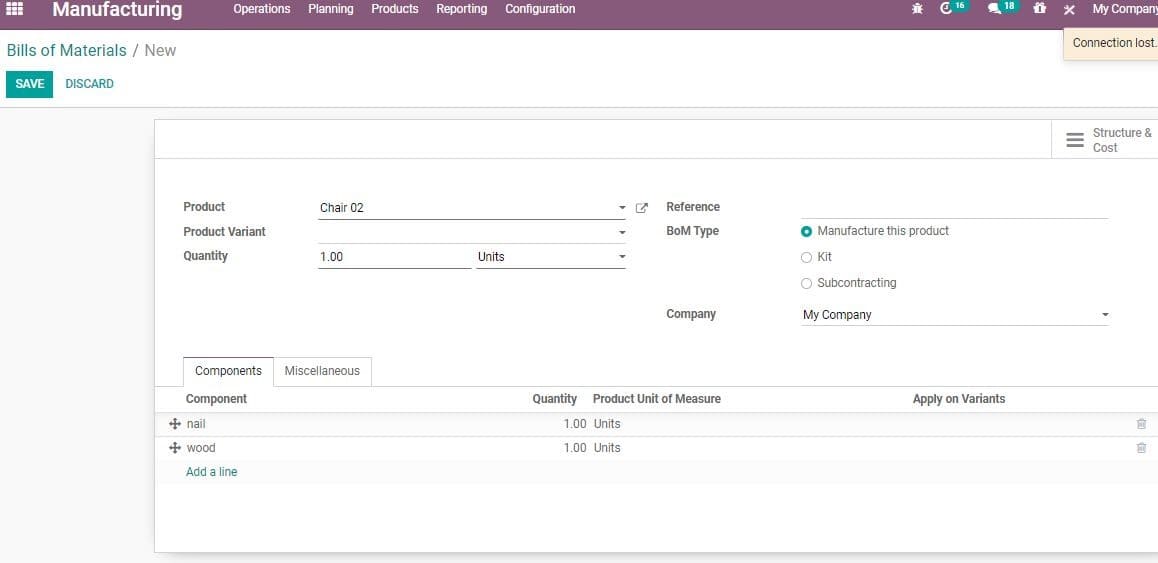

Here, you can see many attributes in the Create Form. They are explained below:

Product: The user can select a product from list. The product can

be selected from the dropdown menu.

Product Variant: On defining product variant the BoM will be prepared

specifically for this variant. Quantity: Quantity of the products to be manufactured.

Routing: This include the details of technical procedures for manufacturing

the product. If a routing is specified we can say that the production orders will

be executed through work order. If not, everything will be included in the production

order.

Reference: This field is used to distinguish between different

BoM for same product.

Specify the BoM Type: This helps the user to categorise the BoM

for Manufacture this product/Kit/Subcontracting.

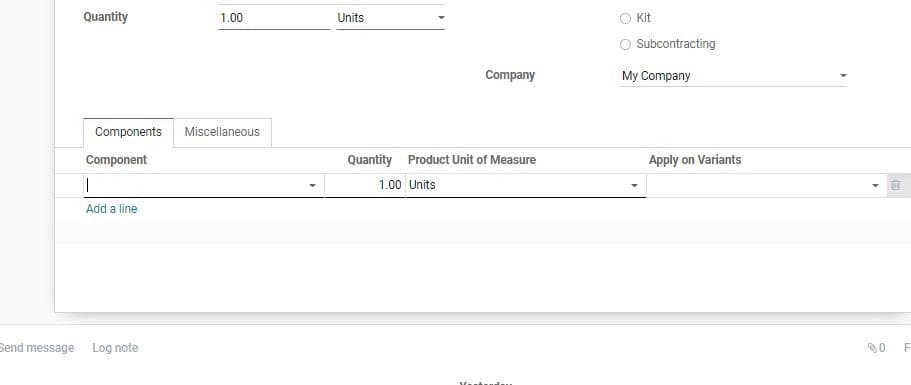

Below this you can find Add a line option. This field can be used to provide the

details of raw materials used for the production.

Component: The component used for the process

Quantity Product unit of measure: It indicates the unit of measure

of the product

Apply on Variants: Helps to generate common BOM for all variants

Note:- A BoM can be later Updated/Deleted from Manufacturing >

Products> Bill of Materials.

A user can use BoM for Product Variants. If the Bill of Material is for a single

variant, specify them in the Product Variant field. If the Bill of Material is for

multiple variants the user can specify the variant in the component line. A user

can add many variants for each component.

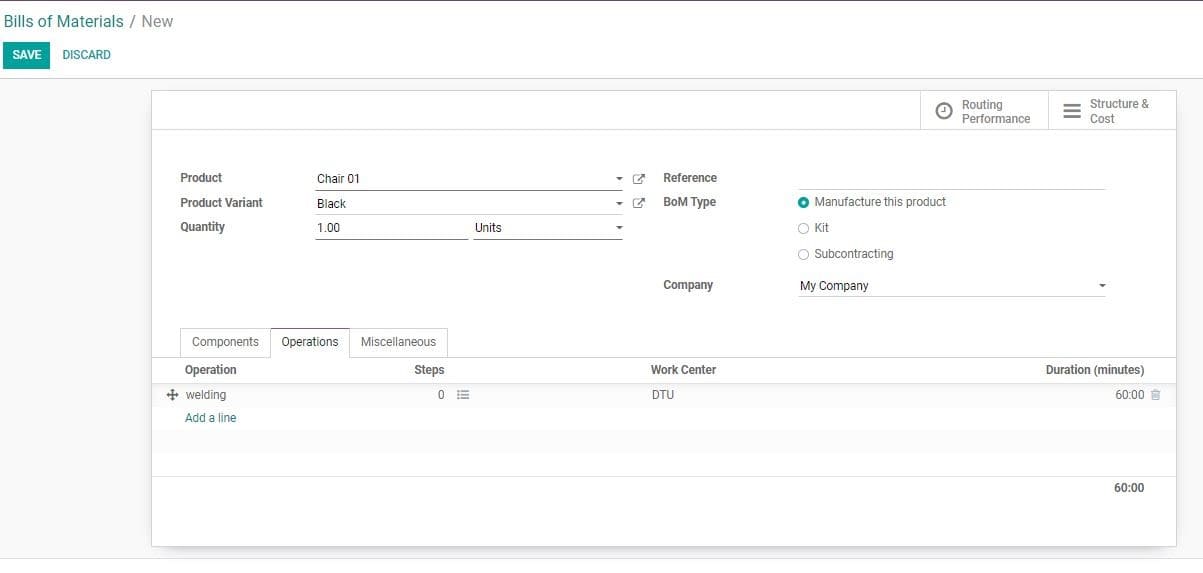

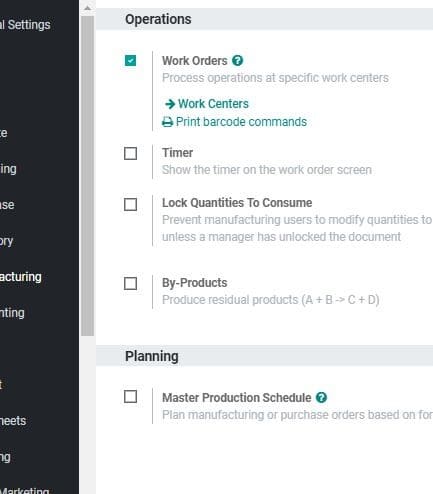

Operations

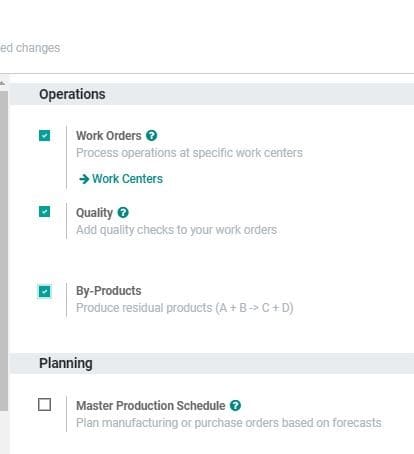

This tab allows the user to add routing. Initially Operations Tab may not be there

in BoM Create form. A user can operations the BoM in Odoo 14. To enable this, go

to Manufacturing > Configurations>Settings> Work Orders feature.

Note:- It should be noted that each BoM will have only single routing.

But each routing can be used several times to meet the requirements.

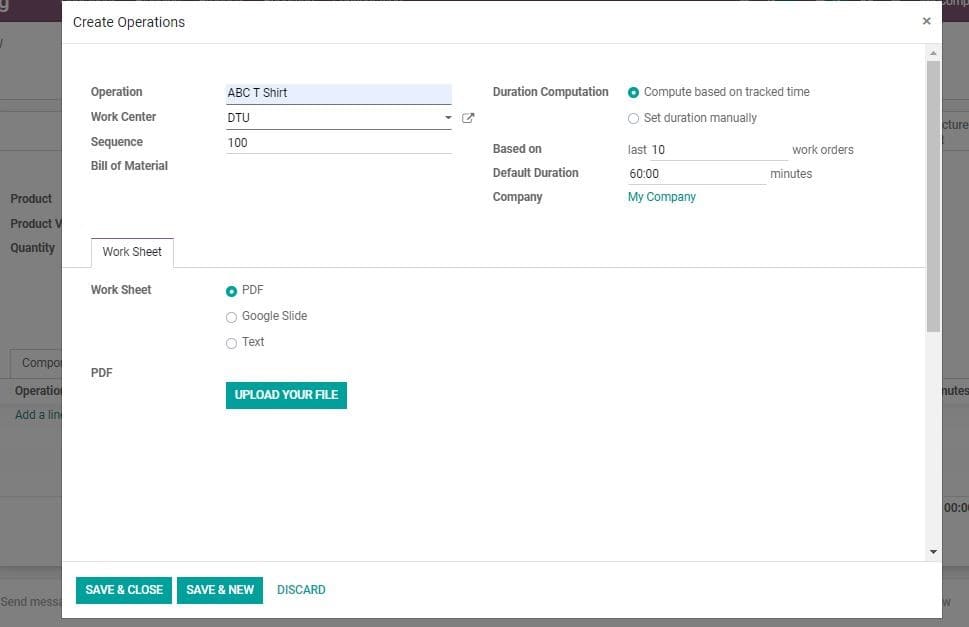

Create Operations

In Odoo 14, routing comes under Operations. A user can create routing by adding

a line to the operations. On clicking Add a Line a new window will be opened. This

window which gives you the Create Operations Form has many fields. Here you can

add the individual steps used in the manufacturing process.

Operation: The activity

Work Centre: The production centre where activities related to

manufacturing take place

Sequence: This defines the order in which the specified BoMs will

be included for production orders

Duration Computation: Calculation of the time required for the

process

It can be done in two ways

1. Compute duration based on tracked time

2. Set duration manually

A work sheet tab also is provided in the form. This enables you to decide up on

what type of work sheet has to be uploaded. It could be PDF, Google slide or Text.

The user can upload the file in the form.

After adding the routing, the user can save the operation window.

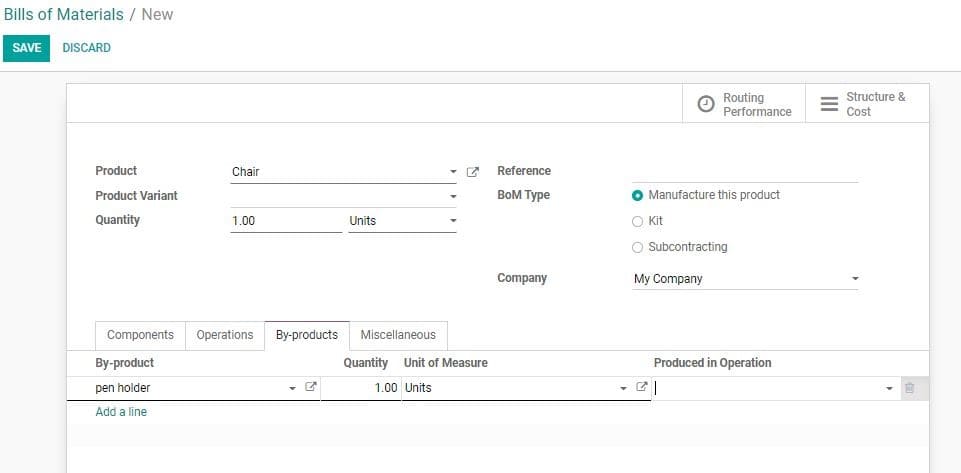

Adding by-products

In Odoo we can define a by-product as the product manufactured apart from the primary

product given in the Bill of Material.

A user can add by-products to a BoM, go to Manufacturing > Configurations>Settings>

Work Orders feature.

The user can enable the by-product feature by checking the box and saving the changes.

After activating the feature in the settings, you can add your By-Products to your

BoMs. One can add as many By-Products as they want. However, it should be registered

during which operation the by-product is produced.