Rules and Routes

The product movement of the Odoo platform is configured based on the routes of operations

which have been specified. The products are moved from its respective storage locations

or to it based on the orders applicable, these movements are set based on the route

of operation which is strictly followed and monitored in the Odoo platform.

The routes are defined based on the rule of product movement set. The product movement

based on the push and pull rules will determine the operation. The push and pull

rile are specified for each route and the locations of the product movements which

would certify for the efficient product removal and movement in the company inventory.

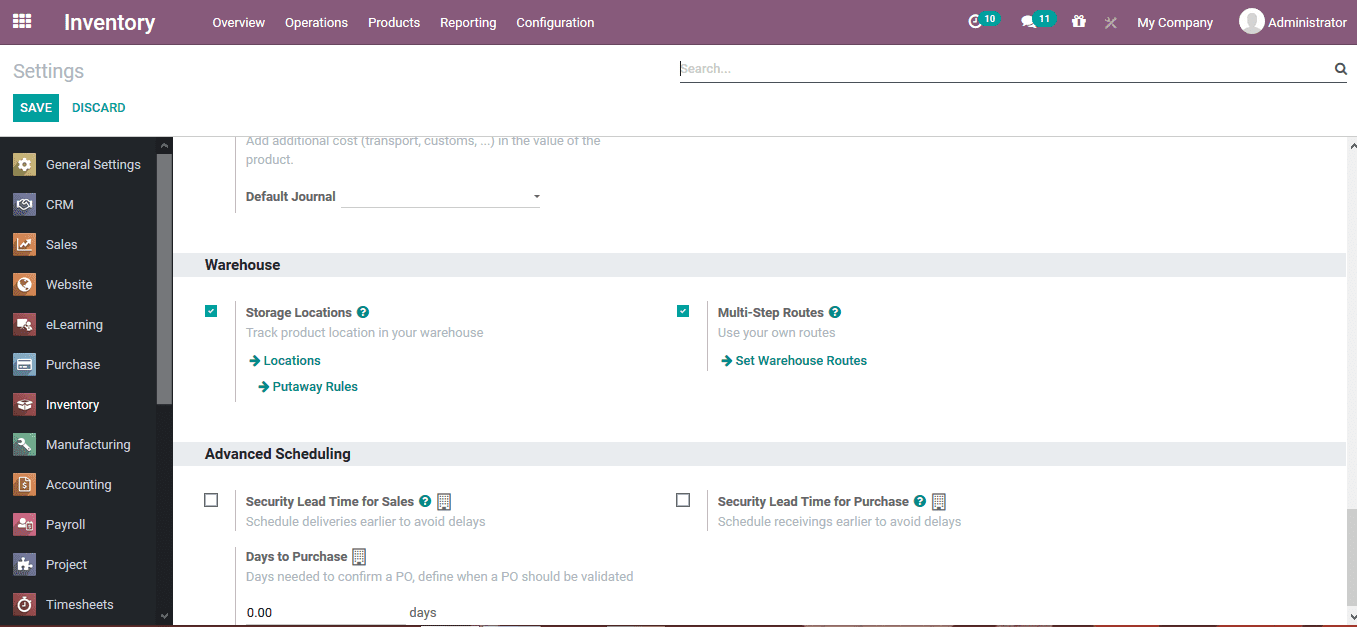

The routes in the Odoo platform can be configured after the multi-step routes operation

is being enabled in the settings menu of the inventory module.

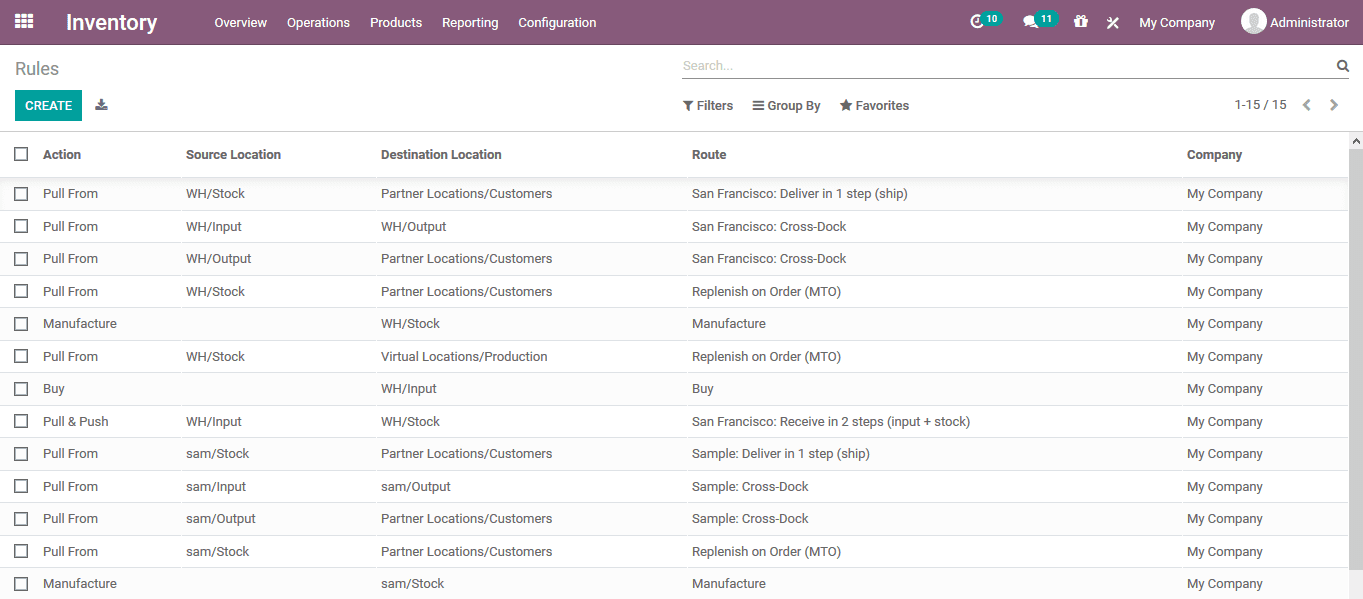

Rules

The rules can be defined in the rules menu which can be accessed from the configuration

tab of the inventory module. New rules can be created in the creation tab and the

existing ones can be edited by selecting the respective ones available.

In the creation window the user can provide the rule name, action, operation type,

source location, destination location, supply method, applicable route and the lead

times for the operation.

Routes

Routes of product movement are described in the product menu under the inventory

tab. The route of operations are described during the product creation or are edited

as per the operational terminologies of the company.

Below are the most commonly used routes of operation:

Drop-shipping: Deliver to customers straight from your vendor

Cross-Docking: Unload incoming material and directly transfer to

the customers without moving to the respective inventory locations

Pick - Pack - Ship: Deliver to customers in one step (delivery

order) or multiple steps: picking, packing, shipping.

Push & Pull Routes: Design your own product routes to automate

transfer orders between warehouses or locations.

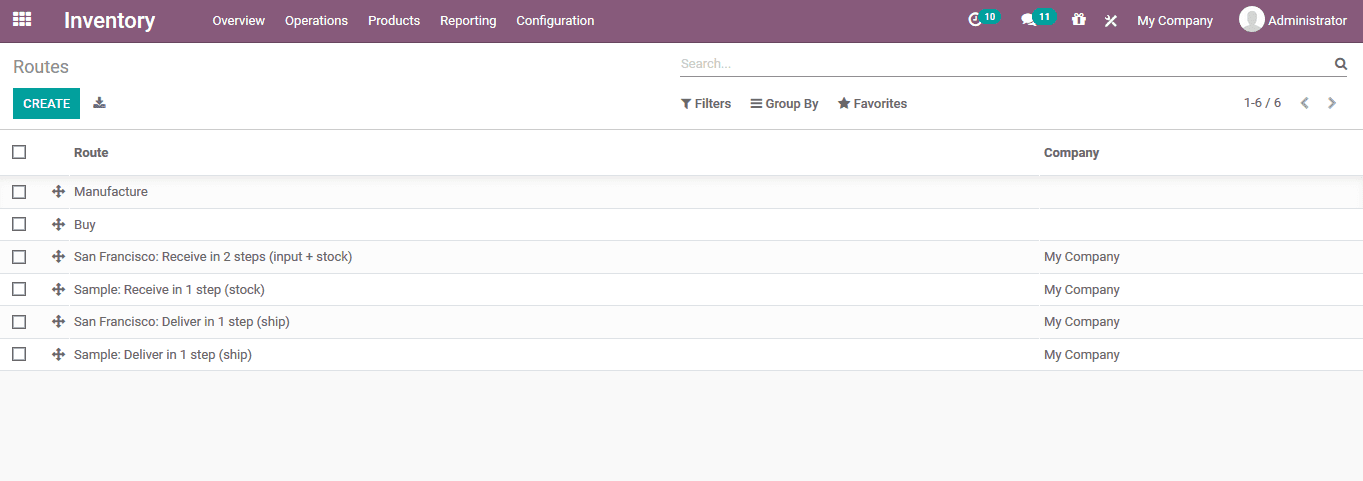

The Odoo product routes can be configured in the routes menu available in the configuration

tab of the inventory module. The existing routes and their operations can be modified

in the menu as well as new routes of operation could be created in the creation

tab available.

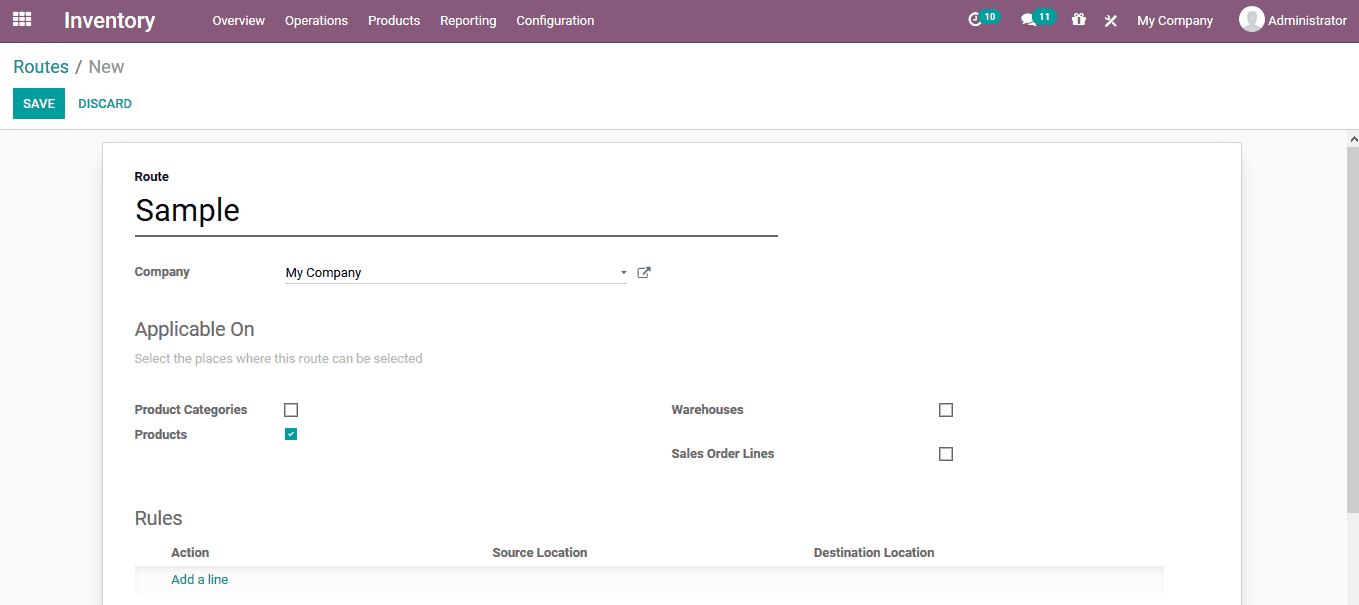

In the creation tab the user can assign a new route name and company if operating

with multiple companies. The rout applicability can be assigned to the products,

product categories, warehouses and sales order lines. The rules of product movement

can be assigned in the rules menu available by selecting to add a line option available.

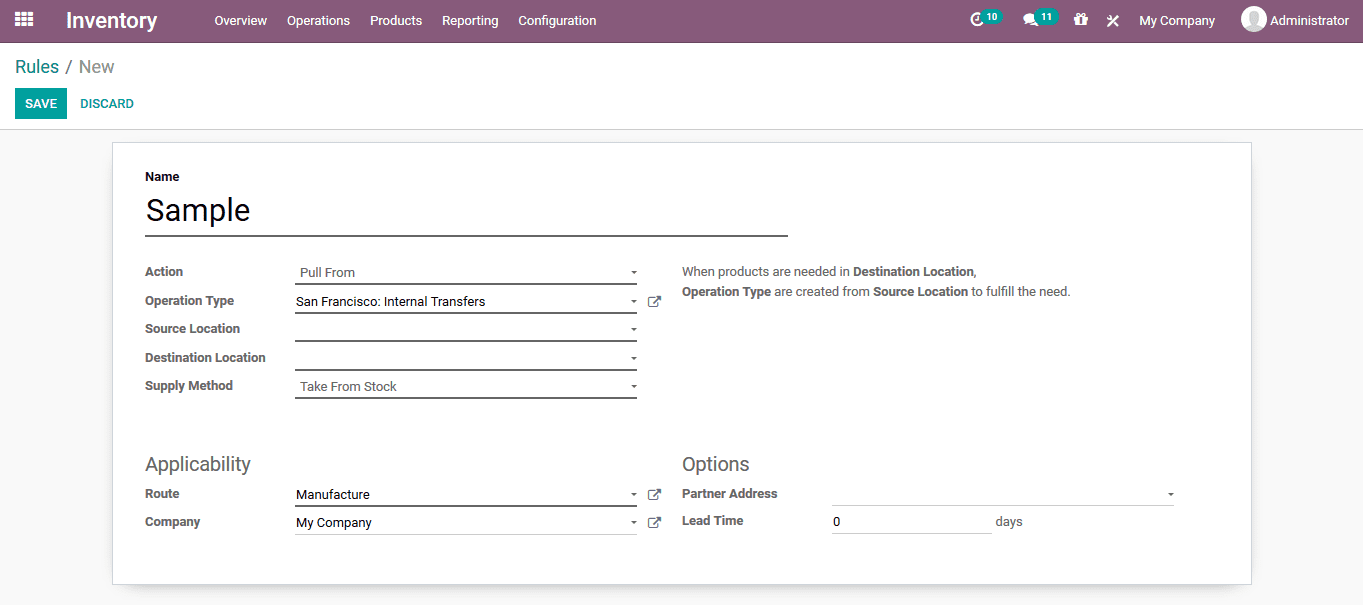

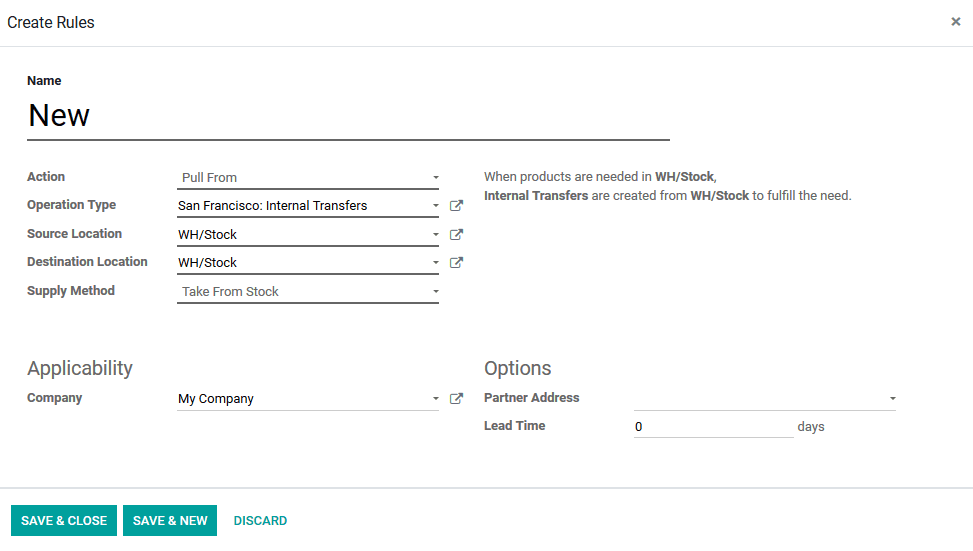

On selecting to add rules to the respective route operation the User is depicted

with a pop up window as shown below. The user should provide the rule name, allocate

action type, operational type, source location, destination location and the supply

method.

The user can assign more than one rule to the route and it can be done in the same

manner by selecting the add a line option available and defining the rule.

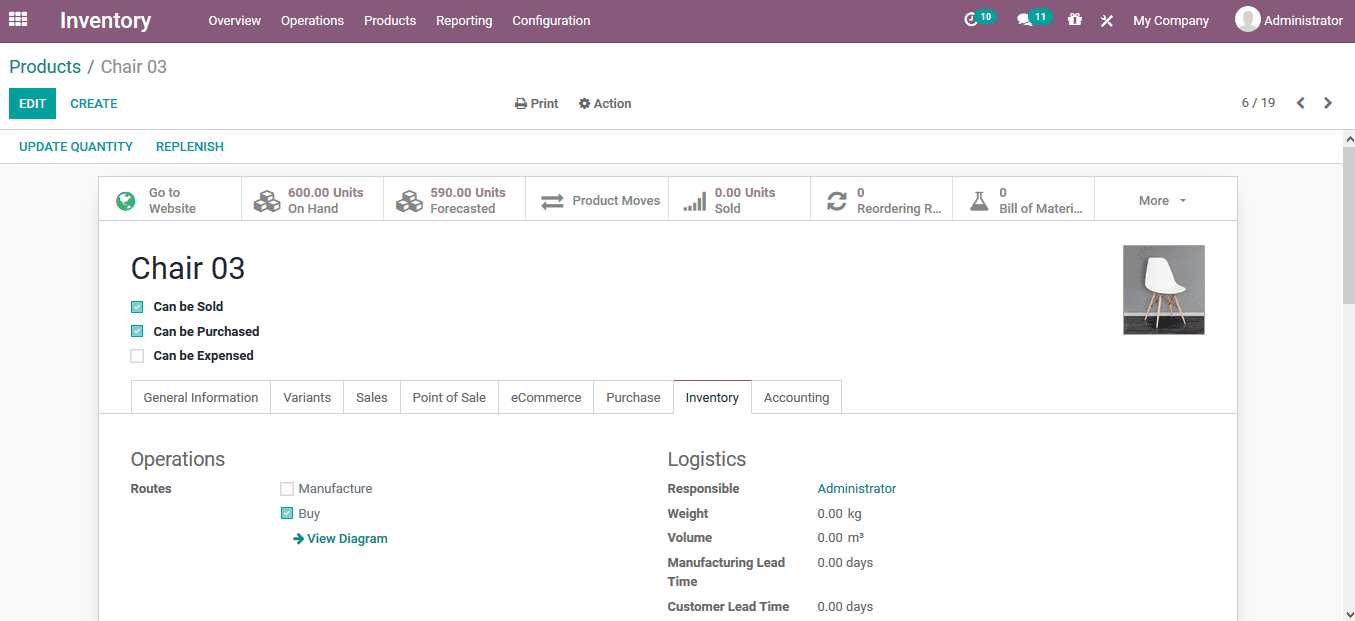

The routes of a product operation can be viewed under the respective product description

in the inventory menu of the product window. The routes of operation can be chosen

from the respective one available based on the warehouse settings configured.

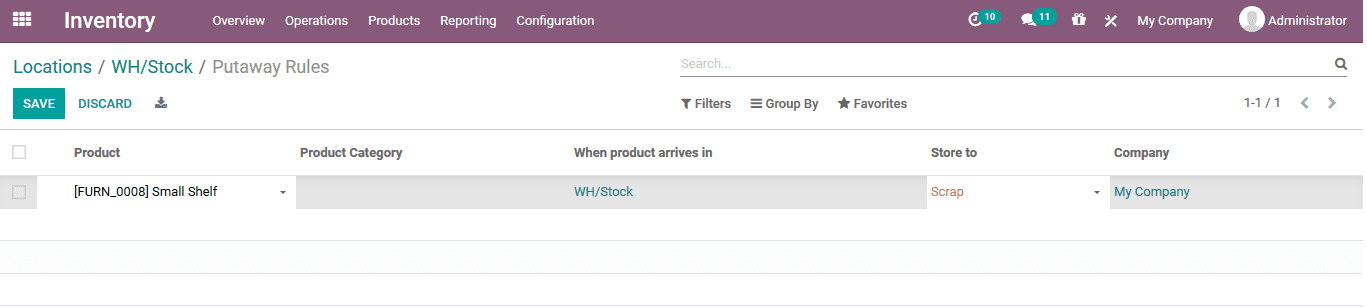

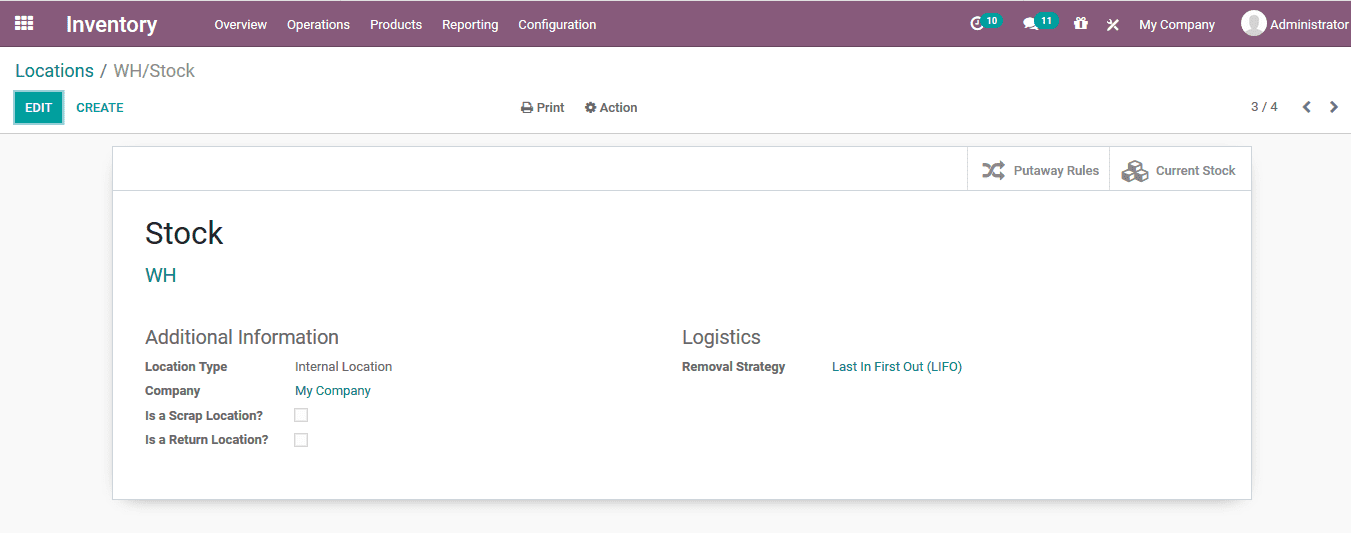

Put away rules

At certain instances of company inventory operation the product cannot be stored

together but they should be put in different aspects of inventory. Certain chemicals

and precision components should be stored in containers which will provide artificial

environment situations for the product to e remain fresh and not corroded.

The put away rule can be configured in the storage locations available and can be

described in the put away rule menu available with respect to each warehouse location.

The put away rule can be seen in the menu and new ones can be created by accessing

the creation menu. In the creation menu the user can assign the product and the

storage location, the source location, product category and the company of operation

are auto allocated.