All sectors depend on manufacturing, so effective administration of operations is important. The capabilities provided by enterprise resource planning solutions may be used to manage industrial processes and grow enterprises. A specific module for managing manufacturing activities and guaranteeing thorough product production management, Odoo's manufacturing module and its sub-modules. Operations are more efficient and effective by integration of these modules with the production module.

The effective Odoo Manufacturing Order Management system creates manufacturing orders and enables users to personalize processes and establish work centers. Additionally, it encourages the development of Bills of Materials (BoM) and contracts out production work to outside parties. Businesses can manage operations, automate preventative and corrective maintenance, and arrange maintenance requests thanks to the integration of maintenance, PLM(Product Lifecycle Management), and quality modules in Odoo 16 Manufacturing ERP. Maintenance support includes quick request tracking, quality warnings, and manufacturing component approval procedures. It is essential for manufacturing businesses to manage engineering changes and keep a social network active. Manufacturing and Odoo PLM interact, ensuring ongoing contact and the growth of a social network. Continual communication and the growth of a social network are ensured by the integration of manufacturing and Odoo PLM. Overall, Manufacturing ERP in Odoo 16 is a very useful tool that aids companies in managing, planning, and controlling operations, producing reports that contribute to the overall success of a business.

Odoo Manufacturing is a software program that significantly aids manufacturers in;

* Real-time manufacturing planning.

* Editing previous Manufacturing Orders.

* Repairing the Order Creation.

* Handling of unpaid orders.

* Assistance for barcode.

* Order Generation.

* Work center capacity management in manufacturing.

With the help of the ERP platform, users can establish production orders for a range of items and tailor the procedure to fit their business needs. Along with customizing work orders, they may make orders utilizing Routing and the work center. Odoo Manufacturing is a useful tool for creating unbuilt and scrap orders. It enables users to discard broken or partially damaged items, disassemble produced goods, and return them to the raw material category.

Unbuilding Manufactured Products

A product can be disassembled by removing its parts. In rare circumstances, a manufacturing business may need to unbuild a product. Purchasing things might also result in it happening. Keeping track of such unbuilt orders is crucial in these circumstances. As we just covered, an unbuilt order for a previously created product may be created using the Odoo 16 Manufacturing platform.

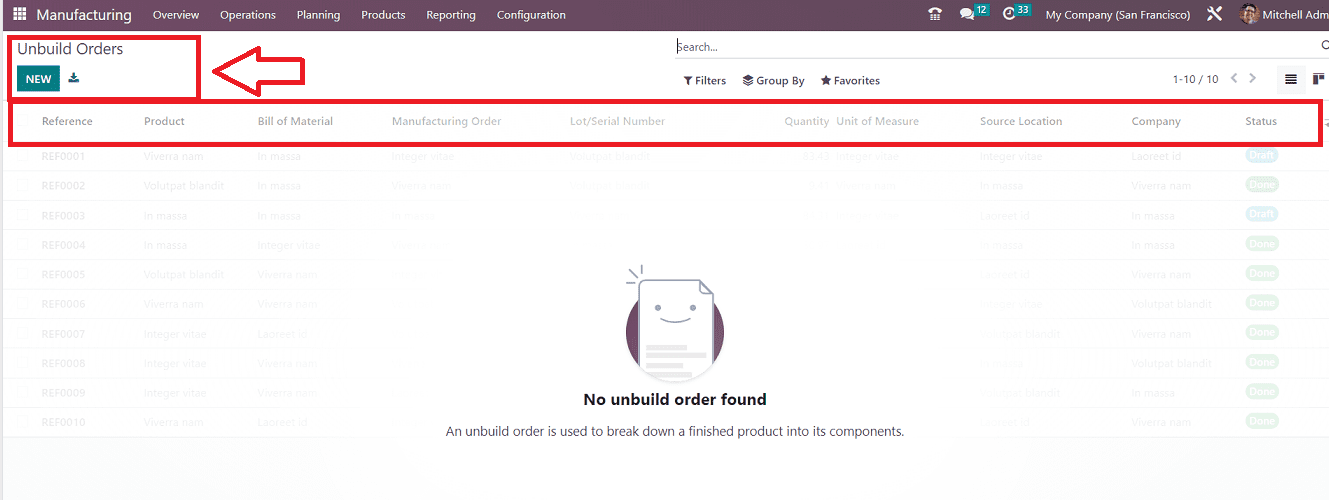

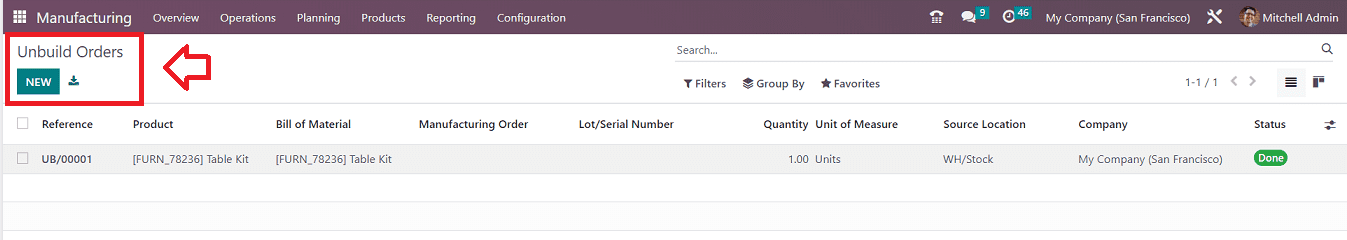

Go to the “Unbuild Orders” option from the “Operations” menu to do this. You will receive a distinct platform to handle Unbuild Orders independently and create Unbuild Orders for acquired goods.

In the “Unbilled Orders” window, you can see the dashboard of all the order References, Products, Bills of Material, Manufacturing Order, Lot/Serial Number, Quantity, Unit of Measure, etc., as shown in the above screenshot. You can open the new configuration form by clicking on the “NEW” button.

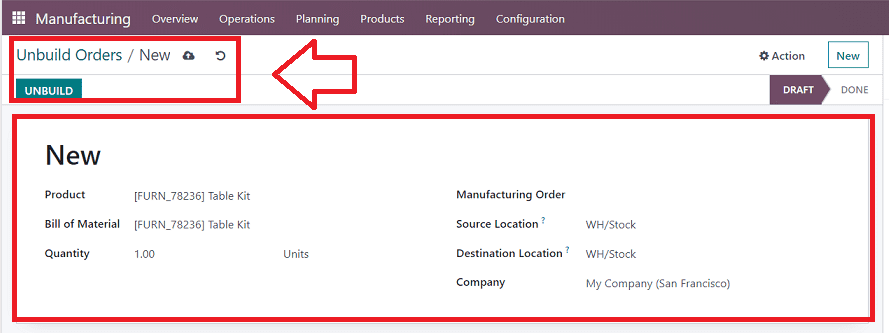

The newly opened Configuration form window can be used to configure new Unbilled Orders. You can enter the Unbilled Order Name in the blank field inside the form. Then, provide the name of the “Product,” “Bill of Materials,” and “Quantity,” as seen in the above image. If the product is made in your business, you can include the “Manufacturing Order” in the relevant field. The “Source Location” field allows you to specify where the product is at the moment. You may provide the destination location in the “Destination Location” field for where you wish to keep the product's parts after the Unbuilding process is finished. You can fill in the appropriate boxes with the Lot/Serial Number and the Company. When you are done with the unbuild process, click the “UNBUILD” button.

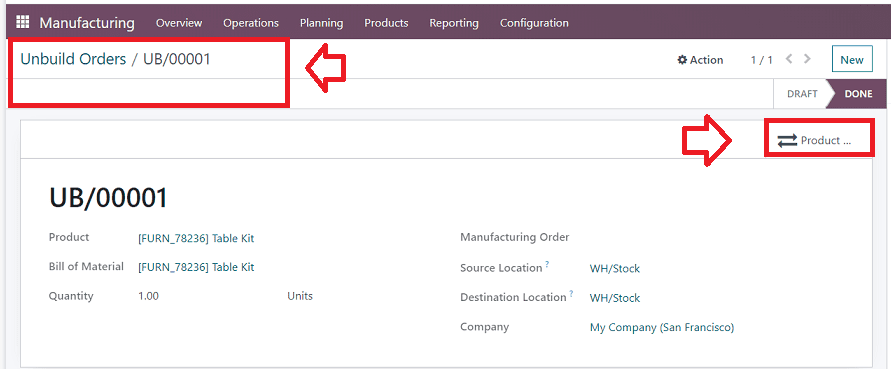

Your unbuilt order will be stored in the Odoo database, and a "Products" smart button will appear in the configuration form so you can access the details of every component used in the unbuilt product as a dashboard, as shown below.

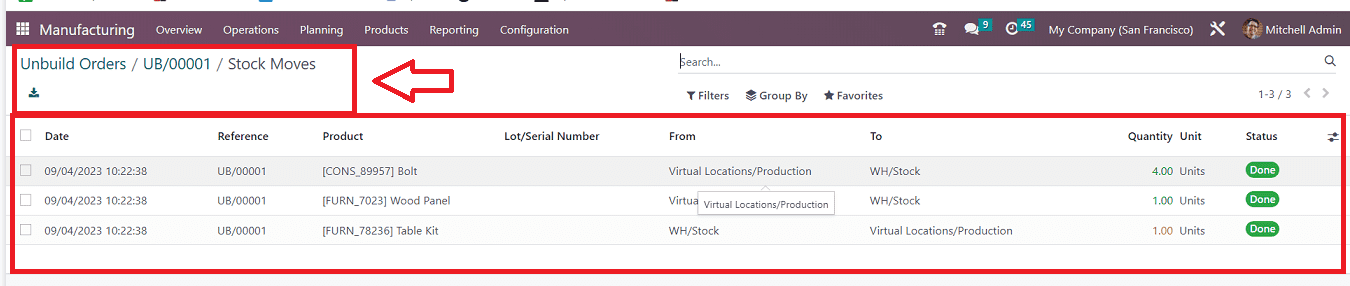

This “Stock Moves'' dashboard will provide the details of the component’s unbuilding date, Reference, Product, Lot/ Serial Number, Quantity, Unit, etc. The newly created Unbuild Order can also be managed from the “Unbuil Orders” dashboard.

These are the features available in the Odoo 16 Manufacturing Module to manage Unbuilt orders and scrap orders. Large manufacturing businesses can quickly deconstruct their defective goods, organize them out, and then place them back in the raw material categories with every record.

To read more about the new features in Odoo 16 manufacturing, refer to our blog What Are The New Features in Odoo 16 Manufacturing