For the production process, a manufacturing process needs more than one component and more than one quantity. These items are included in the bill of materials along with their quantities. Because production sometimes needs more components than what is specified in the BOM, components are items that occasionally run the risk of being damaged. In such circumstances, the operator wants to increase the quantity or number of components after the production process has begun. In certain cases, the user must stop this extra addition of components, or sometimes the user must alert the operator to this extra consumption. This capability is offered by Odoo to lessen component waste and improve effective inventory management.

Odoo's flexible consumption function is a cutting-edge tool that enables users to dynamically allocate raw materials based on their actual production needs. It permits the effective use of raw materials and minimizes production waste.

The finalized order will instantly be Locked by Odoo to prevent further changes. Another technique that aids in streamlining the production process is this one. It is also possible for the user to stop this lockout if necessary.

In this article, let's look at each of them independently.

Flexible Consumption

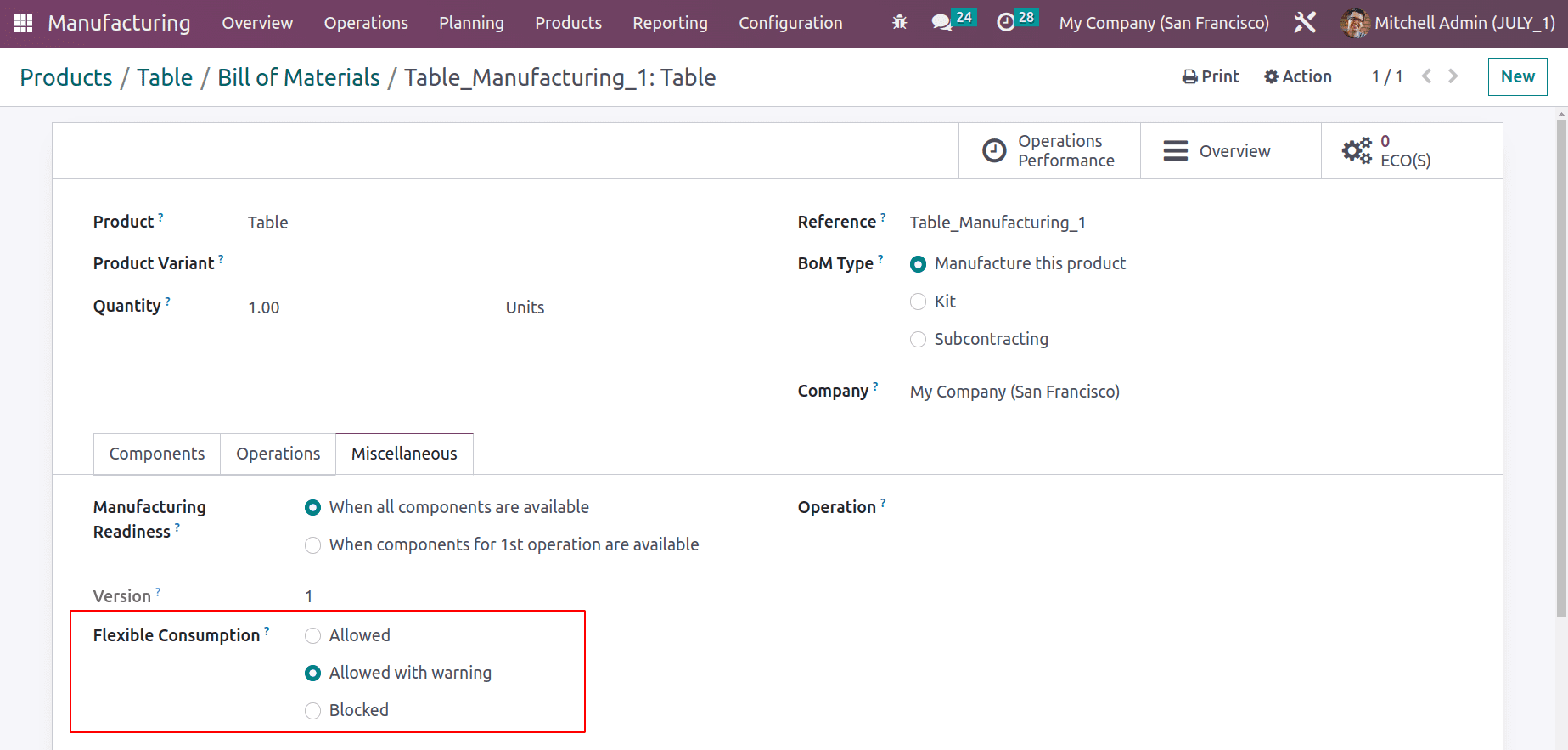

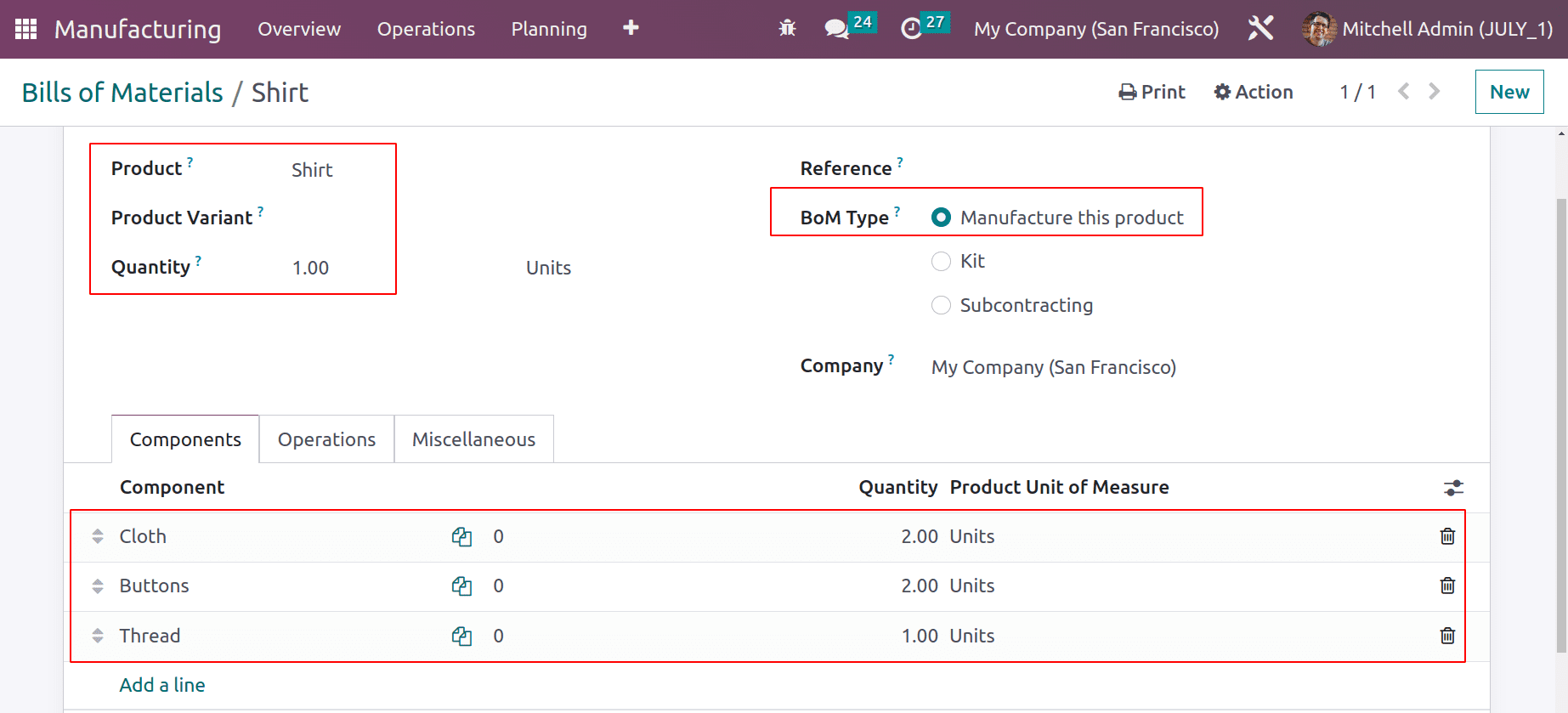

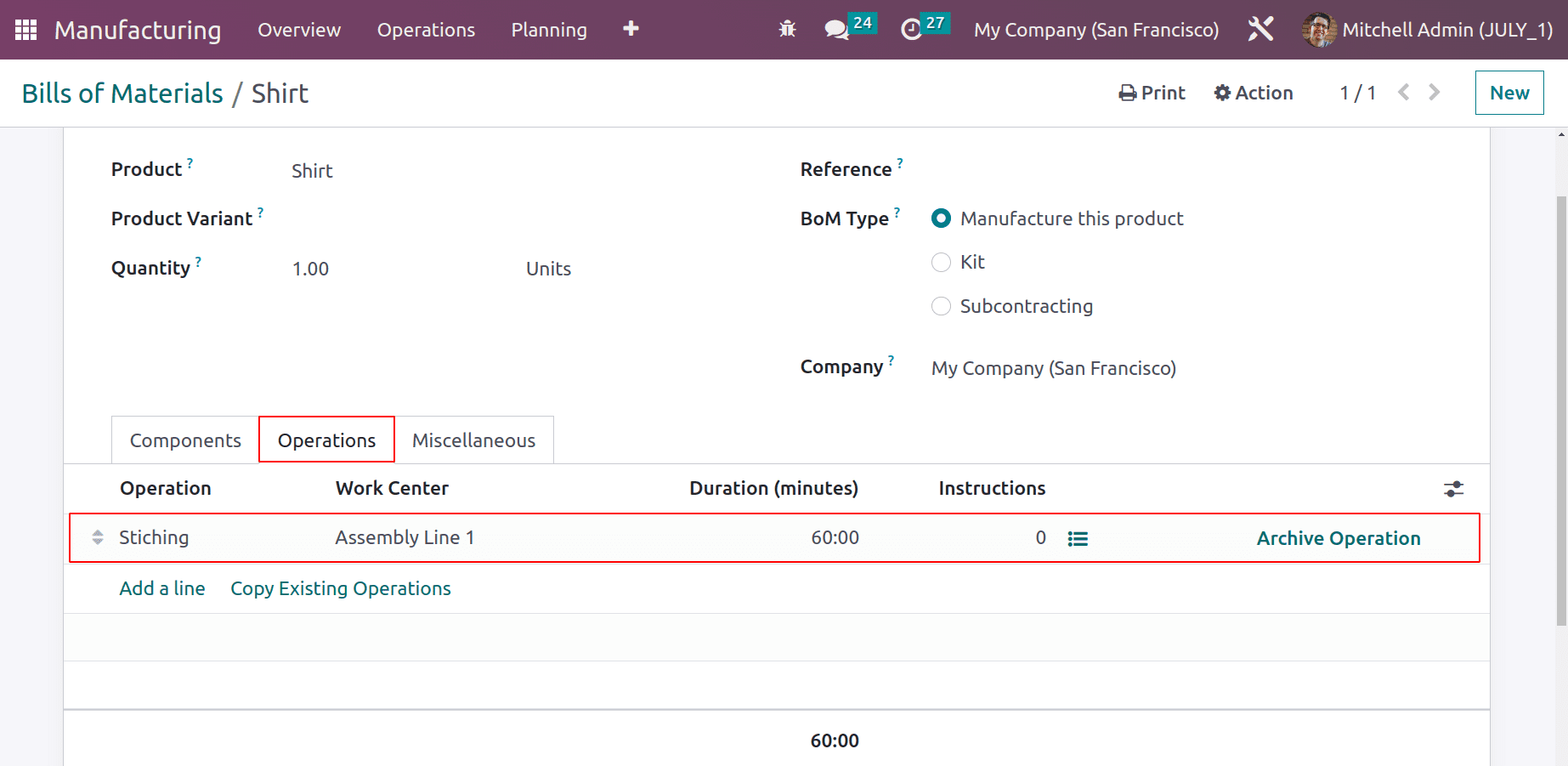

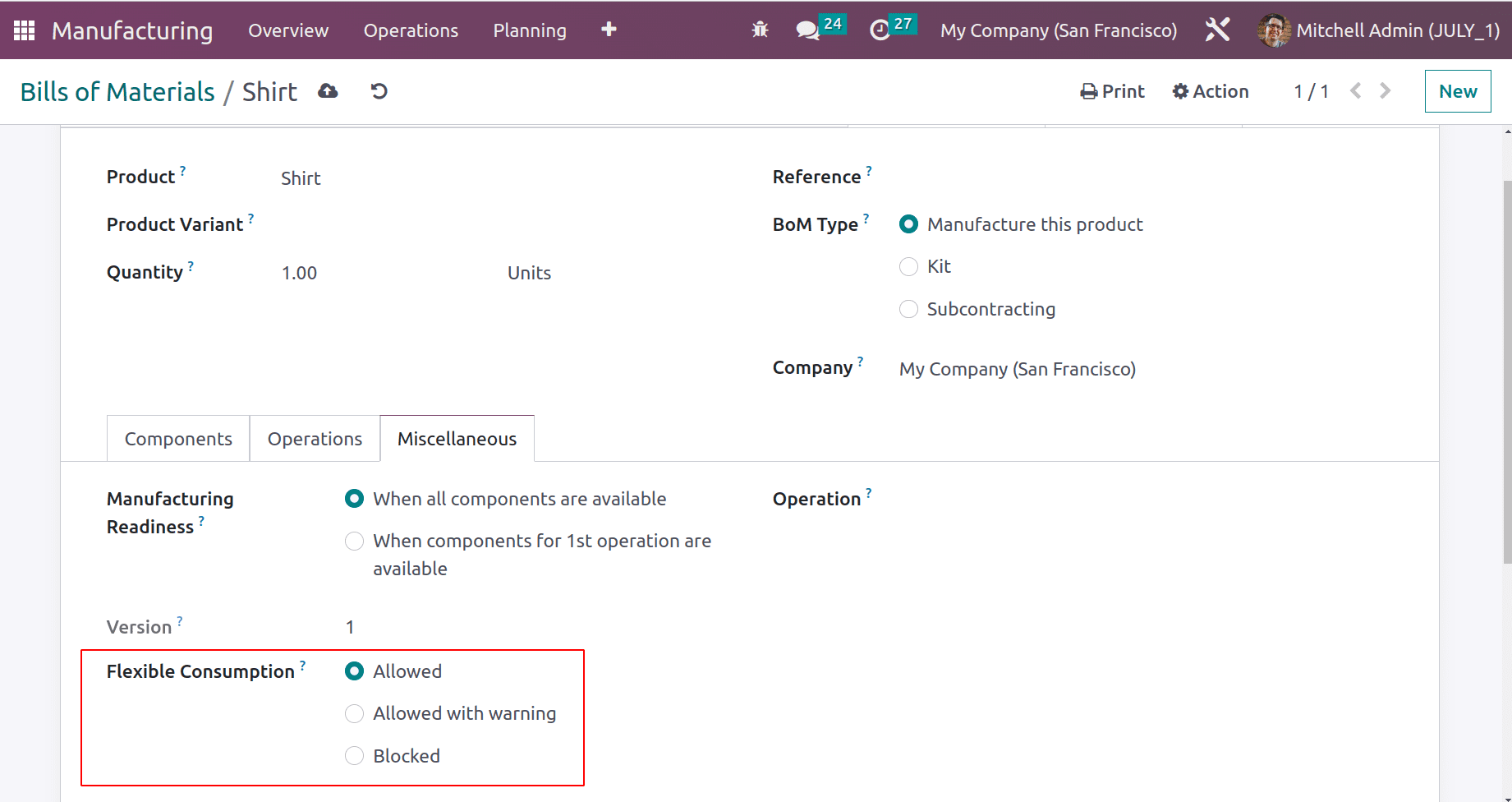

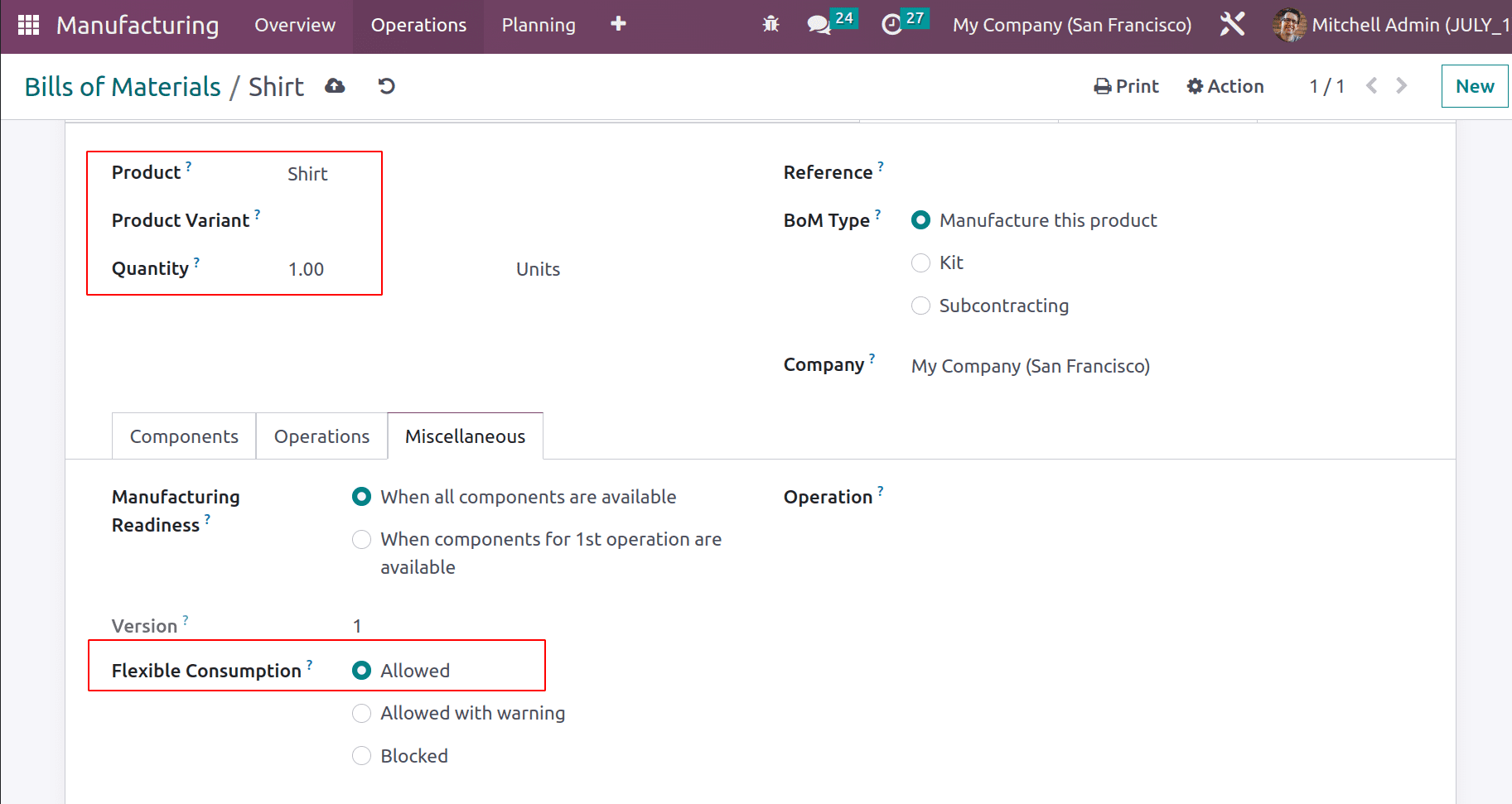

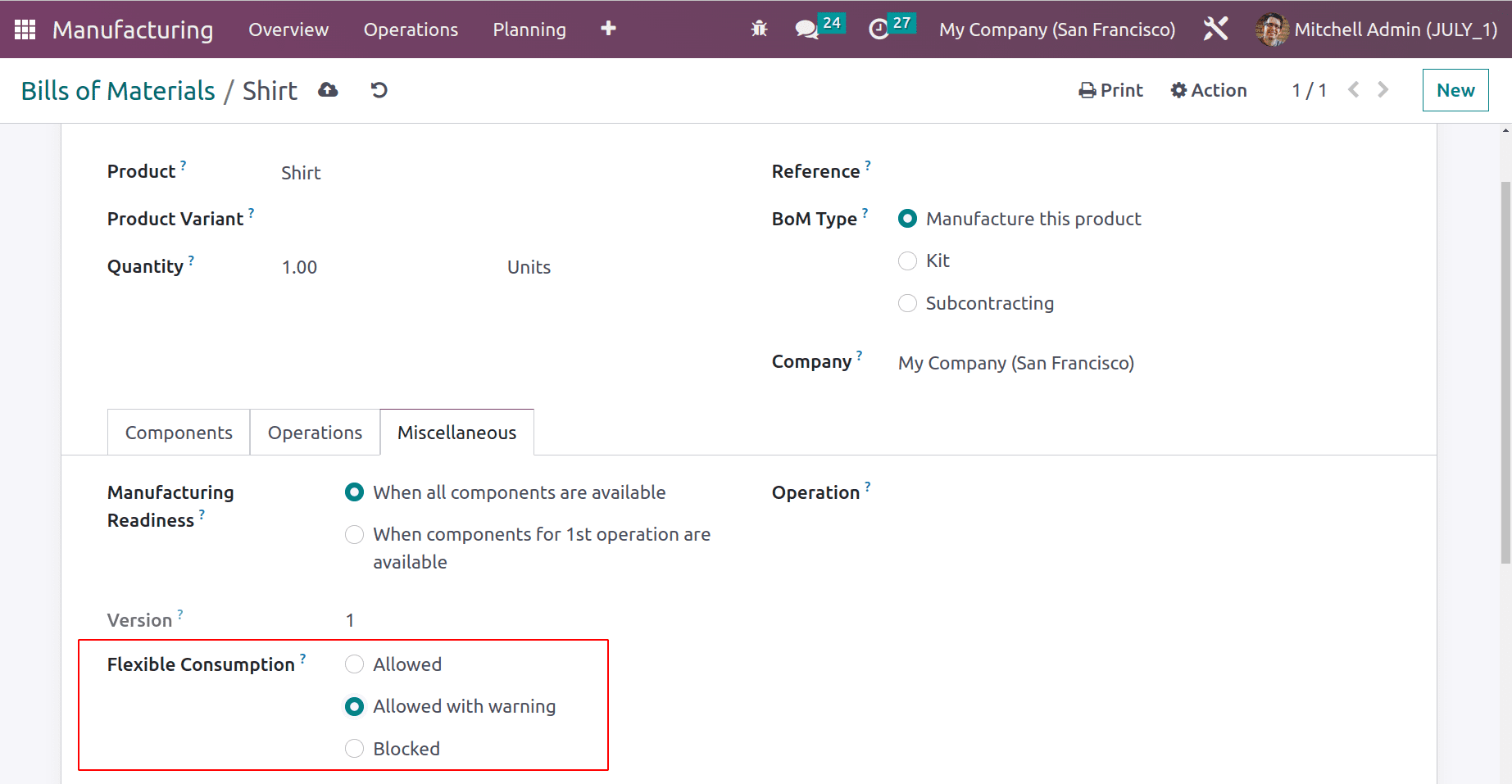

The Bill of Material contains a display of the Flexible Consumption function. Thus make a new Bill of Material for manufacturing using the Bill of Material from the product tab.

The Bom was developed for only one quantity of Shirt. One unit of cloth, two units of buttons, and one unit of thread make up the item.

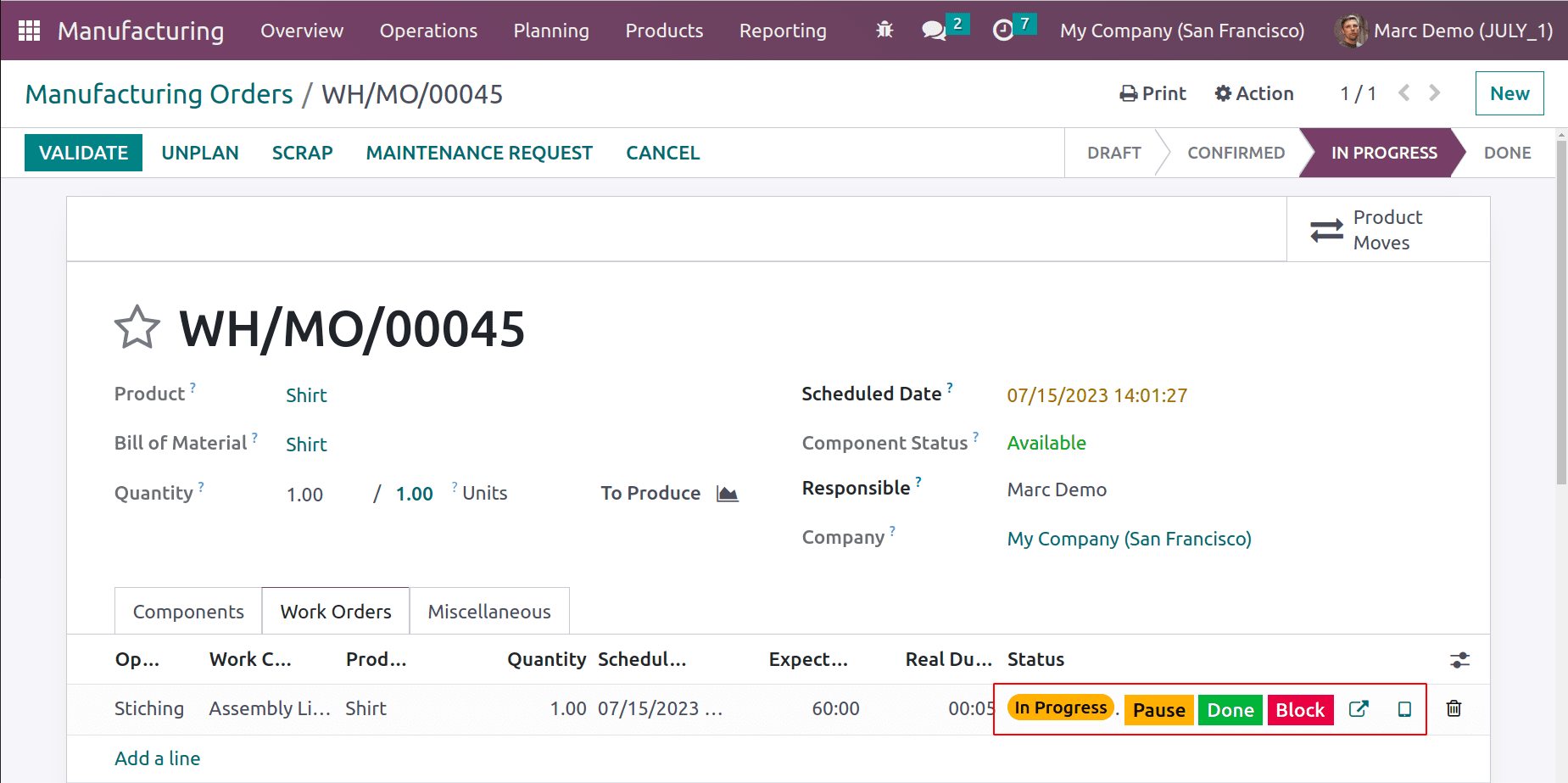

An operation named Stitching will perform the production of shirts from the workcenter Assembly Line 1.

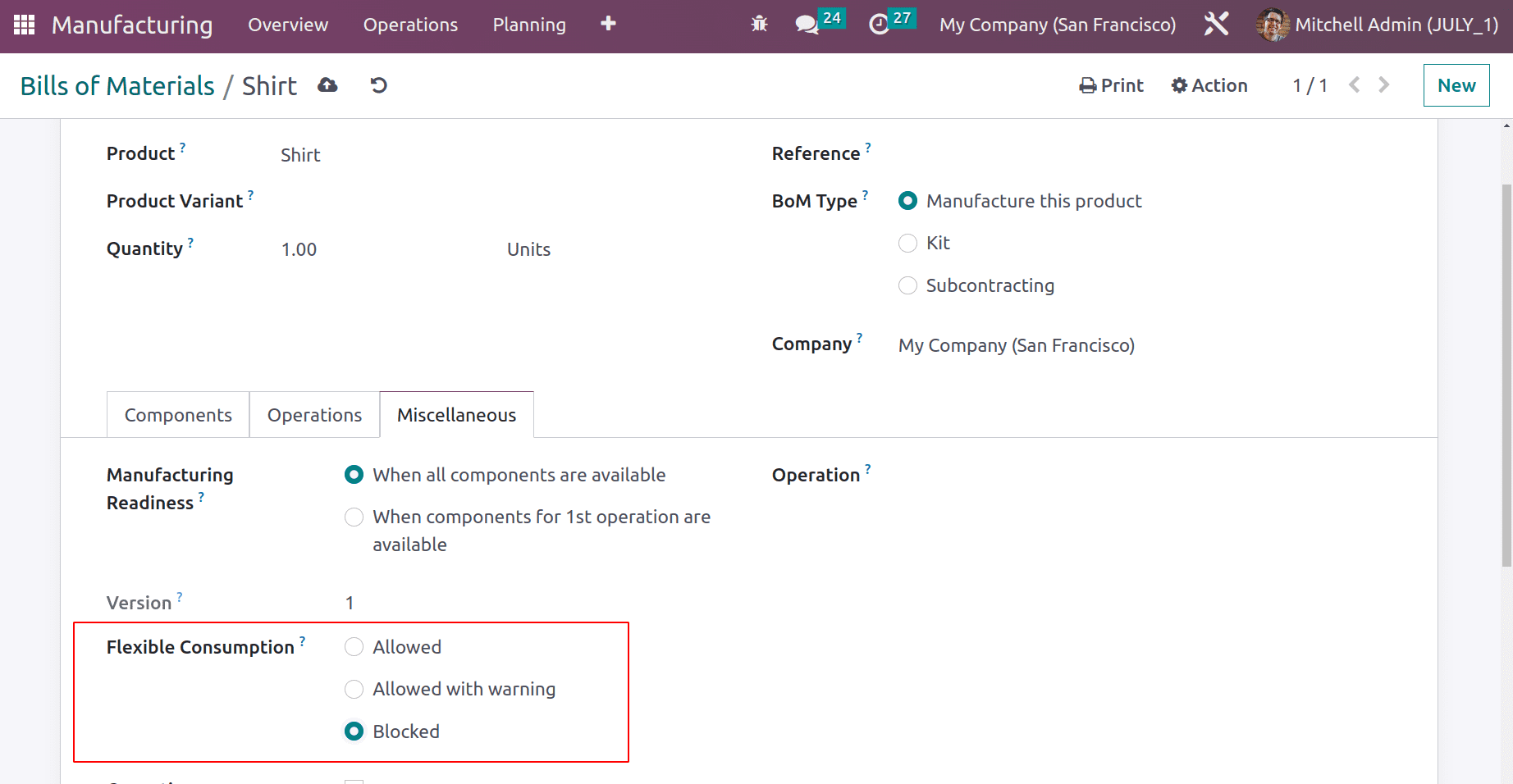

In the Miscellaneous tab, flexible consumption options are displayed. This states that the operator may consume a different quantity of components than what is specified on the BoM. There are three possibilities.

Allowed: Consumption of additional or fewer components is permitted for all users.

Allowed with Warning: All manufacturing users may consume more or fewer components as long as they provide a summary of the difference in consumption when closing the manufacturing order.

Blocked: When the Bom consumption is not followed, the manager can only close the manufacturing order only after confirming with a piece of warning information.

Let's check each one separately by using the same Bill of materials.

Flexible Consumption Allowed

Set the Flexible consumption as Allowed and save the Bill of materials. Log in to Odoo as a manufacturing User.

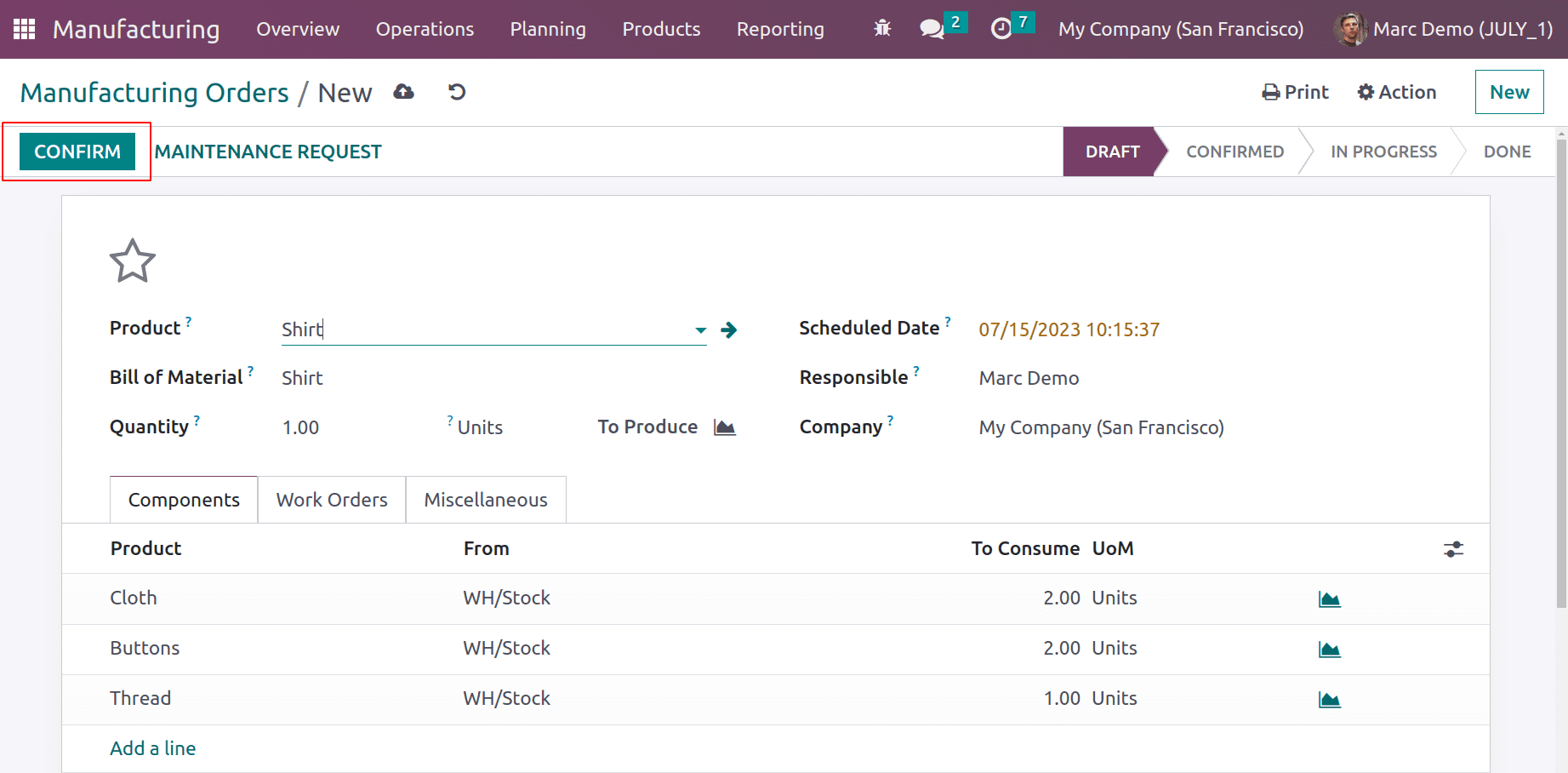

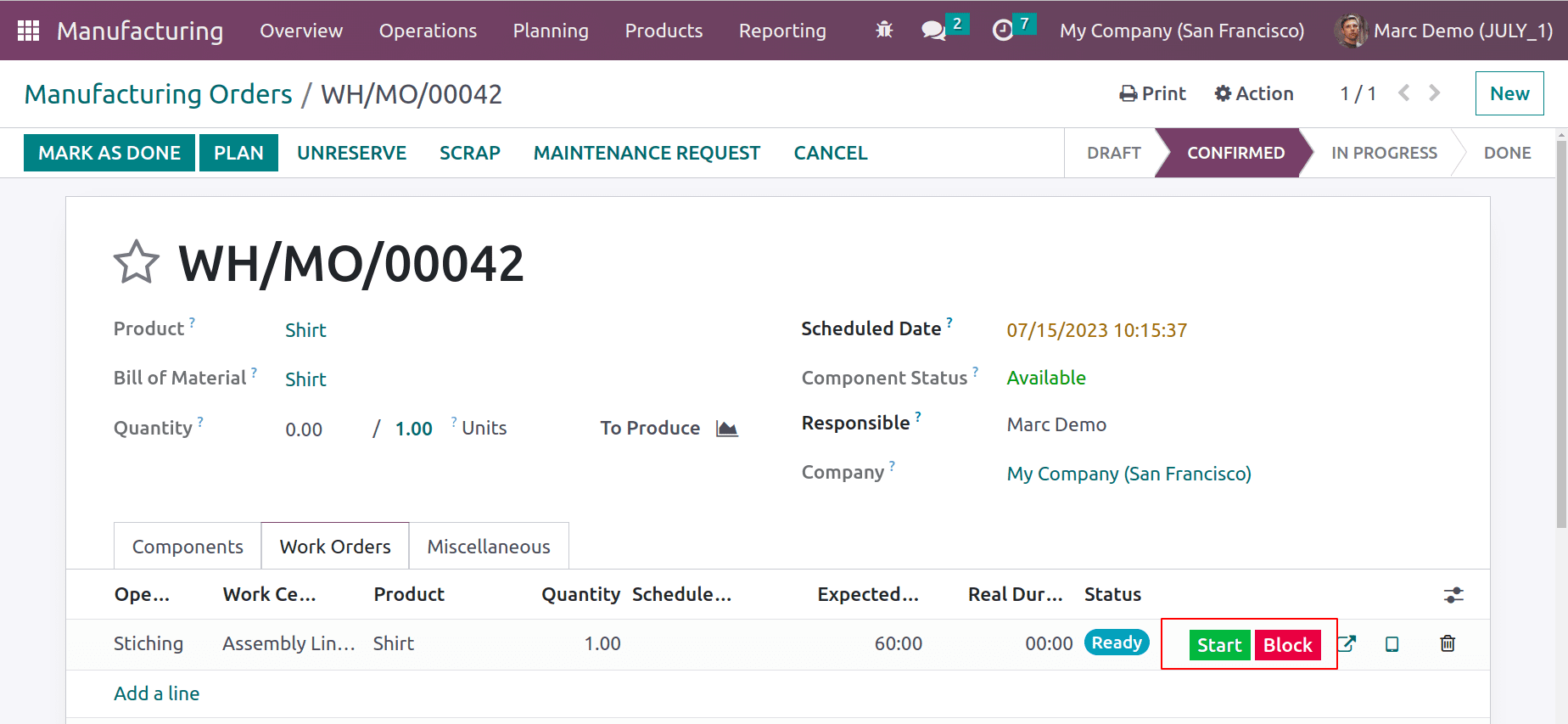

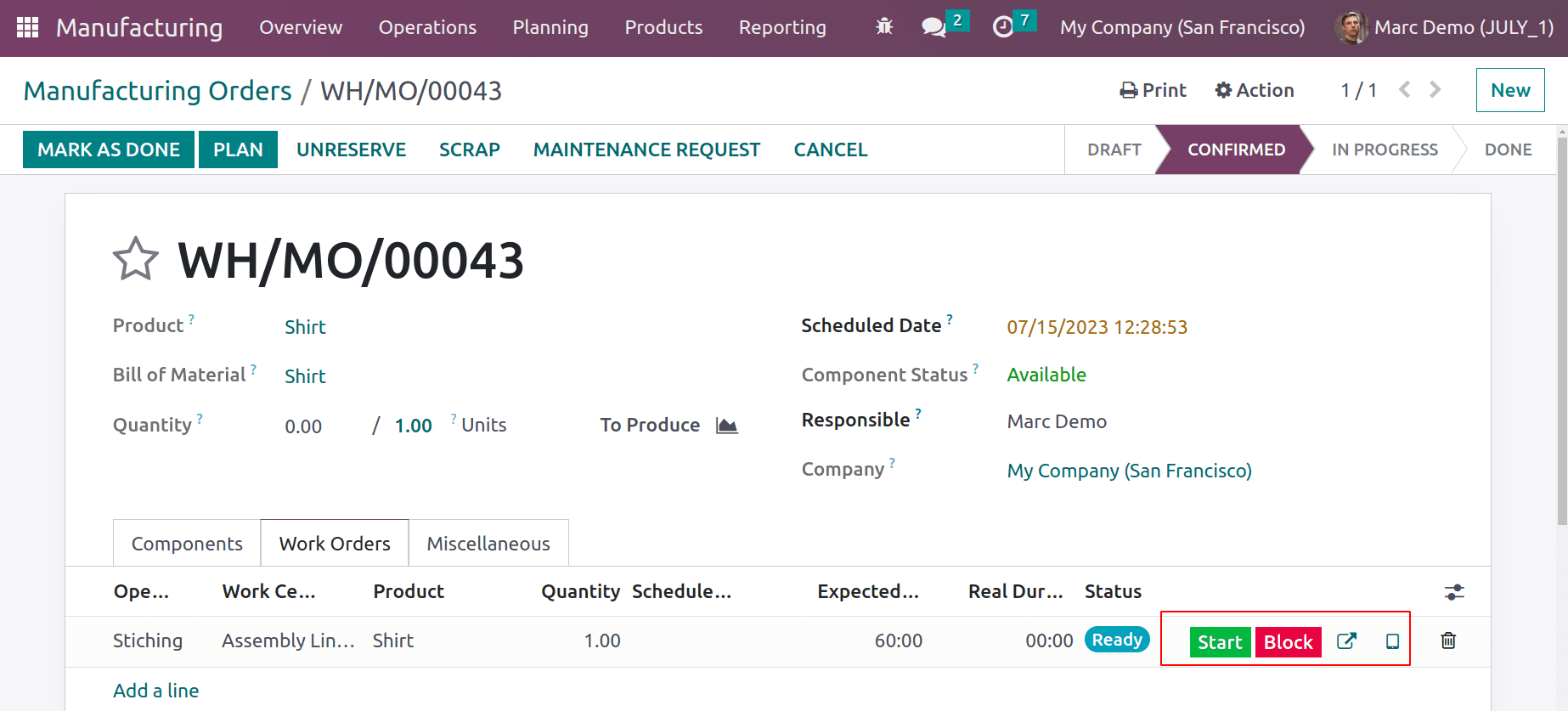

Here the Odoo Manufacturing user Marc Demo created a new manufacturing order for the product Shirt. Confirm the order and start the operation from the Operations tab.

Users can start the operation by clicking the Start button. for stitching a shirt.

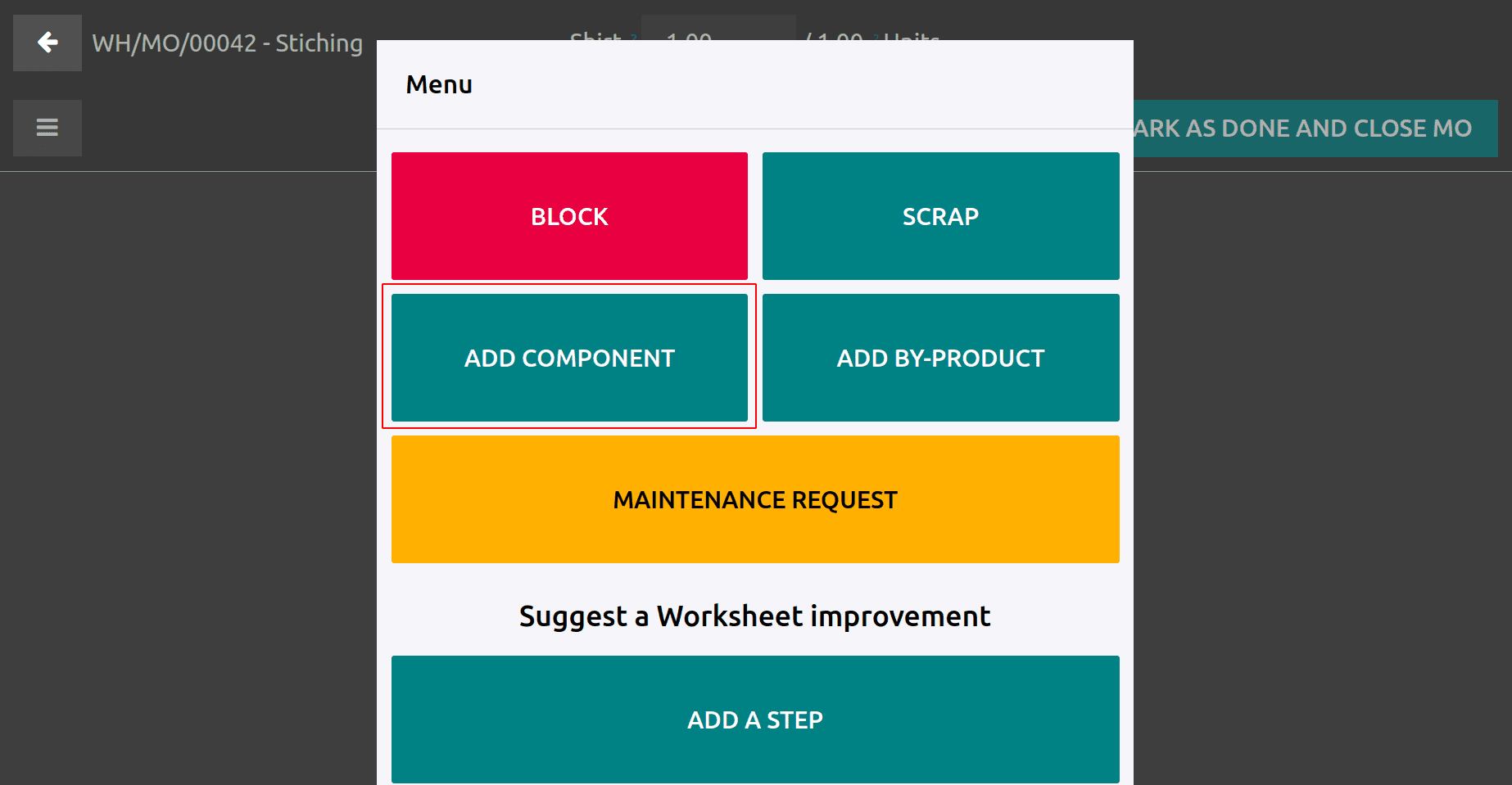

After starting the operation here the component Button is added to only 2 quantities in the BiIll of material, but the user needs 5 quantities. In such cases, the user can add more quantity. So from the tablet view of operation choose the Add component button.

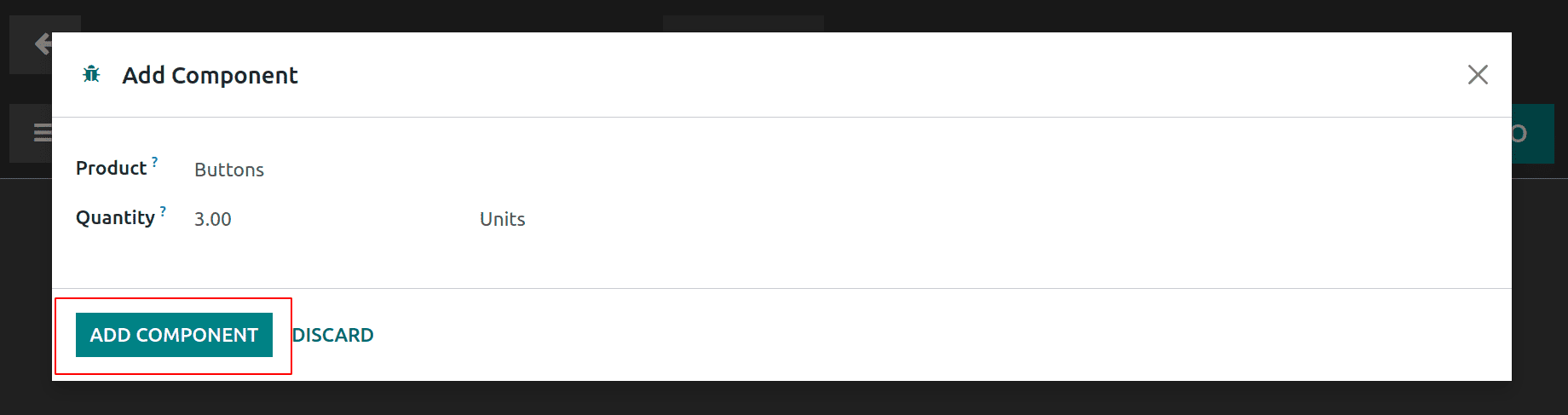

Add 3 quantities of Button and click on ADD COMPONENT button to add an extra quantity

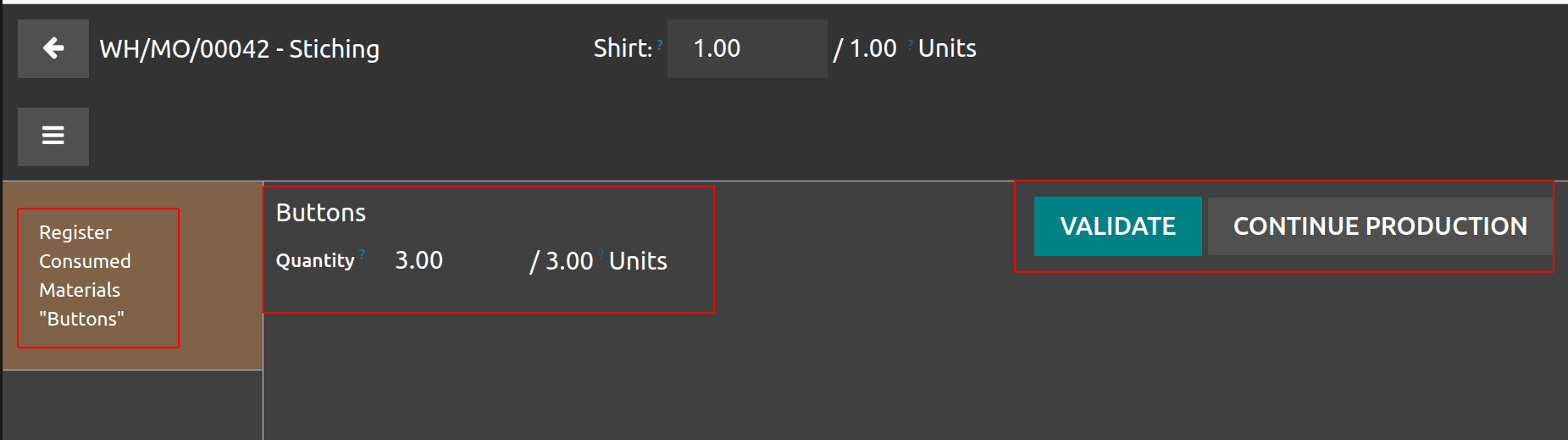

Then the added additional 3 quantities will register. The user can either continue the production or Validate the order.

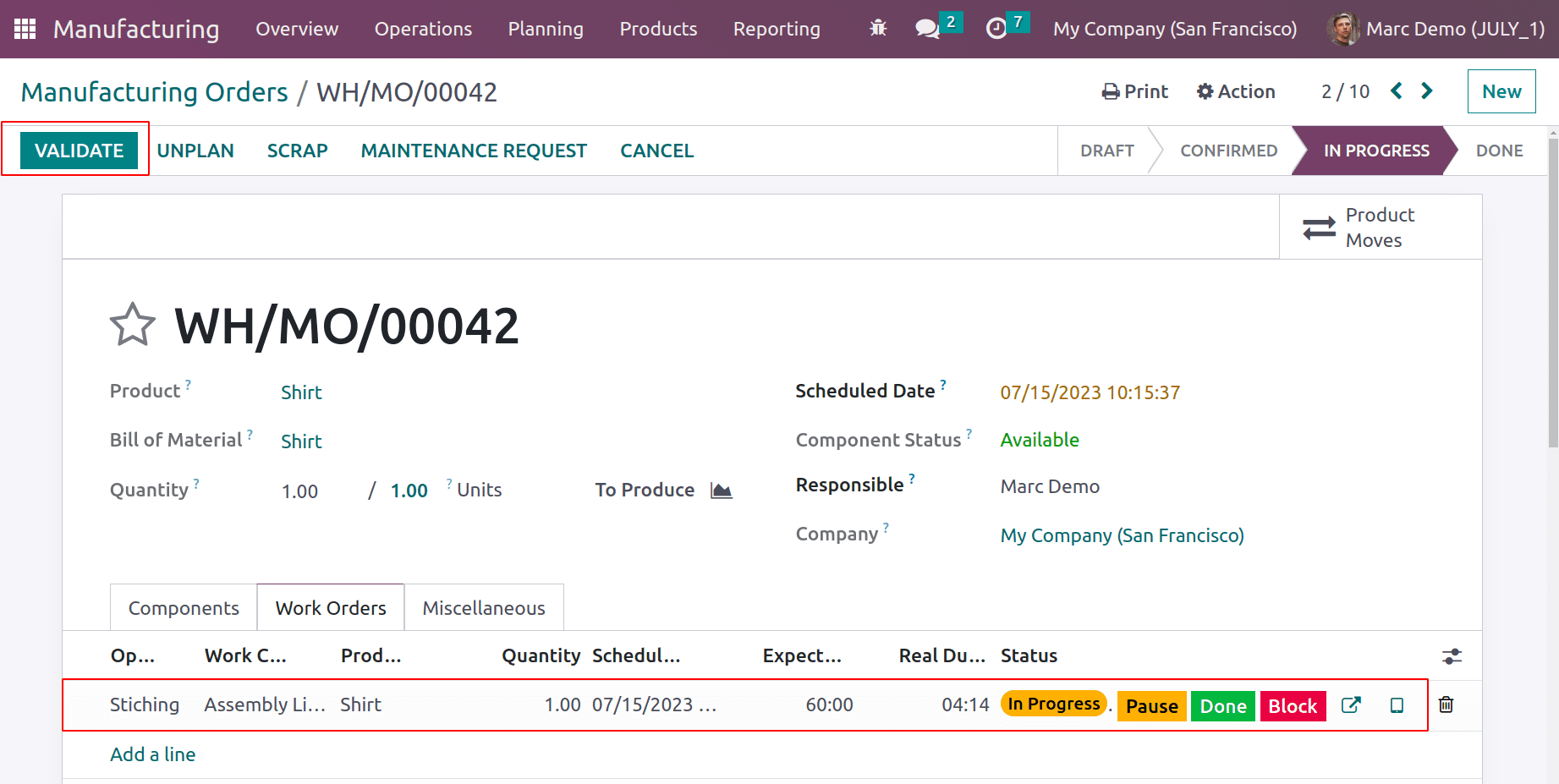

After completion of the work order processing and Validate the production.

Then click the Mark as done button to close the order. Here nothing will happen because the user added an extra quantity of components.

Flexible consumption Allowed with a Warning

Admin can edit the Bill of material and change the Flexible consumption as Allowed with a warning.

With this method, users can start Manufacturing and while more quantities are consumed than the quantities in BoM, will register with a warning. Create a new order for the product and confirm the order. After confirmation the operations are in the Ready state, the user can start the operation.

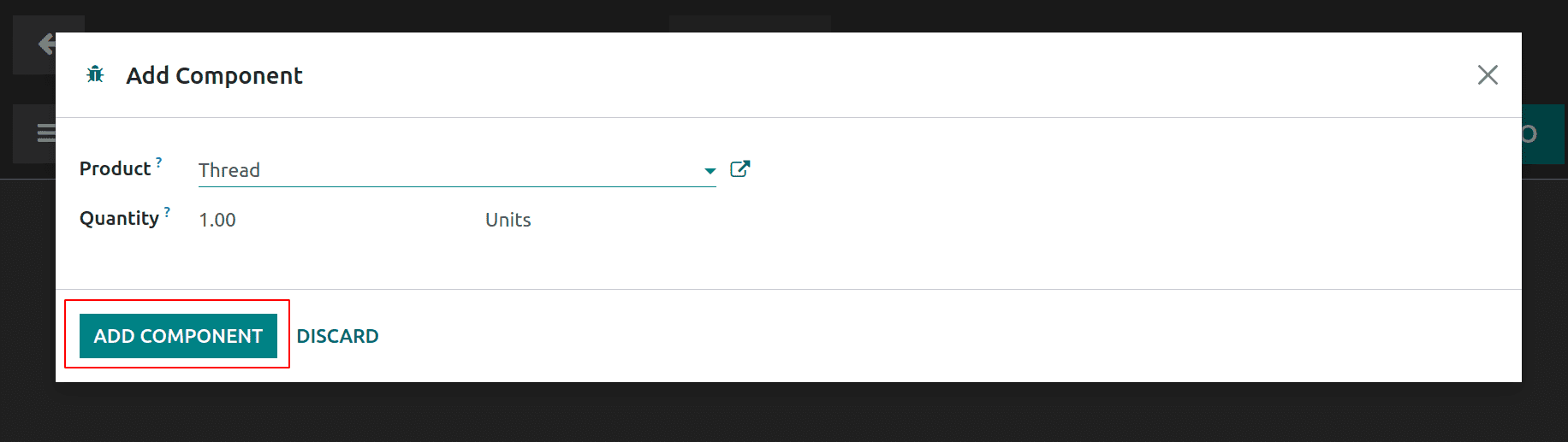

Assume that the operator wants the component Thread because the visiting one is damaged. So the Add Component button is used to add additional Thread.

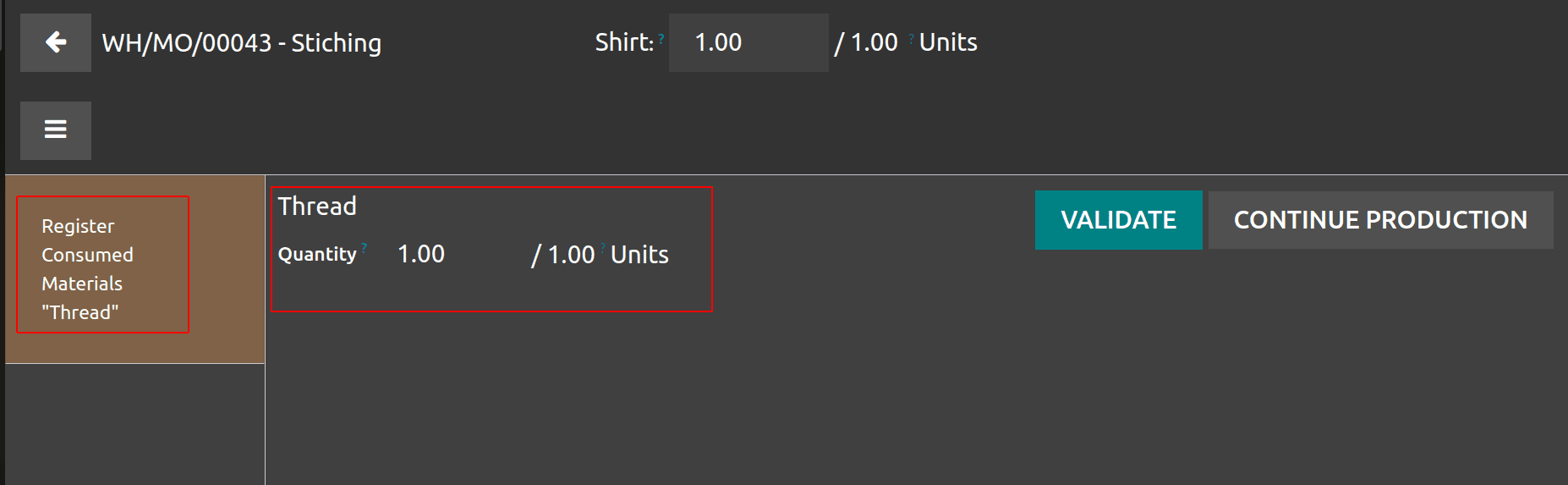

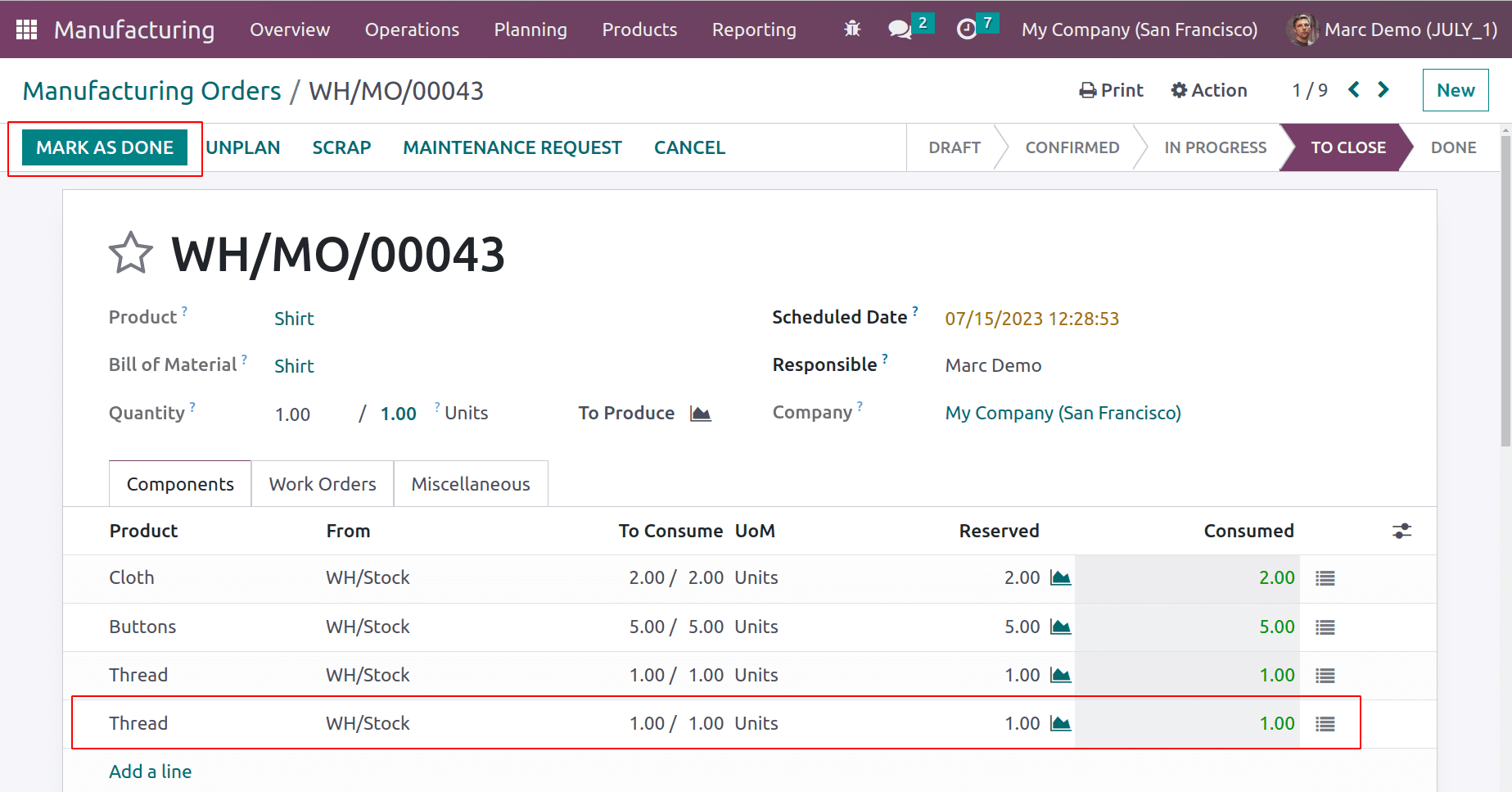

An additional quantity of Thread is added. Then continue the operation. After completing the operation click on the Mark as Done button.

Here shows the additional added component. Click on the Mark as Done button. Then a warning message will appear there.

The Consumption warning message shows that the user added an extra one more quantity, he can either confirm it if he added the component purposefully. Else discard it. So click on the Confirm button to close the Manufacturing order.

Flexible consumption Blocked

The last one is Blocked. Here the user can't add any extra product to the manufacturing. The user must complete the production process by using components with the quantity specified inside the Bill of material.

Admin can change the type of flexible consumption into Block. Then save the BoM.

The user logged in and created a new manufacturing order again for the same product. Order confirmed and can start the production by clicking the Start button of operation.

Here the user wished to add an additional sequence to the product, which is not specified inside the Bom. So the user chose the Add Component button from the tablet view to add a new component.

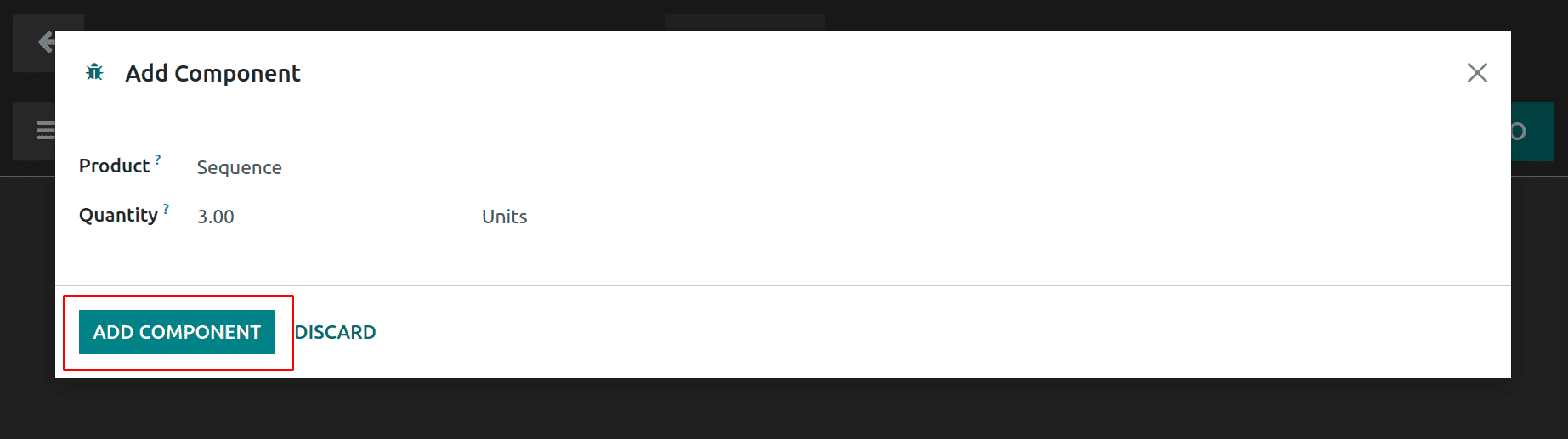

We have added a new component Sequence with 3 quantities. To add click on the Add component button.

New component is Registered inside the order. Validate the operation to complete.

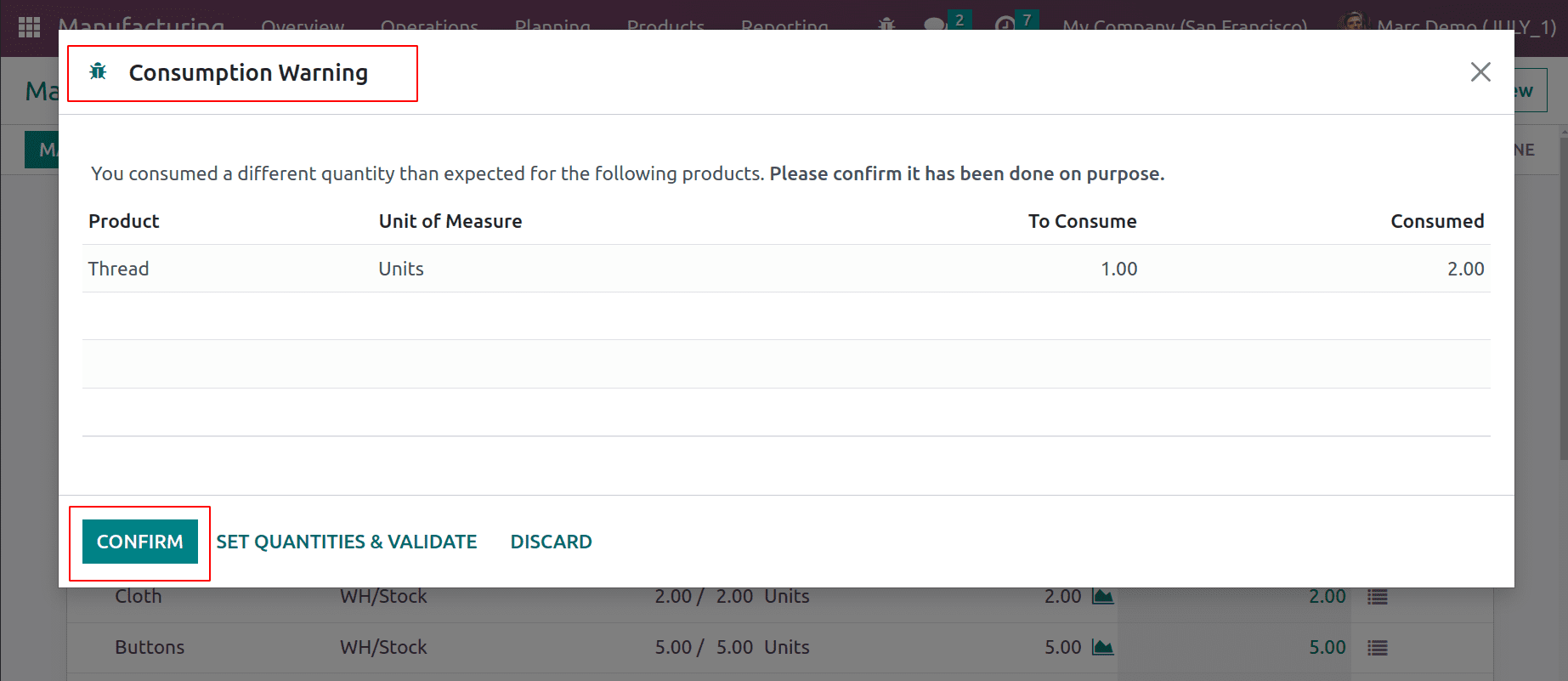

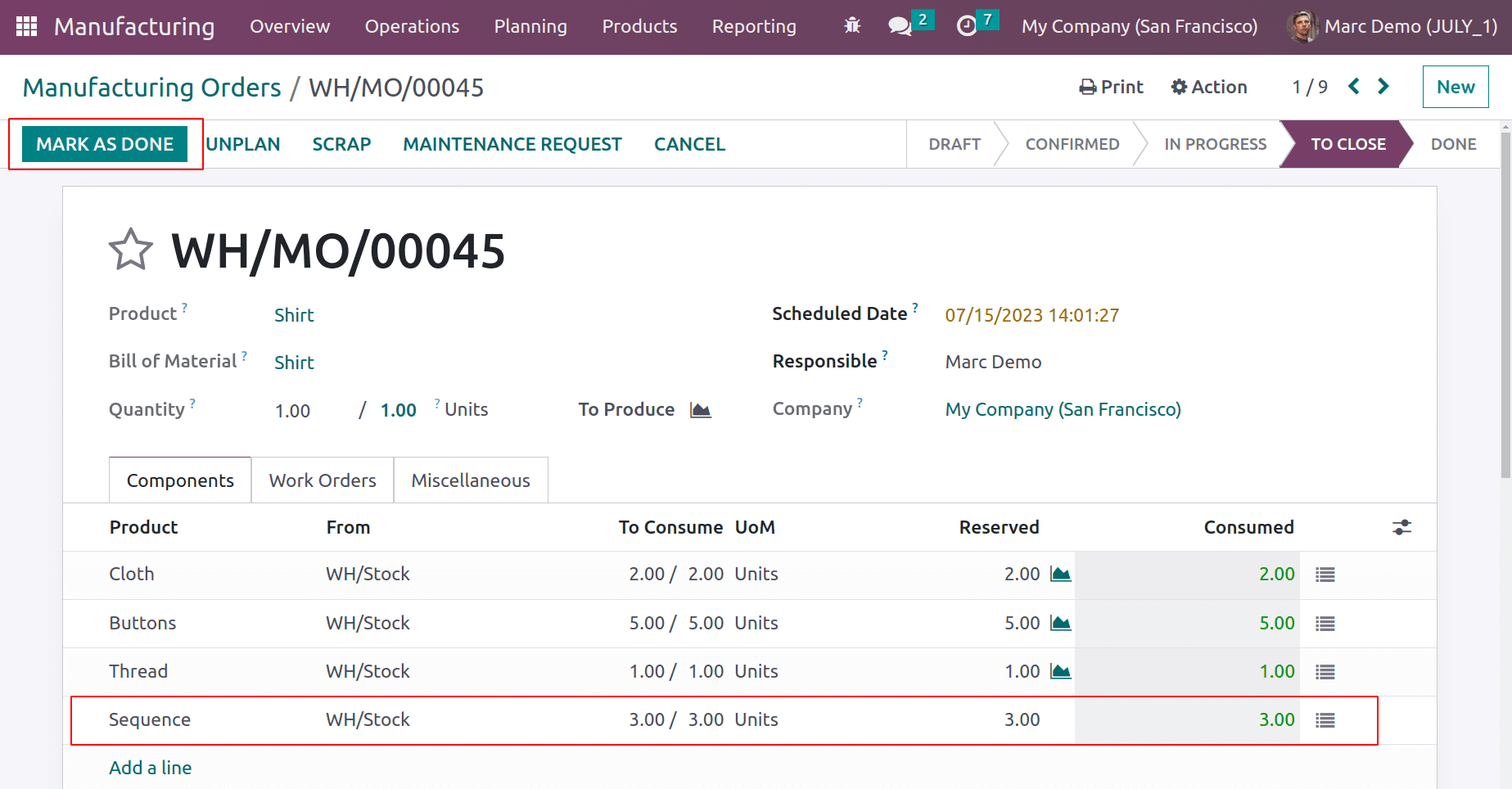

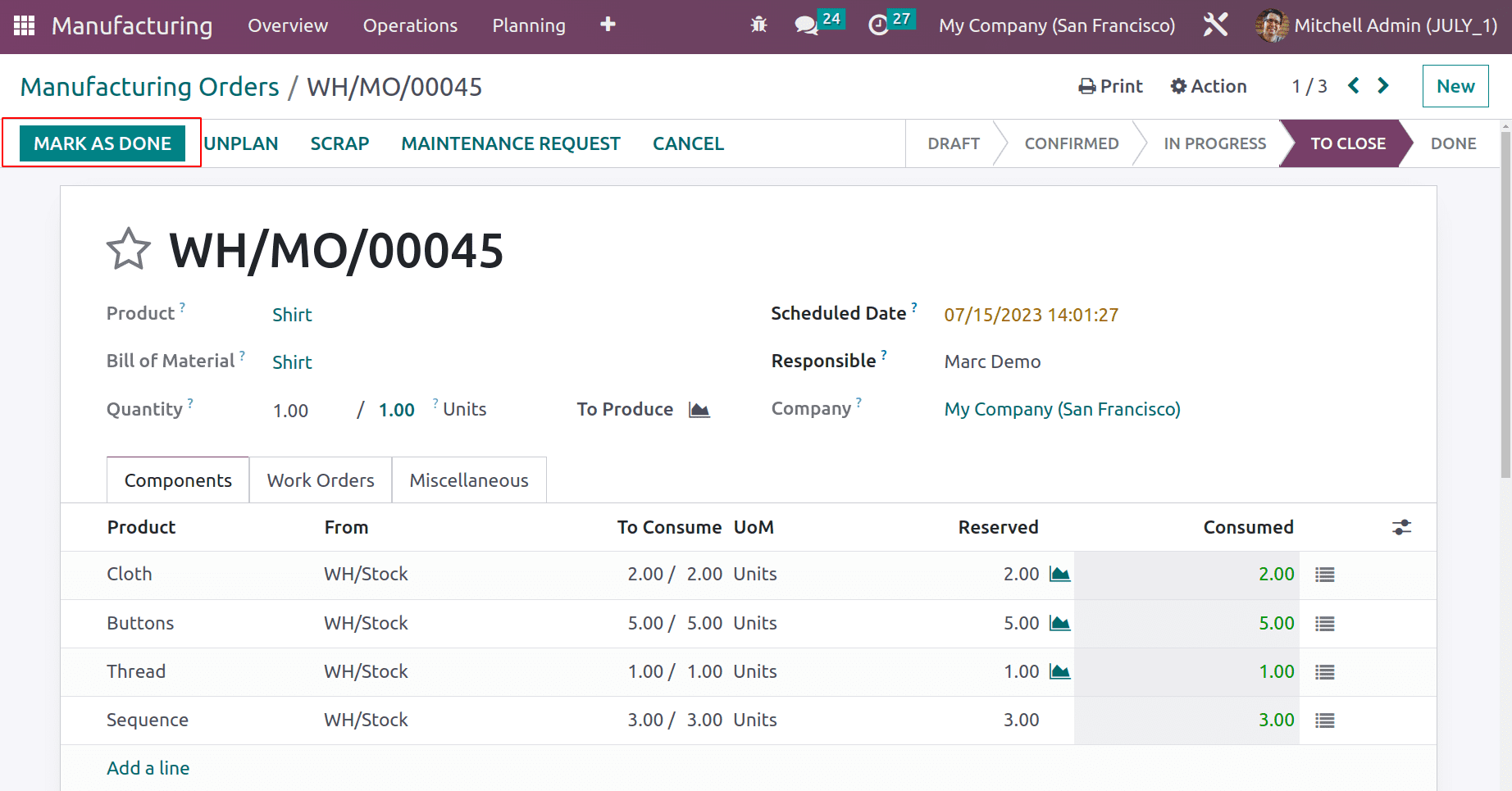

A new component Sequence with 3 quantities is additionally added in the component tab. Click on the Mark as Done button to close the order,

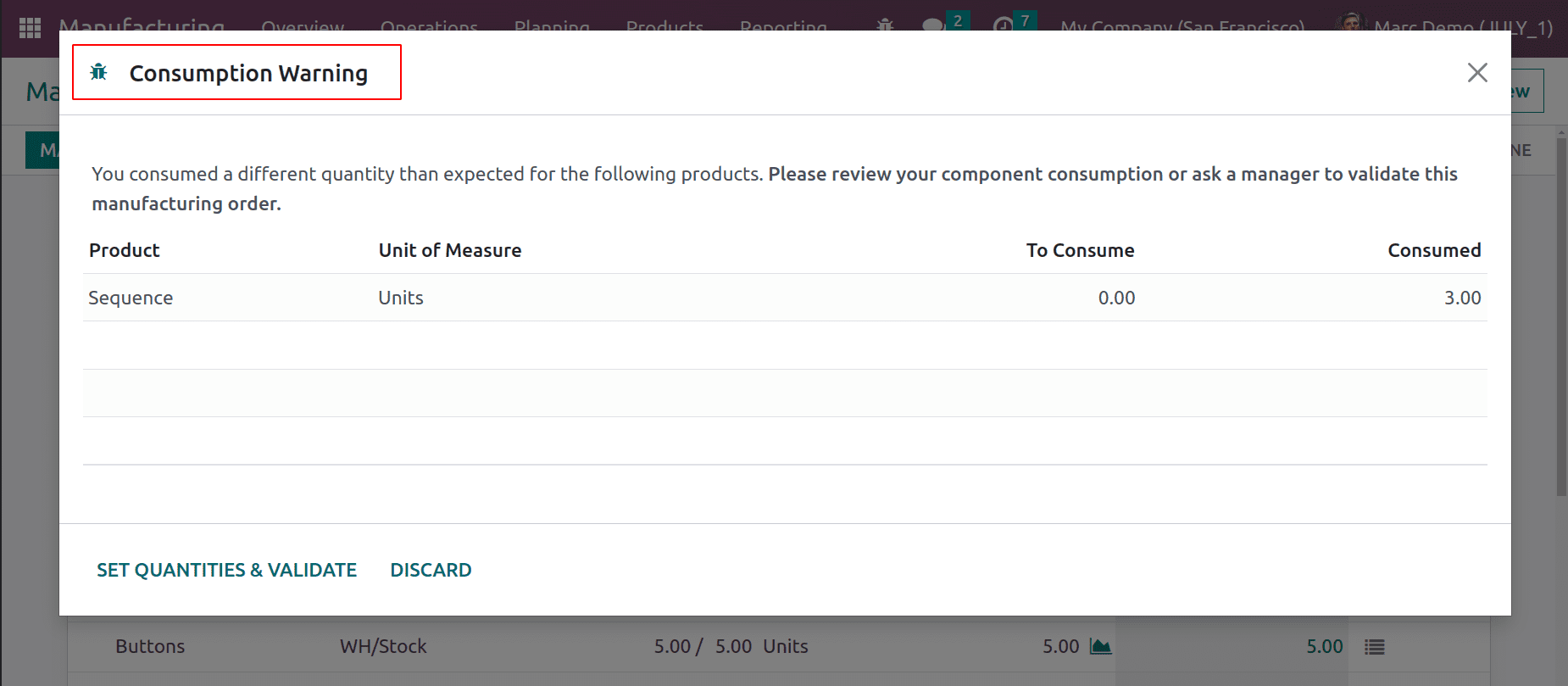

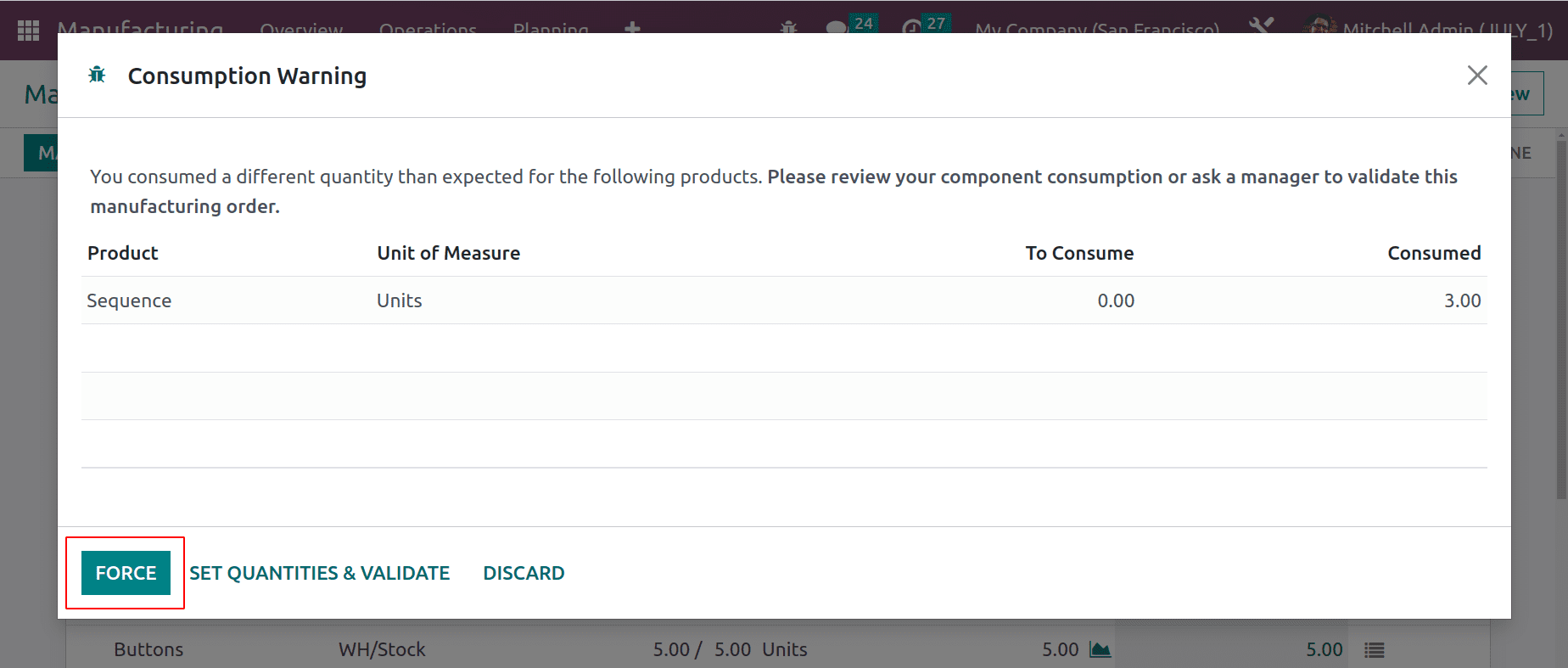

Another Consumption warning arrived there. This shows a message that the user used a different quantity of product for production, which is not mentioned in the BoM. So needs the Manager's approval to close the Manufacturing order. So the user can't close the order.

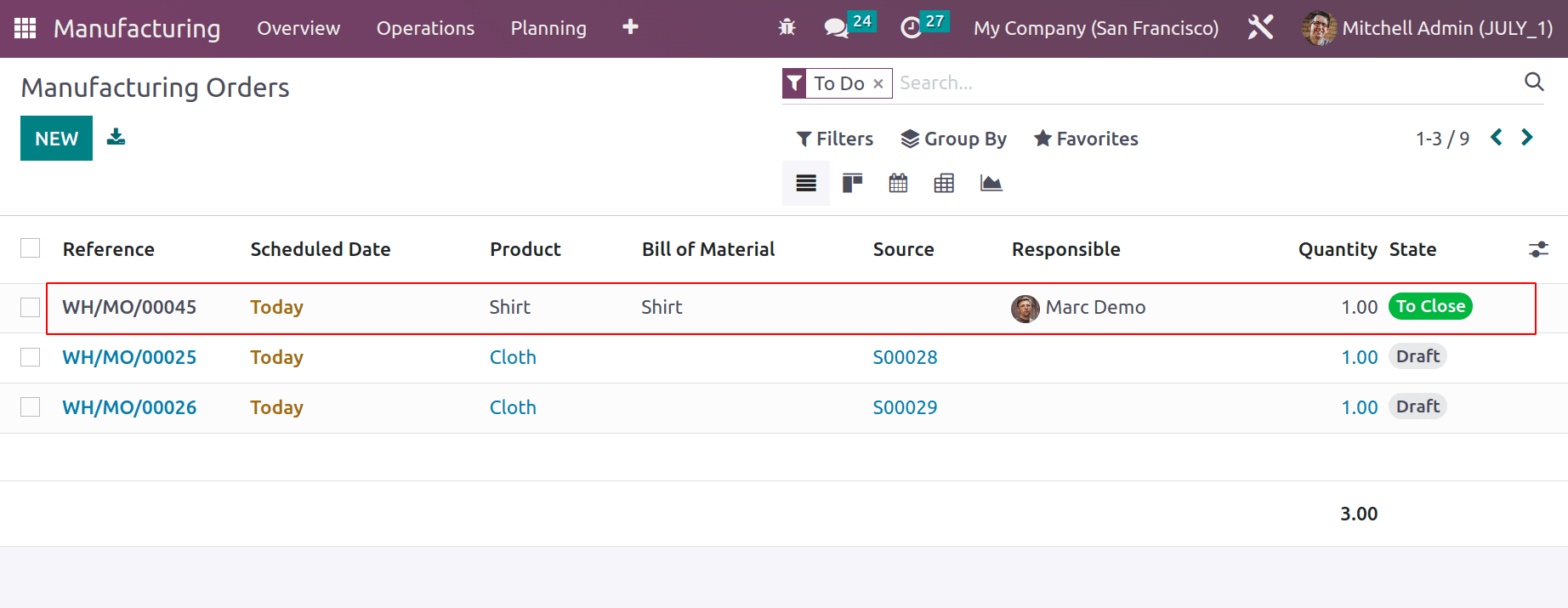

When the admin Login to the system he shows the Manufacturing order to close. Here the order is created by the User Marc Demo. Which is currently in the To Close stage. Open the order.

Only the Admin with manager access can close the order. So click on the Mark as Done button.

Which shows the same Consumption warning. But the manager can forcefully close the order by neglecting the message if it is necessary. So click on the Force button.

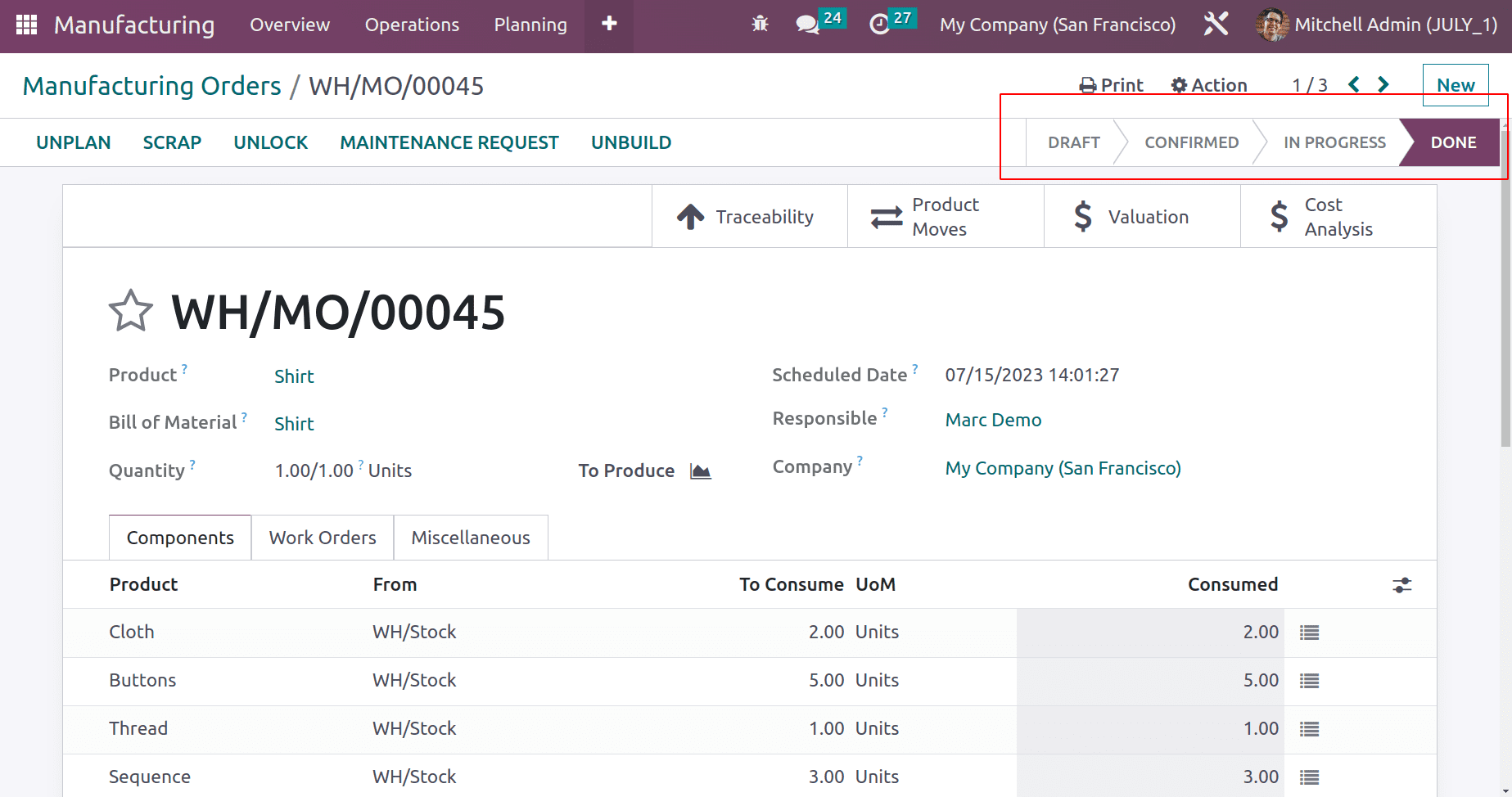

Then the manufacturing order is completed and moved to the Done stage.

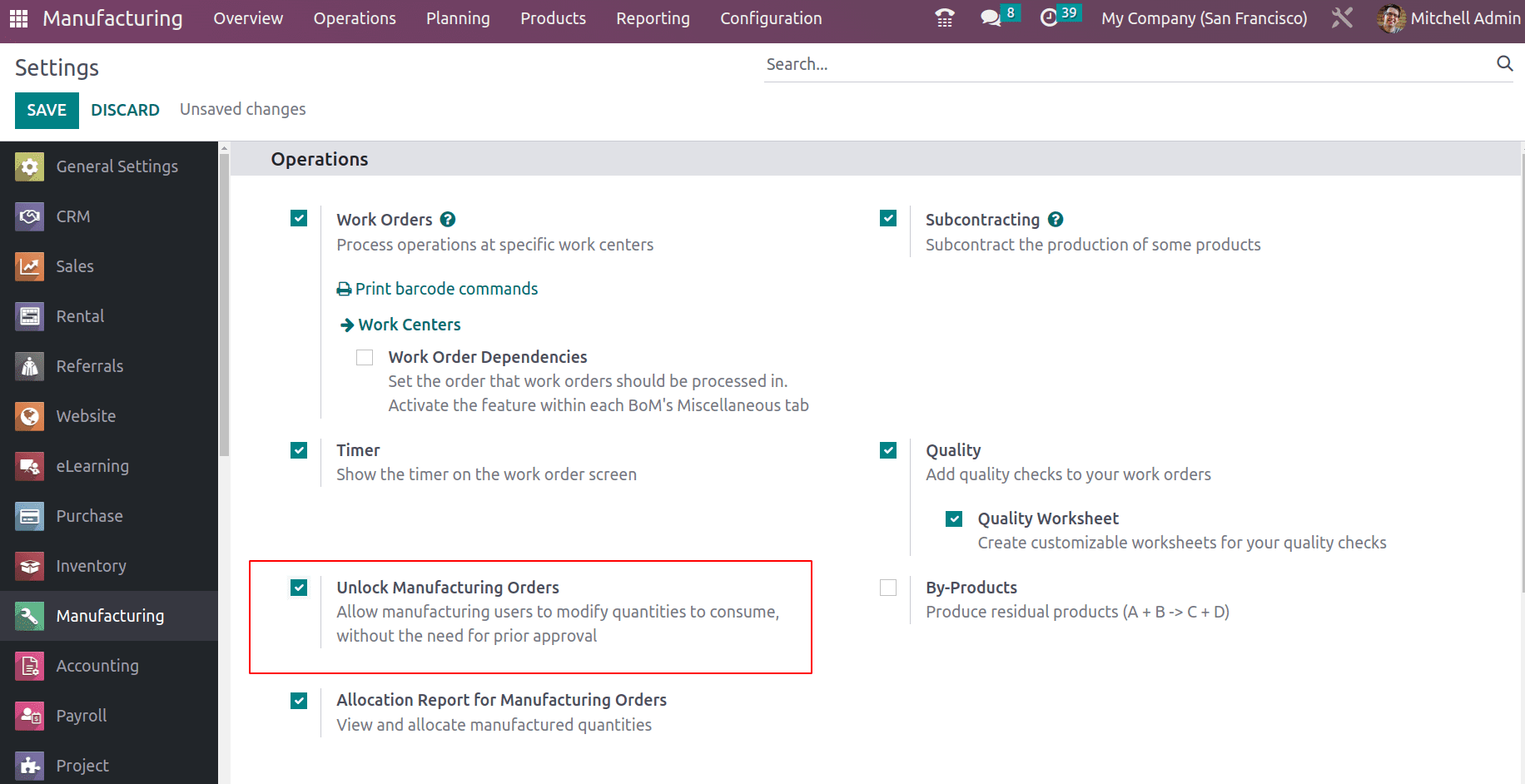

Unlock Manufacturing Order

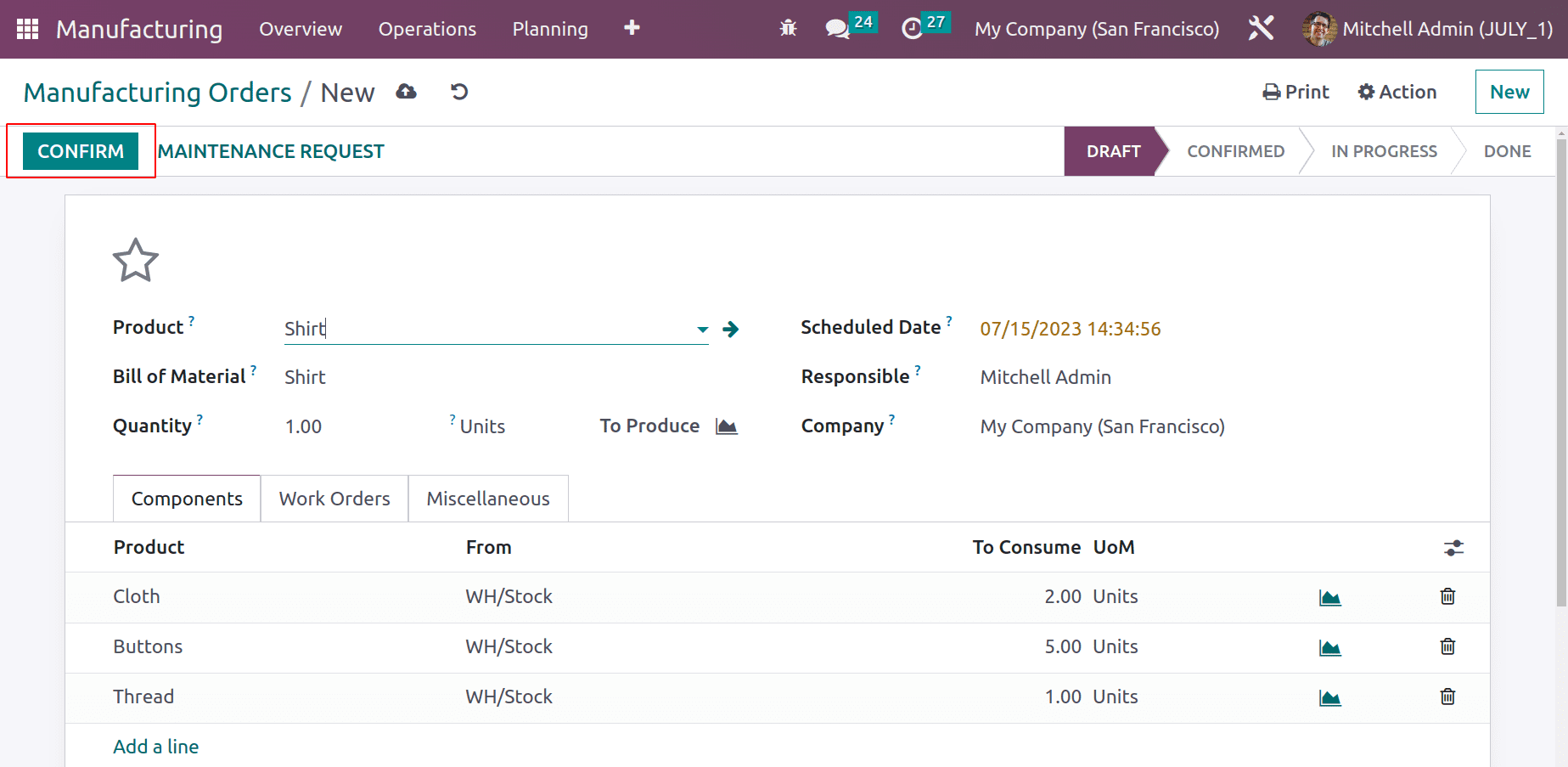

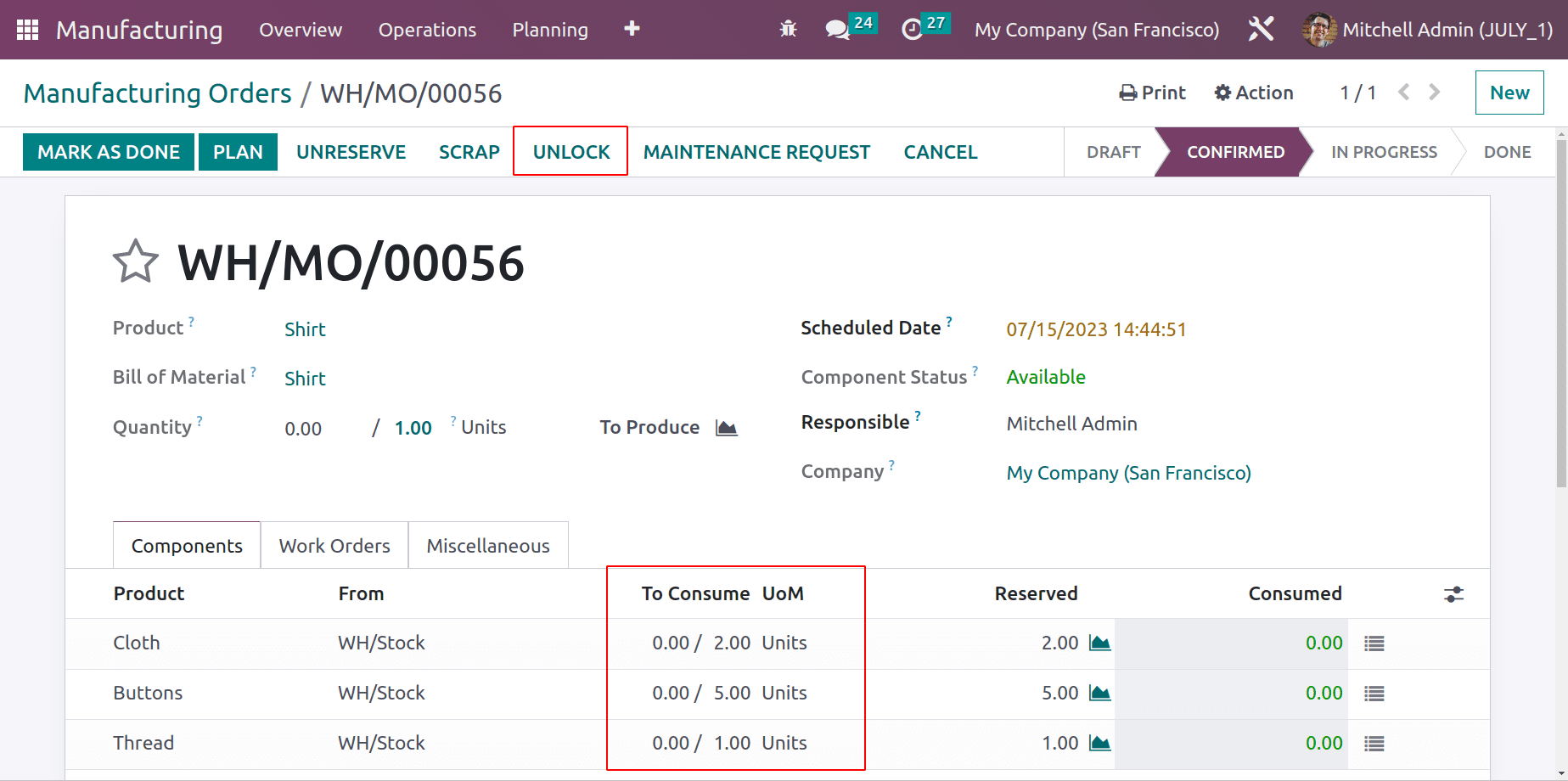

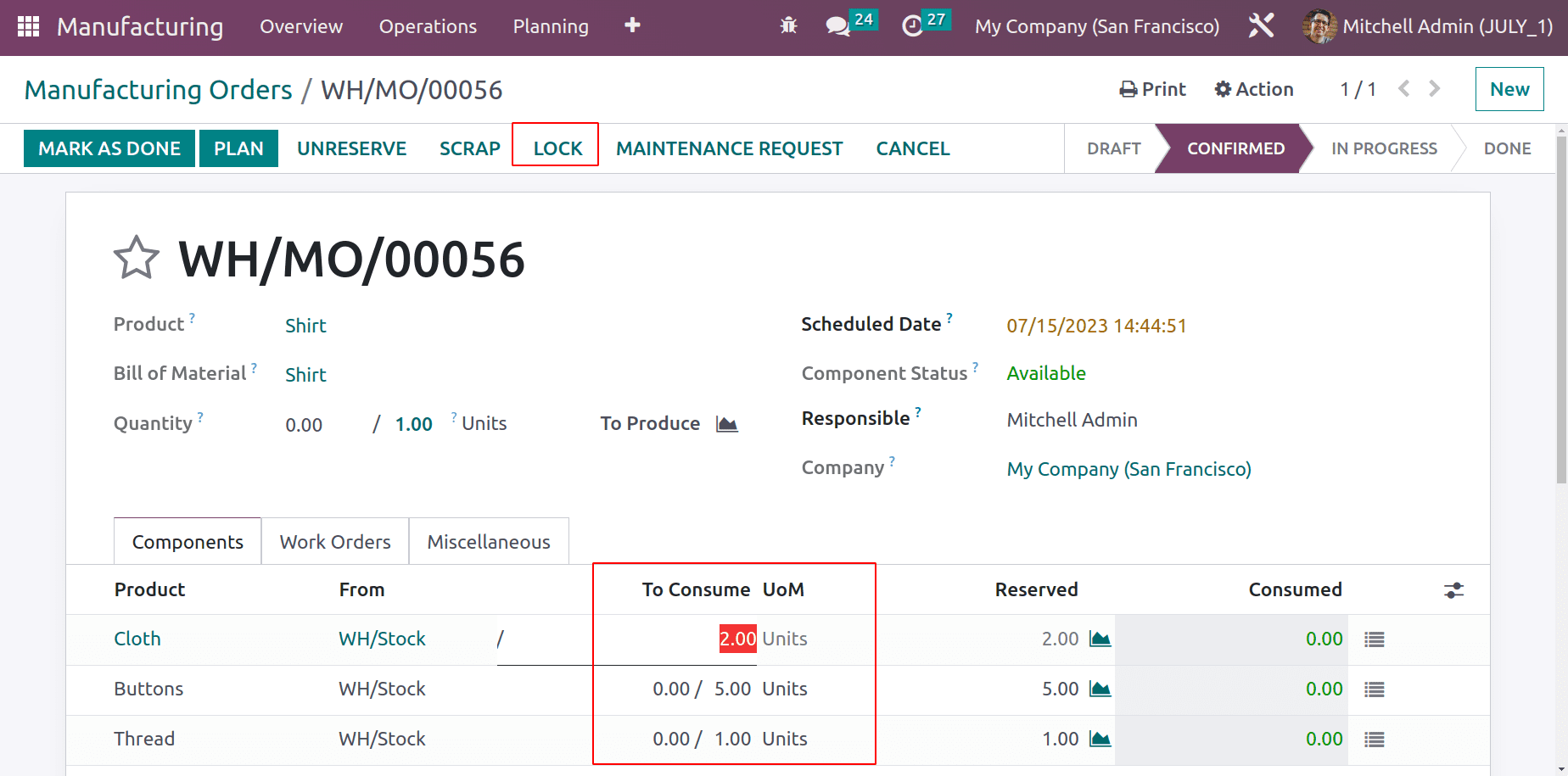

Odoo will automatically Lock the components ‘To consume’ of the manufacturing order after confirmation. So the user can only edit the order after unlocking. Let's check it. Create a new manufacturing order for the product Shirt using the same Bill of Material.

Here the components with quantity are shown. Confirm the order by clicking the confirm button. After confirmation, the order will turn automatically to a CONFIRMED stage. If the user is trying to edit the Consumed quantity, editing is not possible here.

The user can edit the confirmed order only after unlocking it. After editing the order user can again lock the order by using the Lock button.

In conclusion, one can control the material consumption and also control the locking option to track the components used according to the Bill of materials. We define a Bill of material to keep how many components are required to manufacture one unit of the product. Sometimes more components need to be consumed and if this kind of consumption is uncontrollable it will create uncertainty in your inventory and also in finance. Using the above mentioned two features we will be able to overcome the headache of controlling material consumption.

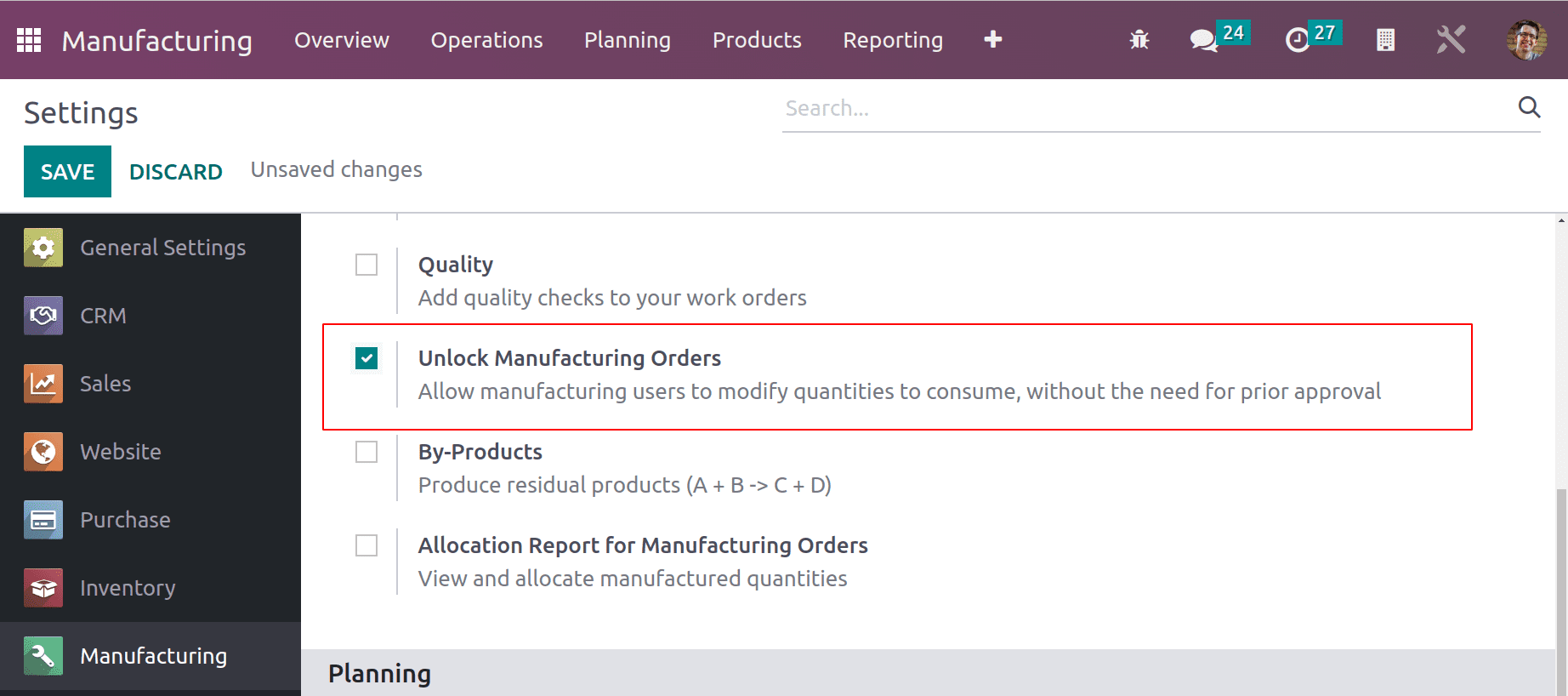

If the user did not want to lock the button after confirmation, enable the Unlock manufacturing order option from Configuration Settings. Go to settings and enable Unlock manufacturing order option and save the configuration.

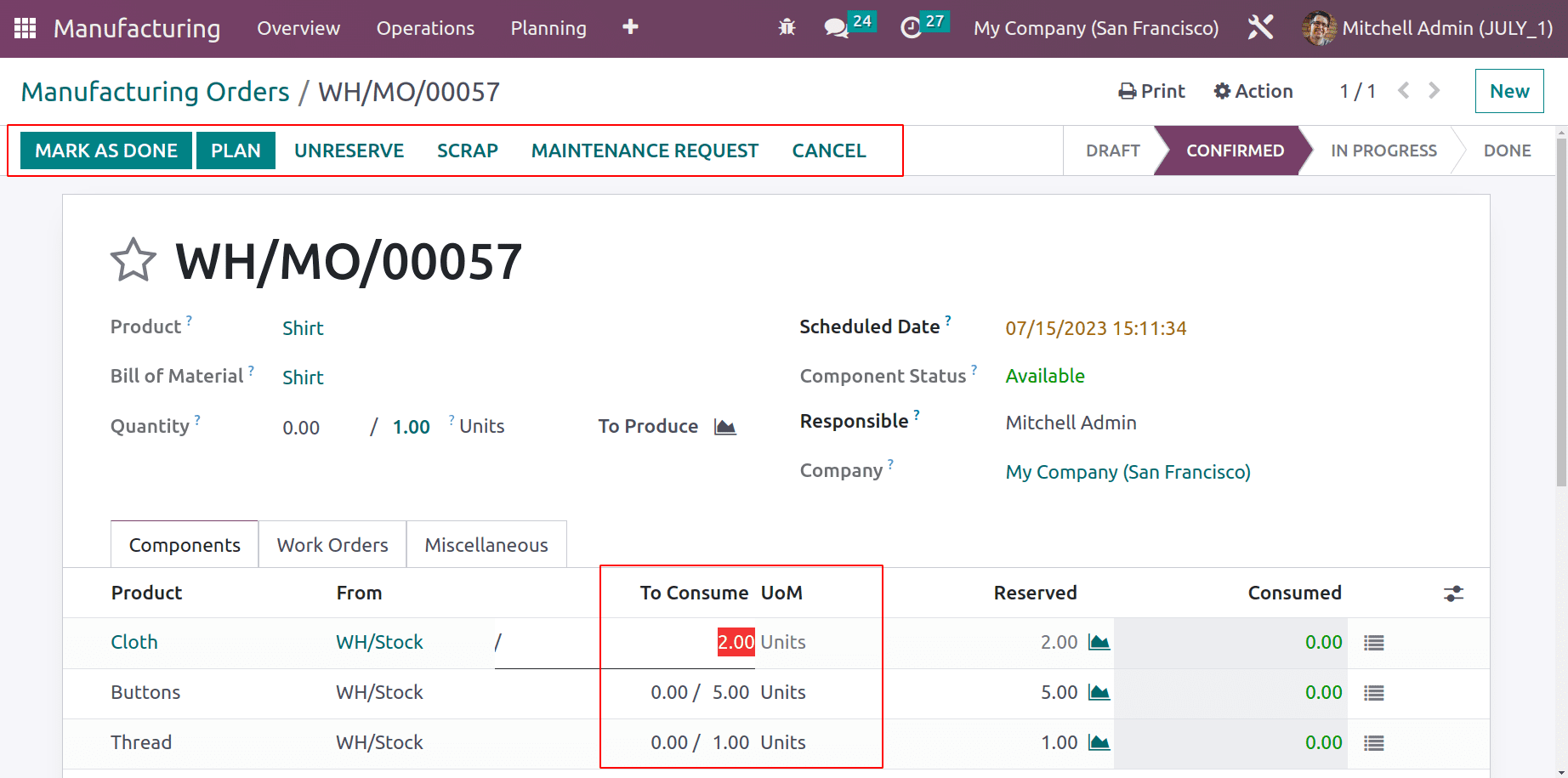

The user creates a new manufacturing order for a product shirt using the previously created Bill of Material again and confirms the order. Here the order is not locked, so the user can easily edit the order without unlocking.

An organization's manufacturing process is crucial. Careless component usage will cost the business money. Therefore, it is crucial for production that raw materials are allocated and used properly. Therefore, in manufacturing, flexible consumption and unlock manufacturing are crucial.

To read more about the important features of the Odoo 16 Manufacturing Module, take a look to our industry page Odoo 16 Manufacturing.