The textile industry is a field where strong business is carried out. Since clothing comes under the category of both regular need an occasional luxury, both the common man and the rich class are considered consumers of this category. So the radius of work for the textile industry is figuratively limitless. The textile industry has to go through a lot of matters for its well-functioning and maintenance of a proper business.

Starting from the pre-production stage to product manufacturing, each work should be carried out precisely and accurately for making an error-free business environment and attaining maximum profit. To make the matter simple, a Manufacturing ERP software can be used for aiding the works in the textile industry. An ERP software helps in effectively carrying out the works in the textile industry with less effort. Thus a business person can earn maximum profit in the field just by investing in a correct ERP.

Odoo/Open ERP software is an excellent choice when it comes to a field like textile industry. This blog discusses the various advantages of using Odoo/Open ERP software for the textile industry.

The advantages of an ERP for the textile industry can be listed below:

a) Quality control of the raw materials.

b) Well-arranged production and inventory.

c) Scrapping of damaged products.

d) Production without overflow and underflow.

e) Surveillance of the products.

f) Planned stock removal

g) Business intelligence

h) Customer satisfaction

i) Creating invoices and reports.

Now let’s look briefly into all the advantages

Quality control of raw materials

The base of manufacturing is the quality of its raw materials. No compromise shall happen to the quality part of the raw materials since it will affect the entire production. To meet these criteria quality control in ERP software for textile industry can be used. In the ERP software, we have the option to set the desired quality of the raw materials. Through the feature, the raw materials are always subjected to quality check and only if it is cleared, it gets selected as an approved product. Also, a quality check is thoroughly carried out after each stage of production like stitching, dying, printing, labeling, and packing. Thus all stages of production are controlled under quality check using the ERP software.

Well-arranged production and inventory

The production can be pre-set according to the hierarchy using the ERP for textile industry. The various stages of production like stitching, dying, printing and packing can be arranged using the work order feature in the ERP software. The works which are done at different locations are linked together using the ERP software for textile industry.

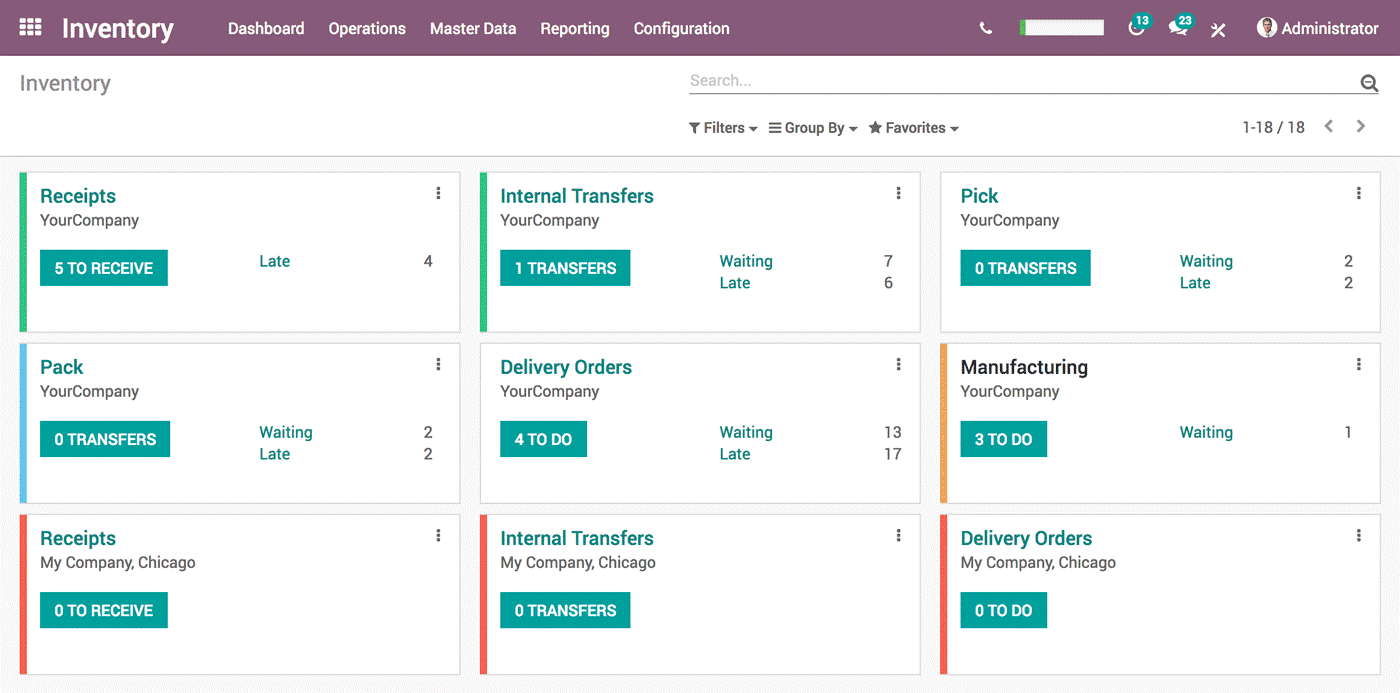

A well-arranged inventory is a big asset to any manufacturing industry. Strong inventory management can be carried out using the ERP software for textile industry. With the inventory management feature, activities like delivery orders, stock transfers etc. are carried out smoothly.

Also, products are aligned with barcodes for their easy tracking. Stock movement facility is provided in the ERP software inventory management which ensures correct product movement. With negative inventory feature, the user has the privilege to plan their production even before the availability of the raw materials.

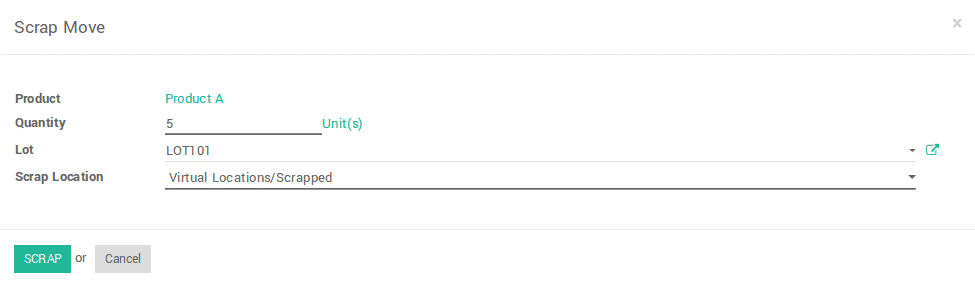

Scrapping of products

Scrap is a common term for any manufacturing industry. Similarly in the case of the textile industry to scraps are common. It shall always be ensured that scraps never gets mixed with the regular stock which will create great problems. So the scrap management facility in the open ERP software can be used. With this scraps are handled accordingly and moved to the scrap location without providing any chance for error.

Production without overflow or underflow

Production according to demand is the key to success for the textile industry. To make this happen the master production schedule feature in the ERP software can be used. Using MPS the purchasing and production can be effectively balanced and maintained. With the forecasting detail provided by MPS in the ERP software planned production is always assured. Altogether the accuracy in production is increased which will ensure that no overflow or underflow happens in the case of production.

Surveillance of products

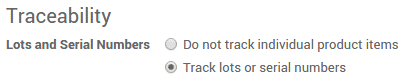

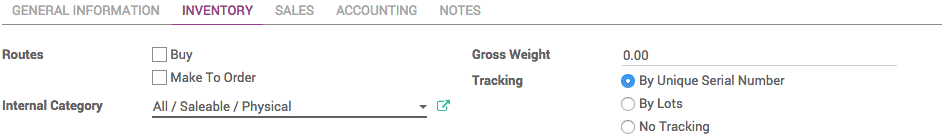

The complete tracking of the product is done with this feature. It gives the bird’s eye view of what is happening in the industry. Details regarding the stock, buyers, products etc., is known using the traceability feature in ERP software for textile industry. The tracking is done by assigning serial numbers to the products. The minute details provided by the industry like tags, barcodes, product labels etc. will be beneficial to attract sales also.

Planned stock removal

The stock removal strategy is very much connected with the movement of products or we can say they are inclusive events. When a product is to be moved Odoo/Open ERP software check the availability of products and determines how many can be assigned for shipping. This assigning is made possible via removal strategy. Odoo/Open ERP software removal strategy is completely based on the product category or based on the location.

In the case of the textile industry it deals with perishable goods, so old stocks should be cleared before new stocks to avoid stocking outdated products and thus reducing demand. To make this happen the first in first out technique (FIFO) is used for stock removal by the ERP software for textile industry.

Ensuring customer satisfaction

Stiff competition is happening in the field of textile manufacturing. Each and every firm are trying out new innovations to place themselves on the prime position. To tackle the competition and to achieve desirable sales strong customer relationship management is essential which can be provided by the ERP for textile industry. With the ERP software strong sales, subtle marketing and effective communication with customers are always maintained. Marketing gimmicks like loyalty, discounts etc. can be provided to customers through ERP software CRM. Analyzing our sales and planning accordingly is also made possible via ERP software textile industry.

Human resource management

The human resource management feature can be used for all the matters regarding workers of the firm. Maintaining the work quality is very important and this is achieved by making the most out of human resource. To maintain this the HRM feature in ERP software for textile can be used.

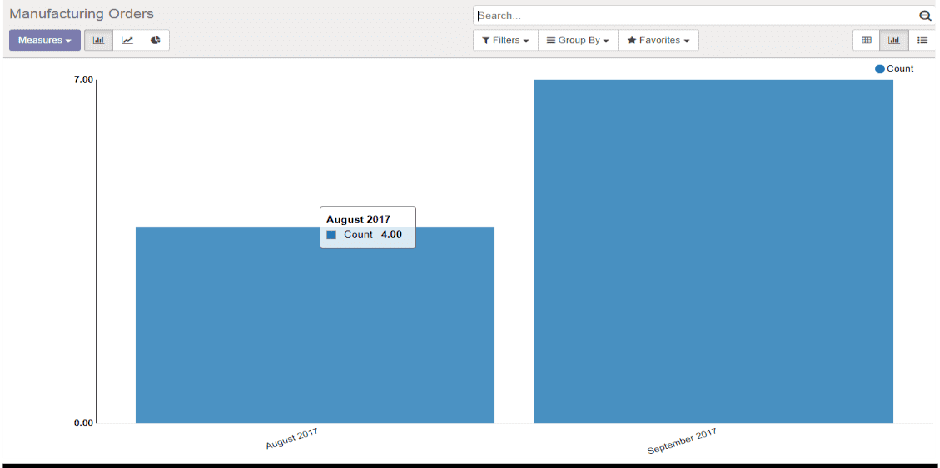

Business intelligence

Detailed analysis of a business is made possible using ERP software. This step is, in turn, important since it is the way with which development and profit is attained. This is done by analyzing the performance of work centers and production. If there is any sort of unbalance on that sections alternative production strategies can also be introduced using ERP software for textile industry.

Creating invoice and reports

With the invoicing feature in the ERP software, all the transactions are carried out which saves a considerable amount of time. The ERP software for textile industry is capable of integrating with shipping, order entries etc. which reduce a lot of work stress.

With the reporting feature in the ERP software, reports can be generated based on sales, production, and work. Evaluation and later planning can be done with this feature.

Thus Odoo/Open ERP software for textile industry will be your final pit stop if you are looking for a proper solution to handle your textile industry business.

If you are interested in Odoo implementation for your business, kindly drop your message to info@cybrosys.com. We can guide you better with Odoo pricing and support plans for executing your organization goals. Cybrosys Technologies is an exponent in Odoo ERP solutions with more than 10 years of experience.